Types Of Rotational Moulding Machine Water Tank . Mold preparation begins by selecting or creating a mold based on the desired product design. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Types of machines used for rotational molding. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. When choosing a plastic water tank, two common manufacturing methods are often considered: There are several types of rotational molding machines: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. A mold and cooler in one unit where the molding. The rotomolding process involves several steps:

from www.rotomolding-machine.com

The rotomolding process involves several steps: Types of machines used for rotational molding. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. When choosing a plastic water tank, two common manufacturing methods are often considered: A mold and cooler in one unit where the molding. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. There are several types of rotational molding machines: Mold preparation begins by selecting or creating a mold based on the desired product design. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines.

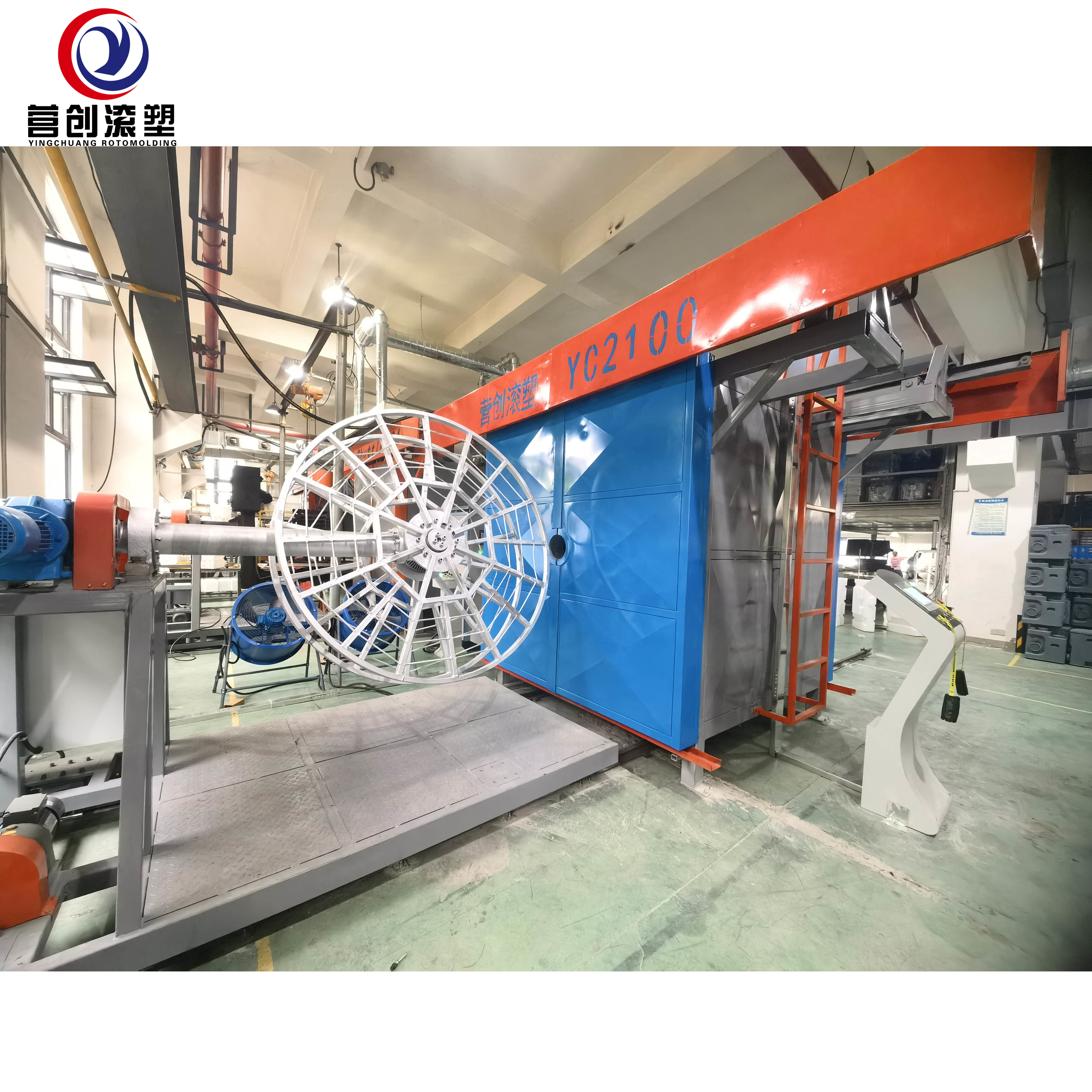

Rotational molding Machine Shuttle Rotomolding Machine For Plastic Water Tank

Types Of Rotational Moulding Machine Water Tank Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. A mold and cooler in one unit where the molding. When choosing a plastic water tank, two common manufacturing methods are often considered: There are several types of rotational molding machines to consider, and the best one for your operation will depend on. The rotomolding process involves several steps: Types of machines used for rotational molding. There are several types of rotational molding machines: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. Mold preparation begins by selecting or creating a mold based on the desired product design.

