Gear Shaper Hobbing . the hob and gear blank are rotated continuously until all teeth are cut. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. It involves using a special machine called a gear hobber, which uses a. The profile is formed by the. gear hobbing process is commonly used to cut teeth into gears. Hobbing is only possible for external gears.gear. The hob is rotated and fed against the gear blank,.

from engineeringlearn.com

The hob is rotated and fed against the gear blank,. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. The profile is formed by the. Hobbing is only possible for external gears.gear. It involves using a special machine called a gear hobber, which uses a. gear hobbing process is commonly used to cut teeth into gears. the hob and gear blank are rotated continuously until all teeth are cut. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears. a hob is a cylindrical cutting tool that is used to create the teeth on a gear.

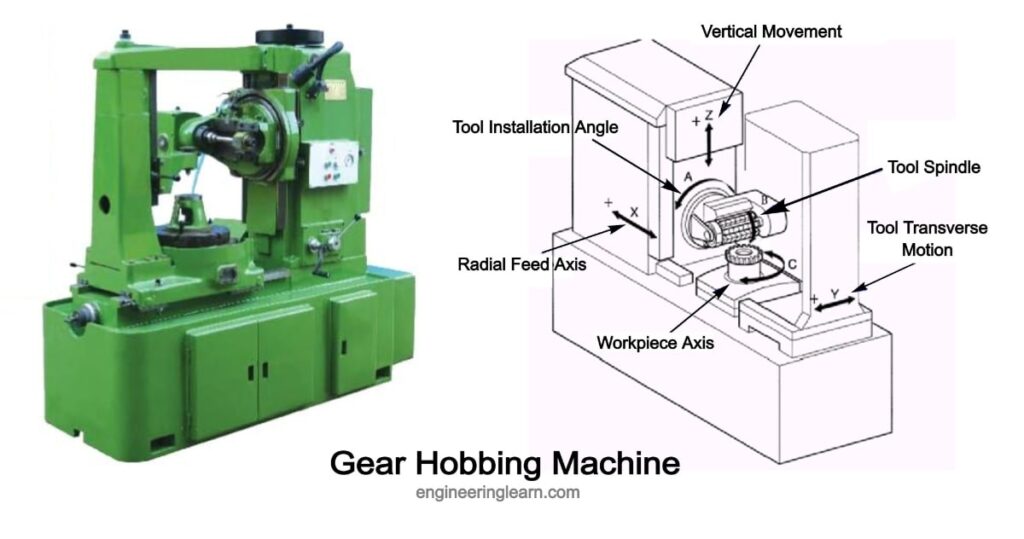

Gear Hobbing Machine Definition, Types, Uses, Working & Construction

Gear Shaper Hobbing Hobbing is only possible for external gears.gear. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. The profile is formed by the. Hobbing is only possible for external gears.gear. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears. the hob and gear blank are rotated continuously until all teeth are cut. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. gear hobbing process is commonly used to cut teeth into gears. It involves using a special machine called a gear hobber, which uses a. The hob is rotated and fed against the gear blank,. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at.

From longfordgear.co.uk

Gear Cutting Shaping & Hobbing Longford Gear Cutting Co Ltd Gear Shaper Hobbing a hob is a cylindrical cutting tool that is used to create the teeth on a gear. The profile is formed by the. the hob and gear blank are rotated continuously until all teeth are cut. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. gear. Gear Shaper Hobbing.

From www.motorgearengineer.com

Gear Hobbing Service Introduction, Working, and Applications Gear Shaper Hobbing the hob and gear blank are rotated continuously until all teeth are cut. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. The profile is formed by the. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the. Gear Shaper Hobbing.

From www.fictiv.com

The 3 Essential Methods for Gear Machining Fictiv Gear Shaper Hobbing a hob is a cylindrical cutting tool that is used to create the teeth on a gear. It involves using a special machine called a gear hobber, which uses a. gear hobbing process is commonly used to cut teeth into gears. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of. Gear Shaper Hobbing.

From www.sourceint.com

Gear Hobbing and Shaping For Precision Source International Gear Shaper Hobbing gear hobbing process is commonly used to cut teeth into gears. the hob and gear blank are rotated continuously until all teeth are cut. It involves using a special machine called a gear hobber, which uses a. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. . Gear Shaper Hobbing.

From www.youtube.com

Free Hobbing Method .Gear cutting YouTube Gear Shaper Hobbing gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. It involves using a special machine called a gear hobber, which uses a. The profile is formed by the. gear hobbing is more versatile in producing various gear types, while gear shaping. Gear Shaper Hobbing.

