Lead Time Formula In Kanban . Lead time can be calculated using the following formula: Explore the key differences between cycle time and lead time. Each letter stands for the following: Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: N is the number of kanban cards needed before you replenish inventory. The lead time measures the time from the moment the customer makes a request to the time they receive something. Kanban lead time is the time it takes for the team to complete an item from the time it was requested (appeared in the backlog). Number of kanban = dt(1+x)/c. Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. D is the demand for the part (i.e.,. Optimize cycle time with insights from a. Learn how to measure both in kanban and discover strategies to shorten the gap. The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is.

from blogagile360.blogspot.com

Each letter stands for the following: The lead time measures the time from the moment the customer makes a request to the time they receive something. Lead time can be calculated using the following formula: D is the demand for the part (i.e.,. Kanban lead time is the time it takes for the team to complete an item from the time it was requested (appeared in the backlog). Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Optimize cycle time with insights from a. N is the number of kanban cards needed before you replenish inventory. Learn how to measure both in kanban and discover strategies to shorten the gap. Explore the key differences between cycle time and lead time.

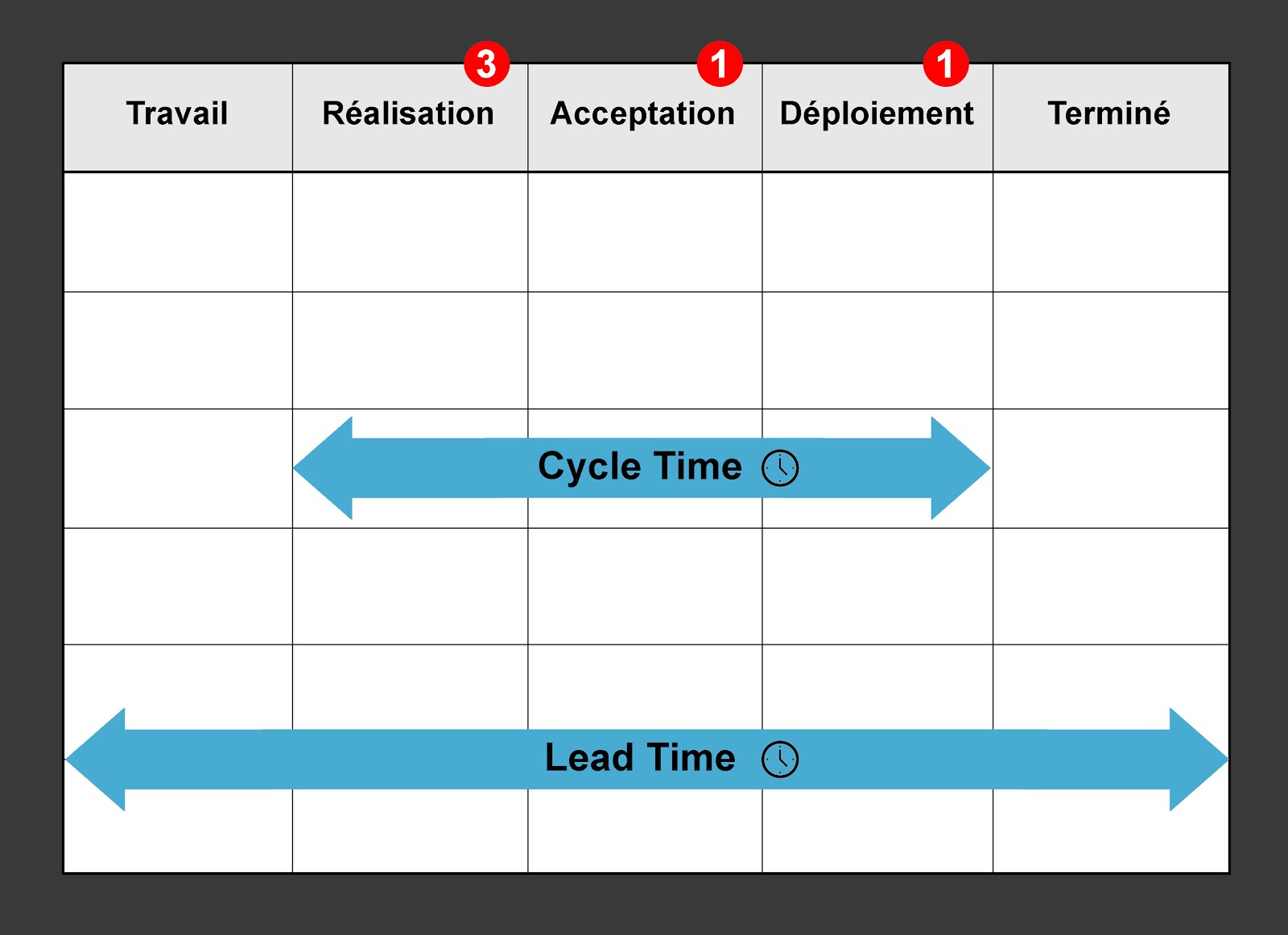

Kanban Cycle time & Lead time

Lead Time Formula In Kanban Each letter stands for the following: Kanban lead time is the time it takes for the team to complete an item from the time it was requested (appeared in the backlog). Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. Lead time can be calculated using the following formula: Learn how to measure both in kanban and discover strategies to shorten the gap. N is the number of kanban cards needed before you replenish inventory. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Optimize cycle time with insights from a. D is the demand for the part (i.e.,. Explore the key differences between cycle time and lead time. Each letter stands for the following: Number of kanban = dt(1+x)/c. The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is. The lead time measures the time from the moment the customer makes a request to the time they receive something.

From www.freshworks.com

Kanban vs Scrum Differentiation and Dissection Freshservice Thoughts Lead Time Formula In Kanban D is the demand for the part (i.e.,. Lead time can be calculated using the following formula: Learn how to measure both in kanban and discover strategies to shorten the gap. Explore the key differences between cycle time and lead time. Kanban lead time is the time it takes for the team to complete an item from the time it. Lead Time Formula In Kanban.

From 3back.com

