What Is Chamfer Features . Chamfered edges, also known as beveled edges, offer several advantages across different applications. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. A chamfer is an angle on the edge of a workpiece. Where precision is a must. Mechanical engineers are involved in chamfering in several ways. Especially in industries like aerospace, automotive, etc; The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Depending on component size, this may seem like a simple adjustment, but its implications are profound.

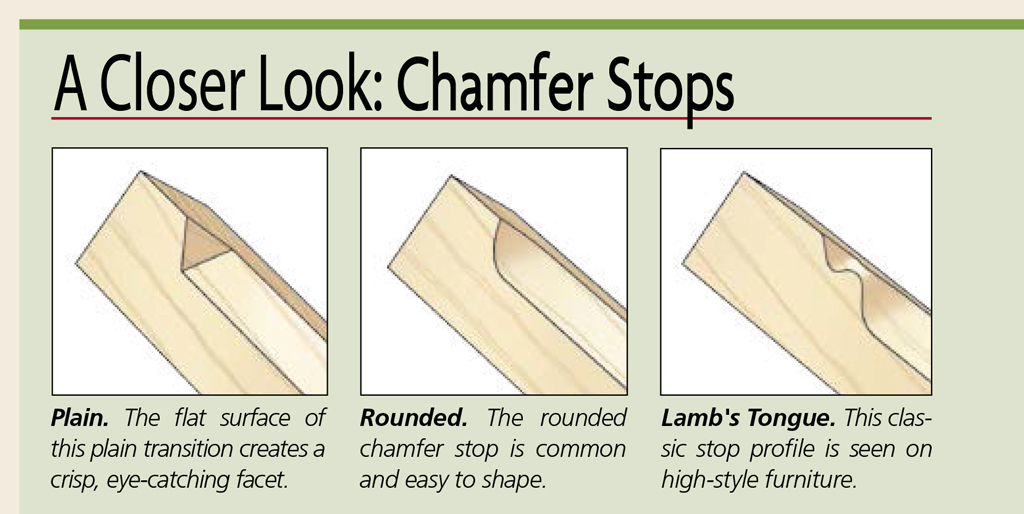

from www.woodsmith.com

Chamfered edges, also known as beveled edges, offer several advantages across different applications. Where precision is a must. Mechanical engineers are involved in chamfering in several ways. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. A chamfer is an angle on the edge of a workpiece. Especially in industries like aerospace, automotive, etc; Depending on component size, this may seem like a simple adjustment, but its implications are profound. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece.

The Versatile Chamfer Woodsmith

What Is Chamfer Features Depending on component size, this may seem like a simple adjustment, but its implications are profound. Where precision is a must. Especially in industries like aerospace, automotive, etc; Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Chamfered edges, also known as beveled edges, offer several advantages across different applications. A chamfer is an angle on the edge of a workpiece. Mechanical engineers are involved in chamfering in several ways. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Depending on component size, this may seem like a simple adjustment, but its implications are profound.

From www.youtube.com

Learn SolidWorks Chamfer Feature Tutorial _ SolidWorks Video Tutorials What Is Chamfer Features A chamfer is an angle on the edge of a workpiece. Mechanical engineers are involved in chamfering in several ways. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make. What Is Chamfer Features.

From www.youtube.com

Surfaces & Splines 09 Build Better Chamfers YouTube What Is Chamfer Features Where precision is a must. Mechanical engineers are involved in chamfering in several ways. Especially in industries like aerospace, automotive, etc; Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. The purpose of chamfering is to remove sharp edges, improve the appearance of the. What Is Chamfer Features.

From www.slideshare.net

Dimensioning standards What Is Chamfer Features Chamfered edges, also known as beveled edges, offer several advantages across different applications. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Especially in industries like aerospace, automotive, etc;. What Is Chamfer Features.

From www.educba.com

Chamfer in AutoCAD How to Use Chamfer Command in AutoCAD? What Is Chamfer Features A chamfer is an angle on the edge of a workpiece. Especially in industries like aerospace, automotive, etc; Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a. What Is Chamfer Features.

From www.3qmachining.com

Difference Between a Fillet and Chamfer, Everything You Need To Know What Is Chamfer Features Mechanical engineers are involved in chamfering in several ways. Chamfered edges, also known as beveled edges, offer several advantages across different applications. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Chamfers are a design feature where two surfaces meet at an angle different from 90. What Is Chamfer Features.

