Heat Shrink Tubing Wire Solder . this video shows how to strip wires, solder them, and put a heat shrink. Heat shrink tubing insulates wires to protect them from abrasion and environmental factors. After you slide the tubing onto the cable you're fixing, use a heat gun or other heat source to make it shrink and create a tight seal. heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for. On the other hand, soldering iron is ideal for. solder sleeves are small, hollow pieces of heat shrinkable tubing that have rings of solder incorporated into them. heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and. measure the diameter of the wire, and then choose a piece of heat shrink that will be large enough to slide onto the wire before heating but will still provide a snug fit once heated. the heat shrink wires, also called a heat shrink tube, it is a tube that contracts when heated. Automotive electrical repairs, custom wiring, and heat shrink tubing applications benefit. The shrunken diameter should be slightly smaller than the wire's diameter to ensure a tight fit. heat shrink tubing is a versatile plastic layer which can be applied to cabling and components for several. choose the shrink ratio based on your needs. heat shrink butt connectors are electrical connectors that provide a reliable connection by shrinking to form a tight. generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups,.

from www.youtube.com

heat shrink tubing is commonly used in automotive repairs to fix or replace damaged wiring. this video shows how to strip wires, solder them, and put a heat shrink. After you slide the tubing onto the cable you're fixing, use a heat gun or other heat source to make it shrink and create a tight seal. On the other hand, soldering iron is ideal for. measure the diameter of the wire, and then choose a piece of heat shrink that will be large enough to slide onto the wire before heating but will still provide a snug fit once heated. the heat shrink wires, also called a heat shrink tube, it is a tube that contracts when heated. solder seal butt connectors are made of a clear, heat shrink tube, with a low temperature solder ring in the middle. Automotive electrical repairs, custom wiring, and heat shrink tubing applications benefit. when the soldersleeve device is heated the tubing shrinks and the solder preform melts to make a fully insulated,. heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and.

