Linear Rails Binding . When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. Support mechanics are one of the most critical components in a linear motion design. 2x = distance from shaft to. In a nutshell, if either the drive force (fa) or applied load force. Use these formulas and examples when using simplicity bearings with a cantilevered load. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. 1x = bearing separation on same shaft. Round rails on left and profile rails on right. It is often displayed numerically as x:y, where x is. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). The binding ratio is often displayed. They set the stage for the achievable performance in. The root cause of binding lies in friction,.

from www.vevor.com.au

In a nutshell, if either the drive force (fa) or applied load force. When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). They set the stage for the achievable performance in. Support mechanics are one of the most critical components in a linear motion design. 2x = distance from shaft to. Use these formulas and examples when using simplicity bearings with a cantilevered load. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. 1x = bearing separation on same shaft. Round rails on left and profile rails on right.

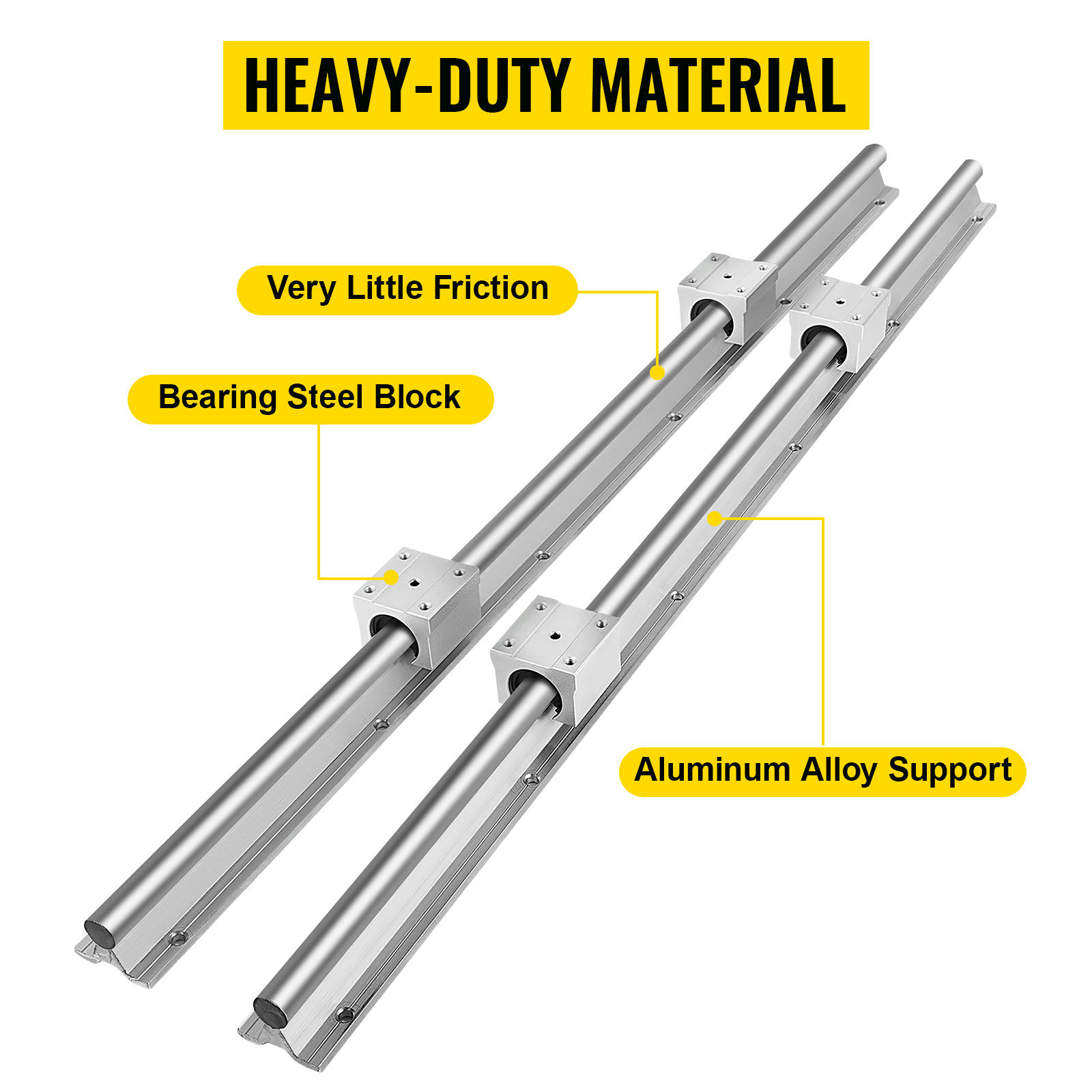

SBR201000mm 2 Linear Rail Set 4 Block CNC Set smooth sliding linear

Linear Rails Binding The binding ratio is often displayed. Support mechanics are one of the most critical components in a linear motion design. The root cause of binding lies in friction,. When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. They set the stage for the achievable performance in. Use these formulas and examples when using simplicity bearings with a cantilevered load. It is often displayed numerically as x:y, where x is. 2x = distance from shaft to. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. 1x = bearing separation on same shaft. In a nutshell, if either the drive force (fa) or applied load force. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). Round rails on left and profile rails on right. The binding ratio is often displayed.

From www.vevor.com

VEVOR Linear Guide Rail Set, SBR16 800mm, 2 PCS 31.5 in/800 mm SBR16 Linear Rails Binding Support mechanics are one of the most critical components in a linear motion design. The root cause of binding lies in friction,. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. In a nutshell, if. Linear Rails Binding.

From www.nepal.ubuy.com

Buy Linear Rails and Bearings Linear Rail 2X SBR162000mm Linear Slide Linear Rails Binding 1x = bearing separation on same shaft. Support mechanics are one of the most critical components in a linear motion design. It is often displayed numerically as x:y, where x is. The binding ratio is often displayed. They set the stage for the achievable performance in. When using drylin®, it is important to ensure that all acting forces follow the. Linear Rails Binding.

From kiwimotion.co.uk

Linear Motion Products Automation Components Kiwi Motion Linear Rails Binding When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. 1x = bearing separation on same shaft. Use these formulas and examples when using simplicity bearings with a cantilevered load. Support mechanics are one of the most critical components in a linear motion design. They set the stage for the achievable performance in. The. Linear Rails Binding.