From wlgunsu.en.made-in-china.com

Water Tank Making Rotomolding Machine Rotational Molding Equipment China Rotational Molding Types Of Rotational Moulding Machine Water Tank Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. There are several types of rotational molding machines: There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle. Types Of Rotational Moulding Machine Water Tank.

From rotomold.en.made-in-china.com

Rotational Moulding Machine Water Tank and Plastic Chair Moulding Machine; Rotomolding Machine Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines to consider, and the best one for your operation will depend on. The rotomolding process involves several steps: There are several types of rotational molding machines: Types of machines used for rotational molding. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. When choosing a plastic water. Types Of Rotational Moulding Machine Water Tank.

From www.rotomolding-machine.com

500 Liter Water Tank Two Arms Rotational Moulding Machine Types Of Rotational Moulding Machine Water Tank The rotomolding process involves several steps: Mold preparation begins by selecting or creating a mold based on the desired product design. Types of machines used for rotational molding. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle. Types Of Rotational Moulding Machine Water Tank.

From www.tradeindia.com

Water Tank Rotational Moulding Machine at 600000.00 INR in Satara Chaurasia Roto Plast Types Of Rotational Moulding Machine Water Tank When choosing a plastic water tank, two common manufacturing methods are often considered: Mold preparation begins by selecting or creating a mold based on the desired product design. A mold and cooler in one unit where the molding. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Types of. Types Of Rotational Moulding Machine Water Tank.

From www.rotomolding-machine.com

Multifunctional Water Tank Rotational Molding Machine With Touch Screen Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. Types of machines used for rotational molding. A mold and cooler in one unit where the molding. There are several types of rotational molding machines to consider, and the best one for your. Types Of Rotational Moulding Machine Water Tank.

From www.rotationalmachine.com

PLC Control Biaxial Rotational Moulding Machine Water Tanks for Sale Buy PLC Control Types Of Rotational Moulding Machine Water Tank Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. Types of machines used for rotational molding. There are several types of rotational molding machines: There are several types of rotational molding machines to consider, and the. Types Of Rotational Moulding Machine Water Tank.

From rotomold.en.made-in-china.com

Water Tank Making Machine Rotating Molding Rotational Moulding Machine China Water Tank Making Types Of Rotational Moulding Machine Water Tank When choosing a plastic water tank, two common manufacturing methods are often considered: A mold and cooler in one unit where the molding. The rotomolding process involves several steps: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. There are several types of rotational molding machines to consider, and the. Types Of Rotational Moulding Machine Water Tank.

From rotomold.en.made-in-china.com

Water Tank Machine by Rotomoulding Rotational Moulding Machine China Water Tank Making Machine Types Of Rotational Moulding Machine Water Tank Mold preparation begins by selecting or creating a mold based on the desired product design. Types of machines used for rotational molding. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. The rotomolding process involves. Types Of Rotational Moulding Machine Water Tank.

From www.indiamart.com

water tank making rotational moulding machine, Rotational Molding Machines, रोटेशनल मोल्डिंग Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. Types of machines used for rotational molding. There are several types of rotational molding machines to consider, and the. Types Of Rotational Moulding Machine Water Tank.

From www.rotationalmachine.com

PLC Touch Screen Control Biaxial Rotational Moulding Machine Water Tanks for Sale Buy Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines: There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Mold preparation begins by selecting or creating a mold based on the desired product design. A mold and cooler in one unit where the molding. When choosing a plastic water tank, two. Types Of Rotational Moulding Machine Water Tank.

From www.indiamart.com

Plastic Water Storage Tank Making 4 arm bi axial Rotational Moulding Machine at Rs 1600000 Types Of Rotational Moulding Machine Water Tank Mold preparation begins by selecting or creating a mold based on the desired product design. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. When choosing a plastic water tank, two common manufacturing methods are often considered: Mold preparation, loading the mold, heating and rotating the mold, and cooling. Types Of Rotational Moulding Machine Water Tank.

