Braze Vs Weld Steel . The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. Therefore, this method has no molten puddle and there is no. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Larger assemblies dissipate heat, making it. Determine the optimal metal joining method for your project with our expert comparison. Both brazing and welding join metals but. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Brazing heats a broad area, often the entire assembly. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. First, a brazed joint is a strong joint. Brazing uses a filler metal with a. Welding is better for joining large assemblies.

from mechrockss.blogspot.com

Brazing heats a broad area, often the entire assembly. Therefore, this method has no molten puddle and there is no. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Determine the optimal metal joining method for your project with our expert comparison. Larger assemblies dissipate heat, making it. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Both brazing and welding join metals but. Welding is better for joining large assemblies.

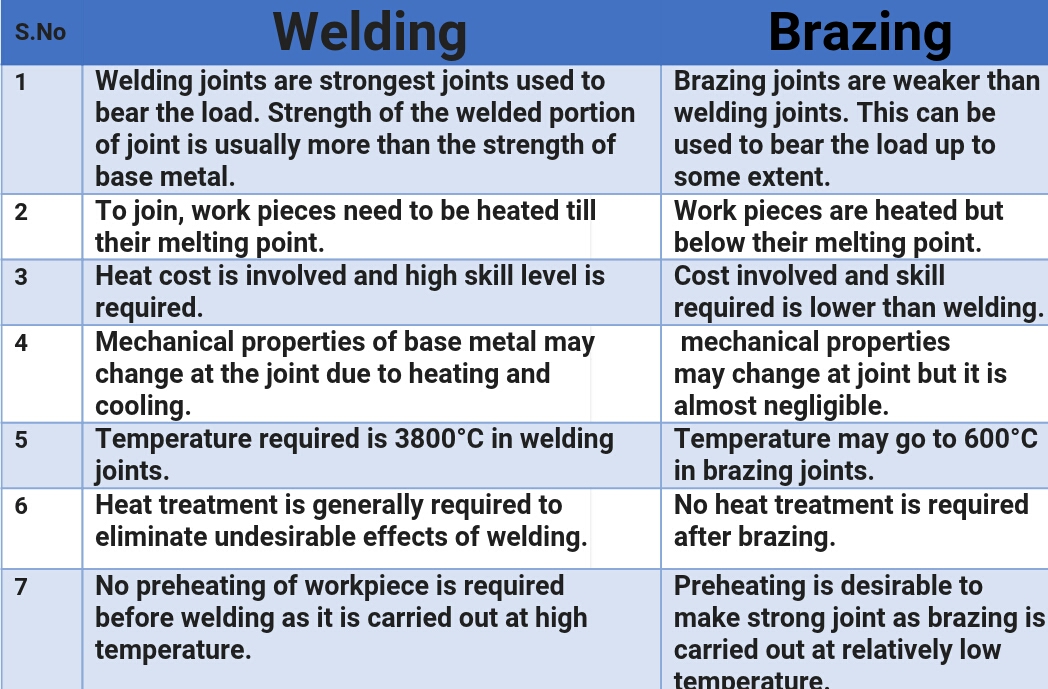

Mechrockss DIFFERENCE BETWEEN WELDING AND BRAZING EXPLAINED

Braze Vs Weld Steel Welding is better for joining large assemblies. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Therefore, this method has no molten puddle and there is no. Both brazing and welding join metals but. Determine the optimal metal joining method for your project with our expert comparison. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. Brazing heats a broad area, often the entire assembly. Brazing uses a filler metal with a. First, a brazed joint is a strong joint. Larger assemblies dissipate heat, making it. Welding is better for joining large assemblies.

From workshopinsider.com

Welding VS Brazing What Is The Difference? Insider Braze Vs Weld Steel Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Both brazing and welding join metals but. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. The basic difference is. Braze Vs Weld Steel.

From mechrockss.blogspot.com

Mechrockss DIFFERENCE BETWEEN WELDING AND BRAZING EXPLAINED Braze Vs Weld Steel Brazing uses a filler metal with a. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Brazing heats a broad area, often the entire assembly. Therefore, this method has no molten puddle and there is no. Both brazing and welding join metals but. Welding is better. Braze Vs Weld Steel.

From hxehcvmue.blob.core.windows.net

Metal Brazing Vs Welding at Heather Williams blog Braze Vs Weld Steel A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Brazing uses a filler metal with a. Determine the optimal metal joining method for your project with our expert. Braze Vs Weld Steel.

From es.slideshare.net

Brazing Steel to Aluminum Braze Vs Weld Steel Brazing uses a filler metal with a. Brazing heats a broad area, often the entire assembly. Therefore, this method has no molten puddle and there is no. Larger assemblies dissipate heat, making it. Welding is better for joining large assemblies. Both brazing and welding join metals but. Unlike welding, brazing only melts the filler metal and uses it as a. Braze Vs Weld Steel.