From www.emag.com

VL 4 H Gear Hobbing Machine for Fast Gear Cutting Gear Shaper Hobbing the hob and gear blank are rotated continuously until all teeth are cut. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears. gear hobbing process is commonly used to cut teeth into gears. Hobbing is only possible for external gears.gear. The hob is rotated and fed against. Gear Shaper Hobbing.

From engineeringlearn.com

Gear Hobbing Machine Definition, Types, Uses, Working & Construction Gear Shaper Hobbing gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. It involves using a special machine called a gear hobber, which uses a. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears.. Gear Shaper Hobbing.

From www.youtube.com

Gear Shaping and Hobbing YouTube Gear Shaper Hobbing It involves using a special machine called a gear hobber, which uses a. gear hobbing process is commonly used to cut teeth into gears. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. The profile is formed by the. the hob and gear blank are rotated continuously. Gear Shaper Hobbing.

From learnmech.com

Gear Hobbing Parts, Working, Diagram, Advantages, Disadvantages Gear Shaper Hobbing The profile is formed by the. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. gear hobbing is a process in which gear is cut by a generating process by. Gear Shaper Hobbing.

From www.youtube.com

Gear Manufacturing Methods i.e.Gear Hobbing and Gear Shaping YouTube Gear Shaper Hobbing gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. The profile is formed by the. gear hobbing process is commonly used. Gear Shaper Hobbing.

From www.tec-science.com

Gear cutting (gear manufacturing) tecscience Gear Shaper Hobbing The hob is rotated and fed against the gear blank,. The profile is formed by the. Hobbing is only possible for external gears.gear. the hob and gear blank are rotated continuously until all teeth are cut. gear hobbing process is commonly used to cut teeth into gears. a hob is a cylindrical cutting tool that is used. Gear Shaper Hobbing.

From www.bid-on-equipment.com

FELLOWS GEAR SHAPER CO.MILES Gear Hobbing MachineGear Shaper Gear Shaper Hobbing The hob is rotated and fed against the gear blank,. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. The profile is formed by the. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob. Gear Shaper Hobbing.

From www.broachingjobshops.com

Gear Hobbing Companies Gear Hobbing Services Gear Shaper Hobbing gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. The profile is formed by the. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. gear hobbing is more versatile in. Gear Shaper Hobbing.

From www.youtube.com

Gear hobbing YouTube Gear Shaper Hobbing gear hobbing process is commonly used to cut teeth into gears. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. The profile is formed by the. the hob and gear blank are rotated continuously until all teeth are cut. Hobbing is only possible for external gears.gear. The hob is. Gear Shaper Hobbing.

From www.youtube.com

Gear Hobbing Process Compilation Kompilasi Proses Gear Hobbing Gear Shaper Hobbing gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears. Hobbing is only possible for external gears.gear. It involves using a special machine called a gear hobber, which uses a. The profile is formed by the. a hob is a cylindrical cutting tool that is used to create the. Gear Shaper Hobbing.

From longfordgear.co.uk

Gear Cutting Shaping & Hobbing Longford Gear Cutting Co Ltd Gear Shaper Hobbing Hobbing is only possible for external gears.gear. The profile is formed by the. It involves using a special machine called a gear hobber, which uses a. The hob is rotated and fed against the gear blank,. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. gear hobbing is. Gear Shaper Hobbing.

From integrity.mu

Gear Hobbing and Hardening Integrity.mu Gear Shaper Hobbing gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. The profile is formed by the. gear hobbing is more versatile in producing various gear types, while gear shaping is more. Gear Shaper Hobbing.

From www.sourceint.com

Gear Hobbing and Shaping For Precision Source International Gear Shaper Hobbing gear hobbing process is commonly used to cut teeth into gears. It involves using a special machine called a gear hobber, which uses a. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable. Gear Shaper Hobbing.

From www.zhygear.com

Gear Hobbing vs. Gear Shaping Choosing the Right Gear Cutting Method Gear Shaper Hobbing gear hobbing process is commonly used to cut teeth into gears. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. The. Gear Shaper Hobbing.

From www.researchgate.net

Typical cutting methods of spur gears 2 (a) shaping, (b) forming, and Gear Shaper Hobbing It involves using a special machine called a gear hobber, which uses a. The profile is formed by the. the hob and gear blank are rotated continuously until all teeth are cut. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. The hob is rotated and fed against. Gear Shaper Hobbing.

From longfordgear.co.uk

Gear Cutting Shaping & Hobbing Longford Gear Cutting Co Ltd Gear Shaper Hobbing Hobbing is only possible for external gears.gear. the hob and gear blank are rotated continuously until all teeth are cut. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. gear hobbing process is commonly used to cut teeth into gears. The profile is formed by the. . Gear Shaper Hobbing.

