Workholding For Thin Parts . A new video series looks at technology and practices for thriving as a very small. Vacuum workholding for thin parts: Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum workholding for thin parts: It also holds the material in a relatively free state and can be a great way to. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down.

from pawsworkholding.com

Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. It also holds the material in a relatively free state and can be a great way to. Vacuum workholding for thin parts: When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. A new video series looks at technology and practices for thriving as a very small. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum workholding for thin parts: Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down.

Custom Workholding Solutions PAWS Workholding

Workholding For Thin Parts When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down. Vacuum workholding for thin parts: Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. It also holds the material in a relatively free state and can be a great way to. Vacuum workholding for thin parts: Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. A new video series looks at technology and practices for thriving as a very small. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum.

From lang-technik.co.uk

Workholding Lang Technik UK Workholding For Thin Parts Vacuum workholding for thin parts: Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. It also holds the material in a relatively free state and can be a great way to. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with. Workholding For Thin Parts.

From www.3erp.com

Find the best way to load your workpiece for CNC Machining Workholding For Thin Parts It also holds the material in a relatively free state and can be a great way to. Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Vacuum workholding for thin parts: Vacuum workholding for thin parts: When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution. Workholding For Thin Parts.

From bnrdesigninc.com

Workholding or fixture Workholding For Thin Parts A new video series looks at technology and practices for thriving as a very small. Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. Vacuum workholding for thin parts: Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down. It also holds the material in. Workholding For Thin Parts.

From hwr-usa.com

HWR Workholding USA Successfully holding thinwalled parts with 8 Workholding For Thin Parts Vacuum workholding for thin parts: Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. A new video series looks at technology and practices for thriving as a very small. Vacuum workholding for thin parts: Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. When you absolutely can’t hold. Workholding For Thin Parts.

From pawsworkholding.com

Custom Workholding Solutions PAWS Workholding Workholding For Thin Parts It also holds the material in a relatively free state and can be a great way to. Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. Proper workholding setup ensures that the workpiece does not move or deform during. Workholding For Thin Parts.

From www.miteebite.com

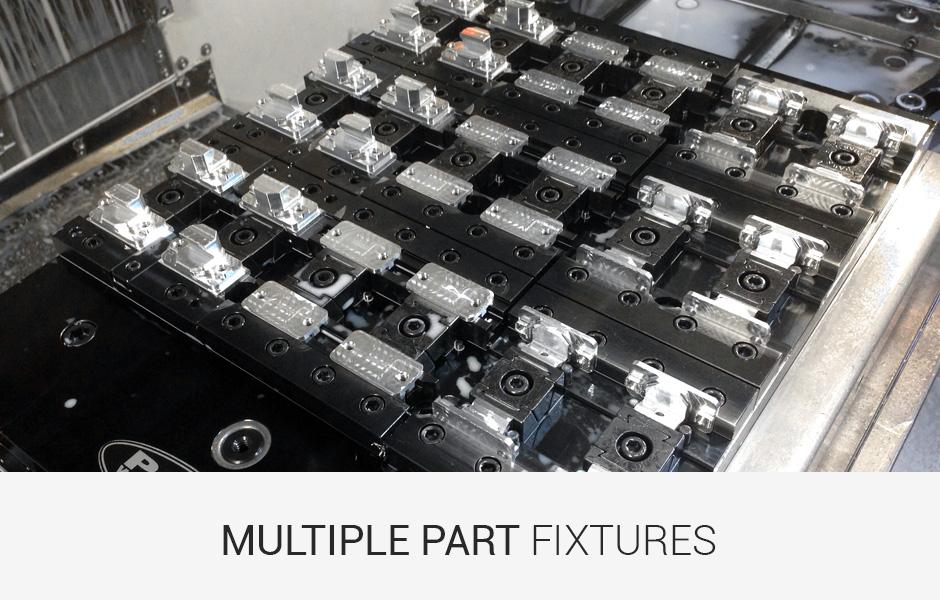

12/11/15 Highdensity workholding gears up MiteeBite Products LLC. Workholding For Thin Parts It also holds the material in a relatively free state and can be a great way to. Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down. Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. A new video series looks at technology and practices. Workholding For Thin Parts.

