Casting Wax Melting Temperature . Many variations are formulated to suit differing requirements. Many variations are formulated to suit differing requirements. Key properties such as melting. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Structure of investment casting wax. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting process works, how to make multiples of your designs, what size The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Metal pouring temperature will vary slightly depending upon particular alloy used. Structure of investment casting wax. Should the temperature exceed these. With a 40% wax fill. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Key properties such as melting. Generally, most ic & ws waxes.

from www.slideserve.com

Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Many variations are formulated to suit differing requirements. Structure of investment casting wax. Key properties such as melting. With a 40% wax fill. Should the temperature exceed these. Generally, most ic & ws waxes. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting process works, how to make multiples of your designs, what size Many variations are formulated to suit differing requirements.

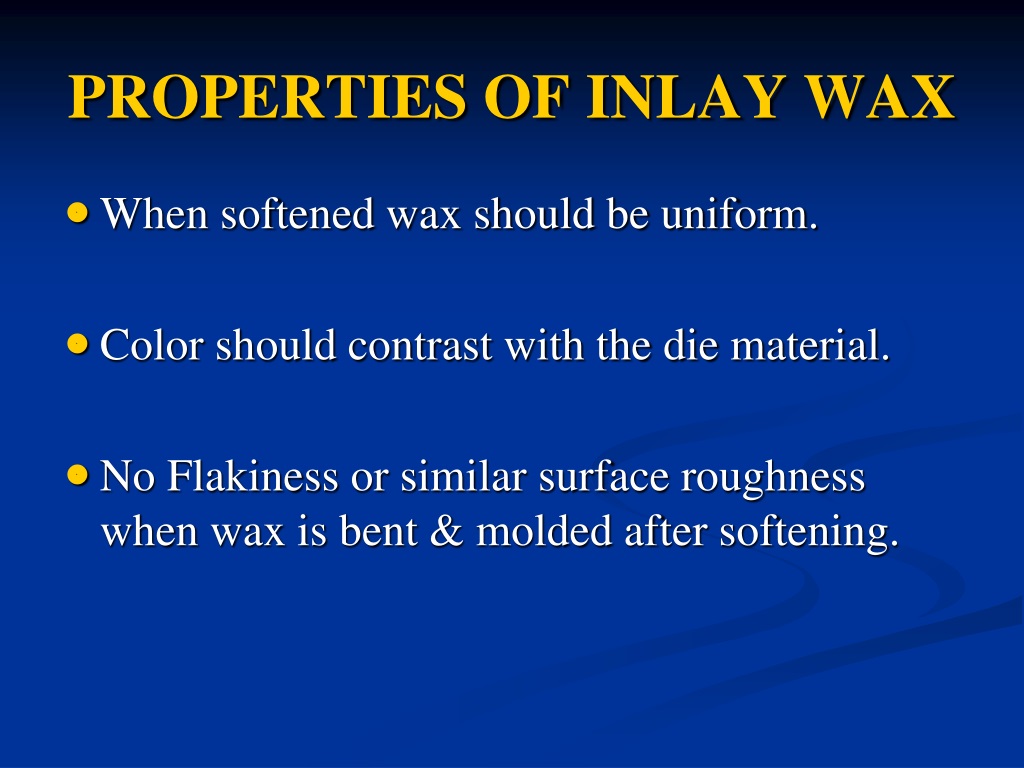

PPT INLAY CASTING WAX PowerPoint Presentation, free download ID9544126

Casting Wax Melting Temperature Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting process works, how to make multiples of your designs, what size As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Metal pouring temperature will vary slightly depending upon particular alloy used. Many variations are formulated to suit differing requirements. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Structure of investment casting wax. Structure of investment casting wax. With a 40% wax fill. Key properties such as melting. Key properties such as melting. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Generally, most ic & ws waxes. Should the temperature exceed these. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Many variations are formulated to suit differing requirements.

