Hydraulic Motor Efficiency . As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by its theoretical flow. Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a hydraulic machine. One simply estimates the cooling requirement based on the efficiency of the. There are three categories of efficiency used to describe hydraulic pumps (and motors): Three simple methods of specifying a cooler are provided. Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor.

from www.youtube.com

Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a hydraulic machine. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. There are three categories of efficiency used to describe hydraulic pumps (and motors): Three simple methods of specifying a cooler are provided. There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor.

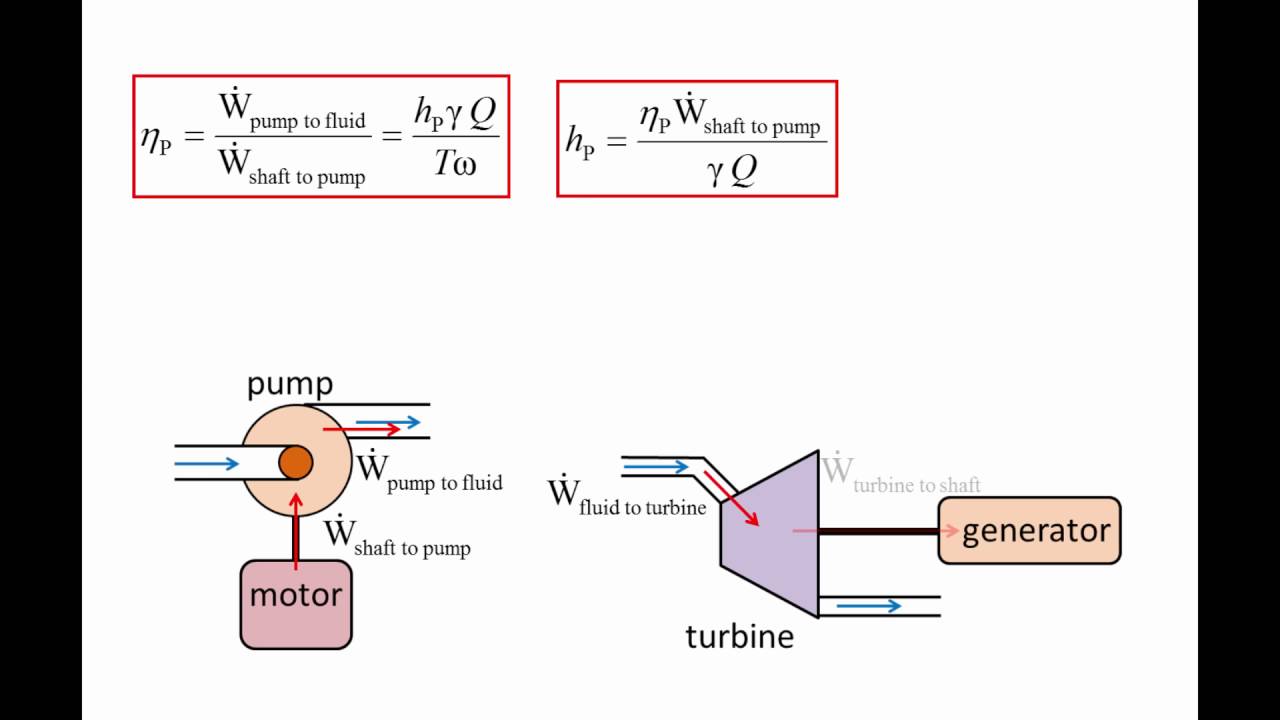

Fluid Mechanics Topic 7.3.3 Definition of pump efficiency & turbine

Hydraulic Motor Efficiency One simply estimates the cooling requirement based on the efficiency of the. One simply estimates the cooling requirement based on the efficiency of the. Three simple methods of specifying a cooler are provided. Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a hydraulic machine. As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by its theoretical flow. There are three categories of efficiency used to describe hydraulic pumps (and motors):

From www.hyspecs.com.au

Hydraulic Power Hyspecs Hydraulics Australia Hydraulic Motor Efficiency There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by. Hydraulic Motor Efficiency.

From www.youtube.com

Hydraulic pump efficiency explained YouTube Hydraulic Motor Efficiency Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by its theoretical flow. Starting torque for common gear, vane, and piston motors ranges between. Hydraulic Motor Efficiency.

From www.powermotiontech.com

Efficient Hydraulic Systems Deliver The Power Power & Motion Hydraulic Motor Efficiency As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a hydraulic machine. Torque ripple is the difference between minimum and maximum torque delivered at a. Hydraulic Motor Efficiency.