From www.fastradius.com

Workholding for CNC Manufacturing Resources Fast Radius Workholding For Thin Parts When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Vacuum workholding for thin parts: Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. A new video series looks at technology and practices for thriving as a very small. Holding metal parts with magnetic. Workholding For Thin Parts.

From www.harveyperformance.com

Workholding Styles & Considerations In The Loupe Workholding For Thin Parts Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. A new video series looks at technology and practices for thriving as a very small. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Magnetic workholding systems use powerful magnets. Workholding For Thin Parts.

From www.newulmprecisiontool.com

Workholding Fixtures New Ulm Precision Tool Workholding For Thin Parts Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum workholding for thin parts: When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Holding metal parts with magnetic chucks offers many advantages over traditional. Workholding For Thin Parts.

From www.youtube.com

The OnePerson Machine Shop Machining Thin Parts using Vacuum Workholding For Thin Parts Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum workholding for thin parts: A new video series looks at technology and practices for thriving as a very small. When you absolutely can’t hold. Workholding For Thin Parts.

From www.methods-equipment.com

Workholding Methods & Equipment Associates Workholding For Thin Parts Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum workholding for thin parts: Vacuum workholding for thin parts: Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. When you absolutely can’t hold parts in a vise, the smartvac. Workholding For Thin Parts.

From www.youtube.com

Workholding for Round Parts Samples of Chucks, Mandrels, Collets and Workholding For Thin Parts Vacuum workholding for thin parts: It also holds the material in a relatively free state and can be a great way to. Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. When you absolutely. Workholding For Thin Parts.

From www.trunniontable.com

Custom CNC Workholding Martin Trunnion Tables Workholding For Thin Parts Vacuum workholding for thin parts: Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down. Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent. Workholding For Thin Parts.

From www.cnccookbook.com

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills Workholding For Thin Parts Vacuum workholding for thin parts: A new video series looks at technology and practices for thriving as a very small. Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down. Vacuum workholding for thin parts: When you absolutely can’t hold. Workholding For Thin Parts.

From toolnotes.com

Lathe Workholding ToolNotes Workholding For Thin Parts Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. A new video series looks at technology and practices for thriving as a very small. Vacuum workholding for thin parts: It also holds the material in a relatively free state and can be a great way to. Vacuum workholding is great for securing. Workholding For Thin Parts.

From pawsworkholding.com

Custom Workholding Solutions PAWS Workholding Workholding For Thin Parts When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Vacuum workholding for thin parts: Vacuum workholding for thin parts: It also holds the material in a relatively free state and can be a great way to. Holding metal parts with magnetic chucks offers many advantages over traditional. Workholding For Thin Parts.

From pawsworkholding.com

ID Collet PAWS Workholding Workholding For Thin Parts Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum workholding is. Workholding For Thin Parts.

From www.youtube.com

Workholding Tips for Thin Parts with Paul DeBolt! YouTube Workholding For Thin Parts Vacuum workholding for thin parts: Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. It also holds the material in a relatively free state and can be a great way to. A new video. Workholding For Thin Parts.

From www.precisionpartsfast.com

NEW! Workholding for Tight Tolerance Parts Precision Parts Fast Workholding For Thin Parts Vacuum workholding for thin parts: Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold. Workholding For Thin Parts.

From pawsworkholding.com

Workholding Solutions PAWS Workholding Workholding For Thin Parts Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. A new video series looks at technology and practices for thriving as a very small. Vacuum workholding is great for securing. Workholding For Thin Parts.

From www.pinterest.com

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills Workholding For Thin Parts Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. Vacuum workholding for thin parts: Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. A new video series looks at technology and practices for thriving as a very small. Vacuum workholding for thin parts: Vacuum workholding is great for. Workholding For Thin Parts.

