Spiral Wound Gasket M And Y Values . The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. Spiral wound gaskets with internal or external rings, i.e. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input.

from mungfali.com

Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Spiral wound gaskets with internal or external rings, i.e.

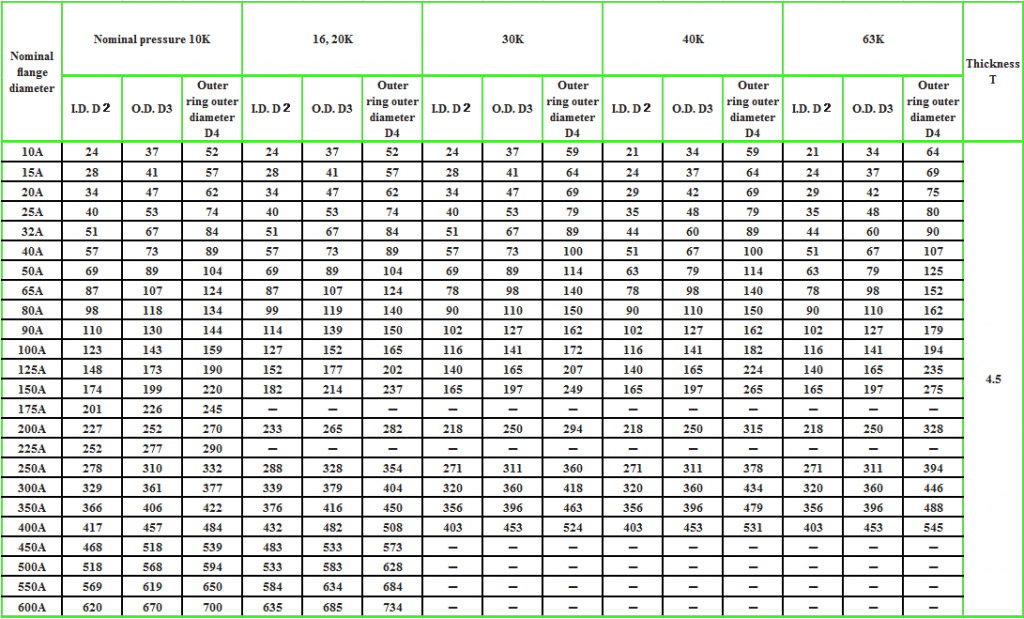

Spiral Wound Gasket Dimensions Chart

Spiral Wound Gasket M And Y Values Spiral wound gaskets with internal or external rings, i.e. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. Spiral wound gaskets with internal or external rings, i.e. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary.

From whatispiping.com

What is a Spiral Wound Gasket? Applications, Types, Construction, and Spiral Wound Gasket M And Y Values This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. Spiral wound gaskets with internal or external rings, i.e. 47 rows these values are used in formulas in the. Spiral Wound Gasket M And Y Values.

From mungfali.com

Spiral Wound Gasket Dimensions Chart Spiral Wound Gasket M And Y Values Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or. Spiral Wound Gasket M And Y Values.

From thepiping.com

what is spiral wound gasket Spiral Wound Gasket M And Y Values 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. Spiral wound gaskets with internal or external rings, i.e. In flange. Spiral Wound Gasket M And Y Values.

From ponasa.condesan-ecoandes.org

Spiral Wound Gasket Torque Chart Spiral Wound Gaskets Torque Values Spiral Wound Gasket M And Y Values Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1. Spiral Wound Gasket M And Y Values.

From www.pgg.om

Gasket Factors “M” and “Y” Premium Gulf Gasket Spiral Wound Gasket M And Y Values This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section. Spiral Wound Gasket M And Y Values.

From www.hawleys.com.au

316SS & Graphite Spiral Wound Gasket CRIR Spiral Wound Gasket M And Y Values Spiral wound gaskets with internal or external rings, i.e. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. The ‘m’. Spiral Wound Gasket M And Y Values.

From hardhatengineer.com

Learn about Spiral Wound Gasket and Color Code Spiral Wound Gasket M And Y Values Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section. Spiral Wound Gasket M And Y Values.

From www.qger.qa

Spiral Wound Gaskets Qatar German Gasket Factory Spiral Wound Gasket M And Y Values The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gaskets with internal or external rings, i.e. This table lists many commonly used gasket materials and contact facings with suggested design values of m. Spiral Wound Gasket M And Y Values.

From bceweb.org

Spiral Wound Gasket Torque Chart A Visual Reference of Charts Chart Spiral Wound Gasket M And Y Values 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Spiral wound gaskets with internal or external rings, i.e. In flange. Spiral Wound Gasket M And Y Values.

From www.lfpco.com

Dimensions of spiral wound gaskets for ASME B16.47 series A flanges Spiral Wound Gasket M And Y Values Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Spiral wound gaskets with internal or external rings, i.e. Styles ‘cg’ and ‘cgi’ can be compressed to the ring. Spiral Wound Gasket M And Y Values.

From uniklinger.com

UNI KLINGER LIMITED Spiral Wound Gasket M And Y Values 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gaskets with internal or external rings, i.e. Spiral wound gasket is the precision engineered solution to such. Spiral Wound Gasket M And Y Values.

From espiral-wound-gaskets.com

CG Spiral Wound Gasket Sunshine™ Gaskets Spiral Wound Gasket M And Y Values 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if. Spiral Wound Gasket M And Y Values.

From hswhite.com

Spiral Wound Gaskets H.S. White Specifications & Color Chart Spiral Wound Gasket M And Y Values Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. Spiral wound gaskets with internal or external rings, i.e. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Styles ‘cg’ and ‘cgi’ can be compressed to the ring. Spiral Wound Gasket M And Y Values.

