Spray Drying Emulsions . Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. (ii) homogenization of the dispersion; According to bakry et al. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. (i) preparation of a stable emulsion; These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. The oil droplet size (ods) in the powder is critical for.

from www.mdpi.com

The oil droplet size (ods) in the powder is critical for. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. According to bakry et al. (ii) homogenization of the dispersion; Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. (i) preparation of a stable emulsion;

Molecules Free FullText Spray Drying for the Encapsulation of Oils

Spray Drying Emulsions Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. The oil droplet size (ods) in the powder is critical for. (ii) homogenization of the dispersion; Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. According to bakry et al. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. (i) preparation of a stable emulsion;

From armfield.co.uk

FT30MKIII Spray Dryer Armfield Spray Drying Emulsions (i) preparation of a stable emulsion; A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. (ii) homogenization of the dispersion; The oil droplet size. Spray Drying Emulsions.

From www.academia.edu

(PDF) Effects of Spray Drying on W/O/W Multiple Emulsions Prepared from Spray Drying Emulsions These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. (ii) homogenization of the dispersion; The oil droplet size (ods) in the powder is critical for. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation. Spray Drying Emulsions.

From www.youtube.com

The Spray Drying Process Normal Operations YouTube Spray Drying Emulsions These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. Spray drying, a popular particle formation and drying method,. Spray Drying Emulsions.