From blog.thepipingmart.com

How to Melt Steel for Casting? A Complete Guide Casting Wax Melting Temperature The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Generally, most ic & ws waxes. Many variations are formulated to suit differing requirements. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. As was explained in the section on structure of waxes,. Casting Wax Melting Temperature.

From www.youtube.com

Melting Point of WAX Part 1 YouTube Casting Wax Melting Temperature Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Many variations are formulated to suit differing requirements. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Structure of investment casting wax. Structure of investment casting wax. Many variations are formulated to suit differing requirements. Check out. Casting Wax Melting Temperature.

From infogr.am

Melting and Freezing Points of Wax by gorozpep Infogram Casting Wax Melting Temperature Many variations are formulated to suit differing requirements. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Structure of investment casting wax. Should the temperature exceed these. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Key properties such as melting. Key properties such as melting.. Casting Wax Melting Temperature.

From www.youtube.com

Precision Investment Casting, or Lost Wax Casting Process Expandable Mold Casting Processes Casting Wax Melting Temperature Metal pouring temperature will vary slightly depending upon particular alloy used. Key properties such as melting. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Key properties such as melting. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight. Casting Wax Melting Temperature.

From one-ball.com

Wax Temperature Chart ONE MFG Store Casting Wax Melting Temperature Many variations are formulated to suit differing requirements. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. With a 40% wax fill. Key properties such as melting. Many variations are formulated to suit differing requirements. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Check out. Casting Wax Melting Temperature.

From fakephysicist.com

How To Measure the Melting Point of Candle Wax using Arduino Fake Physicist Casting Wax Melting Temperature Many variations are formulated to suit differing requirements. Key properties such as melting. Structure of investment casting wax. Structure of investment casting wax. Key properties such as melting. Metal pouring temperature will vary slightly depending upon particular alloy used. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or.. Casting Wax Melting Temperature.

From katherinewall.z13.web.core.windows.net

Candle Wax Temperature Chart Casting Wax Melting Temperature Metal pouring temperature will vary slightly depending upon particular alloy used. Structure of investment casting wax. Key properties such as melting. With a 40% wax fill. Should the temperature exceed these. Key properties such as melting. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Melting wax at too high of. Casting Wax Melting Temperature.

From www.numerade.com

Table 2. Melting/Freezing Point Temperature Ranges for Hydrocarbons Hydrocarbon Freezing or Casting Wax Melting Temperature Structure of investment casting wax. Generally, most ic & ws waxes. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Key properties such as melting. With a 40% wax fill. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Structure of investment casting. Casting Wax Melting Temperature.

From www.slideserve.com

PPT Dental waxes PowerPoint Presentation, free download ID6698340 Casting Wax Melting Temperature The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Key properties such as melting. Many variations are formulated to suit differing requirements. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Melting wax at too high of a temperature (overheating) can alter. Casting Wax Melting Temperature.

From vietnamcastiron.com

Metal Casting Process Updates on Metalworking operation in Foundry Casting Wax Melting Temperature Structure of investment casting wax. Should the temperature exceed these. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Many variations are formulated to suit differing requirements. Key properties such as melting. Many variations are formulated to suit differing requirements. With a 40% wax fill. Key properties such. Casting Wax Melting Temperature.

From www.youtube.com

what is casting wax and their uses in dentistry use inlay wax in dentistry use sheet casting Casting Wax Melting Temperature As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Many variations are formulated to suit differing requirements. Structure of investment casting wax. Generally, most ic & ws waxes. Key properties such as melting. Many variations are formulated to suit differing requirements. Melting wax at too high of a. Casting Wax Melting Temperature.

From www.photon.com.eg

Melting point of wax photon scientific Casting Wax Melting Temperature Should the temperature exceed these. Many variations are formulated to suit differing requirements. Key properties such as melting. Metal pouring temperature will vary slightly depending upon particular alloy used. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Structure of investment casting wax. Generally, most ic & ws waxes. Check out. Casting Wax Melting Temperature.

