Hydroformed Parts . Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Largest bed size is 120″ x 60″. Most of our machines have a maximum. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Largest tube hydroforming process machine is capable of 1,000 tons. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Tolerances will differ based […] We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube.

from edstechnologies.com

When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Largest tube hydroforming process machine is capable of 1,000 tons. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Tolerances will differ based […] Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Most of our machines have a maximum. Largest bed size is 120″ x 60″. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and.

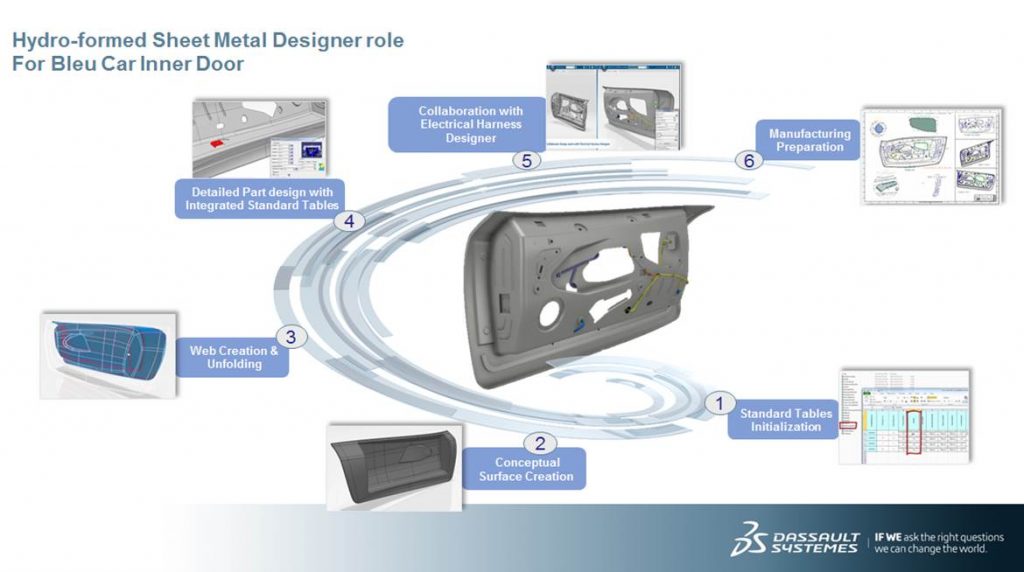

How CATIA 3DEXPERIENCE helps in the design of hydroformingmanufactured

Hydroformed Parts Tolerances will differ based […] When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Most of our machines have a maximum. Tolerances will differ based […] Largest tube hydroforming process machine is capable of 1,000 tons. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Largest bed size is 120″ x 60″.

From stampingsimulation.com

Hydroforming Sheet Metal Common Applications and Benefits Hydroformed Parts When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Most of our machines have a maximum. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Largest bed size is 120″ x 60″. Largest tube hydroforming process machine is capable of 1,000. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for. Hydroformed Parts.

From millsproducts.com

Tubular Hydroforming Aluminum Considerations Mills Products Hydroformed Parts Most of our machines have a maximum. Largest tube hydroforming process machine is capable of 1,000 tons. Largest bed size is 120″ x 60″. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. We’ve been making metal parts in the usa for over 110 years,. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Largest bed size is 120″ x 60″. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Most of our machines have a maximum. We’ve been making metal. Hydroformed Parts.

From vulcantoolcompany.com

Trimming Hydroformed Parts Vulcan Tool Company Hydroformed Parts Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Tolerances will differ based […] When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Largest tube hydroforming process machine is capable of 1,000 tons. Largest bed size. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Tolerances will differ based […] When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Most. Hydroformed Parts.

From edstechnologies.com

How CATIA 3DEXPERIENCE helps in the design of hydroformingmanufactured Hydroformed Parts Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Most of our machines have a. Hydroformed Parts.

From www.thefabricator.com

R&D Update Processes for hydroforming sheet metal, Part I Hydroformed Parts Tolerances will differ based […] Largest bed size is 120″ x 60″. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Most of our machines have a maximum. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Automotive body structures have incorporated hydroformed. Hydroformed Parts.

From thelibraryofmanufacturing.com

Rubber Forming Of Sheet Metal Hydroformed Parts Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Tolerances will differ based […] Largest. Hydroformed Parts.

From www.metalworkingworldmagazine.com

Hydroforming today Metal Working World Magazine Hydroformed Parts Tolerances will differ based […] When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Largest bed size is 120″ x 60″. Largest tube hydroforming process machine is. Hydroformed Parts.

From stampingsimulation.com

Hydroforming Sheet Metal Common Applications and Benefits Hydroformed Parts Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Tolerances will differ based […] Largest bed size is 120″ x 60″. Hydroformed parts have minimal surface. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts Largest tube hydroforming process machine is capable of 1,000 tons. Largest bed size is 120″ x 60″. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Most of our machines have a maximum. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation. Hydroformed Parts.

From www.youtube.com

Hydroforming Companies YouTube Hydroformed Parts Largest bed size is 120″ x 60″. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved,. Hydroformed Parts.