Kanban Deciphering Lead Time And Cycle Time 3Back Lead Time Formula In Kanban Number of kanban = dt(1+x)/c. Optimize cycle time with insights from a. Explore the key differences between cycle time and lead time. N is the number of kanban cards needed before you replenish inventory. Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. The lead time. Lead Time Formula In Kanban.

From www.youtube.com

What is Kanban? Kanban Visual Systems Explained in 4 stages Easily Lead Time Formula In Kanban Each letter stands for the following: Lead time can be calculated using the following formula: Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. Explore the key differences between cycle time and lead time. D is the demand for the part (i.e.,. The lead time is. Lead Time Formula In Kanban.

From leanmanufacturingtools.org

Kanban Systems; Design, Types and Implementation Lead Time Formula In Kanban Optimize cycle time with insights from a. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Kanban lead time is the time it takes for the team to complete an item from the time it was requested (appeared in the backlog). D is the demand for the part. Lead Time Formula In Kanban.

From businessfluency.com.br

A Quick Guide to Understanding Lead Time Business Fluency Lead Time Formula In Kanban N is the number of kanban cards needed before you replenish inventory. Lead time can be calculated using the following formula: The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is. Learn how to measure both in kanban and discover. Lead Time Formula In Kanban.

From berriprocess.com

Lead Time Berriprocess Agility Lead Time Formula In Kanban Lead time can be calculated using the following formula: Number of kanban = dt(1+x)/c. The lead time measures the time from the moment the customer makes a request to the time they receive something. N is the number of kanban cards needed before you replenish inventory. Kanban lead time is the time it takes for the team to complete an. Lead Time Formula In Kanban.

From www.tipsographic.com

FREE DOWNLOAD > How to Read a Cumulative Flow Diagram in Kanban with Lead Time Formula In Kanban Explore the key differences between cycle time and lead time. N is the number of kanban cards needed before you replenish inventory. The lead time measures the time from the moment the customer makes a request to the time they receive something. Kanban lead time is the time it takes for the team to complete an item from the time. Lead Time Formula In Kanban.

From cin7.com

What Is Manufacturing Lead Time? Cin7 Lead Time Formula In Kanban The lead time measures the time from the moment the customer makes a request to the time they receive something. Number of kanban = dt(1+x)/c. Learn how to measure both in kanban and discover strategies to shorten the gap. Explore the key differences between cycle time and lead time. Each letter stands for the following: N is the number of. Lead Time Formula In Kanban.

From kanbantool.com

What is Cycle Time? Kanban Tool Lead Time Formula In Kanban Each letter stands for the following: Kanban lead time is the time it takes for the team to complete an item from the time it was requested (appeared in the backlog). The lead time measures the time from the moment the customer makes a request to the time they receive something. Optimize cycle time with insights from a. Kanban cycle. Lead Time Formula In Kanban.

