Parts Of A Casting Mold . Die casting mold is an important tool for manufacturing metal die casting parts. The engineers contemplate the final product and create detailed designs with its typical specifications. The essential die cast mold components include: Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving high. Needless to say, we are constantly surrounded by objects that have come. Most parts of any car's body and engine are made in molds. The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. Resins for casting are supplied in two liquid parts which when combined in the right This includes the cavity, core, inserts, sliders, and. The first step is to create a 3d model of the part that needs to be produced. Understanding its components, design, production. This includes comprehension of tolerance, geometry, and complexity of the final component. The most common way of making a cast is to fill the mould with a liquid which changes into a solid, as is the case with resins or plaster. The casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape. This model should include all the necessary features, such as draft angles, fillets, and undercuts.

from www.semanticscholar.org

The first step is to create a 3d model of the part that needs to be produced. What is the casting design process? Needless to say, we are constantly surrounded by objects that have come. The engineers contemplate the final product and create detailed designs with its typical specifications. Die casting mold is an important tool for manufacturing metal die casting parts. Resins for casting are supplied in two liquid parts which when combined in the right Understanding its components, design, production. This includes comprehension of tolerance, geometry, and complexity of the final component. This includes the cavity, core, inserts, sliders, and. The most common way of making a cast is to fill the mould with a liquid which changes into a solid, as is the case with resins or plaster.