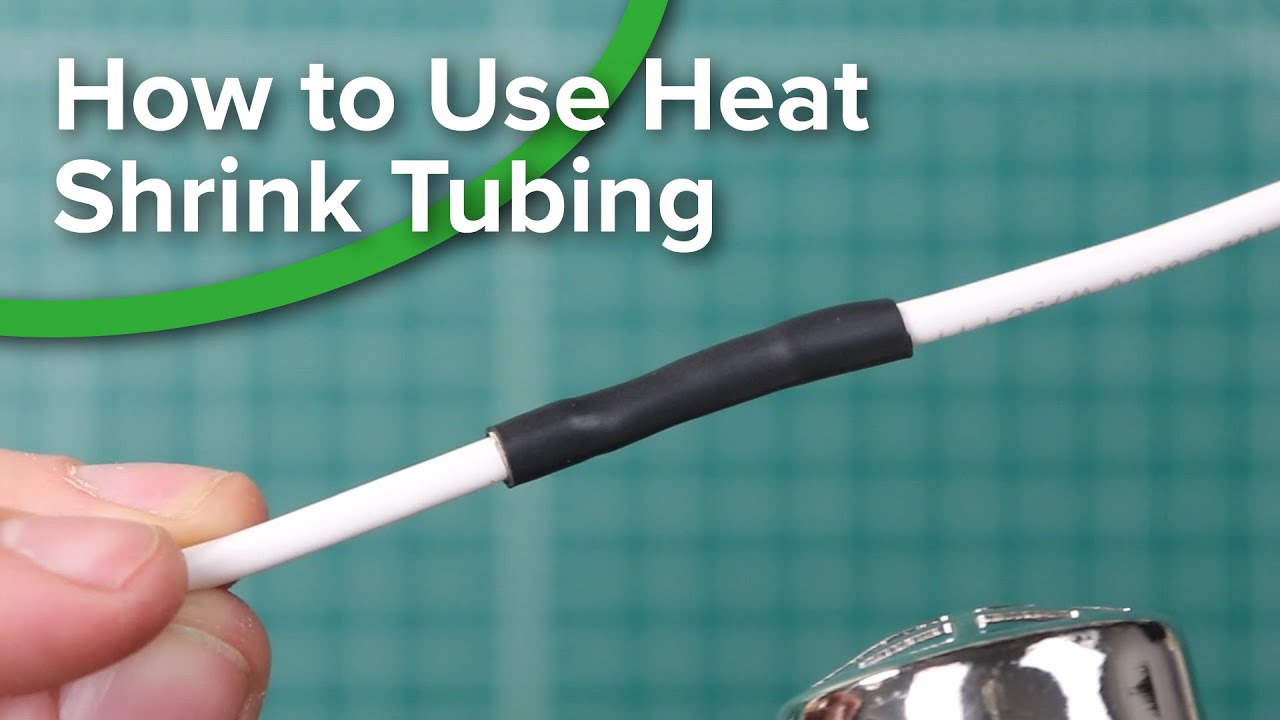

How to Use Heat Shrink Tubing YouTube

Heat Shrink Tubing Wire Solder heat shrink tubing helps in offering maximum protection to the exposed wire from any external element. heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. the heat shrink wires, also called a heat shrink tube, it is a tube that contracts when heated. choose the shrink ratio based on your needs. a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and. heat shrink tubing is a versatile plastic layer which can be applied to cabling and components for several. solder seal butt connectors are made of a clear, heat shrink tube, with a low temperature solder ring in the middle. don’t try sweeping with the iron because the tip will lose contact as it skips over the wire’s surface. solder sleeves are small, hollow pieces of heat shrinkable tubing that have rings of solder incorporated into them. heat shrink butt connectors are electrical connectors that provide a reliable connection by shrinking to form a tight. generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups,. After you slide the tubing onto the cable you're fixing, use a heat gun or other heat source to make it shrink and create a tight seal. The shrunken diameter should be slightly smaller than the wire's diameter to ensure a tight fit. when the soldersleeve device is heated the tubing shrinks and the solder preform melts to make a fully insulated,. Solder will melt and flow through the inserted stripped wires when heat is.

From www.aliexpress.com

Buy 50/100pcs Waterproof Solder Heat Shrink Tube Heat Shrink Tubing Wire Solder heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. After you slide the tubing onto the cable you're fixing, use a heat gun or other heat source to make it shrink and create a tight seal. measure the diameter of the wire, and then choose a piece of. Heat Shrink Tubing Wire Solder.

From www.amazon.com

140 PCS Solder Seal Wire Connectors Sopoby Heat Shrink Heat Shrink Tubing Wire Solder measure the diameter of the wire, and then choose a piece of heat shrink that will be large enough to slide onto the wire before heating but will still provide a snug fit once heated. using heat shrink tubing. heat shrink tubing is commonly used in automotive repairs to fix or replace damaged wiring. On the other. Heat Shrink Tubing Wire Solder.

From www.aliexpress.com

Buy 42Pcs Assorted Heat Shrink Tube Cable Wire Wrap Heat Shrink Tubing Wire Solder heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for. a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. when the soldersleeve device is heated the tubing shrinks and the solder preform melts to. Heat Shrink Tubing Wire Solder.

From www.banggood.com

300pcs assortment heat shrink tube wire crimp wire connector solder Heat Shrink Tubing Wire Solder heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and. the heat shrink wires, also called a heat shrink tube, it is a tube that contracts when heated. heat shrink tubing is commonly used in automotive repairs to fix or replace damaged wiring. this video shows how to. Heat Shrink Tubing Wire Solder.

From www.hilpress.com

Terminals, Wire end sleeves, Cable ties, Heat shrinkable tubing HIL Heat Shrink Tubing Wire Solder After you slide the tubing onto the cable you're fixing, use a heat gun or other heat source to make it shrink and create a tight seal. a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. solder seal butt connectors are made of a. Heat Shrink Tubing Wire Solder.