From www.wikihow.com

How to Build a Metal Melting Furnace for Casting 15 Steps Casting Wax Melting Temperature Key properties such as melting. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Should the temperature exceed these. Generally, most ic & ws waxes. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting. Casting Wax Melting Temperature.

From blendedwaxes.com

Melting Point Factors for Common Waxes Blended Waxes Casting Wax Melting Temperature Should the temperature exceed these. Key properties such as melting. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Many variations are formulated to suit differing requirements. Many variations are formulated to suit differing requirements. Generally, most ic & ws waxes. Check out our beginners guide for jewellers covering the different. Casting Wax Melting Temperature.

From www.thecrucible.org

Lost Wax Casting Guide Definition & Process [+ How To Start] Casting Wax Melting Temperature As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Many variations are formulated to suit differing requirements. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Should the temperature exceed these. Structure of investment casting wax. Many variations are formulated to suit differing. Casting Wax Melting Temperature.

From ponasa.condesan-ecoandes.org

Wax Melting Point Chart Ponasa Casting Wax Melting Temperature Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Should the temperature exceed these. Key properties such as melting. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Key properties such as melting. As was explained in the section on structure of. Casting Wax Melting Temperature.

From www.youtube.com

Ceramic Processing L410 Polymer melting point Tm and glass transition temperature Tg YouTube Casting Wax Melting Temperature As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Structure of investment casting wax. Generally, most ic & ws waxes. Should the temperature exceed these. Key properties such as melting.. Casting Wax Melting Temperature.

From www.slideserve.com

PPT INLAY CASTING WAX PowerPoint Presentation, free download ID9544126 Casting Wax Melting Temperature Structure of investment casting wax. Many variations are formulated to suit differing requirements. Should the temperature exceed these. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. With a 40% wax fill. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Structure of investment casting wax.. Casting Wax Melting Temperature.

From www.candleers.com

At What Temperature Does Candle Wax Melt (Wax Melting Point) Candleers Casting Wax Melting Temperature Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Structure of investment casting wax. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Should the temperature exceed these. Many variations are formulated to suit differing requirements. Key properties such as melting. Metal pouring temperature will vary. Casting Wax Melting Temperature.

From www.youtube.com

Melting Point of Wax (part 2) YouTube Casting Wax Melting Temperature Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting process works, how to make multiples of your designs, what size Metal pouring temperature will vary slightly depending upon particular alloy used. Castable wax 40 resin offers high detail and surface smoothness, with handling. Casting Wax Melting Temperature.

From www.devianceanddesire.com

Illustrated Guide Wax Melting Points Casting Wax Melting Temperature Should the temperature exceed these. Metal pouring temperature will vary slightly depending upon particular alloy used. Generally, most ic & ws waxes. Structure of investment casting wax. Many variations are formulated to suit differing requirements. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. As was explained in the section on. Casting Wax Melting Temperature.

From eureka.patsnap.com

Quick casting wax melting device for precise casting production Eureka Patsnap develop Casting Wax Melting Temperature Should the temperature exceed these. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Generally, most ic & ws waxes. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the. Casting Wax Melting Temperature.

From comertys.com

Foundry Casting Waxes COMERTYS Casting Wax Melting Temperature Should the temperature exceed these. Structure of investment casting wax. Generally, most ic & ws waxes. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting process works, how to make multiples of your designs, what size Key properties such as melting. Many variations. Casting Wax Melting Temperature.

From slidetodoc.com

Dental waxes Prepared by Dental Materials Department Yenepoya Casting Wax Melting Temperature Metal pouring temperature will vary slightly depending upon particular alloy used. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. Should the temperature exceed these. Generally, most ic & ws waxes. With a 40% wax fill. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to. Casting Wax Melting Temperature.