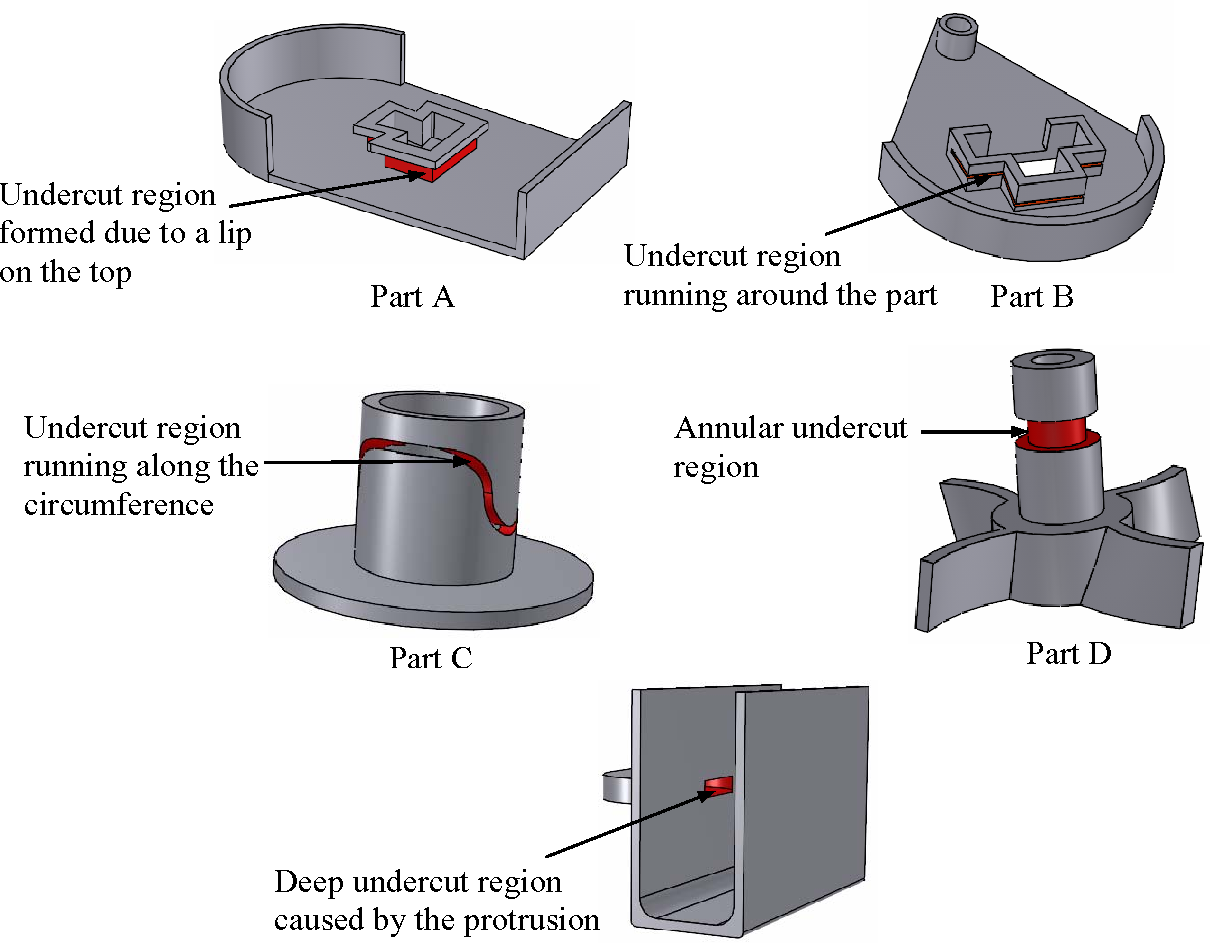

Figure 13 from Geometric Algorithms for Automated Design of Side

Parts Of A Casting Mold The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. This includes the cavity, core, inserts, sliders, and. The casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape. Most parts of any car's body and engine are made in molds. This includes comprehension of tolerance, geometry, and complexity of the final component. The essential die cast mold components include: The engineers contemplate the final product and create detailed designs with its typical specifications. The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. What is the casting design process? Die casting mold is an important tool for manufacturing metal die casting parts. Understanding its components, design, production. The first step is to create a 3d model of the part that needs to be produced. This model should include all the necessary features, such as draft angles, fillets, and undercuts. Needless to say, we are constantly surrounded by objects that have come. Resins for casting are supplied in two liquid parts which when combined in the right The most common way of making a cast is to fill the mould with a liquid which changes into a solid, as is the case with resins or plaster.

From www.plasticmoulds.net

Structure of Injection Mold Parts Of A Casting Mold Die casting mold is an important tool for manufacturing metal die casting parts. The most common way of making a cast is to fill the mould with a liquid which changes into a solid, as is the case with resins or plaster. This model should include all the necessary features, such as draft angles, fillets, and undercuts. The essential die. Parts Of A Casting Mold.

From blog.thepipingmart.com

Advantages and Disadvantages of Shell Mold Casting Parts Of A Casting Mold What is the casting design process? The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. The most common way of making a cast is to fill the mould with a liquid which changes into a solid, as is the case with resins or plaster. This includes the cavity, core, inserts, sliders,. Parts Of A Casting Mold.

From bernierinc.com

Diferent Parts of Sand Mold Features • Bernier Metals Parts Of A Casting Mold This model should include all the necessary features, such as draft angles, fillets, and undercuts. The essential die cast mold components include: This includes the cavity, core, inserts, sliders, and. Most parts of any car's body and engine are made in molds. Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for. Parts Of A Casting Mold.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Parts Of A Casting Mold Die casting mold is an important tool for manufacturing metal die casting parts. Understanding its components, design, production. The first step is to create a 3d model of the part that needs to be produced. The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. The casting design process is a manufacturing. Parts Of A Casting Mold.

From www.mechanicaleducation.com

Shell Mold Casting Advantages And Disadvantages Mechanical Education Parts Of A Casting Mold The first step is to create a 3d model of the part that needs to be produced. The essential die cast mold components include: Needless to say, we are constantly surrounded by objects that have come. What is the casting design process? Die casting mold is an important tool for manufacturing metal die casting parts. This includes the cavity, core,. Parts Of A Casting Mold.

From www.sculpteo.com

Learn how to create a basic mold using a 3D printed shape Parts Of A Casting Mold The first step is to create a 3d model of the part that needs to be produced. Understanding its components, design, production. This model should include all the necessary features, such as draft angles, fillets, and undercuts. Die casting mold is an important tool for manufacturing metal die casting parts. The casting design process is a manufacturing process where molten. Parts Of A Casting Mold.

From www.youtube.com

Casting Metal Parts into 3D Printed Molds YouTube Parts Of A Casting Mold The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. This model should include all the necessary features, such as draft angles, fillets, and undercuts. Die casting mold is an important tool for manufacturing metal die casting parts. What is the casting design process? Die casting or die casting mold making is. Parts Of A Casting Mold.

From www.youtube.com

Gating System Parts in Casting Process [Pattern, Mold, Gate, Sprue Parts Of A Casting Mold Die casting mold is an important tool for manufacturing metal die casting parts. The engineers contemplate the final product and create detailed designs with its typical specifications. Most parts of any car's body and engine are made in molds. The most common way of making a cast is to fill the mould with a liquid which changes into a solid,. Parts Of A Casting Mold.

From www.researchgate.net

Schematic representation of a die casting mold Download Scientific Parts Of A Casting Mold Die casting mold is an important tool for manufacturing metal die casting parts. This model should include all the necessary features, such as draft angles, fillets, and undercuts. The first step is to create a 3d model of the part that needs to be produced. The gate and runner system is crucial in controlling the flow of molten metal into. Parts Of A Casting Mold.