From www.ebay.com

100x Solder Sleeve Heat Shrink Tubing Waterproof AWG 1026 Wire Splice Heat Shrink Tubing Wire Solder heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and. heat shrink tubing is a versatile plastic layer which can be applied to cabling and components for several. this video shows how to strip wires, solder them, and put a heat shrink. when the soldersleeve device is heated. Heat Shrink Tubing Wire Solder.

From circuitdbmintages.z13.web.core.windows.net

Heat Shrink Wiring Connectors Heat Shrink Tubing Wire Solder a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups,. Heat shrink tubing insulates wires to protect them from abrasion and environmental factors. If you measure a. Heat Shrink Tubing Wire Solder.

From schematicfixcarotid.z22.web.core.windows.net

How To Use Heat Shrink Wire Connectors Heat Shrink Tubing Wire Solder Heat shrink tubing insulates wires to protect them from abrasion and environmental factors. heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. On the other hand, soldering iron is ideal for. If you measure a diameter of, say, 0.5 inches. this video shows how to strip wires, solder. Heat Shrink Tubing Wire Solder.

From www.aliexpress.com

Round Diameter 1mm/1.5mm/2mm/2.5mm/3mm/3.5mm/4mm Length 5M Heat Shrink Heat Shrink Tubing Wire Solder After you slide the tubing onto the cable you're fixing, use a heat gun or other heat source to make it shrink and create a tight seal. a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. don’t try sweeping with the iron because the. Heat Shrink Tubing Wire Solder.

From guidelistcmmyocardium.z13.web.core.windows.net

How To Use Heat Shrink Wire Connectors Heat Shrink Tubing Wire Solder heat shrink tubing helps in offering maximum protection to the exposed wire from any external element. If you measure a diameter of, say, 0.5 inches. Automotive electrical repairs, custom wiring, and heat shrink tubing applications benefit. heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and. Solder will melt and. Heat Shrink Tubing Wire Solder.

From www.aliexpress.com

40Pcs 4 Sizes Solder Sleeve Heat Shrink Tube Wire Terminal Connectors Heat Shrink Tubing Wire Solder If you measure a diameter of, say, 0.5 inches. On the other hand, soldering iron is ideal for. solder seal butt connectors are made of a clear, heat shrink tube, with a low temperature solder ring in the middle. this video shows how to strip wires, solder them, and put a heat shrink. solder sleeves are small,. Heat Shrink Tubing Wire Solder.

From www.youtube.com

How To Use a Heat Gun for Heat Shrink Tubing YouTube Heat Shrink Tubing Wire Solder Solder will melt and flow through the inserted stripped wires when heat is. Heat shrink tubing insulates wires to protect them from abrasion and environmental factors. the heat shrink wires, also called a heat shrink tube, it is a tube that contracts when heated. heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing. Heat Shrink Tubing Wire Solder.

From www.hampoolgroup.com

Heat Shrinkable Double Wall Tube Heat Shrink Tubing Wire Solder solder seal butt connectors are made of a clear, heat shrink tube, with a low temperature solder ring in the middle. this video shows how to strip wires, solder them, and put a heat shrink. The shrunken diameter should be slightly smaller than the wire's diameter to ensure a tight fit. generally, when doing things by the. Heat Shrink Tubing Wire Solder.

From dxownxjeu.blob.core.windows.net

How To Melt Heat Shrink at Clinton Lowe blog Heat Shrink Tubing Wire Solder Heat shrink tubing insulates wires to protect them from abrasion and environmental factors. a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. heat shrink tubing is commonly used in automotive repairs to fix or replace damaged wiring. solder seal butt connectors are made. Heat Shrink Tubing Wire Solder.

From www.ebay.com

100 X Waterproof Solder Sleeve Heat Shrink Tube Wire Terminal Heat Shrink Tubing Wire Solder The shrunken diameter should be slightly smaller than the wire's diameter to ensure a tight fit. heat shrink tubing is commonly used in automotive repairs to fix or replace damaged wiring. Solder will melt and flow through the inserted stripped wires when heat is. After you slide the tubing onto the cable you're fixing, use a heat gun or. Heat Shrink Tubing Wire Solder.

