Chemical Etching Depth . The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results.

from sites.utexas.edu

Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,.

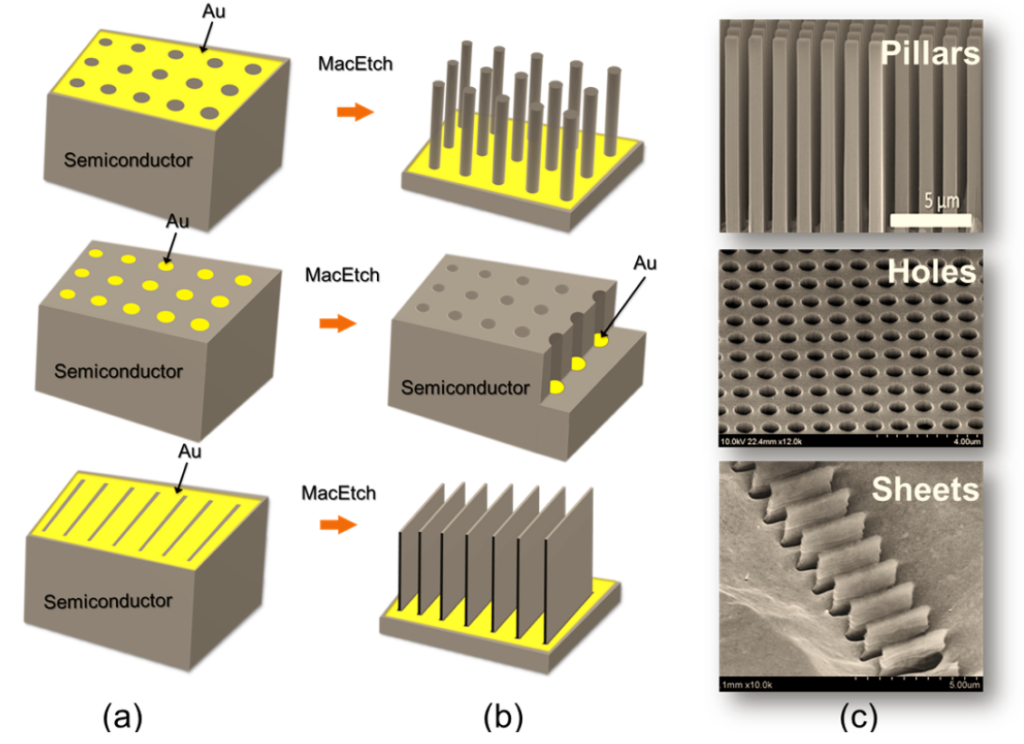

MetalAssisted Chemical Etching (MacEtch)

Chemical Etching Depth Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. The controlled parameters are etching chamber pressure, bias power, and gas flow rate.

From www.laser2etch.com

Chemical Etching Process Laser2Etch Chemical Etching Depth Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly. Chemical Etching Depth.

From metaletching.com

Chemical Etching VS Laser Cutting Advanced Metal Etching® Chemical Etching Depth Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. Chemical etching, also known as. Chemical Etching Depth.

From www.qualitetch.com

Photo Etching Chemical Etching Acid Etching UK Qualitetch Chemical Etching Depth Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. The depth of a chemical. Chemical Etching Depth.

From www.researchgate.net

(PDF) Wet Chemical Etching of Si, Si1−xGex, and Ge in HFH2O2CH3COOH Chemical Etching Depth The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. The tested trenches’. Chemical Etching Depth.

From nanohub.org

Resources ECE 695Q Lecture 44 Etching Watch Presentation Chemical Etching Depth Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. The depth of a chemical. Chemical Etching Depth.

From grish.com

What is the Difference Between Chemical Etching and Engraving? Grish Chemical Etching Depth The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. At its core, chemical etching involves the selective removal of material from a substrate using. Chemical Etching Depth.

From slidetodoc.com

Chapter 10 Etching 1 2 3 4 5 Chemical Etching Depth Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes. Chemical Etching Depth.

From www.mdpi.com

Rapid Fabrication of Smooth MicroOptical Components on Glass by Chemical Etching Depth The controlled parameters are etching chamber pressure, bias power, and gas flow rate. Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. The tested trenches’ width ranged from 15 to 1500 µm and their depth. Chemical Etching Depth.

From www.laser2etch.com

What is chemical etching? and how can you add it to your business? Chemical Etching Depth At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. The tested trenches’ width ranged. Chemical Etching Depth.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Chemical Etching Depth At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from The tested trenches’ width ranged from 15 to 1500. Chemical Etching Depth.

From www.mdpi.com

Sustainability Free FullText Fabrication of Black Silicon via Chemical Etching Depth The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. Chemical etching is a manufacturing. Chemical Etching Depth.