From longfordgear.co.uk

Gear Cutting Shaping & Hobbing Longford Gear Cutting Co Ltd Gear Shaper Hobbing the hob and gear blank are rotated continuously until all teeth are cut. It involves using a special machine called a gear hobber, which uses a. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. gear hobbing is more versatile in producing various gear types, while gear shaping is. Gear Shaper Hobbing.

From ipmiengineering.com

Gear Hobbing Kansas City Machine Shop Custom Machined Parts & Services Gear Shaper Hobbing a hob is a cylindrical cutting tool that is used to create the teeth on a gear. The profile is formed by the. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. gear hobbing process is commonly used to cut teeth into gears. Hobbing is only possible. Gear Shaper Hobbing.

From theequipmenthub.com

Gear Shaping vs Gear Hobbing Gear Manufacturing Machines Gear Shaper Hobbing gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. The hob is rotated and fed against the gear blank,. The profile is formed by the. gear hobbing process is commonly used to cut teeth into gears. Hobbing is only possible for. Gear Shaper Hobbing.

From www.wto-tools.com

Gear Hobbing Gear Shaper Hobbing gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears. The hob is rotated and fed against the gear blank,. Hobbing is only possible for external gears.gear. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. gear hobbing process is. Gear Shaper Hobbing.

From wdlstore.en.made-in-china.com

Durable in Use Metal Gear Manufacturing Shaper Gear Hobbing Machine Gear Shaper Hobbing the hob and gear blank are rotated continuously until all teeth are cut. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. Hobbing is only possible for external gears.gear. The hob is rotated and fed against the gear blank,. gear hobbing is a process in which gear is cut. Gear Shaper Hobbing.

From www.maxwelltools.com

What is Gear Hobbing? Maxwell Tools Company Gear Shaper Hobbing The profile is formed by the. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. gear shaping is handled on a gear shaping. Gear Shaper Hobbing.

From www.snyderindustriesinc.com

Gear Cutting, Shaping & Hobbing Snyder Industries, Inc. Gear Shaper Hobbing The profile is formed by the. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. the hob and gear blank are rotated continuously until all teeth are cut. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank. Gear Shaper Hobbing.

From www.liebherr.com

Gear hobbing machines Liebherr Liebherr Gear Shaper Hobbing The hob is rotated and fed against the gear blank,. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears. the hob and gear blank are rotated continuously until all teeth. Gear Shaper Hobbing.

From longfordgear.co.uk

Gear Cutting Shaping & Hobbing Longford Gear Cutting Co Ltd Gear Shaper Hobbing gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. the hob and gear blank are rotated continuously until all teeth are cut. The hob is rotated and fed against the gear blank,. a hob is a cylindrical cutting tool that is used to create the teeth on. Gear Shaper Hobbing.

From true-gear.com

Explaining Gear Shaping & Gear Hobbing Gear Shaper Hobbing It involves using a special machine called a gear hobber, which uses a. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. The profile is formed by the. Hobbing is only possible for external gears.gear. the hob and gear blank are rotated continuously until all teeth are cut. The hob. Gear Shaper Hobbing.

From www.snyderindustriesinc.com

Gear Cutting, Shaping & Hobbing Snyder Industries, Inc. Gear Shaper Hobbing The profile is formed by the. The hob is rotated and fed against the gear blank,. gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called. Gear Shaper Hobbing.

From www.broachingjobshops.com

Gear Hobbing Companies Gear Hobbing Services Gear Shaper Hobbing The hob is rotated and fed against the gear blank,. The profile is formed by the. a hob is a cylindrical cutting tool that is used to create the teeth on a gear. It involves using a special machine called a gear hobber, which uses a. gear shaping is handled on a gear shaping machine, while gear hobbing. Gear Shaper Hobbing.

From www.slideserve.com

PPT THE INDEXING MECHANISM OF GEAR HOBBING MACHINE PowerPoint Gear Shaper Hobbing gear shaping is handled on a gear shaping machine, while gear hobbing requires the use of a gear hobbing. The hob is rotated and fed against the gear blank,. It involves using a special machine called a gear hobber, which uses a. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable. Gear Shaper Hobbing.

From www.bid-on-equipment.com

FELLOWS GEAR SHAPER CO.MILES Gear Hobbing MachineGear Shaper 316305 Gear Shaper Hobbing It involves using a special machine called a gear hobber, which uses a. the hob and gear blank are rotated continuously until all teeth are cut. gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at. gear shaping is handled on. Gear Shaper Hobbing.