From www.printables.com

Double Linear Rails Y Axis Ender 3 v1 por KaminoKGY Descargar modelo Linear Rails Binding 1x = bearing separation on same shaft. The root cause of binding lies in friction,. 2x = distance from shaft to. They set the stage for the achievable performance in. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. It is often displayed numerically as x:y, where x is. Support mechanics. Linear Rails Binding.

From bigamart.com

Linear Guide Rail, Linear Rail Shaft, 2Pcs 11.8inch 0.47inch SBR12UU Linear Rails Binding For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. 1x = bearing separation on same shaft. 2x = distance from shaft to. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). Use these formulas and examples when. Linear Rails Binding.

From www.isel-us.com

Linear Rail Linear Motion Rails Linear Motion Components Linear Rails Binding The root cause of binding lies in friction,. In a nutshell, if either the drive force (fa) or applied load force. They set the stage for the achievable performance in. 1x = bearing separation on same shaft. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion).. Linear Rails Binding.

From www.youtube.com

Linear rails guide and test on Ender 3 and Ender 5 YouTube Linear Rails Binding Support mechanics are one of the most critical components in a linear motion design. Round rails on left and profile rails on right. They set the stage for the achievable performance in. Use these formulas and examples when using simplicity bearings with a cantilevered load. When using drylin®, it is important to ensure that all acting forces follow the 2:1. Linear Rails Binding.

From www.vevor.com

VEVOR Linear Guide Rail Set, SFC20 1000mm, 2 PCS 39.4 in/1000 mm SFC20 Linear Rails Binding Support mechanics are one of the most critical components in a linear motion design. Use these formulas and examples when using simplicity bearings with a cantilevered load. It is often displayed numerically as x:y, where x is. 1x = bearing separation on same shaft. Round rails on left and profile rails on right. For illustration purposes, the lowest common coefficient. Linear Rails Binding.

From kiwimotion.co.uk

Linear Rail and Guides 255mm Linear Rails CPC UK Supplier Linear Rails Binding Round rails on left and profile rails on right. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. In a nutshell, if either the drive force (fa) or applied load force. Use these formulas and examples when using simplicity bearings with a cantilevered load. The root cause of binding lies in. Linear Rails Binding.

From www.vevor.ca

VEVOR 2 x HSR 151500 mm Linear Guideway Rail with 4Pcs Pillow Block Linear Rails Binding In a nutshell, if either the drive force (fa) or applied load force. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). The root cause of binding lies in friction,. Use these formulas and examples when using simplicity bearings with a cantilevered load. When using drylin®,. Linear Rails Binding.

From www.fullstopindia.com

The Benefits of Using Linear Guide Rails in Manufacturing Processes Linear Rails Binding 1x = bearing separation on same shaft. 2x = distance from shaft to. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. It is often displayed numerically as x:y, where x is. The root cause of binding lies in friction,. In a nutshell, if either the drive force (fa) or applied. Linear Rails Binding.

