Define Equipment Downtime . Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. This downtime can significantly impact a company's. Downtime can be planned or unplanned: Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Simply put, downtime refers to a period during which a system is unavailable. Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with preventive, predictive,. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Learn what machine downtime is, how to calculate it, and how to minimize it with preventive maintenance, error codes, and. Machine downtime refers to any period in which a piece of equipment is not in operation. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Unplanned downtime is just what it. This could be a fault,.

from rabinia.com

On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Simply put, downtime refers to a period during which a system is unavailable. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Learn what machine downtime is, how to calculate it, and how to minimize it with preventive maintenance, error codes, and. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Downtime can be planned or unplanned: This could be a fault,.

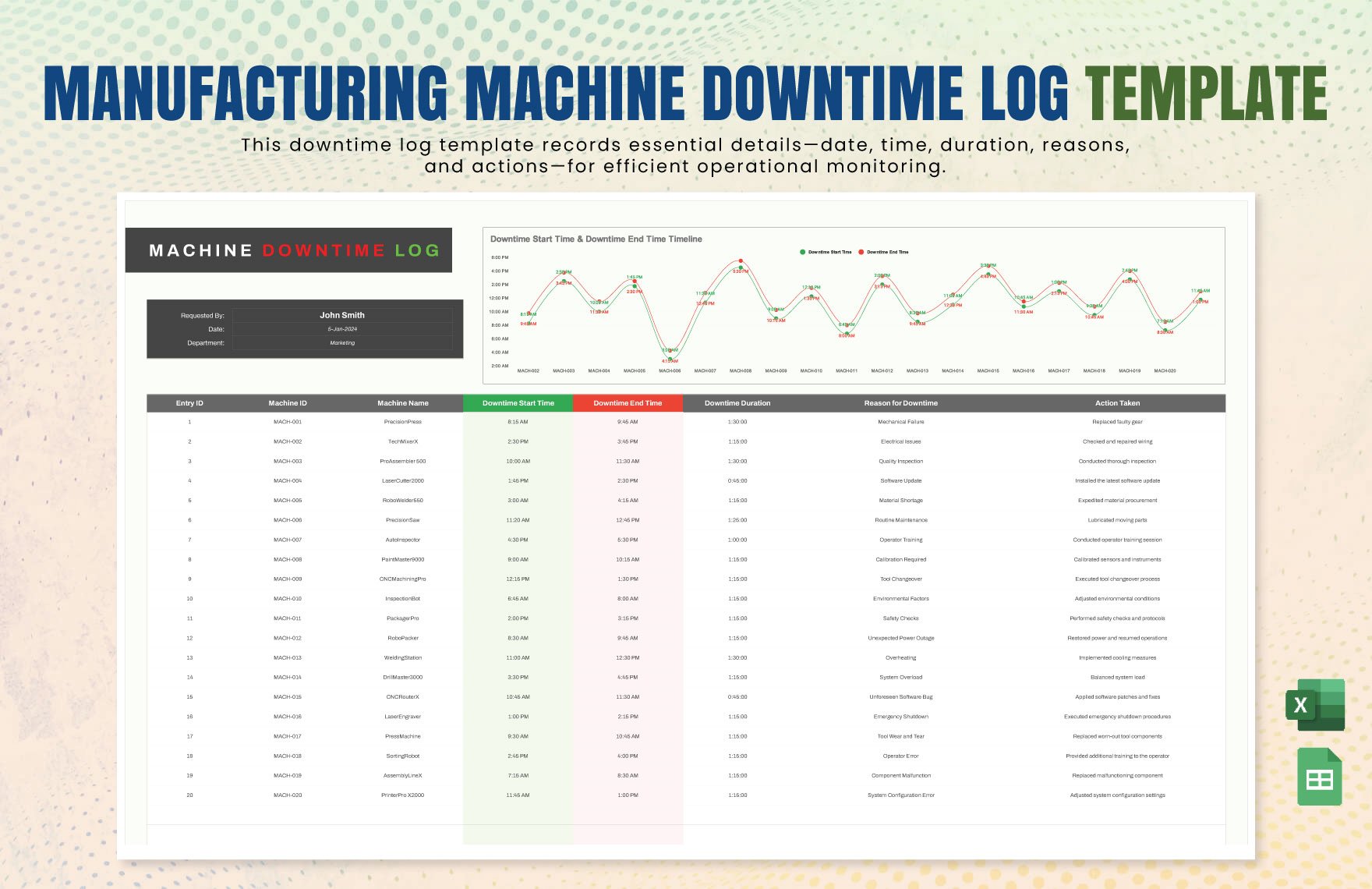

Manufacturing Machine Downtime Log Template In Excel,, 51 OFF

Define Equipment Downtime Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with preventive, predictive,. Unplanned downtime is just what it. This downtime can significantly impact a company's. Simply put, downtime refers to a period during which a system is unavailable. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Downtime can be planned or unplanned: Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Machine downtime refers to any period in which a piece of equipment is not in operation. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Learn what machine downtime is, how to calculate it, and how to minimize it with preventive maintenance, error codes, and. This could be a fault,. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with preventive, predictive,.