From www.stle.org

Machinery Hydraulic Motor Efficiency Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Mechanical efficiency is the ratio of. Hydraulic Motor Efficiency.

From www.researchgate.net

Simplified hydraulic circuit schematic for the motor efficiency test Hydraulic Motor Efficiency Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. There are three categories of efficiency used to describe hydraulic pumps (and motors): Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. One simply estimates the cooling requirement based on the efficiency of the. As industries evolve and demand for efficient and reliable. Hydraulic Motor Efficiency.

From www.researchgate.net

Mechanical, volumetric, and total efficiency of the hydraulic motor Hydraulic Motor Efficiency One simply estimates the cooling requirement based on the efficiency of the. There are three categories of efficiency used to describe hydraulic pumps (and motors): As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. Hydraulic motor efficiency at low speeds or starting from a resting position often. Hydraulic Motor Efficiency.

From www.tytorobotics.com

Brushless Motor Power and Efficiency Analysis — Tyto Robotics Hydraulic Motor Efficiency Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by its theoretical flow. Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. There are three categories of efficiency used to describe hydraulic pumps (and motors): One simply estimates the cooling requirement based on the efficiency of the. Torque ripple. Hydraulic Motor Efficiency.

From www.youtube.com

EFFICIENCY OF TURBINE HYDRAULIC EFFICIENCY MECHANICAL EFFICIENCY Hydraulic Motor Efficiency One simply estimates the cooling requirement based on the efficiency of the. There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. There are three categories of efficiency used to describe hydraulic pumps (and motors): There are three categories of efficiency used to describe. Hydraulic Motor Efficiency.

From fluidpowerjournal.com

Efficient Hydraulic Systems Fluid Power Journal Hydraulic Motor Efficiency Three simple methods of specifying a cooler are provided. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. There are three categories of efficiency used to describe hydraulic pumps (and motors): There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need. Hydraulic Motor Efficiency.

From www.researchgate.net

Simplified hydraulic circuit schematic for the motor efficiency test Hydraulic Motor Efficiency Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. There are three categories of efficiency used to describe hydraulic pumps (and motors): One simply estimates the cooling requirement based on the efficiency of the. There are three categories of efficiency used to describe hydraulic pumps (and motors): Mechanical efficiency is the ratio of. Hydraulic Motor Efficiency.

From www.pumpsandsystems.com

Motor Load, ThreePhase Input & Installing VFDs Hydraulic Motor Efficiency Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. One simply estimates the cooling requirement based on the efficiency of the. Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. There are three categories of efficiency used to describe hydraulic pumps (and motors): Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor.. Hydraulic Motor Efficiency.

From www.mdpi.com

Energies Free FullText Design of a Hydraulic Motor System Driven Hydraulic Motor Efficiency As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by its. Hydraulic Motor Efficiency.

From www.powermotiontech.com

HydraulicElectric Analogies Simple and Efficient Power & Motion Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by its theoretical flow. There are three categories of efficiency used to describe hydraulic pumps (and motors): Torque ripple is the difference between minimum and maximum torque delivered at a. Hydraulic Motor Efficiency.

From www.youtube.com

Exergetic efficiency hydraulic turbine YouTube Hydraulic Motor Efficiency Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a hydraulic machine. There are three categories of efficiency used to describe hydraulic pumps (and motors): There are three categories of efficiency used to describe hydraulic pumps (and motors): Three simple methods of specifying a cooler are provided.. Hydraulic Motor Efficiency.

From hydraulicpumpwopakura.blogspot.com

Hydraulic Pump Hydraulic Pump Efficiency Hydraulic Motor Efficiency Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. One simply estimates the cooling requirement based on the efficiency of the. There are three categories of efficiency used to describe hydraulic pumps (and motors): As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at. Hydraulic Motor Efficiency.

From exotzjcke.blob.core.windows.net

Hydraulic Motor Efficiency Calculator at James Bilbo blog Hydraulic Motor Efficiency Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. As industries evolve and demand for efficient and reliable power solutions. Hydraulic Motor Efficiency.

From www.researchgate.net

Components efficiency comparison. (a) Hydraulic motor's efficiency Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by its theoretical flow. As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at. Hydraulic Motor Efficiency.

From www.youtube.com

How Does A Hydraulic Motor Work Animation YouTube Hydraulic Motor Efficiency Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. Three simple methods of specifying a cooler are provided. Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required. Hydraulic Motor Efficiency.