From www.researchgate.net

Cutting edge chamfer. Chamfer width w, and chamfer angle γ Download What Is Chamfer Features Depending on component size, this may seem like a simple adjustment, but its implications are profound. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Chamfered edges, also known as beveled edges, offer several advantages across different applications. Where precision is a must. Mechanical engineers. What Is Chamfer Features.

From eziil.com

Chamfering 101 Types, Dimensions & Callout What Is Chamfer Features Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. Depending on component size, this may seem like a simple adjustment, but its implications are profound. A chamfer is an angle on the edge of a workpiece. Especially in industries like aerospace, automotive, etc; Where. What Is Chamfer Features.

From solidworkstutorialsforbeginners.com

How to Use SolidWorks Chamfer Tool Features in SolidWorks CAD What Is Chamfer Features Especially in industries like aerospace, automotive, etc; Mechanical engineers are involved in chamfering in several ways. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Chamfered edges, also known as beveled edges, offer several advantages across different applications. Depending on component size, this may seem. What Is Chamfer Features.

From hxeloxuoy.blob.core.windows.net

What Is A Chamfer In Engineering at Karen Kirkland blog What Is Chamfer Features Mechanical engineers are involved in chamfering in several ways. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. A chamfer is an angle on the edge of a workpiece. Chamfered edges, also known as beveled edges, offer several advantages across different applications. Depending on. What Is Chamfer Features.

From www.woodsmith.com

The Versatile Chamfer Woodsmith What Is Chamfer Features The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Depending on component size, this may seem like a simple adjustment, but its implications are profound. A chamfer is an angle on the edge of a workpiece. Chamfers are a design feature where two surfaces meet. What Is Chamfer Features.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is Chamfer Features Mechanical engineers are involved in chamfering in several ways. A chamfer is an angle on the edge of a workpiece. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. Where precision is a must. Especially in industries like aerospace, automotive, etc; The purpose of. What Is Chamfer Features.

From www.youtube.com

Mastercam Tip Chamfer any angle with a 45° Chamfering Tool YouTube What Is Chamfer Features Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Especially in industries like aerospace, automotive, etc; Depending on component size, this may seem like a simple adjustment, but its implications are profound. Chamfers are a design feature where two surfaces meet at an angle different from. What Is Chamfer Features.

From www.youtube.com

Solidworks chamfer YouTube What Is Chamfer Features Mechanical engineers are involved in chamfering in several ways. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. A chamfer is an angle on the edge of a workpiece. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface. What Is Chamfer Features.

From www.oreilly.com

Applying chamfers Learn SOLIDWORKS 2020 [Book] What Is Chamfer Features Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Where precision is a must. Mechanical engineers are involved in chamfering in several ways. Chamfered edges, also known as beveled edges,. What Is Chamfer Features.

From waykenrm.com

Fillet vs Chamfer A Complete Guide for Applications WayKen What Is Chamfer Features Where precision is a must. Chamfered edges, also known as beveled edges, offer several advantages across different applications. Mechanical engineers are involved in chamfering in several ways. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. Chamfering is a precision metal fabrication process that. What Is Chamfer Features.

From cadcamlessons.com

Chamfer SolidWorks Tutorial for Beginners What Is Chamfer Features Depending on component size, this may seem like a simple adjustment, but its implications are profound. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. Where precision is a must. Chamfering is a precision metal fabrication process that involves creating an angled or beveled. What Is Chamfer Features.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is Chamfer Features The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Chamfered edges, also known as beveled edges, offer several advantages across different applications. Mechanical engineers are involved in chamfering in. What Is Chamfer Features.

From www.pmpa.org

Designer’s Guide ThreadsThread Relief and Chamfers Precision What Is Chamfer Features Depending on component size, this may seem like a simple adjustment, but its implications are profound. Where precision is a must. Mechanical engineers are involved in chamfering in several ways. A chamfer is an angle on the edge of a workpiece. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or. What Is Chamfer Features.

From www.youtube.com

Chapter 7 Simple and Advance Chamfer and type of Chamfer in Solidworks What Is Chamfer Features The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Where precision is a must. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface. What Is Chamfer Features.

From www.precastconcretemagnet.com

The Complete Guide to Chamfering Concrete Edges Knowledge What Is Chamfer Features Where precision is a must. Especially in industries like aerospace, automotive, etc; A chamfer is an angle on the edge of a workpiece. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Depending on component size, this may seem like a simple adjustment, but its. What Is Chamfer Features.