From www.rocheindustry.com

Handbook The Ultimate Guide to Metal Casting 2024 Updated Parts Of A Casting Mold This model should include all the necessary features, such as draft angles, fillets, and undercuts. What is the casting design process? The engineers contemplate the final product and create detailed designs with its typical specifications. Die casting mold is an important tool for manufacturing metal die casting parts. The essential die cast mold components include: Most parts of any car's. Parts Of A Casting Mold.

From www.mdpi.com

Materials Free FullText Modeling of Interfacial Tension and Parts Of A Casting Mold Resins for casting are supplied in two liquid parts which when combined in the right The first step is to create a 3d model of the part that needs to be produced. What is the casting design process? Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving high. The essential. Parts Of A Casting Mold.

From govdesignhub.com

Making complex plastic parts with generative design and injection molding Parts Of A Casting Mold The engineers contemplate the final product and create detailed designs with its typical specifications. The casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape. Resins for casting are supplied in two liquid parts which when combined in the right Understanding its components, design, production. The. Parts Of A Casting Mold.

From www.inoxcast.com

How to Choose a Die Casting Mold Supplier in China Inox Cast Parts Of A Casting Mold The first step is to create a 3d model of the part that needs to be produced. The casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape. Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for. Parts Of A Casting Mold.

From www.researchgate.net

PU foam casting mold (a) parts of the mold setup and (b) assembled Parts Of A Casting Mold Most parts of any car's body and engine are made in molds. Die casting mold is an important tool for manufacturing metal die casting parts. This includes the cavity, core, inserts, sliders, and. The essential die cast mold components include: The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. Resins for. Parts Of A Casting Mold.

From www.iqsdirectory.com

Urethane Casting What Is It? How Does It Work? Applications Parts Of A Casting Mold The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. This includes comprehension of tolerance, geometry, and complexity of the final component. This includes the cavity, core, inserts, sliders, and. Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving high. The essential. Parts Of A Casting Mold.

From www.diecasting-mould.com

Permanent Mold Casting vs Die Casting vs Sand Casting What is Parts Of A Casting Mold Most parts of any car's body and engine are made in molds. The first step is to create a 3d model of the part that needs to be produced. Die casting mold is an important tool for manufacturing metal die casting parts. Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for. Parts Of A Casting Mold.

From cejzvipy.blob.core.windows.net

How To Cast A Mold at Mary Monahan blog Parts Of A Casting Mold Most parts of any car's body and engine are made in molds. This includes the cavity, core, inserts, sliders, and. The first step is to create a 3d model of the part that needs to be produced. Understanding its components, design, production. Resins for casting are supplied in two liquid parts which when combined in the right Die casting or. Parts Of A Casting Mold.

From www.injectionmould.org

The slider for plastic injection mold Parts Of A Casting Mold Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving high. Most parts of any car's body and engine are made in molds. The engineers contemplate the final product and create detailed designs with its typical specifications. Needless to say, we are constantly surrounded by objects that have come. What is. Parts Of A Casting Mold.

From www.researchgate.net

Metalmold diecasting system. Download Scientific Diagram Parts Of A Casting Mold The casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape. What is the casting design process? The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. Understanding its components, design, production. This model should include all the. Parts Of A Casting Mold.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Parts Of A Casting Mold This model should include all the necessary features, such as draft angles, fillets, and undercuts. This includes comprehension of tolerance, geometry, and complexity of the final component. Needless to say, we are constantly surrounded by objects that have come. Understanding its components, design, production. The first step is to create a 3d model of the part that needs to be. Parts Of A Casting Mold.

From www.semanticscholar.org

Figure 13 from Geometric Algorithms for Automated Design of Side Parts Of A Casting Mold The engineers contemplate the final product and create detailed designs with its typical specifications. This model should include all the necessary features, such as draft angles, fillets, and undercuts. The most common way of making a cast is to fill the mould with a liquid which changes into a solid, as is the case with resins or plaster. The first. Parts Of A Casting Mold.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Parts Of A Casting Mold What is the casting design process? The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. The first step is to create a 3d model of the part that needs to be produced. Die casting mold is an important tool for manufacturing metal die casting parts. The most common way of making. Parts Of A Casting Mold.

