Haas Ball Screw Bearing Replacement . Do not move the column too far over. Remove the ballscrew [5] and check the support bearings and bearing. Loosely screw the clamp nut on the bearing plate end of the ball screw. If there is resistance or if it binds, the bearings are faulty. Rotate the ballscrew [5] by hand. I'd like to take this as an opportunity to freshen up the machine. Thread the ball nut up the ballscrew toward the. The following sequence is important to ensure proper installation of the ball screw: The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. • tighten the clamp nut, hand tight, on the motor end. Temporarily replace the bearing support housing and push the column towards the control. Orient the ball nut so the oil line can be. Replace the ballscrew into the wedge casting in the reverse order by which it was removed:

from www.haascnc.com

The following sequence is important to ensure proper installation of the ball screw: Remove the ballscrew [5] and check the support bearings and bearing. I'd like to take this as an opportunity to freshen up the machine. Thread the ball nut up the ballscrew toward the. Do not move the column too far over. Loosely screw the clamp nut on the bearing plate end of the ball screw. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: Rotate the ballscrew [5] by hand. Orient the ball nut so the oil line can be. Temporarily replace the bearing support housing and push the column towards the control.

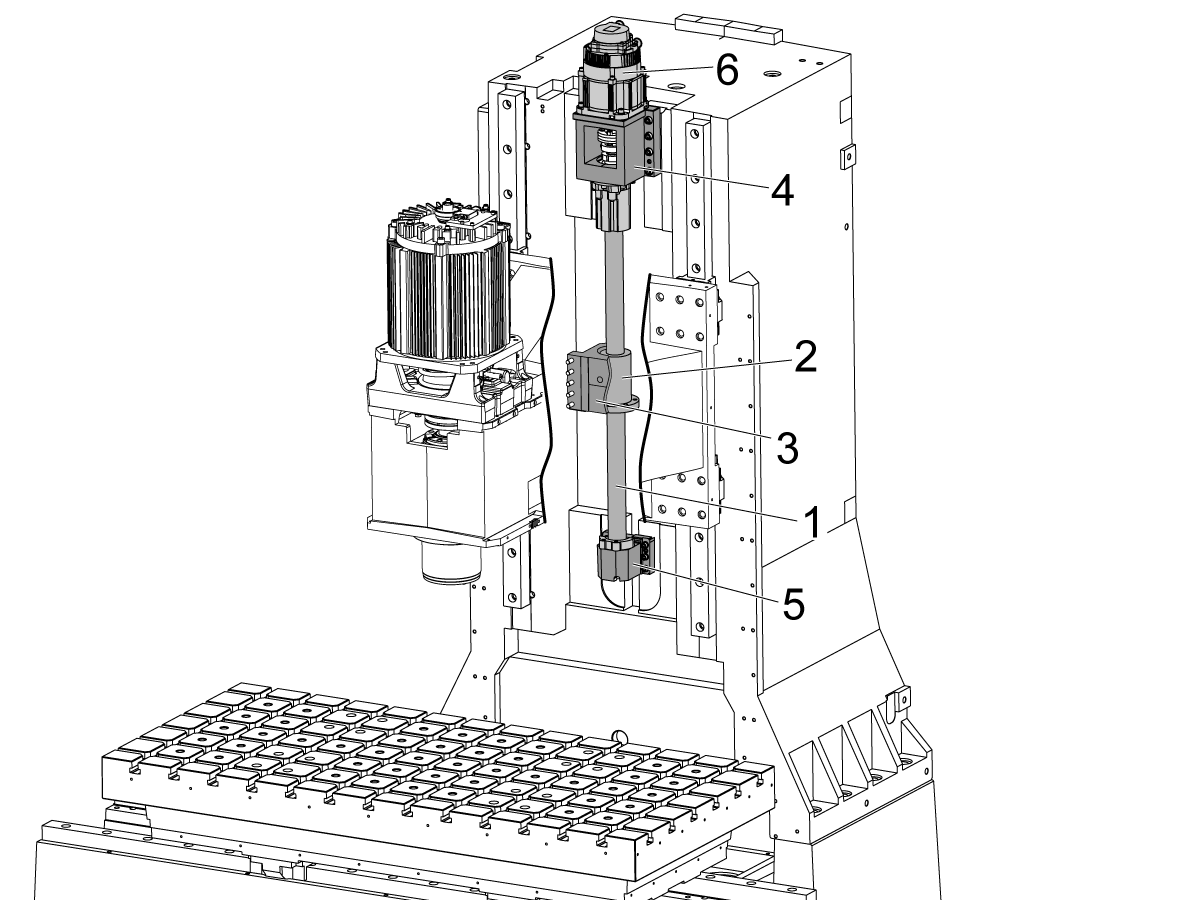

Ballscrew Vertical Axis Replacement

Haas Ball Screw Bearing Replacement The following sequence is important to ensure proper installation of the ball screw: • tighten the clamp nut, hand tight, on the motor end. Temporarily replace the bearing support housing and push the column towards the control. If there is resistance or if it binds, the bearings are faulty. Orient the ball nut so the oil line can be. Rotate the ballscrew [5] by hand. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Thread the ball nut up the ballscrew toward the. Do not move the column too far over. The following sequence is important to ensure proper installation of the ball screw: Remove the ballscrew [5] and check the support bearings and bearing. I'd like to take this as an opportunity to freshen up the machine. Loosely screw the clamp nut on the bearing plate end of the ball screw.

