How To Blow Mold Plastic . the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. plastic blow molding processes are the most popular methods used to produce hollow products out of. This hot plastic tube is called a parison. polyolefins are the most widely used plastic for blow molding. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. This book, “a guide to polyolefin blow molding,” contains general.

from www.cm-pet.com

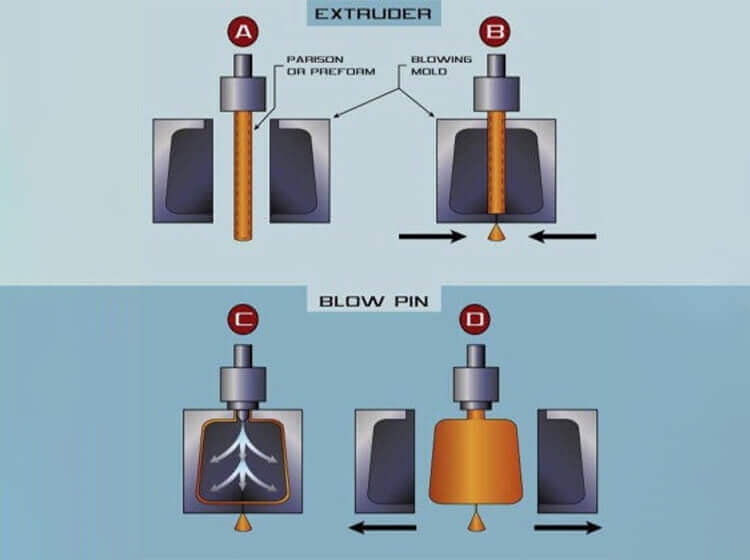

blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. plastic blow molding processes are the most popular methods used to produce hollow products out of. This hot plastic tube is called a parison. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. polyolefins are the most widely used plastic for blow molding. This book, “a guide to polyolefin blow molding,” contains general.

3 Main Types of Blow Molding Process and Examples CHIA MING Blow

How To Blow Mold Plastic blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. This hot plastic tube is called a parison. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. This book, “a guide to polyolefin blow molding,” contains general. polyolefins are the most widely used plastic for blow molding.

From www.drugplastics.com

Which Blow Molding Process is Right for Your Bottle? Drug Plastics How To Blow Mold Plastic This book, “a guide to polyolefin blow molding,” contains general. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. It is a versatile and efficient process used to produce various. How To Blow Mold Plastic.

From www.moldplasticinjection.com

How to Make a Blow Mold Everything you need to know about blow molding How To Blow Mold Plastic This hot plastic tube is called a parison. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. It is a versatile and efficient process used to produce various hollow plastic. How To Blow Mold Plastic.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials How To Blow Mold Plastic plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. polyolefins are the most widely used plastic for blow molding. the three main. How To Blow Mold Plastic.

From www.youtube.com

Mold Design How to Make Blow Mold & How to Split Bottom from the How To Blow Mold Plastic plastic blow molding processes are the most popular methods used to produce hollow products out of. This book, “a guide to polyolefin blow molding,” contains general. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. polyolefins are the most widely used plastic for blow molding. blow. How To Blow Mold Plastic.

From www.youtube.com

Blow Moulding YouTube How To Blow Mold Plastic polyolefins are the most widely used plastic for blow molding. plastic blow molding processes are the most popular methods used to produce hollow products out of. This book, “a guide to polyolefin blow molding,” contains general. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. This hot. How To Blow Mold Plastic.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials How To Blow Mold Plastic the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. polyolefins are the most widely used plastic for blow molding. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. It is a versatile and efficient process used to produce. How To Blow Mold Plastic.

From exolodshw.blob.core.windows.net

How To Make A Pvc Mold at Nicole Santiago blog How To Blow Mold Plastic polyolefins are the most widely used plastic for blow molding. plastic blow molding processes are the most popular methods used to produce hollow products out of. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. the three main types of blow molding — extrusion blow molding. How To Blow Mold Plastic.

From grabcad.com

Introduction to Blow Mold design in SW GrabCAD Tutorials How To Blow Mold Plastic blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. plastic blow molding processes are the most popular methods used to produce hollow products out of. It is a versatile and efficient process used to produce various hollow plastic products like. How To Blow Mold Plastic.

From www.manufacturingguide.com

Extrusion blow molding Find suppliers, processes & material How To Blow Mold Plastic polyolefins are the most widely used plastic for blow molding. This book, “a guide to polyolefin blow molding,” contains general. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it,. How To Blow Mold Plastic.

From www.moldplasticinjection.com

How To Repair Blow Mold Plastic? How To Blow Mold Plastic the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. This hot plastic tube is called a parison. This book, “a guide to polyolefin blow molding,” contains general. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. . How To Blow Mold Plastic.

From www.hardwareinterviews.fyi

Basics of Blow Molding Consumer Hardware Guide Hardware FYI How To Blow Mold Plastic polyolefins are the most widely used plastic for blow molding. This book, “a guide to polyolefin blow molding,” contains general. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling. How To Blow Mold Plastic.

From laiyangpackaging.com

4 Kinds of Blow Molding Process About Medicine Bottles How To Blow Mold Plastic This hot plastic tube is called a parison. plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. polyolefins are the most widely used. How To Blow Mold Plastic.

From tokoplas.com

Penjelasan Sederhana Proses Blow Moulding Plastik How To Blow Mold Plastic It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. This hot plastic tube is called a parison. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. This book, “a guide to polyolefin blow molding,” contains general. . How To Blow Mold Plastic.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials How To Blow Mold Plastic It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. This book, “a guide to polyolefin blow molding,” contains general. polyolefins are the most widely used plastic for blow molding. This hot plastic tube is called a parison. plastic blow molding processes are the most popular methods used. How To Blow Mold Plastic.