From www.researchgate.net

Melting points and latent heats of different paraffin waxes in... Download Scientific Diagram Casting Wax Melting Temperature Should the temperature exceed these. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting process works, how to make multiples of your designs, what size Generally, most ic & ws waxes. Metal pouring temperature will vary slightly depending upon particular alloy used. Castable. Casting Wax Melting Temperature.

From blendedwaxes.com

Melting Point Factors for Common Waxes Blended Waxes Casting Wax Melting Temperature Melting wax at too high of a temperature (overheating) can alter the wax characteristics. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Structure of investment casting wax. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your. Casting Wax Melting Temperature.

From eureka.patsnap.com

Quick casting wax melting device for precise casting production Eureka Patsnap develop Casting Wax Melting Temperature Structure of investment casting wax. Key properties such as melting. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Key properties such as melting. With a 40% wax fill. Many. Casting Wax Melting Temperature.

From www.scribd.com

Solution LW MS LS Waxes Melt Temperature Investment Material Surface Roughness Suit Material Casting Wax Melting Temperature Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Should the temperature exceed these. With a 40% wax fill. Metal pouring temperature will vary slightly depending upon particular alloy used. Generally, most ic & ws waxes. Structure of investment casting wax. The melting temperature should not exceed 85 °c and the. Casting Wax Melting Temperature.

From hxevpsxvo.blob.core.windows.net

What Is The Melting Temperature Of Wax at Holly Hudson blog Casting Wax Melting Temperature Key properties such as melting. Many variations are formulated to suit differing requirements. Should the temperature exceed these. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Structure of investment. Casting Wax Melting Temperature.

From www.cinobee.com

Melting point of different natural waxesNoticeCinobee Bio Industry Corp.,Ltd Casting Wax Melting Temperature Should the temperature exceed these. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting process works, how to make multiples of your designs, what size Generally, most ic & ws waxes. Key properties such as melting. As was explained in the section on. Casting Wax Melting Temperature.

From www.alamy.com

Wax melting Stock Videos & Footage HD and 4K Video Clips Alamy Casting Wax Melting Temperature Many variations are formulated to suit differing requirements. Key properties such as melting. Key properties such as melting. Generally, most ic & ws waxes. Should the temperature exceed these. Metal pouring temperature will vary slightly depending upon particular alloy used. Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Structure of investment casting wax. Structure. Casting Wax Melting Temperature.

From www.researchgate.net

Wax content and wax appearance temperature in different experiments Download Table Casting Wax Melting Temperature Should the temperature exceed these. Generally, most ic & ws waxes. Check out our beginners guide for jewellers covering the different types of wax, how to calculate the weight of your finished metal piece, how the casting process works, how to make multiples of your designs, what size Structure of investment casting wax. Melting wax at too high of a. Casting Wax Melting Temperature.

From eureka.patsnap.com

Quick casting wax melting device for precise casting production Eureka Patsnap develop Casting Wax Melting Temperature Structure of investment casting wax. Should the temperature exceed these. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. With a 40% wax fill. Many variations are formulated to suit. Casting Wax Melting Temperature.

From www.cscasting.com

Melting & Casting Procedure C&S Metal Products Co., Ltd. Casting Wax Melting Temperature Melting wax at too high of a temperature (overheating) can alter the wax characteristics. Many variations are formulated to suit differing requirements. Generally, most ic & ws waxes. Structure of investment casting wax. Should the temperature exceed these. Castable wax 40 resin offers high detail and surface smoothness, with handling characteristics similar to blue carving wax. Key properties such as. Casting Wax Melting Temperature.

From www.youtube.com

Set wax melting temperature04 YouTube Casting Wax Melting Temperature Structure of investment casting wax. The melting temperature should not exceed 85 °c and the holding temperature must be controlled below 80 °c. As was explained in the section on structure of waxes, casting wax passes through a number of phases on heating and/or. Should the temperature exceed these. Many variations are formulated to suit differing requirements. Structure of investment. Casting Wax Melting Temperature.