Seal Flush Line In Centrifugal Pump . The purpose of the mechanical seal. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. The essential elements of a mechanical seal. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. The flushing fluid recirculates from the pump discharge to the seal through a. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. Dealing with problems caused by particulates and slurries. There are many methods for implementing seal flush, but all. Experienced seal people use different terms to. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. By the end of this course you will understand and can identify:

from mungfali.com

The purpose of the mechanical seal. By the end of this course you will understand and can identify: Experienced seal people use different terms to. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. The flushing fluid recirculates from the pump discharge to the seal through a. The essential elements of a mechanical seal. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. Dealing with problems caused by particulates and slurries. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump.

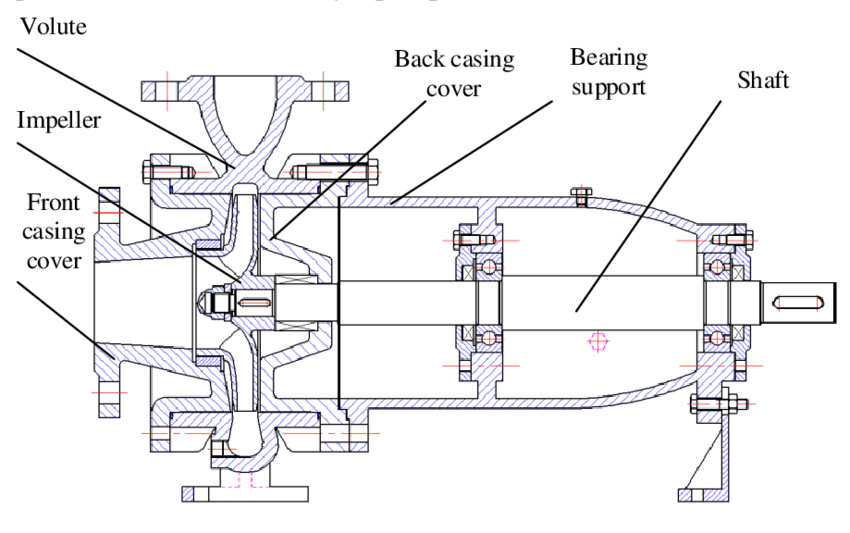

Centrifugal Pump Parts Labeled

Seal Flush Line In Centrifugal Pump Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. Dealing with problems caused by particulates and slurries. By the end of this course you will understand and can identify: Experienced seal people use different terms to. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. The essential elements of a mechanical seal. The flushing fluid recirculates from the pump discharge to the seal through a. The purpose of the mechanical seal. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. There are many methods for implementing seal flush, but all.

From www.deppmann.com

HVAC Centrifugal Pump Internally vs Externally Flushed Mechanical Seals Seal Flush Line In Centrifugal Pump Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. The purpose of the mechanical seal. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. Dealing with problems caused by particulates and slurries. The flushing fluid recirculates from the pump discharge to. Seal Flush Line In Centrifugal Pump.

From mungfali.com

Centrifugal Pump Parts Labeled Seal Flush Line In Centrifugal Pump The purpose of the mechanical seal. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. The essential elements of a mechanical seal. Centrifugal pump mechanical seals play a crucial role in enhancing pump. Seal Flush Line In Centrifugal Pump.

From enggcyclopedia.com

Common types of pumps mechanical seal piping plans Single seals Seal Flush Line In Centrifugal Pump Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. The essential elements of a mechanical seal. By the end of this course you will understand and can identify: Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning. Seal Flush Line In Centrifugal Pump.

From pump-solutions.net

Seal Flush Plans—Process Side, (Wet), (Gas), Atmosphere Side Pump Seal Flush Line In Centrifugal Pump Dealing with problems caused by particulates and slurries. The essential elements of a mechanical seal. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. By the end of this course you will understand and can identify: Process fluids with high particulate concentrations or slurries can impact. Seal Flush Line In Centrifugal Pump.

From www.worldpumps.com

Less waste means more reliability Seal Flush Line In Centrifugal Pump There are many methods for implementing seal flush, but all. By the end of this course you will understand and can identify: Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. The purpose of the mechanical seal. Centrifugal pump mechanical seals play a crucial role in. Seal Flush Line In Centrifugal Pump.

From northerncal.swagelok.com

Why Seal Flushing Is Required and How To Minimize Its Frequency Seal Flush Line In Centrifugal Pump There are many methods for implementing seal flush, but all. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. Experienced seal people use different terms to. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. By the end of this. Seal Flush Line In Centrifugal Pump.

From www.ess4solutions.com

Seal Support Systems for Oil and Gas — ESS Pump & Seal Seal Flush Line In Centrifugal Pump Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Dealing with problems caused by particulates and slurries. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. The essential elements of a mechanical seal.. Seal Flush Line In Centrifugal Pump.