From www.haascnc.com

32mm Ballscrew Bearing Pack Retrofit Kit Installation AD0461 Haas Ball Screw Bearing Replacement Thread the ball nut up the ballscrew toward the. Rotate the ballscrew [5] by hand. Orient the ball nut so the oil line can be. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: Remove the ballscrew [5] and check the support bearings and bearing. Temporarily replace the bearing support housing and push. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

Ballscrew Troubleshooting Guide Haas Ball Screw Bearing Replacement Orient the ball nut so the oil line can be. Remove the ballscrew [5] and check the support bearings and bearing. Thread the ball nut up the ballscrew toward the. I'd like to take this as an opportunity to freshen up the machine. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: The. Haas Ball Screw Bearing Replacement.

From azcncmanufacturing.com

30TAB06 U/GMP4 Ballscrew Bearing Axial Ball Bearing Replacement AZ Haas Ball Screw Bearing Replacement Loosely screw the clamp nut on the bearing plate end of the ball screw. Temporarily replace the bearing support housing and push the column towards the control. Orient the ball nut so the oil line can be. • tighten the clamp nut, hand tight, on the motor end. Rotate the ballscrew [5] by hand. Thread the ball nut up the. Haas Ball Screw Bearing Replacement.

From www.aliexpress.com

Haas Ball Screw Bearing Replacement Remove the ballscrew [5] and check the support bearings and bearing. Thread the ball nut up the ballscrew toward the. The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Loosely screw the clamp nut on the bearing plate end of the ball screw. Rotate the ballscrew [5] by. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

Alimentador de barras 300 husillo de bolas Reemplazo Haas Ball Screw Bearing Replacement Orient the ball nut so the oil line can be. Do not move the column too far over. If there is resistance or if it binds, the bearings are faulty. • tighten the clamp nut, hand tight, on the motor end. Temporarily replace the bearing support housing and push the column towards the control. I'd like to take this as. Haas Ball Screw Bearing Replacement.