From www.smetals.co.uk

Brazing vs. Welding Understanding the Differences and Applications Braze Vs Weld Steel When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Welding is better for joining large assemblies. Brazing uses a filler metal with a. Determine the optimal metal joining method for your project with our expert comparison. Unlike welding, brazing only melts the filler metal and uses it as a sort of. Braze Vs Weld Steel.

From thecontentauthority.com

Braze vs Weld Do These Mean The Same? How To Use Them Braze Vs Weld Steel Both brazing and welding join metals but. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Brazing heats a broad area, often the entire assembly.. Braze Vs Weld Steel.

From mdmtool.com

Difference Between Braze And Weld MDM Tool Supply Braze Vs Weld Steel The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. First, a brazed joint is a strong joint. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Unlike welding, brazing only melts the filler metal and uses it as a sort of. Braze Vs Weld Steel.

From weldingpros.net

Brazing Vs Soldering Vs Welding Crucial Differences 2024 Braze Vs Weld Steel When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Larger assemblies dissipate heat, making it. Therefore, this method has no molten puddle and there is no. First, a brazed joint is a strong joint. Welding is better for joining large assemblies. Both brazing and welding join metals but. Brazing heats a. Braze Vs Weld Steel.

From www.youtube.com

SOLDERING ,BRAZING AND BRAZE WELDING YouTube Braze Vs Weld Steel First, a brazed joint is a strong joint. Larger assemblies dissipate heat, making it. Therefore, this method has no molten puddle and there is no. Determine the optimal metal joining method for your project with our expert comparison. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in. Braze Vs Weld Steel.

From edu.svet.gob.gt

Bernzomatic How To Braze Metal Together Brazing Metal Braze Vs Weld Steel When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Larger assemblies dissipate heat, making it. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Brazing heats a broad area, often the entire assembly. A. Braze Vs Weld Steel.

From kaybrazing.com

Essential Criteria for Brazing Item 1 Proper Design for Brazing Braze Vs Weld Steel Brazing heats a broad area, often the entire assembly. Determine the optimal metal joining method for your project with our expert comparison. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. The basic difference is that the filler metal, a copper alloy, melts at a lower. Braze Vs Weld Steel.

From blog.thepipingmart.com

Exothermic Welding vs Brazing What's the Difference Braze Vs Weld Steel Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. First, a brazed joint is a strong joint. Larger assemblies dissipate heat, making it. Both brazing and welding join metals but. Therefore, this method has no molten puddle and there is no. The basic. Braze Vs Weld Steel.

From www.smetals.co.uk

Brazing vs. Welding Understanding the Differences and Applications Braze Vs Weld Steel Welding is better for joining large assemblies. Brazing heats a broad area, often the entire assembly. First, a brazed joint is a strong joint. Both brazing and welding join metals but. Therefore, this method has no molten puddle and there is no. Determine the optimal metal joining method for your project with our expert comparison. Unlike welding, brazing only melts. Braze Vs Weld Steel.

From blog.thepipingmart.com

Can you Braze Stainless Steel with Brass? Braze Vs Weld Steel A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Brazing uses a filler metal with a. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Larger assemblies dissipate heat,. Braze Vs Weld Steel.

From blog.thepipingmart.com

Brazing vs Gas Welding What's the Difference Braze Vs Weld Steel Determine the optimal metal joining method for your project with our expert comparison. The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. First, a brazed joint is a strong joint. Larger assemblies dissipate heat, making it. Unlike welding, brazing only melts the filler metal and uses it as a sort. Braze Vs Weld Steel.

From www.welderscave.com

What is the Difference between Welding And Brazing Welders Cave Braze Vs Weld Steel When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Brazing uses a filler metal with a. Determine the optimal metal joining method for your project with our expert comparison. Both brazing and welding join metals but. The basic difference is that the filler metal, a copper alloy, melts at a lower. Braze Vs Weld Steel.

From www.weldingtipsandtricks.com

TIG Welding/Brazing with Silicon Bronze Braze Vs Weld Steel Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Determine the optimal metal joining method for your project with our expert comparison. A properly made. Braze Vs Weld Steel.

From www.themetalchic.com

Metalchic Atlas Bronze Brazing vs. Welding What’s the Difference? Braze Vs Weld Steel Larger assemblies dissipate heat, making it. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Welding is better for joining large assemblies. Brazing heats a broad area, often the entire assembly. A properly made brazed joint (like a welded joint) will in many. Braze Vs Weld Steel.

From saferef.in

Welding vs. Brazing Understanding the Crucial Differences Saferef Braze Vs Weld Steel The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Determine the optimal metal joining method for your project with our expert comparison. Both brazing. Braze Vs Weld Steel.