From www.indiamart.com

Plastic Water Storage Tank Making 4 arm bi axial Rotational Moulding Machine at Rs 1600000 Types Of Rotational Moulding Machine Water Tank When choosing a plastic water tank, two common manufacturing methods are often considered: A mold and cooler in one unit where the molding. There are several types of rotational molding machines: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. The rotomolding process involves several steps: Mold preparation begins by. Types Of Rotational Moulding Machine Water Tank.

From www.rotomolding-machine.com

Multifunctional Water Tank Rotational Molding Machine With Touch Screen Types Of Rotational Moulding Machine Water Tank Mold preparation begins by selecting or creating a mold based on the desired product design. A mold and cooler in one unit where the molding. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. When. Types Of Rotational Moulding Machine Water Tank.

From wlgunsu.en.made-in-china.com

Customized Septic Water Tank Making Rotomoulding Machine Small Rotational Molding Machine Water Types Of Rotational Moulding Machine Water Tank Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. There are several types of rotational molding machines: Types of machines used for rotational molding. When choosing a plastic water tank, two common manufacturing methods are often considered: A mold and cooler in one unit where the molding. The rotomolding process. Types Of Rotational Moulding Machine Water Tank.

From www.indiamart.com

Rotational Moulding Machine, For Plastic Water Tank at Rs 3200000 in Ahmedabad Types Of Rotational Moulding Machine Water Tank A mold and cooler in one unit where the molding. Types of machines used for rotational molding. The rotomolding process involves several steps: There are several types of rotational molding machines: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. There are several types of rotational molding machines to consider,. Types Of Rotational Moulding Machine Water Tank.

From www.youtube.com

Plastic Rotational Moulding Machine Water Tank Making Machine Labh Group YouTube Types Of Rotational Moulding Machine Water Tank Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. When choosing a plastic water tank, two common manufacturing methods are often considered: A mold and cooler in one unit where the molding. There are several types of rotational molding machines: The rotomolding process involves several steps: There are several types of rotational molding machines to. Types Of Rotational Moulding Machine Water Tank.

From aprtanks.com.au

Rotational Moulding APR Tanks Water Tanks Rainwater Tanks Adelaide Types Of Rotational Moulding Machine Water Tank When choosing a plastic water tank, two common manufacturing methods are often considered: There are several types of rotational molding machines: The rotomolding process involves several steps: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. A mold and cooler in one unit where the molding. Types of machines used. Types Of Rotational Moulding Machine Water Tank.

From www.neelamfabricator.com

plastic water tank making machine Navconic Capsule Type Water Tank Rotomoulding Machine Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines: There are several types of rotational molding machines to consider, and the best one for your operation will depend on. The rotomolding process involves several steps: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. Types of machines used for rotational molding.. Types Of Rotational Moulding Machine Water Tank.

From inbornrotomould.en.made-in-china.com

Water Tank Making Open Type Rock N Roll Rotational Moulding Machine at Best Price Made in China Types Of Rotational Moulding Machine Water Tank The rotomolding process involves several steps: There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. A. Types Of Rotational Moulding Machine Water Tank.

From rotomold.en.made-in-china.com

Rotational Moulding Machine Water Tank Rotomolding Machine China Plastic Machine and Water Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines: Types of machines used for rotational molding. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. The rotomolding process involves several steps: Mold preparation begins by selecting or creating a mold based on the desired product design. Mold preparation, loading the mold,. Types Of Rotational Moulding Machine Water Tank.

From www.rotationalmachine.com

PLC Control Biaxial Rotational Moulding Machine Water Tanks for Sale Buy PLC Control Types Of Rotational Moulding Machine Water Tank Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. Mold preparation begins by selecting or creating a mold based on the desired product design. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. The rotomolding process involves several steps: Types of machines used for rotational. Types Of Rotational Moulding Machine Water Tank.

From www.rotomolding-machine.com

Rotational Molding Water Tank Manufacturing Machine Customized Multifunctional Types Of Rotational Moulding Machine Water Tank Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. A mold and cooler in one unit where the molding. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. There are several types of rotational molding machines: When choosing a plastic water tank, two common manufacturing. Types Of Rotational Moulding Machine Water Tank.

From www.indiamart.com

Mild Steel Water Storage Tank Making Rotational Moulding Machine, For Industrial, Capacity Upto Types Of Rotational Moulding Machine Water Tank A mold and cooler in one unit where the molding. When choosing a plastic water tank, two common manufacturing methods are often considered: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. There are several types of rotational molding machines: There are several types of rotational molding machines to consider,. Types Of Rotational Moulding Machine Water Tank.

From www.indiamart.com

4 Arm Water Storage Tank Making Bi Axial Rotational Moulding Machine at Rs 2400000 Bakrol Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines: Mold preparation begins by selecting or creating a mold based on the desired product design. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. Types of machines. Types Of Rotational Moulding Machine Water Tank.