From www.researchgate.net

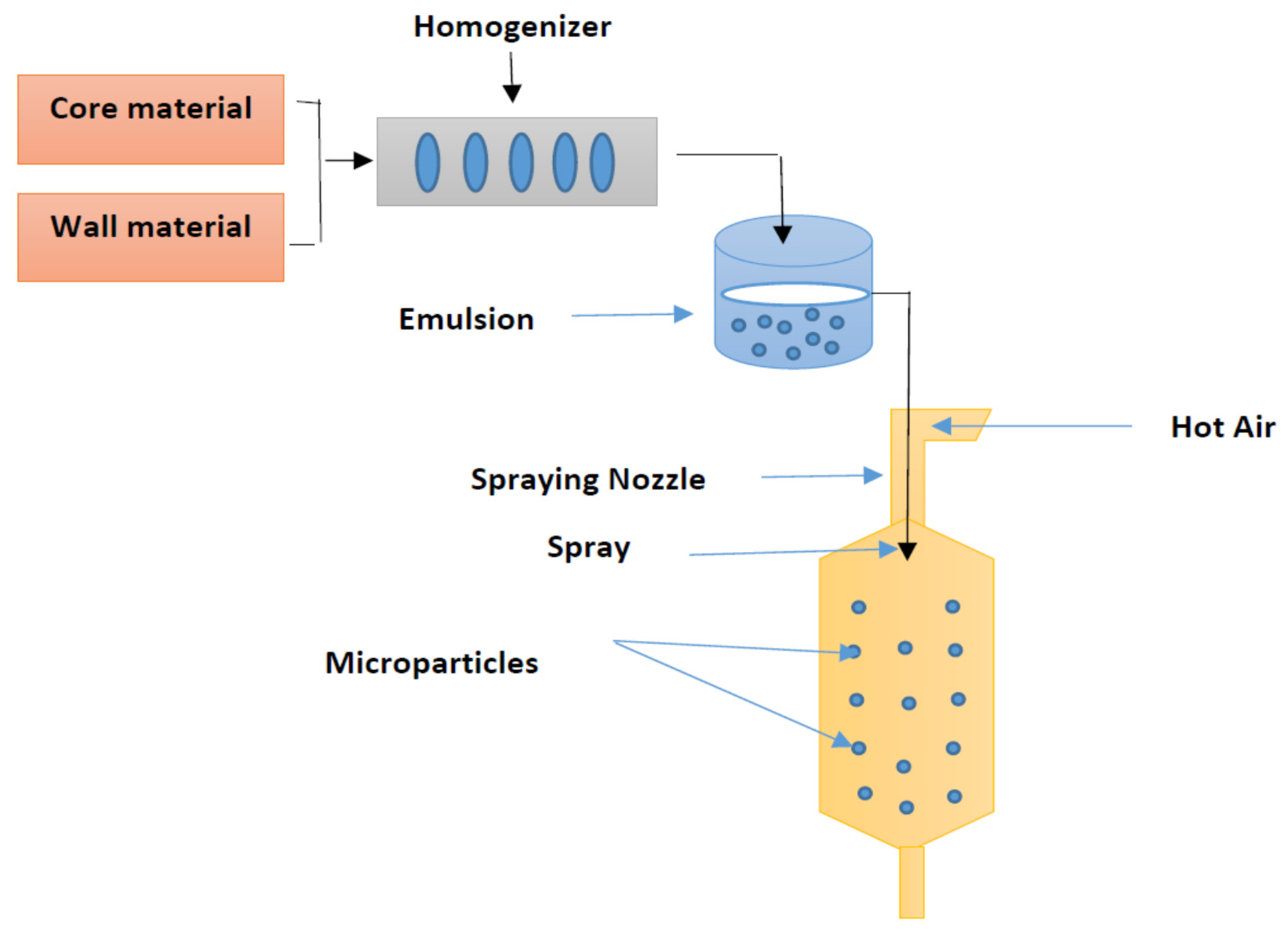

Spray drying technique. Download Scientific Diagram Spray Drying Emulsions (ii) homogenization of the dispersion; Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. The oil droplet size (ods) in the powder is critical for. (i) preparation of a stable emulsion; According to bakry et al. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity. Spray Drying Emulsions.

From pubs.acs.org

Shaping of ZSM5Based Catalysts via Spray Drying Effect on Methanol Spray Drying Emulsions Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. According to bakry et al.. Spray Drying Emulsions.

From ifst.onlinelibrary.wiley.com

Spray drying of emulsions Influence of the emulsifier system on Spray Drying Emulsions (i) preparation of a stable emulsion; According to bakry et al. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. Spray drying is preferred over conventional particle production approaches, such as. Spray Drying Emulsions.

From www.mdpi.com

Polymers Free FullText Effect of Mixed Particulate Emulsifiers on Spray Drying Emulsions Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. (ii) homogenization of the dispersion; Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. These particles are produced by spray drying of an emulsion, in which the dispersed. According to bakry et al. Spray drying, a. Spray Drying Emulsions.

From www.researchgate.net

Schematic Representation of SprayDrying Technology. Download Spray Drying Emulsions Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. According to bakry et al. (i) preparation of a stable. Spray Drying Emulsions.

From www.mdpi.com

Molecules Free FullText Spray Drying for the Encapsulation of Oils Spray Drying Emulsions According to bakry et al. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. These particles are produced by spray drying of an emulsion, in which the dispersed. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for. Spray Drying Emulsions.

From www.researchgate.net

(PDF) Microencapsulation via SprayDrying of GeraniolLoaded Emulsions Spray Drying Emulsions A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. According to bakry et al. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. (ii) homogenization of the dispersion; These particles are produced by. Spray Drying Emulsions.

From www.researchgate.net

Conventional spray drying (SP) and double emulsionsspray drying Spray Drying Emulsions A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. According to bakry et al. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying, a popular. Spray Drying Emulsions.

From pubs.acs.org

Comparison of Techniques for Drying Cellulose Nanocrystal Pickering Spray Drying Emulsions (ii) homogenization of the dispersion; These particles are produced by spray drying of an emulsion, in which the dispersed. The oil droplet size (ods) in the powder is critical for. (i) preparation of a stable emulsion; Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. Spray drying, a popular particle formation and. Spray Drying Emulsions.

From www.researchgate.net

(PDF) Ultrasoundassisted emulsions with biopolymers for spraydrying Spray Drying Emulsions A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. (ii) homogenization of the dispersion; The oil droplet size (ods) in the powder is critical for. These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widespread encapsulation technique. Spray Drying Emulsions.

From www.aveka.com

Spray Drying HighlyEngineered Particles Jet Milling AVEKA Spray Drying Emulsions These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. According to bakry et al. (i) preparation of a stable emulsion; Spray drying, a popular particle formation and drying method, is particularly. Spray Drying Emulsions.

From www.researchgate.net

Schematic representation of spray drying. Schematic representation of Spray Drying Emulsions According to bakry et al. (i) preparation of a stable emulsion; These particles are produced by spray drying of an emulsion, in which the dispersed. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. The oil droplet size (ods) in the powder is critical for. (ii) homogenization of. Spray Drying Emulsions.

From www.researchgate.net

13 Results for spray drying flavor encapsulation, using emulsions Spray Drying Emulsions These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. According to bakry et al. Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. A spray drying process model enabled accurate. Spray Drying Emulsions.

From www.amazon.com

ENCAPSULATION OF NANOEMULSIONS BY SPRAY DRYING Optimization of the Spray Drying Emulsions According to bakry et al. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. (ii) homogenization of the dispersion; (i) preparation of a stable emulsion; These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a. Spray Drying Emulsions.

From www.degruyter.com

Technological solutions for encapsulation Spray Drying Emulsions The oil droplet size (ods) in the powder is critical for. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. These particles are produced by spray drying of an emulsion, in which the dispersed. (ii) homogenization of the dispersion; Spray drying of emulsions is a widely used process in the food industry for. Spray Drying Emulsions.

