Reaming Quota . Check out our recommendations for successful hole reaming. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Reaming is a metal cutting process that enlarges and refines existing holes. How to ream a hole: High surface finish, superb hole quality and close dimensional tolerance. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. It uses a rotating cutting tool called a reamer to remove small. Reaming is a critical precision machining method that demands precise. When reaming a hole it is important to consider how and what you are going to ream.

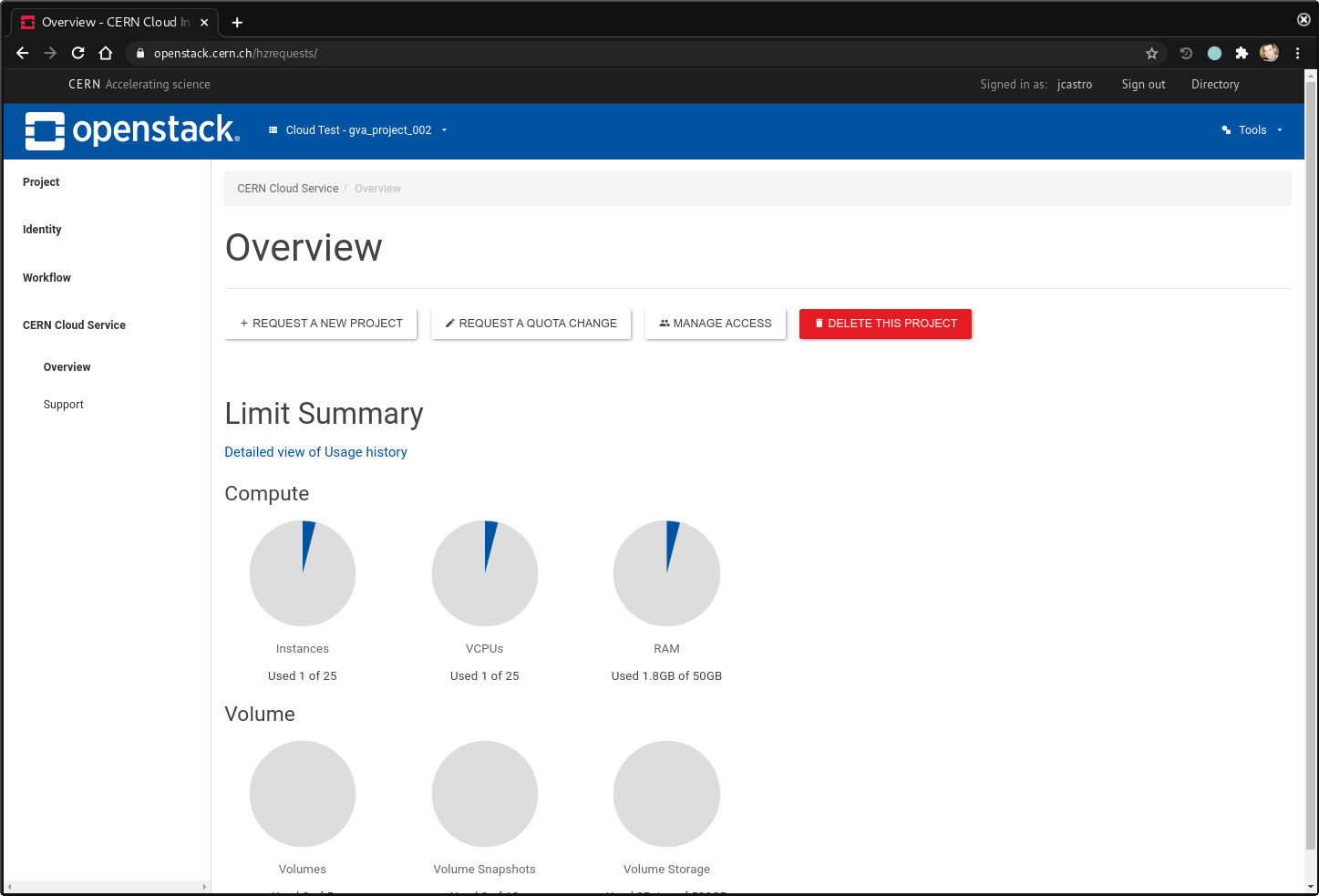

from clouddocs.web.cern.ch

Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. When reaming a hole it is important to consider how and what you are going to ream. High surface finish, superb hole quality and close dimensional tolerance. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming is a critical precision machining method that demands precise. Reaming is a metal cutting process that enlarges and refines existing holes. Check out our recommendations for successful hole reaming. How to ream a hole: It uses a rotating cutting tool called a reamer to remove small.

Requesting quota CERN OpenStack Private Cloud Guide

Reaming Quota Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. How to ream a hole: Reaming is a metal cutting process that enlarges and refines existing holes. It uses a rotating cutting tool called a reamer to remove small. Check out our recommendations for successful hole reaming. High surface finish, superb hole quality and close dimensional tolerance. Reaming is a critical precision machining method that demands precise. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. When reaming a hole it is important to consider how and what you are going to ream.