From www.ebay.com

HAAS HS1 BALL SCREW NSK W3208W24ZC5Z eBay Haas Ball Screw Bearing Replacement If there is resistance or if it binds, the bearings are faulty. The following sequence is important to ensure proper installation of the ball screw: Temporarily replace the bearing support housing and push the column towards the control. • tighten the clamp nut, hand tight, on the motor end. Thread the ball nut up the ballscrew toward the. The document. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

Bar Feeder 300 Ballscrew Replacement Haas Ball Screw Bearing Replacement Rotate the ballscrew [5] by hand. Thread the ball nut up the ballscrew toward the. The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Temporarily replace the bearing support housing and push the column towards the control. If there is resistance or if it binds, the bearings are. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

VMC Ballscrew 32mm Horizontal Plane Replacement Haas Ball Screw Bearing Replacement Orient the ball nut so the oil line can be. The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Remove the ballscrew [5] and check the support bearings and bearing. Temporarily replace the bearing support housing and push the column towards the control. The following sequence is important. Haas Ball Screw Bearing Replacement.

From gtlathetips.blogspot.com

GT Lathe Pics, Tips and Tricks Ball Screw Repair All Machines , All Haas Ball Screw Bearing Replacement I'd like to take this as an opportunity to freshen up the machine. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: Temporarily replace the bearing support housing and push the column towards the control. Remove the ballscrew [5] and check the support bearings and bearing. Rotate the ballscrew [5] by hand. The. Haas Ball Screw Bearing Replacement.

From www.youtube.com

Fitting the new bearings to the Haas spindle YouTube Haas Ball Screw Bearing Replacement The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Orient the ball nut so the oil line can be. Thread the ball nut up the ballscrew toward the. If there is resistance or if it binds, the bearings are faulty. Rotate the ballscrew [5] by hand. Replace the. Haas Ball Screw Bearing Replacement.

From www.youtube.com

Haas Ball Screw repair YouTube Haas Ball Screw Bearing Replacement I'd like to take this as an opportunity to freshen up the machine. Temporarily replace the bearing support housing and push the column towards the control. The following sequence is important to ensure proper installation of the ball screw: Rotate the ballscrew [5] by hand. Thread the ball nut up the ballscrew toward the. If there is resistance or if. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

32mm Ballscrew Bearing Pack Retrofit Kit Installation AD0461 Haas Ball Screw Bearing Replacement I'd like to take this as an opportunity to freshen up the machine. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Rotate the ballscrew [5] by hand. Orient the ball nut. Haas Ball Screw Bearing Replacement.

From www.youtube.com

haas vf8 replaced X axis screw YouTube Haas Ball Screw Bearing Replacement • tighten the clamp nut, hand tight, on the motor end. I'd like to take this as an opportunity to freshen up the machine. Remove the ballscrew [5] and check the support bearings and bearing. If there is resistance or if it binds, the bearings are faulty. Rotate the ballscrew [5] by hand. The following sequence is important to ensure. Haas Ball Screw Bearing Replacement.

From azcncmanufacturing.com

32MM Ballscrew Bearing Axial Ball Bearing Replacement for HAAS P/N 30 Haas Ball Screw Bearing Replacement • tighten the clamp nut, hand tight, on the motor end. Loosely screw the clamp nut on the bearing plate end of the ball screw. Remove the ballscrew [5] and check the support bearings and bearing. Rotate the ballscrew [5] by hand. I'd like to take this as an opportunity to freshen up the machine. Orient the ball nut so. Haas Ball Screw Bearing Replacement.

From www.ebay.com

Haas milling machine VF2 1996 Z Axis Ballscrew ,Nut ,Bearings & Mount Haas Ball Screw Bearing Replacement If there is resistance or if it binds, the bearings are faulty. Orient the ball nut so the oil line can be. Rotate the ballscrew [5] by hand. • tighten the clamp nut, hand tight, on the motor end. The following sequence is important to ensure proper installation of the ball screw: Thread the ball nut up the ballscrew toward. Haas Ball Screw Bearing Replacement.

From parts.haascnc.com

Search Haas Parts Genuine OEM Haas Automation® Parts FactoryDirect Haas Ball Screw Bearing Replacement I'd like to take this as an opportunity to freshen up the machine. Rotate the ballscrew [5] by hand. The following sequence is important to ensure proper installation of the ball screw: Orient the ball nut so the oil line can be. The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a. Haas Ball Screw Bearing Replacement.