From www.fastradius.com

Workholding for CNC Manufacturing Resources Fast Radius Workholding For Thin Parts Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. It also holds the material in a relatively free state and can be a great way to. A new video series looks at technology and. Workholding For Thin Parts.

From hyfore.com

CNC Workholding Equipment Hyfore Workholding For Thin Parts It also holds the material in a relatively free state and can be a great way to. Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. A new video series. Workholding For Thin Parts.

From pawsworkholding.com

ID Collet Workholding Solutions PAWS Workholding Hydraulic Clamping Workholding For Thin Parts Vacuum workholding for thin parts: Vacuum workholding for thin parts: Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces. Workholding For Thin Parts.

From www.youtube.com

Machining Thin Parts! Part 1 WW138 YouTube Workholding For Thin Parts A new video series looks at technology and practices for thriving as a very small. Vacuum workholding for thin parts: Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum. Workholding For Thin Parts.

From www.hschmidt.com

Thick Round Leveling Fixture Hermann Schmidt Precision Workholding Workholding For Thin Parts Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down. It also holds the material in a relatively free state and can be a great way to. Holding metal parts with. Workholding For Thin Parts.

From hyfore.shop

Collets Standard Workholding C Style Workholding For Thin Parts It also holds the material in a relatively free state and can be a great way to. Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Magnetic workholding systems use. Workholding For Thin Parts.

From www.practicalmachinist.com

BIG KAISER’s Workholding Solution for Uneven Parts Practical Workholding For Thin Parts Vacuum workholding for thin parts: It also holds the material in a relatively free state and can be a great way to. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Proper workholding setup ensures that the workpiece does not move or deform during the machining process,. Workholding For Thin Parts.

From www.cnccookbook.com

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills Workholding For Thin Parts It also holds the material in a relatively free state and can be a great way to. Vacuum workholding for thin parts: Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Holding metal parts. Workholding For Thin Parts.

From www.fictiv.com

Introduction to Workholding Options for CNC Machining Fictiv Workholding For Thin Parts It also holds the material in a relatively free state and can be a great way to. A new video series looks at technology and practices for thriving as a very small. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Holding metal parts with magnetic chucks. Workholding For Thin Parts.

From www.canadianmetalworking.com

Photoactivated adhesive workholding secures parts for tighttolerance Workholding For Thin Parts A new video series looks at technology and practices for thriving as a very small. Vacuum workholding for thin parts: Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. It also holds the material in a relatively free state. Workholding For Thin Parts.

From pawsworkholding.com

Custom Workholding Solutions PAWS Workholding Workholding For Thin Parts When you absolutely can’t hold parts in a vise, the smartvac 3 workholding system provides a simple and streamlined solution with vacuum. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. A new video. Workholding For Thin Parts.

From www.youtube.com

ER Collet Thin Part Workholding How To YouTube Workholding For Thin Parts Magnetic workholding systems use powerful magnets to hold ferrous metal workpieces in place. A new video series looks at technology and practices for thriving as a very small. It also holds the material in a relatively free state and can be a great way to. Vacuum workholding for thin parts: Proper workholding setup ensures that the workpiece does not move. Workholding For Thin Parts.

From www.sme.org

Innovations in Workholding Workholding For Thin Parts Vacuum workholding for thin parts: Vacuum workholding is great for securing large, thin parts which otherwise would be difficult to hold down. Vacuum workholding for thin parts: It also holds the material in a relatively free state and can be a great way to. A new video series looks at technology and practices for thriving as a very small. When. Workholding For Thin Parts.

From www.mmsonline.com

Universal Workholding Solution Grips Challenging Parts Modern Machine Workholding For Thin Parts Holding metal parts with magnetic chucks offers many advantages over traditional clamping devices, particularly with delicate or. Proper workholding setup ensures that the workpiece does not move or deform during the machining process, resulting in precise and consistent parts. A new video series looks at technology and practices for thriving as a very small. Vacuum workholding for thin parts: It. Workholding For Thin Parts.