From www.indiamart.com

Best Price TWO ARM BI AXIAL Rotational moulding Machine for making a plastic water tank at Rs Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines: There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Types of machines used for rotational molding. The rotomolding process involves several steps: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines.. Types Of Rotational Moulding Machine Water Tank.

From www.pinterest.com

Rotational molding machine Manufacturer devplastotech Molding, Cool tools, Plastic injection Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines: Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. Types of machines used for rotational molding. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. When choosing a plastic water tank, two common manufacturing methods are often. Types Of Rotational Moulding Machine Water Tank.

From chinaroto.en.made-in-china.com

Fangda Roto Plastic Water Tank Rock and Roll Rotational Moulding Machine China Rotomolding Types Of Rotational Moulding Machine Water Tank Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. When choosing a plastic water tank, two common manufacturing methods are often considered: The rotomolding process involves several steps: A mold and cooler in one unit where the molding. Mold preparation, loading the mold, heating and rotating the mold, and cooling. Types Of Rotational Moulding Machine Water Tank.

From www.iqsdirectory.com

Plastic Water Tanks Type, Uses, Plastics, and Manufacturing Process Types Of Rotational Moulding Machine Water Tank A mold and cooler in one unit where the molding. There are several types of rotational molding machines: Types of machines used for rotational molding. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. There are. Types Of Rotational Moulding Machine Water Tank.

From www.rotomolding-machine.com

Rotational Molding Water Tank Manufacturing Machine Customized Multifunctional Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Types of machines used for rotational molding. A mold and cooler in one unit where the molding. There are several types of rotational molding machines: Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. When. Types Of Rotational Moulding Machine Water Tank.

From cnhzbenfan.en.made-in-china.com

Water Tank Making Rock N Roll Rotational Moulding Machine Rotational Molding Machine and Types Of Rotational Moulding Machine Water Tank Mold preparation begins by selecting or creating a mold based on the desired product design. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. There are several types of rotational molding machines: Types of machines used for rotational molding. When choosing a plastic water tank, two common manufacturing methods. Types Of Rotational Moulding Machine Water Tank.

From www.iqsdirectory.com

Plastic Water Tanks Type, Uses, Plastics, and Manufacturing Process Types Of Rotational Moulding Machine Water Tank The rotomolding process involves several steps: There are several types of rotational molding machines: When choosing a plastic water tank, two common manufacturing methods are often considered: Types of machines used for rotational molding. Several machines are used for rotational molding, including clamshell machines, rock and roll machines, carousel machines, and shuttle machines. A mold and cooler in one unit. Types Of Rotational Moulding Machine Water Tank.

From rotomold.en.made-in-china.com

The Most Popular Rotational Moulding Machine Water Tank China Plastic Machine and Making Machine Types Of Rotational Moulding Machine Water Tank Types of machines used for rotational molding. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. A mold and cooler in one unit where the molding. Mold preparation begins by selecting or creating a mold based on the desired product design. The rotomolding process involves several steps: There are. Types Of Rotational Moulding Machine Water Tank.

From rotomold.en.made-in-china.com

Best Machine for Manufacturing Plastic Water Tanks Rotational Moulding Machine China Plastic Types Of Rotational Moulding Machine Water Tank There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. A mold and cooler in one unit where the molding. When choosing a plastic water tank, two common manufacturing methods are often considered: Types of machines. Types Of Rotational Moulding Machine Water Tank.

From www.rotationalmachine.com

PLC Touch Screen Control Biaxial Rotational Moulding Machine Water Tanks for Sale Buy Types Of Rotational Moulding Machine Water Tank The rotomolding process involves several steps: Mold preparation, loading the mold, heating and rotating the mold, and cooling and demolding. There are several types of rotational molding machines: A mold and cooler in one unit where the molding. When choosing a plastic water tank, two common manufacturing methods are often considered: Several machines are used for rotational molding, including clamshell. Types Of Rotational Moulding Machine Water Tank.

From www.rotomolding-machine.com

Rotational molding Machine Shuttle Rotomolding Machine For Plastic Water Tank Types Of Rotational Moulding Machine Water Tank Types of machines used for rotational molding. When choosing a plastic water tank, two common manufacturing methods are often considered: A mold and cooler in one unit where the molding. There are several types of rotational molding machines to consider, and the best one for your operation will depend on. Several machines are used for rotational molding, including clamshell machines,. Types Of Rotational Moulding Machine Water Tank.