From www.youtube.com

Part 24 (Repacking X axis ball screw) YouTube Haas Ball Screw Bearing Replacement • tighten the clamp nut, hand tight, on the motor end. The following sequence is important to ensure proper installation of the ball screw: Remove the ballscrew [5] and check the support bearings and bearing. The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Orient the ball nut. Haas Ball Screw Bearing Replacement.

From azcncmanufacturing.com

30TAB06 U/GMP4 Ballscrew Bearing Axial Ball Bearing Replacement AZ Haas Ball Screw Bearing Replacement • tighten the clamp nut, hand tight, on the motor end. Temporarily replace the bearing support housing and push the column towards the control. Thread the ball nut up the ballscrew toward the. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: The following sequence is important to ensure proper installation of the. Haas Ball Screw Bearing Replacement.

From cncreplacementparts.com

Ball Screw Nut Removal Tool 32 mm CNC Replacement Parts Haas Ball Screw Bearing Replacement I'd like to take this as an opportunity to freshen up the machine. Do not move the column too far over. If there is resistance or if it binds, the bearings are faulty. • tighten the clamp nut, hand tight, on the motor end. The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack. Haas Ball Screw Bearing Replacement.

From www.ebay.com

Haas milling machine VF2 1996 Z Axis Ballscrew ,Nut ,Bearings & Mount Haas Ball Screw Bearing Replacement The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Rotate the ballscrew [5] by hand. If there is resistance or if it binds, the bearings are faulty. • tighten the clamp nut, hand tight, on the motor end. Replace the ballscrew into the wedge casting in the reverse. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

Ballscrew Troubleshooting Guide Haas Ball Screw Bearing Replacement The following sequence is important to ensure proper installation of the ball screw: Remove the ballscrew [5] and check the support bearings and bearing. Loosely screw the clamp nut on the bearing plate end of the ball screw. Do not move the column too far over. Replace the ballscrew into the wedge casting in the reverse order by which it. Haas Ball Screw Bearing Replacement.

From www.youtube.com

1997 Haas VF2 disassembled demo YouTube Haas Ball Screw Bearing Replacement The following sequence is important to ensure proper installation of the ball screw: Replace the ballscrew into the wedge casting in the reverse order by which it was removed: Temporarily replace the bearing support housing and push the column towards the control. The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a. Haas Ball Screw Bearing Replacement.

From www.youtube.com

Easy way to replace rear Y axis ball screw cover on HAAS TM1 CNC Haas Ball Screw Bearing Replacement Temporarily replace the bearing support housing and push the column towards the control. Remove the ballscrew [5] and check the support bearings and bearing. I'd like to take this as an opportunity to freshen up the machine. • tighten the clamp nut, hand tight, on the motor end. Thread the ball nut up the ballscrew toward the. Rotate the ballscrew. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

32mm Ballscrew Bearing Pack Retrofit Kit Haas Ball Screw Bearing Replacement Rotate the ballscrew [5] by hand. Do not move the column too far over. The following sequence is important to ensure proper installation of the ball screw: Orient the ball nut so the oil line can be. • tighten the clamp nut, hand tight, on the motor end. The document provides instructions for installing a retrofit kit to replace a. Haas Ball Screw Bearing Replacement.

From www.bidspotter.com

Lot of Haas Repair Parts, with Fans, Vector Drive, Ball Screw Bearings Haas Ball Screw Bearing Replacement Temporarily replace the bearing support housing and push the column towards the control. Do not move the column too far over. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. • tighten. Haas Ball Screw Bearing Replacement.

From www.practicalmachinist.com

Worn way or ball screw in X? Haas Ball Screw Bearing Replacement Replace the ballscrew into the wedge casting in the reverse order by which it was removed: I'd like to take this as an opportunity to freshen up the machine. Thread the ball nut up the ballscrew toward the. If there is resistance or if it binds, the bearings are faulty. Rotate the ballscrew [5] by hand. The following sequence is. Haas Ball Screw Bearing Replacement.