From www.cati.com

What's New with CHAMFERS in SOLIDWORKS 2017 Computer Aided Technology What Is Chamfer Features The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Where precision is a must. A chamfer is an angle on the edge. What Is Chamfer Features.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria What Is Chamfer Features A chamfer is an angle on the edge of a workpiece. Where precision is a must. Mechanical engineers are involved in chamfering in several ways. Chamfered edges, also known as beveled edges, offer several advantages across different applications. Especially in industries like aerospace, automotive, etc; The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece,. What Is Chamfer Features.

From pressbooks.pub

Feature Based Features Introduction to SolidWorks Part 1 What Is Chamfer Features Mechanical engineers are involved in chamfering in several ways. Especially in industries like aerospace, automotive, etc; Where precision is a must. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of. What Is Chamfer Features.

From www.woodsmith.com

The Versatile Chamfer Woodsmith What Is Chamfer Features The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Chamfered edges, also known as beveled edges, offer several advantages across different applications.. What Is Chamfer Features.

From leadrp.net

Fillet Vs Chamfer What's The Difference? LEADRP Rapid Prototyping What Is Chamfer Features Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. Where precision is a must. The purpose of chamfering is to remove. What Is Chamfer Features.

From www.slideserve.com

PPT Dimensioning Standards PowerPoint Presentation, free download What Is Chamfer Features Depending on component size, this may seem like a simple adjustment, but its implications are profound. Where precision is a must. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Especially in industries like aerospace, automotive, etc; Chamfered edges, also known as beveled edges, offer several. What Is Chamfer Features.

From support.ptc.com

About Trimming Chamfer Geometry What Is Chamfer Features Especially in industries like aerospace, automotive, etc; The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Chamfered edges, also known as beveled. What Is Chamfer Features.

From www.youtube.com

How to use Solidworks Chamfer Feature SolidWorks Beginner's Tutorial What Is Chamfer Features Especially in industries like aerospace, automotive, etc; Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Depending on component size,. What Is Chamfer Features.

From www.practicalmachinist.com

Understanding Chamfer and Chamfer Mills Practical Machinist What Is Chamfer Features A chamfer is an angle on the edge of a workpiece. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Especially in industries like aerospace, automotive, etc; Mechanical engineers are involved in chamfering in several ways. Where precision is a must. Depending on component size, this. What Is Chamfer Features.

From www.researchgate.net

Details of the chamfer. Download Scientific Diagram What Is Chamfer Features Chamfered edges, also known as beveled edges, offer several advantages across different applications. Mechanical engineers are involved in chamfering in several ways. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Depending on component size, this may seem like a simple adjustment, but its implications are. What Is Chamfer Features.

From fiverrme.com

What is the difference between a bevel and chamfer? What Is Chamfer Features A chamfer is an angle on the edge of a workpiece. Chamfered edges, also known as beveled edges, offer several advantages across different applications. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. The purpose of chamfering is to remove sharp edges, improve the appearance of. What Is Chamfer Features.

From www.youtube.com

Chamfer AutoDesk Inventor Edge Part Feature YouTube What Is Chamfer Features Chamfered edges, also known as beveled edges, offer several advantages across different applications. Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Mechanical engineers are involved in chamfering in several ways. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece,. What Is Chamfer Features.

From www.smlease.com

Fillet vs Chamfer What is the difference Between a Fillet and Chamfer What Is Chamfer Features Chamfering is a precision metal fabrication process that involves creating an angled or beveled surface on the edge or corner of a workpiece. Especially in industries like aerospace, automotive, etc; Chamfered edges, also known as beveled edges, offer several advantages across different applications. A chamfer is an angle on the edge of a workpiece. Chamfers are a design feature where. What Is Chamfer Features.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics What Is Chamfer Features Chamfers are a design feature where two surfaces meet at an angle different from 90 degrees, resulting in a beveled edge instead of a sharp. Especially in industries like aerospace, automotive, etc; Mechanical engineers are involved in chamfering in several ways. Depending on component size, this may seem like a simple adjustment, but its implications are profound. A chamfer is. What Is Chamfer Features.

From www.rapiddirect.com

Fillet vs Chamfers What a Fillet is and How It Differs from Chamfers What Is Chamfer Features Depending on component size, this may seem like a simple adjustment, but its implications are profound. Mechanical engineers are involved in chamfering in several ways. A chamfer is an angle on the edge of a workpiece. Chamfered edges, also known as beveled edges, offer several advantages across different applications. The purpose of chamfering is to remove sharp edges, improve the. What Is Chamfer Features.