From grace-plastic-injection-mold.blogspot.com

Grace plastic injection mold Parts Of A Casting Mold This includes comprehension of tolerance, geometry, and complexity of the final component. Needless to say, we are constantly surrounded by objects that have come. The engineers contemplate the final product and create detailed designs with its typical specifications. The essential die cast mold components include: The most common way of making a cast is to fill the mould with a. Parts Of A Casting Mold.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Parts Of A Casting Mold What is the casting design process? This includes the cavity, core, inserts, sliders, and. Die casting mold is an important tool for manufacturing metal die casting parts. The first step is to create a 3d model of the part that needs to be produced. The most common way of making a cast is to fill the mould with a liquid. Parts Of A Casting Mold.

From www.metals-china.com

Different Metal Casting Processes used in the Manufacture of Parts Parts Of A Casting Mold The gate and runner system is crucial in controlling the flow of molten metal into the mold cavity. Needless to say, we are constantly surrounded by objects that have come. What is the casting design process? The engineers contemplate the final product and create detailed designs with its typical specifications. This includes the cavity, core, inserts, sliders, and. The essential. Parts Of A Casting Mold.

From www.lcrapid.com

The Structure of the Mold LC RAPID MANUFACTURING Co., Ltd Parts Of A Casting Mold Needless to say, we are constantly surrounded by objects that have come. This includes comprehension of tolerance, geometry, and complexity of the final component. Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving high. Die casting mold is an important tool for manufacturing metal die casting parts. Understanding its components,. Parts Of A Casting Mold.

From www.sunrise-metal.com

Die Cast Aluminum Mold Sunrise Metal Aluminium Die Casting Expert Parts Of A Casting Mold What is the casting design process? Die casting mold is an important tool for manufacturing metal die casting parts. Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving high. Needless to say, we are constantly surrounded by objects that have come. The casting design process is a manufacturing process where. Parts Of A Casting Mold.

From www.ace-mold.com

Die Casting Vs Permanent Mold Casting ACE Group Parts Of A Casting Mold Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving high. Most parts of any car's body and engine are made in molds. Resins for casting are supplied in two liquid parts which when combined in the right The essential die cast mold components include: The casting design process is a. Parts Of A Casting Mold.

From precisecast.com

Sand Casting Process Metal Sand Casting Company in the USA Parts Of A Casting Mold Resins for casting are supplied in two liquid parts which when combined in the right Most parts of any car's body and engine are made in molds. The essential die cast mold components include: This includes the cavity, core, inserts, sliders, and. This includes comprehension of tolerance, geometry, and complexity of the final component. The gate and runner system is. Parts Of A Casting Mold.

From reliance-foundry.com

Sand Casting Metal Casting Resources Parts Of A Casting Mold Die casting mold is an important tool for manufacturing metal die casting parts. Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving high. This model should include all the necessary features, such as draft angles, fillets, and undercuts. This includes the cavity, core, inserts, sliders, and. Most parts of any. Parts Of A Casting Mold.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Parts Of A Casting Mold Most parts of any car's body and engine are made in molds. The first step is to create a 3d model of the part that needs to be produced. Needless to say, we are constantly surrounded by objects that have come. Die casting or die casting mold making is a crucial part of today’s industrial manufacturing, which allows for achieving. Parts Of A Casting Mold.

From www.iqsdirectory.com

Sand Casting Construction, Types, Applications, and Advantages Parts Of A Casting Mold This includes the cavity, core, inserts, sliders, and. Needless to say, we are constantly surrounded by objects that have come. The first step is to create a 3d model of the part that needs to be produced. The casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a. Parts Of A Casting Mold.

From news.ewmfg.com

Investment Casting vs. Die Casting 7 Considerations When Choosing a Parts Of A Casting Mold Most parts of any car's body and engine are made in molds. The essential die cast mold components include: This includes comprehension of tolerance, geometry, and complexity of the final component. This includes the cavity, core, inserts, sliders, and. The first step is to create a 3d model of the part that needs to be produced. Die casting mold is. Parts Of A Casting Mold.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Parts Of A Casting Mold Resins for casting are supplied in two liquid parts which when combined in the right The most common way of making a cast is to fill the mould with a liquid which changes into a solid, as is the case with resins or plaster. Most parts of any car's body and engine are made in molds. The casting design process. Parts Of A Casting Mold.

From vietnamcastiron.com

Instructions for Making Sand Casting Molds in detail Step by Step Parts Of A Casting Mold What is the casting design process? This includes the cavity, core, inserts, sliders, and. Understanding its components, design, production. Most parts of any car's body and engine are made in molds. The essential die cast mold components include: Needless to say, we are constantly surrounded by objects that have come. Die casting mold is an important tool for manufacturing metal. Parts Of A Casting Mold.