Semiconductor Process Technologies . The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: Let’s discuss six critical semiconductor manufacturing steps: In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Deposition, photoresist, lithography, etch, ionization and packaging.

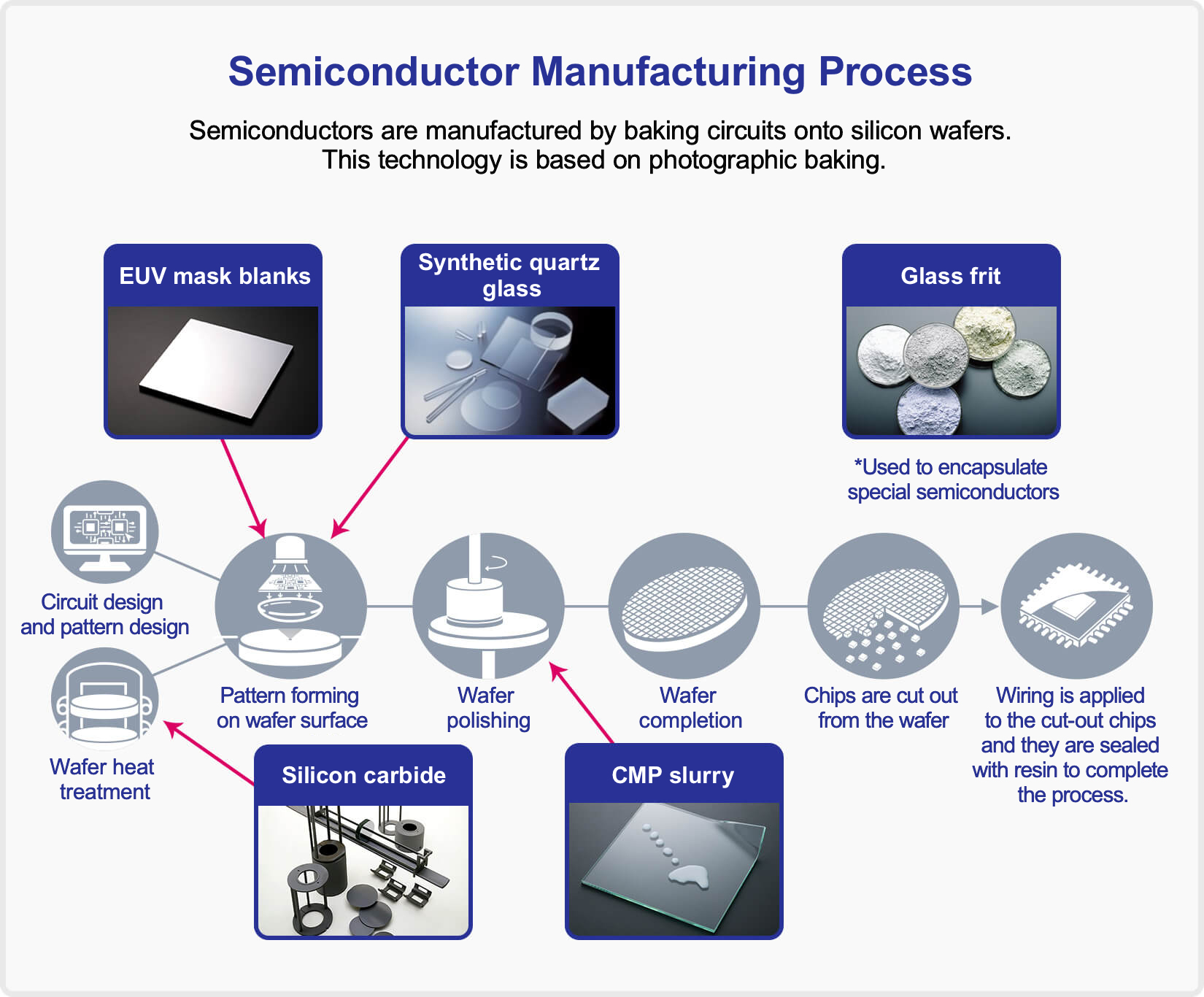

from www.agc.com

Let’s discuss six critical semiconductor manufacturing steps: The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Deposition, photoresist, lithography, etch, ionization and packaging. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer.