From edmontonvalve.swagelok.com

Understanding How the API Plan 52 Seal System Works For Canadian Operations Seal Flush Line In Centrifugal Pump Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. The flushing fluid recirculates from the pump discharge to the seal through a. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box. Seal Flush Line In Centrifugal Pump.

From www.alibaba.com

Sanitary Seal Impeller Stainless Steel Flushing Double Mechanical Seal Seal Flush Line In Centrifugal Pump The essential elements of a mechanical seal. By the end of this course you will understand and can identify: Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. The purpose of the mechanical seal. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Process fluids with high particulate. Seal Flush Line In Centrifugal Pump.

From pump-solutions.net

Seal Flush Plans—Process Side, (Wet), (Gas), Atmosphere Side Pump Seal Flush Line In Centrifugal Pump Experienced seal people use different terms to. The purpose of the mechanical seal. Dealing with problems caused by particulates and slurries. The flushing fluid recirculates from the pump discharge to the seal through a. By the end of this course you will understand and can identify: The essential elements of a mechanical seal. Optimized seal flush piping arrangements are needed. Seal Flush Line In Centrifugal Pump.

From www.youtube.com

Mechanical Seal Maintenance Xylem Bell & Gossett Series e80SC Inline Seal Flush Line In Centrifugal Pump Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. Dealing with problems caused by particulates and slurries. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. There are many methods for implementing seal flush, but all. Optimized seal flush piping arrangements. Seal Flush Line In Centrifugal Pump.

From www.youtube.com

Seal flush plan 53B Seal flush plan 53A & 53C Dual seal flushing Seal Flush Line In Centrifugal Pump The flushing fluid recirculates from the pump discharge to the seal through a. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Experienced seal people use different terms to. Centrifugal pump mechanical seals play a crucial role in enhancing pump. Seal Flush Line In Centrifugal Pump.

From www.linkedin.com

Stainless steel centrifugal pump mechanical seal flushing scheme inventory Seal Flush Line In Centrifugal Pump Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. The flushing fluid recirculates from the pump discharge to the seal through a. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. By the end of this course you will understand and. Seal Flush Line In Centrifugal Pump.

From hevvypumps.com

Differences Between Flush and Quench In Slurry Pump Seal Support Plans Seal Flush Line In Centrifugal Pump There are many methods for implementing seal flush, but all. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. The essential elements of a mechanical seal. Centrifugal pump mechanical seals play. Seal Flush Line In Centrifugal Pump.

From www.alibaba.com

Sanitary Seal Impeller Stainless Steel Flushing Double Mechanical Seal Seal Flush Line In Centrifugal Pump Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. There are many methods for implementing seal flush, but all. Experienced seal people use different terms to. Optimized seal flush piping. Seal Flush Line In Centrifugal Pump.

From www.linkedin.com

Centrifugal Pumps Part I Mechanical seals Seal Flush Line In Centrifugal Pump The flushing fluid recirculates from the pump discharge to the seal through a. Dealing with problems caused by particulates and slurries. By the end of this course you will understand and can identify: Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. The purpose of the mechanical. Seal Flush Line In Centrifugal Pump.

From www.idrochemical.com

NCL inline centrifugal pumps Idrochemical Seal Flush Line In Centrifugal Pump The essential elements of a mechanical seal. The purpose of the mechanical seal. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. There are many methods for implementing seal flush, but all. Optimized seal flush piping arrangements are. Seal Flush Line In Centrifugal Pump.

From www.centrifugal-slurrypump.com

Mechanical Seal 6 / 4 D AH Centrifugal Slurry Pump with External Seal Flush Line In Centrifugal Pump The flushing fluid recirculates from the pump discharge to the seal through a. The essential elements of a mechanical seal. Experienced seal people use different terms to. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. By the end of this course you will understand and can identify: Optimized seal flush piping arrangements. Seal Flush Line In Centrifugal Pump.

From mavink.com

Centrifugal Pump Mechanical Seal Diagram Seal Flush Line In Centrifugal Pump The flushing fluid recirculates from the pump discharge to the seal through a. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Experienced seal people use different terms to. There are many methods for implementing seal flush, but all. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the. Seal Flush Line In Centrifugal Pump.

From www.youtube.com

Mechanical Seal Piping Plans inar Session 3 Siewert Equipment Seal Flush Line In Centrifugal Pump Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. Dealing with problems caused by particulates and slurries. The. Seal Flush Line In Centrifugal Pump.

From www.youtube.com

Mechanical Seal flush plan 62 Atmospheric side seal flush plan 61 Seal Flush Line In Centrifugal Pump Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. The purpose of the mechanical seal. Experienced seal people use different terms to. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by. Seal Flush Line In Centrifugal Pump.

From www.ogj.com

BEYOND BACKTOBASICS PROCESS PRINCIPLES AND CONCEPTS3 Maintaining Seal Flush Line In Centrifugal Pump The essential elements of a mechanical seal. There are many methods for implementing seal flush, but all. Experienced seal people use different terms to. The purpose of the mechanical seal. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. The flushing fluid recirculates from the pump discharge. Seal Flush Line In Centrifugal Pump.