From www.slideserve.com

PPT Machine Reaming PowerPoint Presentation, free download ID1290175 Reaming Quota Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. When reaming a hole it is important to consider how and what you are going to ream. High surface finish, superb hole quality and close dimensional tolerance. It uses a rotating cutting tool called a reamer to remove small. Reaming is a. Reaming Quota.

From www.dreamstime.com

Inspiration Showing Sign Process Improvement. Word Written on Reaming Quota How to ream a hole: Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. When reaming a hole it is important to consider how and what you are going to ream. It. Reaming Quota.

From blog.pandadoc.com

Sales Operations & Quota Setting by Josh Gillespie [Advanced Guide] Reaming Quota Reaming is a metal cutting process that enlarges and refines existing holes. High surface finish, superb hole quality and close dimensional tolerance. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. It. Reaming Quota.

From jmproto.com

What is reaming and how is it done? Jmproto Reaming Quota It uses a rotating cutting tool called a reamer to remove small. Reaming is a metal cutting process that enlarges and refines existing holes. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. How to ream a hole: High surface finish, superb hole quality and close dimensional tolerance. When reaming. Reaming Quota.

From www.youtube.com

How to Setup Roaming and Mandatory profile with Quota YouTube Reaming Quota Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. Reaming is a critical precision machining method that demands precise. Reaming is a metal cutting process that enlarges and refines existing holes. When reaming a hole it is important to consider how and what you are going to ream. Learn. Reaming Quota.

From www.dreamstime.com

Inspiration Showing Sign Process Improvement. Business Approach Reaming Quota Reaming is a critical precision machining method that demands precise. It uses a rotating cutting tool called a reamer to remove small. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. How to ream a hole: Reaming is a metal cutting process that enlarges and refines existing holes. Reaming may. Reaming Quota.

From soyacincau.com

now offers double quota for data roaming SoyaCincau Reaming Quota High surface finish, superb hole quality and close dimensional tolerance. Check out our recommendations for successful hole reaming. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. How to ream a hole: Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from. Reaming Quota.

From www.quotapath.com

What is considered a good quota attainment rate? QuotaPath Reaming Quota Check out our recommendations for successful hole reaming. When reaming a hole it is important to consider how and what you are going to ream. High surface finish, superb hole quality and close dimensional tolerance. It uses a rotating cutting tool called a reamer to remove small. Reaming is a critical precision machining method that demands precise. Learn when and. Reaming Quota.

From www.tencentcloud.com

Quota Management Tencent Cloud Reaming Quota It uses a rotating cutting tool called a reamer to remove small. Check out our recommendations for successful hole reaming. When reaming a hole it is important to consider how and what you are going to ream. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. High surface finish,. Reaming Quota.

From aws.amazon.com

Introducing selfservice quota management and higher default service Reaming Quota Reaming is a critical precision machining method that demands precise. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. How to ream a hole: Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Reaming is a metal cutting process that. Reaming Quota.

From www.youtube.com

69 Apply a Quota on a Roaming Profile YouTube Reaming Quota High surface finish, superb hole quality and close dimensional tolerance. Reaming is a critical precision machining method that demands precise. How to ream a hole: It uses a rotating cutting tool called a reamer to remove small. Check out our recommendations for successful hole reaming. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection,. Reaming Quota.

From www.xactlycorp.com

How to the Challenge of Constantly Changing Quotas Xactly Reaming Quota Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. High surface finish, superb hole quality and close dimensional tolerance. When reaming a hole it is important to consider how and. Reaming Quota.

From klgadgetguy.com

U Mobile's introduces RoamOnz with dedicated roaming quota to 12 Reaming Quota High surface finish, superb hole quality and close dimensional tolerance. Check out our recommendations for successful hole reaming. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. It uses a rotating cutting. Reaming Quota.

From axy7.com

Mastering quotas in Salesforce best practices for understanding and Reaming Quota Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. How to ream a hole: Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Check out our recommendations for successful hole reaming. When reaming a hole it is important to consider. Reaming Quota.

From www.timetackle.com

Sales quota Why should you set Sales quotas and how do use them? Tackle Reaming Quota It uses a rotating cutting tool called a reamer to remove small. High surface finish, superb hole quality and close dimensional tolerance. When reaming a hole it is important to consider how and what you are going to ream. How to ream a hole: Reaming is a metal cutting process that enlarges and refines existing holes. Generally, the rough reaming. Reaming Quota.

From www.slideserve.com

PPT Machine Reaming PowerPoint Presentation, free download ID1290175 Reaming Quota Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. How to ream. Reaming Quota.

From forms.app

What is quota sampling Types, examples & steps to follow forms.app Reaming Quota Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. How to ream a hole: Reaming is a metal cutting process that enlarges and refines existing holes. Check out our recommendations for successful hole reaming. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming. Reaming Quota.

From www.ctemag.com

Reaming can be most costeffective way to produce accurate holes Reaming Quota Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. It uses a rotating cutting tool called a reamer to remove small. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Reaming is a critical precision machining method that demands precise.. Reaming Quota.