Semiconductor|AGC,an evryday essential part of our world|AGC

Semiconductor Process Technologies Deposition, photoresist, lithography, etch, ionization and packaging. Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding:

From www.horiba.com

Semiconductor Manufacturing Process Semiconductor Process Technologies Let’s discuss six critical semiconductor manufacturing steps: In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. Deposition, photoresist, lithography, etch, ionization and packaging. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process. Semiconductor Process Technologies.

From www.slideserve.com

PPT Semiconductor Process Technology PowerPoint Presentation, free download ID9677313 Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. Let’s discuss six critical semiconductor manufacturing steps: In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. The semiconductor industry is going through massive advancements in digital, analog, tools,. Semiconductor Process Technologies.

From www.criticalmanufacturing.com

Digital Transformation in the Semiconductor Industry Semiconductor Process Technologies Deposition, photoresist, lithography, etch, ionization and packaging. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: Let’s discuss six critical semiconductor manufacturing steps: The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. The. Semiconductor Process Technologies.

From www.slideserve.com

PPT Semiconductor Manufacturing Technology Semiconductor Manufacturing Processes PowerPoint Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. Let’s discuss six critical semiconductor manufacturing steps: With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: In order for silicon to. Semiconductor Process Technologies.

From stock.adobe.com

Silicon Wafer during Photolithography Process inside Complex Computer Chip Production Machine Semiconductor Process Technologies The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and packaging. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: In. Semiconductor Process Technologies.

From nancy-rubin.com

What Is Semiconductor Manufacturing nancyrubin Semiconductor Process Technologies The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Let’s discuss six critical semiconductor manufacturing steps: With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: The semiconductor manufacturing process involves the creation of. Semiconductor Process Technologies.

From suireng.ie

Semiconductor Wafer Fabrication Facility Suir Engineering Semiconductor Process Technologies With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: Let’s discuss six critical semiconductor manufacturing steps: The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Deposition, photoresist, lithography, etch, ionization and packaging. The. Semiconductor Process Technologies.

From www.scribd.com

Trends in Semiconductor Process Technology PDF Semiconductor Process Technologies Let’s discuss six critical semiconductor manufacturing steps: The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like. Semiconductor Process Technologies.

From www.rappler.com

What is a semiconductor? An electrical engineer explains how they work and how they're made Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology. Semiconductor Process Technologies.

From www.horiba.com

Semiconductor Manufacturing Process with HORIBA Semiconductor Process Technologies Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel. Semiconductor Process Technologies.

From www.fuchs.com

Nye Semiconductor FUCHS Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an. Semiconductor Process Technologies.

From semiconductor.samsung.com

A short introduction to semiconductor fabrication Samsung Semiconductor EMEA Semiconductor Process Technologies With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. The semiconductor industry is going through massive advancements in digital, analog,. Semiconductor Process Technologies.

From futuresoftech.com

semiconductor fabrication technology Semiconductor anymore amd Semiconductor Process Technologies The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: In order for silicon to turn into a semiconductor. Semiconductor Process Technologies.

From www.slideserve.com

PPT Semiconductor Manufacturing Technology Semiconductor Manufacturing Processes PowerPoint Semiconductor Process Technologies With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. In order for silicon to. Semiconductor Process Technologies.

From slidetodoc.com

Semiconductor Process Technology What is Semiconductor Process Technology Semiconductor Process Technologies The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Deposition, photoresist, lithography, etch, ionization and packaging. In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel. Semiconductor Process Technologies.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Semiconductor Process Technologies In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. Let’s discuss six critical semiconductor manufacturing steps: With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: The semiconductor manufacturing process. Semiconductor Process Technologies.

From www.agc.com

Semiconductor|AGC,an evryday essential part of our world|AGC Semiconductor Process Technologies With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: Let’s discuss six critical semiconductor manufacturing steps: In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. Deposition, photoresist, lithography, etch,. Semiconductor Process Technologies.

From www.renesas.com

Semiconductor Device Manufacturing Process, Challenges and Opportunities Renesas Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an. Semiconductor Process Technologies.