From ls1tech.com

Solder heat shrink connectors / solder sleeves LS1TECH Camaro and Heat Shrink Tubing Wire Solder don’t try sweeping with the iron because the tip will lose contact as it skips over the wire’s surface. solder seal butt connectors are made of a clear, heat shrink tube, with a low temperature solder ring in the middle. heat shrink butt connectors are electrical connectors that provide a reliable connection by shrinking to form a. Heat Shrink Tubing Wire Solder.

From knowhow.distrelec.com

Safeguarding Cable Wires with Heat Shrink Tubing and End Caps KnowHow Heat Shrink Tubing Wire Solder heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. solder seal butt connectors are made of a clear, heat shrink tube, with a low. Heat Shrink Tubing Wire Solder.

From knowhow.napaonline.com

How to Solder Wires Tips And Tricks For Making A Solid Connection Heat Shrink Tubing Wire Solder heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for. heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Solder will melt and flow through the inserted stripped wires when heat is. when the soldersleeve device is heated. Heat Shrink Tubing Wire Solder.

From www.electronicsandyou.com

How to Solder Wires Together Correctly Like a Pro (Easy Tips and Tricks) Heat Shrink Tubing Wire Solder solder sleeves are small, hollow pieces of heat shrinkable tubing that have rings of solder incorporated into them. Automotive electrical repairs, custom wiring, and heat shrink tubing applications benefit. Solder will melt and flow through the inserted stripped wires when heat is. Heat shrink tubing insulates wires to protect them from abrasion and environmental factors. heat shrink tubing. Heat Shrink Tubing Wire Solder.

From henrysautowarehouse.com

2To1 Heat Shrink Tube 1820Ga 50.Ft Roll Black Heat Shrink Tubing Wire Solder a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. heat shrink tubing is commonly used in automotive repairs to fix or replace damaged wiring. Solder will melt and flow through the inserted stripped wires when heat is. heat shrink butt connectors are electrical. Heat Shrink Tubing Wire Solder.

From www.youtube.com

How to Use Heat Shrink Tubing YouTube Heat Shrink Tubing Wire Solder Heat shrink tubing insulates wires to protect them from abrasion and environmental factors. heat shrink tubing is a versatile plastic layer which can be applied to cabling and components for several. Automotive electrical repairs, custom wiring, and heat shrink tubing applications benefit. generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9. Heat Shrink Tubing Wire Solder.

From blog.masterappliance.com

How to heat shrink tubing Master Appliance Industrial Heat Guns Heat Shrink Tubing Wire Solder Solder will melt and flow through the inserted stripped wires when heat is. solder seal butt connectors are made of a clear, heat shrink tube, with a low temperature solder ring in the middle. heat shrink butt connectors are electrical connectors that provide a reliable connection by shrinking to form a tight. choose the shrink ratio based. Heat Shrink Tubing Wire Solder.

From www.dhgate.com

Shop Wires & Cables Online, Heat Shrink Tubing Insulation Shrinkable Heat Shrink Tubing Wire Solder heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and. Solder will melt and flow through the inserted stripped wires when heat is. heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for. heat shrink tubing, also known as a. Heat Shrink Tubing Wire Solder.

From www.aliexpress.com

8MetersetHeatShrinkTubekit123456810mm2.jpg Heat Shrink Tubing Wire Solder On the other hand, soldering iron is ideal for. heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and. After you slide the tubing onto the cable you're fixing, use a heat gun or other heat source to make it shrink and create a tight seal. The shrunken diameter should be. Heat Shrink Tubing Wire Solder.

From www.eeworldonline.com

The basics of heat shrink tubing, Part 1 Electrical Engineering News Heat Shrink Tubing Wire Solder heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for. measure the diameter of the wire, and then choose a piece of heat shrink that will be large enough. Heat Shrink Tubing Wire Solder.

From jboards.ecwid.com

Solder Heat Shrink Connector 100pcs Heat Shrink Tubing Wire Solder heat shrink butt connectors are electrical connectors that provide a reliable connection by shrinking to form a tight. heat shrink tubing is a versatile plastic layer which can be applied to cabling and components for several. when the soldersleeve device is heated the tubing shrinks and the solder preform melts to make a fully insulated,. this. Heat Shrink Tubing Wire Solder.