From www.welderscave.com

What Is The Difference Between Welding And Brazing Braze Vs Weld Steel Larger assemblies dissipate heat, making it. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. First, a brazed joint is a strong joint. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a. Braze Vs Weld Steel.

From migtigstickweld.com

Welding vs Brazing What Are the Essential Differences? Braze Vs Weld Steel A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. First, a brazed joint is a strong joint. Determine the optimal metal joining method for your project with our expert comparison. Both brazing and welding join metals but. When comparing brazing vs braze welding, both brazing &. Braze Vs Weld Steel.

From rexarc.com

Difference Between Braze Welding and Gas Welding Explained Rexarc Braze Vs Weld Steel Both brazing and welding join metals but. Determine the optimal metal joining method for your project with our expert comparison. The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. Brazing heats a broad area, often the entire assembly. Brazing uses a filler metal with a. First, a brazed joint is. Braze Vs Weld Steel.

From blog.thepipingmart.com

Brazing Aluminium vs Welding What's the Difference Braze Vs Weld Steel The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. Brazing uses a filler metal with a. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Determine the optimal metal joining method for your project with our expert comparison. Therefore, this method. Braze Vs Weld Steel.

From www.youtube.com

Differences between Welding and Brazing Mechanical Engineering YouTube Braze Vs Weld Steel Larger assemblies dissipate heat, making it. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Brazing uses a filler metal with a. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Determine the optimal metal joining method. Braze Vs Weld Steel.

From www.diffzy.com

Welding vs. Brazing What's The Difference (With Table) Braze Vs Weld Steel Both brazing and welding join metals but. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Brazing heats a broad area, often the entire assembly.. Braze Vs Weld Steel.

From www.smetals.co.uk

Brazing vs. Welding Understanding the Differences and Applications Braze Vs Weld Steel A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. First, a brazed joint is a strong joint. The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. Both brazing and welding join metals but. Therefore, this method. Braze Vs Weld Steel.

From www.youtube.com

Difference between brazing and braze welding II Brazing & Braze Welding Braze Vs Weld Steel Therefore, this method has no molten puddle and there is no. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. The basic difference is that the filler metal,. Braze Vs Weld Steel.

From weldersadvice.com

How to Braze Weld Steel A Beginner's Guide Welders Advice Braze Vs Weld Steel Larger assemblies dissipate heat, making it. The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: A properly made brazed joint (like a welded joint) will in many cases be as strong or. Braze Vs Weld Steel.

From www.brilliantdiy.com

[Video] Ultimate Comparison Showing The Differences Between Tig Brazing Braze Vs Weld Steel First, a brazed joint is a strong joint. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: Brazing uses a filler metal with a. The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. Therefore, this method has no molten puddle and. Braze Vs Weld Steel.

From www.mingledorffs.com

Soldering, Brazing, and Welding Mingledorff's Braze Vs Weld Steel Larger assemblies dissipate heat, making it. Both brazing and welding join metals but. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. First, a brazed joint is a strong joint. Brazing uses a filler metal with a. A properly made brazed joint (like. Braze Vs Weld Steel.

From blog.thepipingmart.com

Fusion Welding vs Brazing What's the Difference Braze Vs Weld Steel Welding is better for joining large assemblies. Determine the optimal metal joining method for your project with our expert comparison. Brazing uses a filler metal with a. First, a brazed joint is a strong joint. Larger assemblies dissipate heat, making it. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: A. Braze Vs Weld Steel.

From www.bernzomatic.com

Bernzomatic How To Braze Metal Together Brazing Metal Braze Vs Weld Steel When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Therefore, this method has no molten puddle and there is no. Larger assemblies dissipate heat, making it. Determine the. Braze Vs Weld Steel.

From www.clickmetal.co.uk

Differences between brazing and welding Clickmetal Braze Vs Weld Steel Therefore, this method has no molten puddle and there is no. Brazing uses a filler metal with a. When comparing brazing vs braze welding, both brazing & braze welding are joining processes having three distinct characteristics: A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Both. Braze Vs Weld Steel.

From www.youtube.com

Welding, brazing and soldering differences. Braze vs. Weld. Beginner Braze Vs Weld Steel A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Therefore, this method has no molten puddle and there is no. Determine the optimal metal joining method for your project with our expert comparison. Brazing uses a filler metal with a. When comparing brazing vs braze welding,. Braze Vs Weld Steel.

From www.pinterest.co.uk

TIg Brazing vs Tig Welding Brazing, Welding, Tig welding Braze Vs Weld Steel The basic difference is that the filler metal, a copper alloy, melts at a lower temperature than the casting. First, a brazed joint is a strong joint. A properly made brazed joint (like a welded joint) will in many cases be as strong or stronger than the metals being joined. Determine the optimal metal joining method for your project with. Braze Vs Weld Steel.