From www.academia.edu

(PDF) Spray Drying of Highsucrose Dairy Emulsions Feasibility and Spray Drying Emulsions (i) preparation of a stable emulsion; According to bakry et al. (ii) homogenization of the dispersion; Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying, a popular particle formation and drying method, is particularly effective for. Spray Drying Emulsions.

From www.intechopen.com

Figure 7. Spray Drying Emulsions A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. (i) preparation of a stable emulsion; The oil droplet size (ods) in the powder is critical for. These particles are produced by spray drying of an emulsion, in which the dispersed. (ii) homogenization of the dispersion; Spray drying, a. Spray Drying Emulsions.

From www.fraunhofer.de

Spray drying Perfect dosing thanks to drug capsules Spray Drying Emulsions A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. These particles are produced by spray drying of an emulsion, in which the dispersed. According to bakry et al. (ii) homogenization of the dispersion; The oil droplet size (ods) in the powder is critical for. Spray drying is preferred. Spray Drying Emulsions.

From ytdrying.en.made-in-china.com

Centrifugal Spray Power Drying Machine of ABS Emulsion China ABS Spray Drying Emulsions These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. A spray drying process model enabled accurate prediction of dryer outlet temperature and. Spray Drying Emulsions.

From www.researchgate.net

Conventional spray drying (SP) and double emulsionsspray drying Spray Drying Emulsions Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. (ii) homogenization of the dispersion; Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing. Spray Drying Emulsions.

From www.researchgate.net

Formation of PLGA nanoparticles by double (W/O/W) emulsion, spray Spray Drying Emulsions Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. Spray drying, a. Spray Drying Emulsions.

From www.scientistlive.com

Spray drying with a three channel nozzle Scientist Live Spray Drying Emulsions Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. The oil droplet size (ods) in the powder is critical for. (i) preparation of a stable emulsion; According to bakry et al. These particles are produced by spray drying of an emulsion, in which the dispersed. A spray drying process model enabled accurate prediction. Spray Drying Emulsions.

From www.mdpi.com

Foods Free FullText SprayDried Infant Formula Emulsion Stability Spray Drying Emulsions According to bakry et al. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. (i) preparation of a stable emulsion; The oil droplet size (ods) in the powder is. Spray Drying Emulsions.

From www.researchgate.net

(PDF) Microencapsulation by Spray Drying of Multiple Emulsions Spray Drying Emulsions Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. The oil droplet size (ods) in the powder is critical for. (i) preparation of a stable emulsion; Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. (ii) homogenization. Spray Drying Emulsions.

From www.plant-ex.com

The Process of Spray Drying PlantEx Spray Drying Emulsions Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of. Spray Drying Emulsions.

From pdfslide.net

(PDF) MODELING AND SIMULATION OF MILK EMULSION DRYING IN SPRAY … · A Spray Drying Emulsions (ii) homogenization of the dispersion; Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection. Spray Drying Emulsions.

From www.mdpi.com

Life Free FullText Microencapsulation via SprayDrying of Geraniol Spray Drying Emulsions Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. According to bakry et al. Spray drying of emulsions is a widely used process in the food industry for production of, for example,. Spray Drying Emulsions.

From www.alaquainc.com

Spray Drying Process Application and Feature Alaqua Inc Spray Drying Emulsions These particles are produced by spray drying of an emulsion, in which the dispersed. The oil droplet size (ods) in the powder is critical for. Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. According to bakry et al. A spray drying process model enabled accurate prediction of dryer outlet temperature and. Spray Drying Emulsions.

From www.youtube.com

Spray drying of an emulsion using a Mini SprayDrier Buchi B290 YouTube Spray Drying Emulsions Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. According to bakry et al. A spray drying process model enabled accurate prediction of dryer outlet temperature and collection relative humidity for a range of spray. Spray drying of emulsions is a widely used process in the food industry for production of, for. Spray Drying Emulsions.

From dorsatech.ir

Article Details Spray Drying Emulsions Spray drying of emulsions is a widespread encapsulation technique to produce a large variety of powdered formulations. These particles are produced by spray drying of an emulsion, in which the dispersed. Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated. According to bakry et al.. Spray Drying Emulsions.

From www.hovione.com

Spray drying Hovione Spray Drying Emulsions (ii) homogenization of the dispersion; Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. The oil droplet size (ods) in the powder is critical for. Spray drying of emulsions is a widespread encapsulation technique to produce. Spray Drying Emulsions.

From www.researchgate.net

The flow curves of emulsions with FOCE before spray drying A and after Spray Drying Emulsions (i) preparation of a stable emulsion; The oil droplet size (ods) in the powder is critical for. Spray drying is preferred over conventional particle production approaches, such as emulsion/solvent evaporation method, due to. Spray drying, a popular particle formation and drying method, is particularly effective for continuously producing dry solids. Spray drying of emulsions is a widespread encapsulation technique to. Spray Drying Emulsions.