From businessmap.io

A 6Step Agile Transformation Roadmap to Success Lead Time Formula In Kanban D is the demand for the part (i.e.,. Explore the key differences between cycle time and lead time. Each letter stands for the following: Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Optimize cycle time with insights from a. Kanban cycle time is the time it takes. Lead Time Formula In Kanban.

From www.myagilepartner.com

Understanding Kanban Metrics Key Indicators for Successful Product Lead Time Formula In Kanban Explore the key differences between cycle time and lead time. The lead time measures the time from the moment the customer makes a request to the time they receive something. D is the demand for the part (i.e.,. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Kanban. Lead Time Formula In Kanban.

From slides.com

Kanban Lead Time Formula In Kanban D is the demand for the part (i.e.,. Lead time can be calculated using the following formula: Optimize cycle time with insights from a. N is the number of kanban cards needed before you replenish inventory. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Kanban lead time. Lead Time Formula In Kanban.

From kaiten.ru

Lead Time vs Cycle Time в чем разница Lead Time Formula In Kanban Kanban lead time is the time it takes for the team to complete an item from the time it was requested (appeared in the backlog). Each letter stands for the following: Explore the key differences between cycle time and lead time. N is the number of kanban cards needed before you replenish inventory. The lead time measures the time from. Lead Time Formula In Kanban.

From blog.tara.ai

Lead Time vs Cycle Time in Kanban A 2023 Guide Lead Time Formula In Kanban Each letter stands for the following: Learn how to measure both in kanban and discover strategies to shorten the gap. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Number of kanban = dt(1+x)/c. Kanban lead time is the time it takes for the team to complete an. Lead Time Formula In Kanban.

From www.pinterest.com

Lead time, Process cycle time, etc. Lean kanban, Business process Lead Time Formula In Kanban N is the number of kanban cards needed before you replenish inventory. Learn how to measure both in kanban and discover strategies to shorten the gap. D is the demand for the part (i.e.,. Number of kanban = dt(1+x)/c. The lead time is the time from the moment when the request was made by a client and placed on a. Lead Time Formula In Kanban.

From businessmap.io

Cycle Time Maximized Productivity from Start to Finish Lead Time Formula In Kanban Optimize cycle time with insights from a. The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is. Lead time can be calculated using the following formula: Each letter stands for the following: Kanban lead time is the time it takes. Lead Time Formula In Kanban.

From kanbantool.com

Managing and Measuring Flow Kanban Tool Lead Time Formula In Kanban Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Lead time can be calculated using the following formula: Optimize cycle time with insights from a. The lead time measures the time from the moment the customer makes a request to the time they receive something. N is the. Lead Time Formula In Kanban.

From supplychaingamechanger.com

Lead Time The Ultimate Guide! Supply Chain Game Changer™ Lead Time Formula In Kanban Learn how to measure both in kanban and discover strategies to shorten the gap. Explore the key differences between cycle time and lead time. D is the demand for the part (i.e.,. Number of kanban = dt(1+x)/c. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Each letter. Lead Time Formula In Kanban.

From www.gorillaroi.com

Free lead time calculator, formula, and management Gorilla ROI Lead Time Formula In Kanban Each letter stands for the following: Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Optimize cycle time with insights from a. Learn how to measure both in kanban and discover strategies to shorten the gap. Number of kanban = dt(1+x)/c. N is the number of kanban cards. Lead Time Formula In Kanban.

From www.scrum.as

Scrum Academy International Kanban Master Foundation Lead Time and Lead Time Formula In Kanban Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is. The lead time measures the time from. Lead Time Formula In Kanban.

From blog.tara.ai

Lead Time vs Cycle Time in Kanban A 2023 Guide Lead Time Formula In Kanban N is the number of kanban cards needed before you replenish inventory. Learn how to measure both in kanban and discover strategies to shorten the gap. Explore the key differences between cycle time and lead time. Number of kanban = dt(1+x)/c. Each letter stands for the following: The lead time measures the time from the moment the customer makes a. Lead Time Formula In Kanban.

From getnave.com

Lead Time vs Cycle Time in Kanban Everything You Need to Know Nave Lead Time Formula In Kanban Each letter stands for the following: The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is. Number of kanban = dt(1+x)/c. N is the number of kanban cards needed before you replenish inventory. Kanban lead time is the time it. Lead Time Formula In Kanban.