From www.pinterest.com

BLOG & NEWS Linear guide rails available soon MakerBeam Rails Linear Rails Binding The binding ratio is often displayed. They set the stage for the achievable performance in. When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. It is often displayed numerically as x:y, where x is. In a nutshell, if either the drive force (fa) or applied load force. Support mechanics are one of the. Linear Rails Binding.

From www.indiamart.com

Standard Stainless Steel Linear Rail Linear Ways Blocks & Rails at Rs Linear Rails Binding For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. The binding ratio is often displayed. In a nutshell, if either the drive force (fa) or applied load force. Round rails on left and profile rails on right. The “binding ratio” is officially defined as the maximum ratio of moment arm distance. Linear Rails Binding.

From www.reddit.com

Linear rails binding? r/ElegooMars Linear Rails Binding 2x = distance from shaft to. Use these formulas and examples when using simplicity bearings with a cantilevered load. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. Support mechanics are one of the most critical components in a linear motion design. 1x = bearing separation on same shaft. Round rails. Linear Rails Binding.

From www.vevor.ca

VEVOR Linear Rail Slide 2PCs 16mm x 1000mm Linear Bearing Slide Set Linear Rails Binding For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. The root cause of binding lies in friction,. In a nutshell, if either the drive force (fa) or applied load force. 1x = bearing separation on same shaft. The “binding ratio” is officially defined as the maximum ratio of moment arm distance. Linear Rails Binding.

From www.iqsdirectory.com

Linear Rails Types, Applications, Benefits, and Design Linear Rails Binding Use these formulas and examples when using simplicity bearings with a cantilevered load. 2x = distance from shaft to. In a nutshell, if either the drive force (fa) or applied load force. When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. It is often displayed numerically as x:y, where x is. The binding. Linear Rails Binding.

From kiwimotion.co.uk

Linear Rail and Guides 255mm Linear Rails CPC UK Supplier Linear Rails Binding They set the stage for the achievable performance in. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). 2x = distance from shaft to. The binding ratio is often displayed. The root cause of binding lies in friction,. Round rails on left and profile rails on. Linear Rails Binding.

From www.vevor.com.au

SBR201000mm 2 Linear Rail Set 4 Block CNC Set smooth sliding linear Linear Rails Binding Use these formulas and examples when using simplicity bearings with a cantilevered load. The binding ratio is often displayed. Support mechanics are one of the most critical components in a linear motion design. In a nutshell, if either the drive force (fa) or applied load force. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion. Linear Rails Binding.

From eur.vevor.com

VEVOR VEVOR Linear Guide Rail Set, SBR20 1500mm, 2 PCS 59 in/1500 mm Linear Rails Binding Round rails on left and profile rails on right. 1x = bearing separation on same shaft. 2x = distance from shaft to. They set the stage for the achievable performance in. The root cause of binding lies in friction,. Support mechanics are one of the most critical components in a linear motion design. Use these formulas and examples when using. Linear Rails Binding.

From www.vevor.ca

VEVOR 2 x HSR 151500 mm Linear Guideway Rail with 4Pcs Pillow Block Linear Rails Binding Support mechanics are one of the most critical components in a linear motion design. The binding ratio is often displayed. 1x = bearing separation on same shaft. Use these formulas and examples when using simplicity bearings with a cantilevered load. It is often displayed numerically as x:y, where x is. In a nutshell, if either the drive force (fa) or. Linear Rails Binding.

From www.vevor.com.au

VEVOR VEVOR Linear Guide Rail Set, SBR16 2000mm, 2 PCS 78.7 in/2000 mm Linear Rails Binding For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. The root cause of binding lies in friction,. The binding ratio is often displayed. It is often displayed numerically as x:y, where x is. In a nutshell, if either the drive force (fa) or applied load force. The “binding ratio” is officially. Linear Rails Binding.

From www.printables.com

EnderNG Linear Rail Mod (Beta) by phucawf Download free STL model Linear Rails Binding For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. Round rails on left and profile rails on right. The root cause of binding lies in friction,. It is often displayed numerically as x:y, where x. Linear Rails Binding.

From shopee.ph

Linear rail optical axis rail set XY linear rail cross slide Linear Rails Binding It is often displayed numerically as x:y, where x is. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. The root cause of binding lies in friction,. Use. Linear Rails Binding.