From www.cryotos.com

Creating Equipment Downtime Reports with CMMS Define Equipment Downtime Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its. Define Equipment Downtime.

From nanoprecise.io

Reduce Unplanned Downtime Predictive Maintenance Nanoprecise Define Equipment Downtime Downtime can be planned or unplanned: On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled. Define Equipment Downtime.

From gesrepair.com

5 Ways to Reduce Unplanned Manufacturing Downtime Define Equipment Downtime Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Unplanned downtime is just what it. Machine downtime refers to any period in which a piece of equipment is. Define Equipment Downtime.

From www.resco.net

How to Calculate Machine Downtime Resco Define Equipment Downtime Unplanned downtime is just what it. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. This downtime can significantly impact a company's. This could be a fault,. Downtime can be planned or unplanned: Planned. Define Equipment Downtime.

From www.machinemetrics.com

How to Reduce Machine Downtime in Manufacturing MachineMetrics Define Equipment Downtime Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Simply put, downtime refers to a period during which a system is unavailable. Learn what equipment downtime is, how it affects productivity and profitability, and. Define Equipment Downtime.

From limblecmms.com

What Is Downtime? How To Manage It Like A Pro Define Equipment Downtime Unplanned downtime is just what it. Downtime can be planned or unplanned: Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure,. Define Equipment Downtime.

From rabinia.com

Manufacturing Machine Downtime Log Template In Excel,, 51 OFF Define Equipment Downtime Unplanned downtime is just what it. Machine downtime refers to any period in which a piece of equipment is not in operation. This could be a fault,. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. On the other hand, unplanned downtime events usually cause lost productivity and. Define Equipment Downtime.

From www.pinterest.com

Cost of Equipment Downtime InfoGraphic True Cost, Employee Morale, Room Define Equipment Downtime Unplanned downtime is just what it. Simply put, downtime refers to a period during which a system is unavailable. This downtime can significantly impact a company's. Learn what machine downtime is, how to calculate it, and how to minimize it with preventive maintenance, error codes, and. Find out the causes, costs and benefits of downtime, and how to use tools. Define Equipment Downtime.

From www.slideteam.net

Machine Downtime Level Dashboard With Average Utilization Powerpoint Define Equipment Downtime Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. This could be a fault,. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Machine downtime refers to any period in which a piece of equipment is not in operation. Learn what equipment downtime is, how it affects. Define Equipment Downtime.

From www.professionalacademy.com

War on waste downtime theory can minimise waste sources Define Equipment Downtime Learn what machine downtime is, how to calculate it, and how to minimize it with preventive maintenance, error codes, and. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Machine downtime refers to any period in which a piece of equipment is not in operation. Learn what equipment. Define Equipment Downtime.

From www.dornerconveyors.com

3 Ways to Reduce Unplanned Downtime in Manufacturing Dorner Conveyors Define Equipment Downtime Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with preventive, predictive,. Simply put, downtime refers to a period during which a system is unavailable. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Planned downtime typically occurs alongside routine maintenance. Define Equipment Downtime.

From www.resco.net

How to Calculate Machine Downtime Resco Define Equipment Downtime Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. This downtime can significantly impact a company's. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Machine downtime refers to any period in which a piece of equipment. Define Equipment Downtime.

From www.maintwiz.com

How to Reduce Equipment Downtime MaintWiz CMMS Define Equipment Downtime This could be a fault,. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Simply put, downtime refers to a period during which a system is unavailable. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Learn what machine downtime is, how to. Define Equipment Downtime.

From www.youtube.com

EQUIPMENT DOWNTIME॥TRACK AND REDUCE UNPLANNED EQUIPMENT DOWNTIME॥NABH Define Equipment Downtime Downtime can be planned or unplanned: Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Learn how to measure, prevent and reduce machine downtime,. Define Equipment Downtime.

From servicechannel.com

What is Equipment Downtime? (Causes & Preventing Costly Downtimes Define Equipment Downtime This downtime can significantly impact a company's. Simply put, downtime refers to a period during which a system is unavailable. Machine downtime refers to any period in which a piece of equipment is not in operation. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Find out the. Define Equipment Downtime.

From www.youtube.com

Pronunciation of Equipment Definition of Equipment YouTube Define Equipment Downtime Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Learn what machine downtime is, how to calculate. Define Equipment Downtime.

From www.versacall.com

5 Ways to Reduce Manufacturing Downtime with Improved Communication Define Equipment Downtime Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with preventive, predictive,. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Unplanned downtime is just what it. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Simply. Define Equipment Downtime.

From www.youtube.com

What is Equipment? Definition and Meaning YouTube Define Equipment Downtime Downtime can be planned or unplanned: Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. This downtime can significantly impact a company's. Learn what equipment downtime is, how it affects productivity and profitability, and. Define Equipment Downtime.