From learningschooljednoho13.z4.web.core.windows.net

Heat Shrink Tubing 3 Inch Heat Shrink Tubing Wire Solder If you measure a diameter of, say, 0.5 inches. solder sleeves are small, hollow pieces of heat shrinkable tubing that have rings of solder incorporated into them. generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups,. Heat shrink tubing insulates wires to protect them from abrasion and environmental factors.. Heat Shrink Tubing Wire Solder.

From exokeufcv.blob.core.windows.net

Heat Shrink Tubing For 18 Gauge Wire at Manda Salazar blog Heat Shrink Tubing Wire Solder solder sleeves are small, hollow pieces of heat shrinkable tubing that have rings of solder incorporated into them. generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups,. measure the diameter of the wire, and then choose a piece of heat shrink that will be large enough to slide. Heat Shrink Tubing Wire Solder.

From circuitlibluft.z19.web.core.windows.net

How To Heat Shrink Wire Connections Heat Shrink Tubing Wire Solder heat shrink tubing is a versatile, protective material made of plastic used to insulate and protect wires and. Solder will melt and flow through the inserted stripped wires when heat is. On the other hand, soldering iron is ideal for. heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used. Heat Shrink Tubing Wire Solder.

From www.hilpress.com

Terminals, Wire end sleeves, Cable ties, Heat shrinkable tubing HIL Heat Shrink Tubing Wire Solder solder sleeves are small, hollow pieces of heat shrinkable tubing that have rings of solder incorporated into them. Heat shrink tubing insulates wires to protect them from abrasion and environmental factors. The shrunken diameter should be slightly smaller than the wire's diameter to ensure a tight fit. Automotive electrical repairs, custom wiring, and heat shrink tubing applications benefit. . Heat Shrink Tubing Wire Solder.

From exobfutwq.blob.core.windows.net

Heat Shrink Solder Review at Julie Healy blog Heat Shrink Tubing Wire Solder On the other hand, soldering iron is ideal for. a solder sleeve, also known as a heat shrink solder sleeve or solder splice sleeve, is a type of electrical connector used for. solder sleeves are small, hollow pieces of heat shrinkable tubing that have rings of solder incorporated into them. heat shrink tubing, also known as heat. Heat Shrink Tubing Wire Solder.

From www.aliexpress.com

Diameter 3mm 2mm 3.5mm 6mm Length 5M Heat Shrink Tubing Shrinkable Tube Heat Shrink Tubing Wire Solder Solder will melt and flow through the inserted stripped wires when heat is. generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups,. heat shrink butt connectors are electrical connectors that provide a reliable connection by shrinking to form a tight. a solder sleeve, also known as a heat. Heat Shrink Tubing Wire Solder.

From panbo.com

Heat shrink solder sleeve butt connectors, great for skinny boat wires Heat Shrink Tubing Wire Solder heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. the heat shrink wires, also called a heat shrink tube, it is a tube that contracts when heated. heat shrink tubing helps in offering maximum protection to the exposed wire from any external element. Solder will melt and. Heat Shrink Tubing Wire Solder.

From schematicfixjuan.z21.web.core.windows.net

How To Solder Wire To Connector Heat Shrink Tubing Wire Solder solder seal butt connectors are made of a clear, heat shrink tube, with a low temperature solder ring in the middle. heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for. don’t try sweeping with the iron because the tip will lose contact as it skips over the. Heat Shrink Tubing Wire Solder.

From www.youtube.com

Soldering tips & tricks how to put in a heat shrink tubing when you Heat Shrink Tubing Wire Solder heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for. solder sleeves are small, hollow pieces of heat shrinkable tubing that have rings of solder incorporated into them. Automotive electrical repairs, custom wiring, and heat shrink tubing applications benefit. a solder sleeve, also known as a heat shrink. Heat Shrink Tubing Wire Solder.