From www.researchgate.net

Efficiency of hydraulic motor/pump [1]. Download Scientific Diagram Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. One simply estimates the cooling requirement based on the efficiency of the. There are three categories of efficiency used to describe hydraulic pumps (and motors): Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Hydraulic motor efficiency. Hydraulic Motor Efficiency.

From www.powermotiontech.com

How To Calculate Hydraulic Pump and Motor Efficiency Power & Motion Hydraulic Motor Efficiency Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a. Hydraulic Motor Efficiency.

From www.sealandcylinder.com

Motors, Hydraulic Description Seal and Cylinder Source SCS, Inc. Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. There are three categories of efficiency used to describe hydraulic pumps (and motors): Mechanical efficiency is the ratio of. Hydraulic Motor Efficiency.

From www.powermotiontech.com

Fundamentals of Hydraulic Motors Power & Motion Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Three simple methods of specifying a cooler are provided. There are three ways. Hydraulic Motor Efficiency.

From workshopinsider.com

Hydraulic Motor Types A Detailed Guide Insider Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): There are three categories of efficiency used to describe hydraulic pumps (and motors): One simply estimates the cooling requirement based on the efficiency of the. Three simple methods of specifying a cooler are provided. Starting torque for common gear, vane, and piston motors ranges between 70% and. Hydraulic Motor Efficiency.

From www.researchgate.net

Motor efficiency classes (according to IEC60034301) [8], [9 Hydraulic Motor Efficiency As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. There are three categories of efficiency used to describe hydraulic pumps (and motors): Three simple methods of specifying a cooler are provided. Volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency. There are three ways to calculate the efficiency of. Hydraulic Motor Efficiency.

From blog.chesterton.com

Using the Pump Performance Curve to Increase Efficiency Reliability Hydraulic Motor Efficiency Volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency. Three simple methods of specifying a cooler are provided. There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. One simply estimates the cooling requirement based on the efficiency of the. There are three categories of efficiency. Hydraulic Motor Efficiency.

From extrudesign.com

Characteristic curves of Hydraulic Turbines ExtruDesign Hydraulic Motor Efficiency There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Three simple methods of specifying a cooler are provided. There are three categories. Hydraulic Motor Efficiency.

From learnchannel-tv.com

Hydraulic Pumps Hydraulic Motor Efficiency One simply estimates the cooling requirement based on the efficiency of the. There are three categories of efficiency used to describe hydraulic pumps (and motors): Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. There are three ways to calculate the. Hydraulic Motor Efficiency.

From blogs.bu.edu

What is 367 in pump efficiency? Kawasaki Hydraulic Pump Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Three simple methods of specifying a cooler are provided. Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. Hydraulic motor efficiency at low. Hydraulic Motor Efficiency.

From www.youtube.com

Fluid Mechanics Topic 7.3.3 Definition of pump efficiency & turbine Hydraulic Motor Efficiency Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a hydraulic machine. Volumetric. Hydraulic Motor Efficiency.

From blog.republicmanufacturing.com

Motor Efficiency & Ratings Explained Republic Manufacturing Blog Hydraulic Motor Efficiency As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a hydraulic machine. Starting torque for common gear, vane, and piston motors ranges between 70% and. Hydraulic Motor Efficiency.

From calculator.academy

Hydraulic Motor Efficiency Calculator Calculator Academy Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Hydraulic motor efficiency at low speeds or starting from a resting position often determines the design pressure and pump size required in a hydraulic machine. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. Torque ripple is the difference between. Hydraulic Motor Efficiency.

From www.aj-motor.com

Hydraulic Motor Efficiency AJA Technology Hydraulic Motor Efficiency Three simple methods of specifying a cooler are provided. As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Mechanical efficiency is the ratio of actual torque. Hydraulic Motor Efficiency.

From www.linkedin.com

Electric or hydraulic motors—which is more efficient? Hydraulic Motor Efficiency There are three ways to calculate the efficiency of hydraulic pumps and motors which can be used to determine when they need to be changed out. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Starting torque for common gear, vane, and piston motors ranges between 70% and. Hydraulic Motor Efficiency.

From www.xchydraulic.com

How Does The Efficiency of A Hydraulic Motor Impact Its Overall Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. Volumetric efficiency is determined by dividing the actual flow delivered. Hydraulic Motor Efficiency.

From info.texasfinaldrive.com

Hydraulic Motor Efficiency Hydraulic Motor Efficiency There are three categories of efficiency used to describe hydraulic pumps (and motors): Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. As industries evolve and demand for efficient and reliable power solutions grows, hydraulic motors are poised to remain at the forefront of. One simply estimates the. Hydraulic Motor Efficiency.