From www.researchgate.net

Basic etching mechanisms (a) chemical etching, (b) sputtering, (c Chemical Etching Depth At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. Chemical etching is. Chemical Etching Depth.

From www.researchgate.net

(a) The process of chemical etching. (b) KrF excimer laser setup used Chemical Etching Depth The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. Chemical etching is a manufacturing method for. Chemical Etching Depth.

From www.annexpublishers.co

Periodic Micro Hole Texturing with Metal Assisted Chemical Etching for Chemical Etching Depth The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. Chemical etching is a manufacturing. Chemical Etching Depth.

From www.researchgate.net

Zone plate etch depth as a function of etching time, based on image Chemical Etching Depth Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly. Chemical Etching Depth.

From www.researchgate.net

Variation of fabrication depth of Si/Si3N4 sample with etching period Chemical Etching Depth Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50. Chemical Etching Depth.

From www.researchgate.net

A diagram illustrating the production of NWs through metalassisted Chemical Etching Depth At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. Chemical etching is a complex process that. Chemical Etching Depth.

From www.precisionmicro.com

Chemical etching What your competitors don't want you to know! Chemical Etching Depth Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from The controlled parameters are etching chamber pressure, bias power,. Chemical Etching Depth.

From weld.solutions

A StepbyStep Guide to Etching Welds. Weld Solutions Chemical Etching Depth Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. Chemical etching, also known as. Chemical Etching Depth.

From www.iqsdirectory.com

Acid Etching Acid Types, Metal Types, Applications, and Benefits Chemical Etching Depth The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision. Chemical Etching Depth.

From www.researchgate.net

Wet Chemical etching by KOH (19) solution at 70°C. Pyramids limited by Chemical Etching Depth At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining. Chemical Etching Depth.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Chemical Etching Depth The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick. The tested trenches’. Chemical Etching Depth.

From pubs.rsc.org

Photoenhanced metalassisted chemical etching of αgallium oxide grown Chemical Etching Depth Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. Chemical etching is a manufacturing method for. Chemical Etching Depth.

From www.mdpi.com

Nanomaterials Free FullText Impact of Inductively Coupled Plasma Chemical Etching Depth The controlled parameters are etching chamber pressure, bias power, and gas flow rate. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. Chemical etching, also known as. Chemical Etching Depth.

From issuu.com

Chemical Etching Vs Laser Engraving Know what works for you by oto Chemical Etching Depth The controlled parameters are etching chamber pressure, bias power, and gas flow rate. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly. Chemical Etching Depth.

From www.researchgate.net

Depth of etch against etching time. Download Scientific Diagram Chemical Etching Depth At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from Chemical etching is a complex process that relies on. Chemical Etching Depth.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Chemical Etching Depth The controlled parameters are etching chamber pressure, bias power, and gas flow rate. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to. Chemical Etching Depth.

From pubs.rsc.org

Metal assisted chemical etching of silicon in the gas phase a Chemical Etching Depth Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The controlled parameters are etching chamber pressure, bias power,. Chemical Etching Depth.

From ace-uk.net

What Is Chemical Etching? Our Chemical Etching Process ACE Chemical Etching Depth At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. The controlled parameters are etching chamber pressure, bias power, and gas flow rate. Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. The tested trenches’ width ranged. Chemical Etching Depth.

From www.hysonetch.com

What is photo chemical etching Chemical Etching Depth The controlled parameters are etching chamber pressure, bias power, and gas flow rate. The depth of a chemical etching can vary depending on several factors, including the type of metal being etched, the specific etchant used,. Chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. Chemical etching, also. Chemical Etching Depth.

From www.iqsdirectory.com

Flexible Heaters What Is It?, Types, Uses, and Benefits Chemical Etching Depth The controlled parameters are etching chamber pressure, bias power, and gas flow rate. The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. Chemical etching is a complex process that relies on chemical reactions, material properties, and process. Chemical Etching Depth.

From slidetodoc.com

Chapter 10 Etching 1 2 3 4 5 Chemical Etching Depth At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from The depth of a chemical etching can vary depending. Chemical Etching Depth.

From www.thierry-corp.com

Reactive Ion Etching (RIE) Thierry Corporation Chemical Etching Depth The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in practical applications. Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic. Chemical Etching Depth.

From sites.utexas.edu

MetalAssisted Chemical Etching (MacEtch) Chemical Etching Depth Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between. Chemical Etching Depth.

From www.researchgate.net

(a) Schematic illustration of creating surface roughness by chemical Chemical Etching Depth Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from The tested trenches’ width ranged from 15 to 1500 µm and their depth ranged from 50 to 500 µm, which covers nearly all the typical sizes of micromechanical devices in. Chemical Etching Depth.