From www.chokeng.com

ปะเก็นวงแหวนเหล็ก Spiral Wound Gaskets มาตรฐาน EN 15142 DIN EN 1092 Spiral Wound Gasket M And Y Values In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. Spiral wound gaskets with internal or external rings, i.e. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both. Spiral Wound Gasket M And Y Values.

From www.scribd.com

Klinger Gasket Factors Mechanical Engineering Engineering Spiral Wound Gasket M And Y Values Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gaskets with internal or external rings, i.e. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. This table lists many commonly used gasket materials and contact facings with suggested design values of m and. Spiral Wound Gasket M And Y Values.

From mungfali.com

Spiral Wound Gasket Dimensions Chart Spiral Wound Gasket M And Y Values Spiral wound gaskets with internal or external rings, i.e. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. This table. Spiral Wound Gasket M And Y Values.

From mungfali.com

Spiral Wound Gasket Dimensions Chart Spiral Wound Gasket M And Y Values This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. Spiral wound gaskets with internal or external rings, i.e. Spiral wound gasket is the precision engineered solution to such. Spiral Wound Gasket M And Y Values.

From mavink.com

Spiral Wound Gasket Identification Chart Spiral Wound Gasket M And Y Values This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness,. Spiral Wound Gasket M And Y Values.

From blog.thepipingmart.com

Spiral Wound Gaskets Uses, Parts and Thickness Spiral Wound Gasket M And Y Values Spiral wound gaskets with internal or external rings, i.e. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. 47 rows these values are used in formulas in. Spiral Wound Gasket M And Y Values.

From knowledge.callapg.com

Getting To Know Spiral Wound Gaskets Spiral Wound Gasket M And Y Values 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness,. Spiral Wound Gasket M And Y Values.

From www.youtube.com

M & Y Factors in Gaskets (with english subtitles) YouTube Spiral Wound Gasket M And Y Values The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. In flange leakage analysis using asme section viii method, you have. Spiral Wound Gasket M And Y Values.

From mavink.com

Spiral Wound Gasket Identification Chart Spiral Wound Gasket M And Y Values 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. This table lists many commonly used gasket materials and contact facings. Spiral Wound Gasket M And Y Values.

From blog.thepipingmart.com

4 Types of Spiral Wound Gasket and Uses Spiral Wound Gasket M And Y Values This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Spiral wound gaskets with internal or external rings, i.e. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. 47 rows these values are used in formulas in the. Spiral Wound Gasket M And Y Values.

From whatispiping.com

What is a Spiral Wound Gasket? Applications, Types, Construction, and Spiral Wound Gasket M And Y Values Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y. Spiral Wound Gasket M And Y Values.

From blog.naver.com

SPIRAL WOUND GASKET 네이버 블로그 Spiral Wound Gasket M And Y Values In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if. Spiral Wound Gasket M And Y Values.

From www.scribd.com

JIS Standard Spiral Wound Gaskets PDF Spiral Wound Gasket M And Y Values This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gasket is the precision. Spiral Wound Gasket M And Y Values.

From mavink.com

Spiral Wound Gasket Identification Chart Spiral Wound Gasket M And Y Values 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. Spiral wound gaskets with internal or external rings, i.e. This table lists. Spiral Wound Gasket M And Y Values.

From www.semanticscholar.org

Table 2 from ASME B16.20 Spiral Wound Gaskets Performance Testing Spiral Wound Gasket M And Y Values In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section. Spiral Wound Gasket M And Y Values.

From www.scribd.com

Dimensions of Spiral Wound Gaskets ASME B16 Pipe (Fluid Conveyance Spiral Wound Gasket M And Y Values Spiral wound gaskets with internal or external rings, i.e. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to. Spiral Wound Gasket M And Y Values.

From mungfali.com

Spiral Wound Gasket Dimensions Chart Spiral Wound Gasket M And Y Values Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gaskets with internal or. Spiral Wound Gasket M And Y Values.

From mungfali.com

Spiral Wound Gasket Dimensions Chart Spiral Wound Gasket M And Y Values In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. This table lists many commonly used gasket. Spiral Wound Gasket M And Y Values.

From advseal.com

Advanced Sealing Inc. » Gasket Dimensions Spiral Wound Gasket M And Y Values Spiral wound gaskets with internal or external rings, i.e. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. 47 rows these values are used in formulas in the asme boiler and pressure vessel code division 1, section viii, appendix 2 to give an sm1 or sm2. In flange leakage analysis using asme section viii method, you. Spiral Wound Gasket M And Y Values.

From mungfali.com

Spiral Wound Gasket Dimensions Chart Spiral Wound Gasket M And Y Values The ‘m’ value, referred to as the maintenance factor, is the compressive load required on the gasket to maintain the seal. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. 47 rows these values are used. Spiral Wound Gasket M And Y Values.

From www.researchgate.net

Detail of a spiral wound gasket with graphite filler specifically Spiral Wound Gasket M And Y Values This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. Spiral wound gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as. Spiral Wound Gasket M And Y Values.

From www.pgg.om

Spiral Wound Gaskets Premium Gulf Gasket Spiral Wound Gasket M And Y Values This table lists many commonly used gasket materials and contact facings with suggested design values of m and y that generally. In flange leakage analysis using asme section viii method, you have come across two important factors for gaskets as input. Styles ‘cg’ and ‘cgi’ can be compressed to the ring thickness, if necessary. 47 rows these values are used. Spiral Wound Gasket M And Y Values.