From spwindustrial.com

Buy Thrust Bearings Ball Screw X Y Z Axis 32 Mm As Compared To Haas Haas Ball Screw Bearing Replacement If there is resistance or if it binds, the bearings are faulty. Do not move the column too far over. Loosely screw the clamp nut on the bearing plate end of the ball screw. Temporarily replace the bearing support housing and push the column towards the control. I'd like to take this as an opportunity to freshen up the machine.. Haas Ball Screw Bearing Replacement.

From www.bidspotter.com

Lot of Haas Repair Parts, with Fans, Vector Drive, Ball Screw Bearings Haas Ball Screw Bearing Replacement I'd like to take this as an opportunity to freshen up the machine. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: The following sequence is important to ensure proper installation of the ball screw: Thread the ball nut up the ballscrew toward the. Remove the ballscrew [5] and check the support bearings. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

Husillo de bolas Resolución de Problemas Haas Automation Haas Ball Screw Bearing Replacement The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Do not move the column too far over. Orient the ball nut so the oil line can be. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: Thread the ball nut up. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

Ballscrew Vertical Axis Replacement Haas Ball Screw Bearing Replacement Orient the ball nut so the oil line can be. Replace the ballscrew into the wedge casting in the reverse order by which it was removed: The following sequence is important to ensure proper installation of the ball screw: Temporarily replace the bearing support housing and push the column towards the control. Rotate the ballscrew [5] by hand. Remove the. Haas Ball Screw Bearing Replacement.

From www.practicalmachinist.com

Haas Replacing spindle motor bearings Practical Machinist Largest Haas Ball Screw Bearing Replacement Orient the ball nut so the oil line can be. I'd like to take this as an opportunity to freshen up the machine. The document provides instructions for installing a retrofit kit to replace a 32mm ballscrew bearing pack with a new cartridge bearing. Remove the ballscrew [5] and check the support bearings and bearing. Replace the ballscrew into the. Haas Ball Screw Bearing Replacement.

From www.youtube.com

Haas Spindle Bearing Replacement Part1 YouTube Haas Ball Screw Bearing Replacement The following sequence is important to ensure proper installation of the ball screw: Loosely screw the clamp nut on the bearing plate end of the ball screw. Thread the ball nut up the ballscrew toward the. Remove the ballscrew [5] and check the support bearings and bearing. Orient the ball nut so the oil line can be. • tighten the. Haas Ball Screw Bearing Replacement.

From www.made-in-china.com

932384 Ball Screw, Haas Parts China 932384 Haas Ball Screw Bearing Replacement Loosely screw the clamp nut on the bearing plate end of the ball screw. If there is resistance or if it binds, the bearings are faulty. Orient the ball nut so the oil line can be. Temporarily replace the bearing support housing and push the column towards the control. Replace the ballscrew into the wedge casting in the reverse order. Haas Ball Screw Bearing Replacement.

From www.youtube.com

Part 31 (Installing the Y axis ball screw) YouTube Haas Ball Screw Bearing Replacement Remove the ballscrew [5] and check the support bearings and bearing. Rotate the ballscrew [5] by hand. Thread the ball nut up the ballscrew toward the. Do not move the column too far over. I'd like to take this as an opportunity to freshen up the machine. If there is resistance or if it binds, the bearings are faulty. Orient. Haas Ball Screw Bearing Replacement.

From www.haascnc.com

Lathe Axis Motion Haas Service Manual Haas Ball Screw Bearing Replacement Rotate the ballscrew [5] by hand. Remove the ballscrew [5] and check the support bearings and bearing. Orient the ball nut so the oil line can be. Do not move the column too far over. The following sequence is important to ensure proper installation of the ball screw: Loosely screw the clamp nut on the bearing plate end of the. Haas Ball Screw Bearing Replacement.