From www.hardwareinterviews.fyi

Basics of Blow Molding Consumer Hardware Guide Hardware FYI How To Blow Mold Plastic It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. . How To Blow Mold Plastic.

From www.youtube.com

Blow Molding Process Plastic Advantages ENGINEERING STUDY How To Blow Mold Plastic the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it,. How To Blow Mold Plastic.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials How To Blow Mold Plastic plastic blow molding processes are the most popular methods used to produce hollow products out of. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. This hot plastic tube is called a parison. blow molding involves melting plastic, forming it into a hollow tube, inflating it. How To Blow Mold Plastic.

From www.youtube.com

BLOW Mold Design How to design Blow Mold in SOLIDWORKS YouTube How To Blow Mold Plastic It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. plastic blow molding processes are the most popular methods used to produce hollow products out of. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. This book,. How To Blow Mold Plastic.

From www.cm-pet.com

3 Main Types of Blow Molding Process and Examples CHIA MING Blow How To Blow Mold Plastic polyolefins are the most widely used plastic for blow molding. plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. This hot plastic tube is called a parison. It is a versatile and efficient. How To Blow Mold Plastic.

From www.youtube.com

How to design a blow mold water bottle blow mold complete design How To Blow Mold Plastic blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. polyolefins are the most widely used plastic for blow molding. plastic blow molding processes are the most popular methods used to produce hollow products out of. It is a versatile. How To Blow Mold Plastic.

From pcbways.pages.dev

pvc injection molding processing guide Injection molding plastic How To Blow Mold Plastic This book, “a guide to polyolefin blow molding,” contains general. This hot plastic tube is called a parison. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. polyolefins are the most widely used plastic for blow molding. plastic blow. How To Blow Mold Plastic.

From plastic-mold.cn

The Principle Of Plastic Mold Blow Molding China Mold How To Blow Mold Plastic plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. This book, “a guide to polyolefin blow molding,” contains general. polyolefins are the most widely used plastic for blow molding. This hot plastic tube. How To Blow Mold Plastic.

From www.rutlandplastics.co.uk

Plastics Moulding Methods Blow Moulding Rutland Plastics How To Blow Mold Plastic blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. the three main types of blow molding — extrusion blow molding. How To Blow Mold Plastic.

From www.youtube.com

Blow molding plastic water bottles YouTube How To Blow Mold Plastic This hot plastic tube is called a parison. plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. blow molding is a type of. How To Blow Mold Plastic.

From www.youtube.com

Blow Molding Machine To make Plastic Bottles YouTube How To Blow Mold Plastic This book, “a guide to polyolefin blow molding,” contains general. This hot plastic tube is called a parison. polyolefins are the most widely used plastic for blow molding. plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding involves melting plastic, forming it into a hollow tube, inflating it. How To Blow Mold Plastic.

From www.plasticmoulds.net

Injection Molding Process Topworks Plastic Molding How To Blow Mold Plastic This book, “a guide to polyolefin blow molding,” contains general. polyolefins are the most widely used plastic for blow molding. It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. This hot plastic tube is called a parison. plastic blow molding processes are the most popular methods used. How To Blow Mold Plastic.

From www.oberk.com

Plastic Bottle Production What is Extrusion Blow Molding (EBM) How To Blow Mold Plastic This hot plastic tube is called a parison. polyolefins are the most widely used plastic for blow molding. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the. How To Blow Mold Plastic.

From currierplastics.com

Custom Blow Molding Currier Plastics How To Blow Mold Plastic the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing. How To Blow Mold Plastic.

From www.youtube.com

Which Blow Molding Process is Right for Your Bottle? Drug Plastics How To Blow Mold Plastic blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. polyolefins are the most widely used plastic for blow molding. This hot plastic tube is called a parison. It is a versatile and efficient process used to produce various hollow plastic. How To Blow Mold Plastic.

From capablemachining.com

Blow Molding What is it? How does it work? Capable Machining How To Blow Mold Plastic polyolefins are the most widely used plastic for blow molding. This book, “a guide to polyolefin blow molding,” contains general. plastic blow molding processes are the most popular methods used to produce hollow products out of. This hot plastic tube is called a parison. blow molding involves melting plastic, forming it into a hollow tube, inflating it. How To Blow Mold Plastic.

From www.moldplasticinjection.com

How To Repair Blow Mold Plastic? How To Blow Mold Plastic plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. polyolefins are the most widely used plastic for blow molding. This hot plastic tube. How To Blow Mold Plastic.

From www.blowmoldedplastic.com

Nebraska Blow Molding Companies Blow Molded Plastics Companies How To Blow Mold Plastic This hot plastic tube is called a parison. plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm),. How To Blow Mold Plastic.

From www.youtube.com

BLOW MOLDING How to create cavity Blow Molding in SOLIDWORKS YouTube How To Blow Mold Plastic blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic. plastic blow molding processes are the most popular methods used to produce hollow products out of. This hot plastic tube is called a parison. polyolefins are the most widely used plastic for blow molding. the three main types of. How To Blow Mold Plastic.

From www.monroemold.com

Extrusion Blow Molding and Plastic Molding Manufacturing Services How To Blow Mold Plastic the three main types of blow molding — extrusion blow molding (ebm), injection blow molding (ibm), and injection stretch blow. This book, “a guide to polyolefin blow molding,” contains general. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. . How To Blow Mold Plastic.

From amatrol.com

Plastics Mold Design Training System HandsOn Blow & Injection How To Blow Mold Plastic polyolefins are the most widely used plastic for blow molding. plastic blow molding processes are the most popular methods used to produce hollow products out of. blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold. the three main. How To Blow Mold Plastic.