From mavink.com

Semiconductor Process Steps Semiconductor Process Technologies Let’s discuss six critical semiconductor manufacturing steps: The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like. Semiconductor Process Technologies.

From www.slideserve.com

PPT Semiconductor Process Technology PowerPoint Presentation, free download ID9677313 Semiconductor Process Technologies With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: Let’s discuss six critical semiconductor manufacturing steps: The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going. Semiconductor Process Technologies.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Deposition, photoresist, lithography, etch, ionization and packaging. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed. Semiconductor Process Technologies.

From www.gsec.co

Technology to Global Semiconductor Semiconductor Process Technologies Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: The semiconductor industry is going. Semiconductor Process Technologies.

From plasma.oxinst.com

Making and Analysing Semiconductor Devices Video Oxford Instruments Semiconductor Process Technologies Deposition, photoresist, lithography, etch, ionization and packaging. In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going through massive advancements in digital, analog, tools,. Semiconductor Process Technologies.

From futuresoftech.com

international roadmap of semiconductor technology Roadmap Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an. Semiconductor Process Technologies.

From www.researchgate.net

Semiconductor manufacturing steps. Download Scientific Diagram Semiconductor Process Technologies Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel. Semiconductor Process Technologies.

From www.wevolver.com

How are Semiconductors Made? A Comprehensive Guide to Semiconductor Manufacturing Semiconductor Process Technologies Let’s discuss six critical semiconductor manufacturing steps: The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: Deposition, photoresist, lithography, etch, ionization. Semiconductor Process Technologies.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: The semiconductor industry is going through massive advancements in digital, analog, tools,. Semiconductor Process Technologies.

From gonglab.tju.edu.cn

Semiconductor Thin Films天津大学催化天津大学新能源天津大学二氧化碳天津大学化工学院_Energy ; Catalysis Adventure Team TJU Semiconductor Process Technologies With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. Let’s discuss six critical semiconductor manufacturing steps: In order for silicon to. Semiconductor Process Technologies.

From microchipusa.com

A StepbyStep Guide to Semiconductor Manufacturing Microchip USA Semiconductor Process Technologies With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: Let’s discuss six critical semiconductor manufacturing steps: The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going. Semiconductor Process Technologies.

From biz.maxell.com

Tapes for semiconductor manufacturing process Biz.maxell Maxell Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Let’s discuss six critical semiconductor manufacturing steps: In order for silicon to turn into a semiconductor. Semiconductor Process Technologies.

From futuresoftech.com

semiconductor fabrication technology Semiconductor anymore amd Semiconductor Process Technologies The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. In order for silicon to turn into a semiconductor chip, it needs to go through the several complex process of wafer. Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like. Semiconductor Process Technologies.

From www.hardinge.com

Providing Advanced Solutions for the Semiconductor Industry Hardinge The Americas Semiconductor Process Technologies Deposition, photoresist, lithography, etch, ionization and packaging. Let’s discuss six critical semiconductor manufacturing steps: The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: The. Semiconductor Process Technologies.

From www.gallagherseals.com

Basic Semiconductor Manufacturing Process Semiconductor Process Technologies With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed at intel foundry direct connect '24 an extended process technology roadmap adding: The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. Deposition, photoresist, lithography, etch, ionization and packaging. The semiconductor industry is going. Semiconductor Process Technologies.

From www.newport.com

Semiconductor Manufacturing Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Let’s discuss six critical semiconductor manufacturing steps: With execution to our ambitious five nodes in four years (5n4y) goal on track, intel revealed. Semiconductor Process Technologies.

From www.dreamstime.com

Semiconductor Production Isometric Flowchart Stock Vector Illustration of microchip, character Semiconductor Process Technologies The semiconductor manufacturing process involves the creation of semiconductor devices using technologies and processes like silicon deposition, lithography, and quality. Let’s discuss six critical semiconductor manufacturing steps: The semiconductor industry is going through massive advancements in digital, analog, tools, manufacturing technologies, as well as. Deposition, photoresist, lithography, etch, ionization and packaging. With execution to our ambitious five nodes in four. Semiconductor Process Technologies.