From www.slideserve.com

PPT Utilization of PI to track Downtime PowerPoint Presentation, free Define Equipment Downtime This could be a fault,. Unplanned downtime is just what it. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to. Define Equipment Downtime.

From servicechannel.com

What is Equipment Downtime? (Causes & Preventing Costly Downtimes Define Equipment Downtime Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Machine downtime refers to any period in which a piece of equipment is not in operation. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled. Define Equipment Downtime.

From www.pinterest.com

The adoption of Industry 4.0 projects could lead to a 30 to 50 Define Equipment Downtime This downtime can significantly impact a company's. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Simply put, downtime refers to a period during which a system is unavailable. Learn what equipment downtime is, how it affects. Define Equipment Downtime.

From www.cryotos.com

How to Reduce Downtime with Maintenance Technology? Define Equipment Downtime Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. This downtime can significantly impact a company's. Machine downtime refers to any period in which a piece of equipment is not in operation. Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with. Define Equipment Downtime.

From www.1rti.com

The Impact of IT Downtime on a Business Riverside Technologies, Inc. Define Equipment Downtime Unplanned downtime is just what it. On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Downtime can be planned or unplanned: Find out the causes, costs and benefits of downtime, and how to use. Define Equipment Downtime.

From blog.siteuptime.com

Why Downtime and Slow Speeds Affect SEO SiteUptime Blog Define Equipment Downtime Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. Unplanned downtime is just what it. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Learn how to measure, prevent and reduce machine downtime, which is any time. Define Equipment Downtime.

From www.ptonline.com

Machine Monitoring System Adds ‘HandsFree’ Downtime Analysis Define Equipment Downtime Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with preventive, predictive,. Unplanned downtime is just what it. Find out the causes, costs and benefits of downtime, and how to use tools and technologies to optimize maintenance activities. This could be a fault,. Planned downtime typically occurs alongside routine maintenance and doesn’t impede. Define Equipment Downtime.

From www.fogwing.io

Root Causes Of Machine Downtime Fogwing.io Define Equipment Downtime Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with preventive, predictive,. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Downtime can be planned or unplanned: Machine downtime refers to any period in which a piece of equipment is not. Define Equipment Downtime.

From www.intelligentcio.com

Veeam expert asks what planned downtime could be costing you business Define Equipment Downtime Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. This downtime can significantly impact a company's. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Downtime can be planned or unplanned: Unplanned downtime is just what. Define Equipment Downtime.

From www.maxgrip.com

Infographic 5 Benefits to Tracking Equipment Downtime MaxGrip Define Equipment Downtime On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Simply put, downtime refers to a period during which a system is unavailable. Learn. Define Equipment Downtime.

From www.nrx.com

Causes of Downtime in Manufacturing NRX AssetHub Define Equipment Downtime Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Learn what machine downtime is, how to calculate it, and how to minimize it with preventive maintenance, error codes, and. This downtime can significantly impact a company's. Learn how to measure, prevent and reduce machine downtime, which is any. Define Equipment Downtime.

From olisrobotics.com

How Robot Monitoring Can Help Reduce Downtimes in Manufacturing — Olis Define Equipment Downtime On the other hand, unplanned downtime events usually cause lost productivity and lost revenue. Downtime can be planned or unplanned: Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available. Define Equipment Downtime.

From evocon.com

How to Define Machine Breakdown Causes? Evocon Define Equipment Downtime Downtime can be planned or unplanned: Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Learn what machine downtime is, how to calculate it, and how to minimize it with preventive maintenance, error codes, and. This downtime can significantly impact a company's. Simply put, downtime refers to a. Define Equipment Downtime.

From www.assetinfinity.com

Difference Between Downtime & Breakdown Time in Terms of Maintenance Define Equipment Downtime Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Simply put, downtime refers to a period during which a system is unavailable. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is not available to run. Machine downtime refers to any. Define Equipment Downtime.

From pluto-men.com

Cost of Unplanned Downtime in Manufacturing (And How to Avoid That Define Equipment Downtime This downtime can significantly impact a company's. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Downtime can be planned or unplanned: This could be a fault,. Learn what machine downtime is, how to calculate it, and how to minimize it with preventive maintenance, error codes, and. Learn. Define Equipment Downtime.

From cqeacademy.com

Overall Equipment Effectiveness (OEE) CQE Academy Define Equipment Downtime Learn what equipment downtime is, how it affects productivity and profitability, and how to minimize it with preventive, predictive,. Simply put, downtime refers to a period during which a system is unavailable. Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Learn how to measure, prevent and reduce machine downtime, which is any time when production equipment is. Define Equipment Downtime.

From www.resco.net

How to Calculate Machine Downtime Resco Define Equipment Downtime Planned downtime typically occurs alongside routine maintenance and doesn’t impede productivity. Equipment downtime refers to unexpected and unanticipated issues in a piece of equipment due to malfunction, failure, or scheduled maintenance activities. Unplanned downtime is just what it. Equipment downtime refers to any expected or unexpected downtime that impedes a piece of equipment’s ability to perform its intended task. Learn. Define Equipment Downtime.