From ar.inspiredpencil.com

Mechanical Seals For Centrifugal Pumps Seal Flush Line In Centrifugal Pump Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. The flushing fluid recirculates from the pump discharge to the seal through a. There are many methods for implementing seal flush, but all. Experienced seal people use different terms to. The purpose of the mechanical seal. By the end of this course you will understand and. Seal Flush Line In Centrifugal Pump.

From www.modopump.net

One Minute To Understand The Selfflushing Of The Centrifugal Pump Seal Flush Line In Centrifugal Pump Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. The essential elements of a mechanical seal. Dealing with problems caused by particulates and slurries. By the end of this course you will. Seal Flush Line In Centrifugal Pump.

From hevvypumps.com

Differences Between Flush and Quench In Slurry Pump Seal Support Plans Seal Flush Line In Centrifugal Pump Dealing with problems caused by particulates and slurries. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Experienced seal people use different terms to. The flushing fluid recirculates from the pump discharge to the seal through a. By the end of this course you will understand and can identify: The essential elements of a mechanical. Seal Flush Line In Centrifugal Pump.

From pumpbiz.com

AMT 430A95 30 HP 1750 RPM Straight Centrifugal Pump Seal Flush Line In Centrifugal Pump Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. The purpose of the mechanical seal. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. Dealing. Seal Flush Line In Centrifugal Pump.

From jmpcoblog.com

How to Pick a Centrifugal Pump Part 6 Internally Vs. Externally Seal Flush Line In Centrifugal Pump Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. By the end of this course you will understand and can identify: There are many methods for implementing seal flush, but all. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. The. Seal Flush Line In Centrifugal Pump.

From www.sintechpumps.com

Guide for Installing Centrifugal Pumps Sintech Pumps Seal Flush Line In Centrifugal Pump Dealing with problems caused by particulates and slurries. The purpose of the mechanical seal. There are many methods for implementing seal flush, but all. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump.. Seal Flush Line In Centrifugal Pump.

From edmontonvalve.swagelok.com

Solving Seal Flush Plan 11 Challenges More Easily for SAGD Operations Seal Flush Line In Centrifugal Pump The flushing fluid recirculates from the pump discharge to the seal through a. Experienced seal people use different terms to. There are many methods for implementing seal flush, but all. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. The essential elements of a mechanical seal. Dealing. Seal Flush Line In Centrifugal Pump.

From www.vrogue.co

Centrifugal Pump Mechanical Seal Overhauling Maintena vrogue.co Seal Flush Line In Centrifugal Pump Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. The flushing fluid recirculates from the pump discharge to the seal through a. Experienced seal people use different terms to. There are many methods for implementing seal flush, but all. Dealing with problems caused by particulates and slurries. Process fluids with high particulate concentrations. Seal Flush Line In Centrifugal Pump.

From mavink.com

Centrifugal Pump Construction Seal Flush Line In Centrifugal Pump There are many methods for implementing seal flush, but all. The essential elements of a mechanical seal. The flushing fluid recirculates from the pump discharge to the seal through a. By the end of this course you will understand and can identify: The purpose of the mechanical seal. Process fluids with high particulate concentrations or slurries can impact centrifugal pump. Seal Flush Line In Centrifugal Pump.

From www.deppmann.com

Double Suction Pump Specification Mechanical Seals Deppmann Seal Flush Line In Centrifugal Pump Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues. Experienced seal people use different terms to. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal.. Seal Flush Line In Centrifugal Pump.

From abetutorials.blogspot.com

Centrifugal Pumps Overview, Installation, Operation, and Maintenance Seal Flush Line In Centrifugal Pump Experienced seal people use different terms to. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. There are many methods for implementing seal flush, but all. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a. Seal Flush Line In Centrifugal Pump.

From cnkcmp.en.made-in-china.com

Double Mechanical Seal Flushing High Temperature Chemical Centrifugal Seal Flush Line In Centrifugal Pump Process fluids with high particulate concentrations or slurries can impact centrifugal pump and mechanical seal. The purpose of the mechanical seal. Flushing of mechanical seals, on large industrial pumps, is used to extend the life of the seal by cleaning and/or cooling the seal. Centrifugal pump mechanical seals play a crucial role in enhancing pump efficiency and reducing operational issues.. Seal Flush Line In Centrifugal Pump.

From www.ogj.com

BEYOND BACKTOBASICS PROCESS PRINCIPLES AND CONCEPTS3 Maintaining Seal Flush Line In Centrifugal Pump Dealing with problems caused by particulates and slurries. Optimized seal flush piping arrangements are needed to create the most appropriate seal environment. The essential elements of a mechanical seal. The purpose of the mechanical seal. Consumers use the term flushing to describe six different methods of bringing fluid to the stuffing box area of a centrifugal pump. The flushing fluid. Seal Flush Line In Centrifugal Pump.