From www.dreamstime.com

Hydroformed metal parts stock illustration. Illustration of component Hydroformed Parts Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Largest tube hydroforming process machine is capable of 1,000 tons. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. We’ve been making metal parts in the. Hydroformed Parts.

From americanhydroformers.com

The Deep Draw Hydroforming Process & Advantages American Hydroformers Hydroformed Parts Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts Largest tube hydroforming process machine is capable of 1,000 tons. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. We’ve been making metal parts in the. Hydroformed Parts.

From bikerumor.com

Factory Tour Foes Racing, Part 1 How They're Made Bikerumor Hydroformed Parts Tolerances will differ based […] When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Most of our machines have a maximum. Hydroformed parts have minimal surface imperfections, because tight specifications on contour. Hydroformed Parts.

From www.thefabricator.com

R&D Update Sheet hydroforming (part II) The Fabricator Hydroformed Parts Largest tube hydroforming process machine is capable of 1,000 tons. Most of our machines have a maximum. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Tolerances will differ based […] Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of. Hydroformed Parts.

From www.youtube.com

Tubular Hydroforming YouTube Hydroformed Parts Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Largest tube hydroforming process machine is capable of 1,000 tons. We’ve been making metal parts in the usa for over 110 years, and. Hydroformed Parts.

From www.dreamstime.com

Hydroformed metal parts stock illustration. Illustration of shapes Hydroformed Parts We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Hydroformed parts allow for parts consolidation,. Hydroformed Parts.

From www.youtube.com

Hydroforming PART 2 Make Exhaust 2Stroke ( PROTO RS 500 KTM ) YouTube Hydroformed Parts We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Largest bed size is 120″ x 60″. Largest tube hydroforming process machine is capable of 1,000 tons. Hydroformed parts have minimal surface imperfections,. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly.. Hydroformed Parts.

From www.metal-spinners.net

Hydroforming Companies Hydroforming Services Hydroformed Parts When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Largest bed size is 120″ x 60″. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Tolerances will differ based […] Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces. Hydroformed Parts.

From www.helandermetal.com

Hydroforming Hydroforming for Irregular Parts Hydroformed Parts Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Tolerances will differ based […] Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Largest. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts Most of our machines have a maximum. Tolerances will differ based […] Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Largest bed size is 120″ x 60″. We’ve been making metal parts. Hydroformed Parts.

From www.youtube.com

Hydroforming PART 3 Make Exhaust 2Stroke ( PROTO RS 500 KTM ) YouTube Hydroformed Parts Largest bed size is 120″ x 60″. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Tolerances will differ based […] Most of our machines have a maximum. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Hydroformed parts have minimal. Hydroformed Parts.

From www.industrydirections.com

Sustainable and Efficient Hydroforming of Aerospace Component Hydroformed Parts Largest bed size is 120″ x 60″. Largest tube hydroforming process machine is capable of 1,000 tons. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash.. Hydroformed Parts.

From www.polyprod.com

Hydroforming Sheet Metal Polyurethane Products Hydroformed Parts Tolerances will differ based […] We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Automotive. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Largest tube hydroforming process machine is capable of 1,000 tons. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Tolerances will differ based […] Most of. Hydroformed Parts.

From www.amalco.com

Deep Drawing, Hydroforming, and Dip Brazing Metal Parts, Enclosures Hydroformed Parts When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Largest bed size is 120″ x 60″. Most of our machines have a maximum. Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. We’ve been making metal parts in the usa for. Hydroformed Parts.

From www.initiative-automotive.de

HydroformingTechnology ǀ Initiative Automotive Hydroformed Parts When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Hydroformed parts have minimal surface imperfections, because tight specifications on contour and flatness can be achieved, and. Largest tube hydroforming process machine is capable of 1,000 tons. Most of our machines have a maximum. Largest bed size is 120″ x 60″. Automotive. Hydroformed Parts.

From www.dynamicindustrial.com

Hydroforming Hydroformed Parts Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using ahss grades to improve crash. Largest bed size is 120″ x 60″. Most of our machines have a maximum. Tolerances will differ based […] Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the. Hydroformed Parts.

From designlab.gr

Production Methods Hydroforming Makes Complicated, Lightweight Hydroformed Parts When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Largest bed size is 120″ x 60″. Largest tube hydroforming process machine is capable of 1,000 tons. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Hydroformed parts have minimal surface imperfections,. Hydroformed Parts.

From www.thefabricator.com

R&D Update Sheet hydroforming (part II) Hydroformed Parts Largest tube hydroforming process machine is capable of 1,000 tons. When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. We’ve been making metal parts in the usa. Hydroformed Parts.

From usherprecision.com

Hydroforming Usher Precision Manufacturing Hydroformed Parts When designers and engineers consider how to manufacture structural parts, they may think about several options, including tube. Largest bed size is 120″ x 60″. We’ve been making metal parts in the usa for over 110 years, and we’ve earned a reputation for producing. Largest tube hydroforming process machine is capable of 1,000 tons. Most of our machines have a. Hydroformed Parts.