From www.vevor.ca

VEVOR 2 x HSR 151500 mm Linear Guideway Rail with 4Pcs Pillow Block Linear Rails Binding The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). Round rails on left and profile rails on right. The root cause of binding lies in friction,. They set the stage for the achievable performance in. Use these formulas and examples when using simplicity bearings with a. Linear Rails Binding.

From kiwimotion.co.uk

Linear Rail and Guides 255mm Linear Rails CPC UK Supplier Linear Rails Binding The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). It is often displayed numerically as x:y, where x is. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. Round rails on left and profile rails on right.. Linear Rails Binding.

From www.youtube.com

Alignment attempt (linear rails 6040 upgrade) (Linear rail upgrade part Linear Rails Binding In a nutshell, if either the drive force (fa) or applied load force. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). They set the stage for the achievable performance in. When using drylin®, it is important to ensure that all acting forces follow the 2:1. Linear Rails Binding.

From kiwimotion.co.uk

Linear Rail and Guides 255mm Linear Rails CPC UK Supplier Linear Rails Binding The root cause of binding lies in friction,. It is often displayed numerically as x:y, where x is. Use these formulas and examples when using simplicity bearings with a cantilevered load. 2x = distance from shaft to. The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion).. Linear Rails Binding.

From 3ddistributed.com

MGN12 2040 Carriage StopLinear Rail Alignment Tool 3D Distributed Linear Rails Binding 1x = bearing separation on same shaft. 2x = distance from shaft to. The root cause of binding lies in friction,. Support mechanics are one of the most critical components in a linear motion design. Round rails on left and profile rails on right. Use these formulas and examples when using simplicity bearings with a cantilevered load. When using drylin®,. Linear Rails Binding.

From www.indiamart.com

Standard Steel Linear Guide Ways, For Rail Block, Guide Width or Linear Rails Binding Round rails on left and profile rails on right. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. The root cause of binding lies in friction,. The binding ratio is often displayed. 2x = distance from shaft to. Support mechanics are one of the most critical components in a linear motion. Linear Rails Binding.

From tinymachines3d.freshdesk.com

CR10S 400/500 Y Axis Linear Rail Kit Installation Guide Tiny Machines 3D Linear Rails Binding They set the stage for the achievable performance in. 2x = distance from shaft to. Round rails on left and profile rails on right. The root cause of binding lies in friction,. 1x = bearing separation on same shaft. Support mechanics are one of the most critical components in a linear motion design. It is often displayed numerically as x:y,. Linear Rails Binding.

From surmanballscrew.en.made-in-china.com

Original 9mm Linear Rail Carriage Mgn9Hz0c Hiwin Linear Guide Mgn9h Linear Rails Binding When using drylin®, it is important to ensure that all acting forces follow the 2:1 rule. The root cause of binding lies in friction,. 2x = distance from shaft to. It is often displayed numerically as x:y, where x is. Use these formulas and examples when using simplicity bearings with a cantilevered load. For illustration purposes, the lowest common coefficient. Linear Rails Binding.

From www.drdflo.com

Building a 3D Printer Linear Rails Linear Rails Binding The “binding ratio” is officially defined as the maximum ratio of moment arm distance to bearing length, which will not bind (prevent motion). 1x = bearing separation on same shaft. It is often displayed numerically as x:y, where x is. For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. When using. Linear Rails Binding.

From chromedbars.en.made-in-china.com

Osg10500mm External Double Axis Locking Slide Linear Guide Rail with Linear Rails Binding For illustration purposes, the lowest common coefficient of friction commonly found in linear motion systems today is in. 1x = bearing separation on same shaft. They set the stage for the achievable performance in. In a nutshell, if either the drive force (fa) or applied load force. The root cause of binding lies in friction,. The binding ratio is often. Linear Rails Binding.

From www.indiamart.com

LM Guide, रैखिक गाइड in Vikhroli West, Mumbai , Mech Linear Systems Linear Rails Binding It is often displayed numerically as x:y, where x is. 2x = distance from shaft to. They set the stage for the achievable performance in. 1x = bearing separation on same shaft. Use these formulas and examples when using simplicity bearings with a cantilevered load. The root cause of binding lies in friction,. The “binding ratio” is officially defined as. Linear Rails Binding.

From www.aliexpress.com

Linear Rails And Bearings,1Pcs Linear Guide Rail 500Mm +2Pcs Linear Linear Rails Binding 2x = distance from shaft to. In a nutshell, if either the drive force (fa) or applied load force. Round rails on left and profile rails on right. Use these formulas and examples when using simplicity bearings with a cantilevered load. The root cause of binding lies in friction,. The “binding ratio” is officially defined as the maximum ratio of. Linear Rails Binding.