From www.youtube.com

Como Calcular o Lead Time ? YouTube Lead Time Formula In Kanban Lead time can be calculated using the following formula: Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. Explore the key differences between cycle time and lead time. Kanban lead time is the time it takes for the team to complete an item from the time. Lead Time Formula In Kanban.

From getagileright.com

How Kanban Works (The Only Introduction You’ll Ever Need) Get Agile Right Lead Time Formula In Kanban Optimize cycle time with insights from a. Lead time can be calculated using the following formula: Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Each letter stands for the following: Kanban cycle time is the time it takes for the team to complete an item from the. Lead Time Formula In Kanban.

From aktiasolutions.com

Kanban Metrics Aktia Solutions Lead Time Formula In Kanban N is the number of kanban cards needed before you replenish inventory. Number of kanban = dt(1+x)/c. Each letter stands for the following: Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. The lead time is the time from the moment when the request was made. Lead Time Formula In Kanban.

From naiwaen.debuggingsoft.com

leadtimevscycletimekanbanmin naiwaenDebuggingSoft Lead Time Formula In Kanban N is the number of kanban cards needed before you replenish inventory. D is the demand for the part (i.e.,. Optimize cycle time with insights from a. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Each letter stands for the following: The lead time is the time. Lead Time Formula In Kanban.

From chisellabs.com

How to Estimate in Kanban & Agile Kanban Metrics Chisel Lead Time Formula In Kanban Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. Learn how to measure both in kanban and discover strategies to shorten the gap. Explore the. Lead Time Formula In Kanban.

From www.gorillaroi.com

Free lead time calculator, formula, and management Gorilla ROI Lead Time Formula In Kanban Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. Kanban lead time is the time it takes for the team to complete an item from. Lead Time Formula In Kanban.

From getnave.com

Lead Time vs Cycle Time in Kanban Everything You Need to Know Nave Lead Time Formula In Kanban Each letter stands for the following: Kanban cycle time is the time it takes for the team to complete an item from the time they started working on it. N is the number of kanban cards needed before you replenish inventory. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and. Lead Time Formula In Kanban.

From blogagile360.blogspot.com

Kanban Cycle time & Lead time Lead Time Formula In Kanban Learn how to measure both in kanban and discover strategies to shorten the gap. Kanban lead time is the time it takes for the team to complete an item from the time it was requested (appeared in the backlog). Lead time can be calculated using the following formula: Explore the key differences between cycle time and lead time. Each letter. Lead Time Formula In Kanban.

From www.slideteam.net

Kanban Diagram With Process Lead Time Lead Time Formula In Kanban Learn how to measure both in kanban and discover strategies to shorten the gap. Here are basic kanban formulas you can apply to your work situation to help keep estimating less stressful and time consuming: The lead time is the time from the moment when the request was made by a client and placed on a board to when all. Lead Time Formula In Kanban.

From agilismoeningenieriadesoftware.blogspot.com

Agilidad en Ingeniería de Software Scrum Entendiendo los Lead Times Lead Time Formula In Kanban Kanban lead time is the time it takes for the team to complete an item from the time it was requested (appeared in the backlog). Number of kanban = dt(1+x)/c. D is the demand for the part (i.e.,. N is the number of kanban cards needed before you replenish inventory. Learn how to measure both in kanban and discover strategies. Lead Time Formula In Kanban.

From www.youtube.com

Kanban Metrics (Lead Time, Cycle Time, Cumulative Flow Diagram) YouTube Lead Time Formula In Kanban The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is. D is the demand for the part (i.e.,. Learn how to measure both in kanban and discover strategies to shorten the gap. Optimize cycle time with insights from a. Number. Lead Time Formula In Kanban.

From getnave.com

Lead Time vs Cycle Time in Kanban Everything You Need to Know Nave Lead Time Formula In Kanban The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is. Number of kanban = dt(1+x)/c. N is the number of kanban cards needed before you replenish inventory. D is the demand for the part (i.e.,. Here are basic kanban formulas. Lead Time Formula In Kanban.

From toughnickel.com

Using Kanban to Calculate Your JIT Bin Quantities ToughNickel Lead Time Formula In Kanban The lead time is the time from the moment when the request was made by a client and placed on a board to when all work on this item is. Number of kanban = dt(1+x)/c. Lead time can be calculated using the following formula: The lead time measures the time from the moment the customer makes a request to the. Lead Time Formula In Kanban.