From aws.amazon.com

Introducing selfservice quota management and higher default service Reaming Quota Reaming is a metal cutting process that enlarges and refines existing holes. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Check out our recommendations for successful hole reaming. It uses. Reaming Quota.

From docs.revenuegrid.com

Assign Quotas to Users Revenue Grid Knowledge Base Reaming Quota How to ream a hole: Reaming is a metal cutting process that enlarges and refines existing holes. Reaming is a critical precision machining method that demands precise. Check out our recommendations for successful hole reaming. It uses a rotating cutting tool called a reamer to remove small. Reaming may seem like a simple hole finishing operation, but proper understanding of. Reaming Quota.

From www.slideserve.com

PPT Machine Reaming PowerPoint Presentation, free download ID1290175 Reaming Quota Reaming is a metal cutting process that enlarges and refines existing holes. It uses a rotating cutting tool called a reamer to remove small. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. When reaming a hole it is important to consider how and what you are going to ream.. Reaming Quota.

From www.scribd.com

An InDepth Guide to Sales Quotas Types, Objectives, and Methods for Reaming Quota High surface finish, superb hole quality and close dimensional tolerance. It uses a rotating cutting tool called a reamer to remove small. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and. Reaming Quota.

From www.linkedin.com

5 Essential Elements for Setting Sales Quotas Reaming Quota Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. High surface finish, superb hole quality and close dimensional tolerance. It uses a rotating cutting tool called a reamer to remove small. Generally,. Reaming Quota.

From docs.revenuegrid.com

Assign Quotas to Users Revenue Grid Knowledge Base Reaming Quota Check out our recommendations for successful hole reaming. Reaming is a metal cutting process that enlarges and refines existing holes. Reaming is a critical precision machining method that demands precise. It uses a rotating cutting tool called a reamer to remove small. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and. Reaming Quota.

From mechutopia.com

13 Types of Reamers and Reaming Operation Mechutopia Reaming Quota Reaming is a critical precision machining method that demands precise. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. High surface finish, superb hole quality and close dimensional tolerance. When reaming a hole it is important to consider how and what you are going to ream. Check out our recommendations for. Reaming Quota.

From blog.cloudcompapp.com

Commission Anything for Salesforce How to Align Quotas with Reaming Quota Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. It uses a rotating cutting tool called a reamer to remove small. Generally, the rough reaming allowance is set between 0.35 to 0.15. Reaming Quota.

From www.gopigment.com

Back to the Basics of Sales Quota Planning Reaming Quota High surface finish, superb hole quality and close dimensional tolerance. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. It uses a rotating cutting tool called a reamer to remove small. Reaming is a metal cutting process that enlarges and refines existing holes. Check out our recommendations for successful hole reaming.. Reaming Quota.

From aws.amazon.com

Introducing selfservice quota management and higher default service Reaming Quota Check out our recommendations for successful hole reaming. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. How to ream a hole: Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Reaming is a metal cutting process that enlarges and. Reaming Quota.

From purespectrum.helpjuice.com

Create Quotas PureSpectrum Reaming Quota Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Check out our recommendations for successful hole reaming. Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. It uses a rotating cutting tool called a reamer to remove small. Reaming is a. Reaming Quota.

From www.behance.net

First™ Double Roaming Quota Campaign Behance Reaming Quota Learn when and how to use a reamer including reamer speeds and feeds, types, hole size, troubleshooting, and more. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. Reaming is a. Reaming Quota.

From www.dreamstime.com

Inspiration Showing Sign Process Improvement. Business Overview Reaming Quota It uses a rotating cutting tool called a reamer to remove small. Reaming is a critical precision machining method that demands precise. Check out our recommendations for successful hole reaming. High surface finish, superb hole quality and close dimensional tolerance. How to ream a hole: When reaming a hole it is important to consider how and what you are going. Reaming Quota.

From clouddocs.web.cern.ch

Requesting quota CERN OpenStack Private Cloud Guide Reaming Quota Reaming is a critical precision machining method that demands precise. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while the finish reaming allowance ranges from 0.15. When reaming a hole it is important to consider how and what you are going to ream. Reaming is a metal cutting process that enlarges and refines existing holes. How. Reaming Quota.

From www.dreamstime.com

Inspiration Showing Sign Process Improvement. Business Showcase Reaming Quota When reaming a hole it is important to consider how and what you are going to ream. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Reaming is a metal cutting process that enlarges and refines existing holes. Generally, the rough reaming allowance is set between 0.35 to 0.15 mm, while. Reaming Quota.

From snap-tech.com

Introducing selfservice quota management and higher default service Reaming Quota Reaming is a critical precision machining method that demands precise. When reaming a hole it is important to consider how and what you are going to ream. Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. Reaming is a metal cutting process that enlarges and refines existing holes. How to ream. Reaming Quota.

From aws.amazon.com

Introducing selfservice quota management and higher default service Reaming Quota Reaming may seem like a simple hole finishing operation, but proper understanding of reamer selection, operating parameters, and. It uses a rotating cutting tool called a reamer to remove small. Reaming is a metal cutting process that enlarges and refines existing holes. How to ream a hole: Check out our recommendations for successful hole reaming. Reaming is a critical precision. Reaming Quota.