What Should The Gas Setting Be On A Mig Welder . The more heat needed, the higher the gas pressure you’ll use for welding. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). Many factors affect the gas pressure setting in mig welding processes; Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. However, the exact pressure setting can vary depending on. The ideal gas pressure range for mig welding should be three to eight psi; Weld penetration and bead appearance. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. How to set gas pressure on a mig welder; Some wire and gas combinations commonly seen with mig welding are: Setting the gas on your. Different gasses used in mig welding;

from weldguru.com

Different gasses used in mig welding; However, the exact pressure setting can vary depending on. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. Setting the gas on your. Some wire and gas combinations commonly seen with mig welding are: The ideal gas pressure range for mig welding should be three to eight psi; This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. How to set gas pressure on a mig welder;

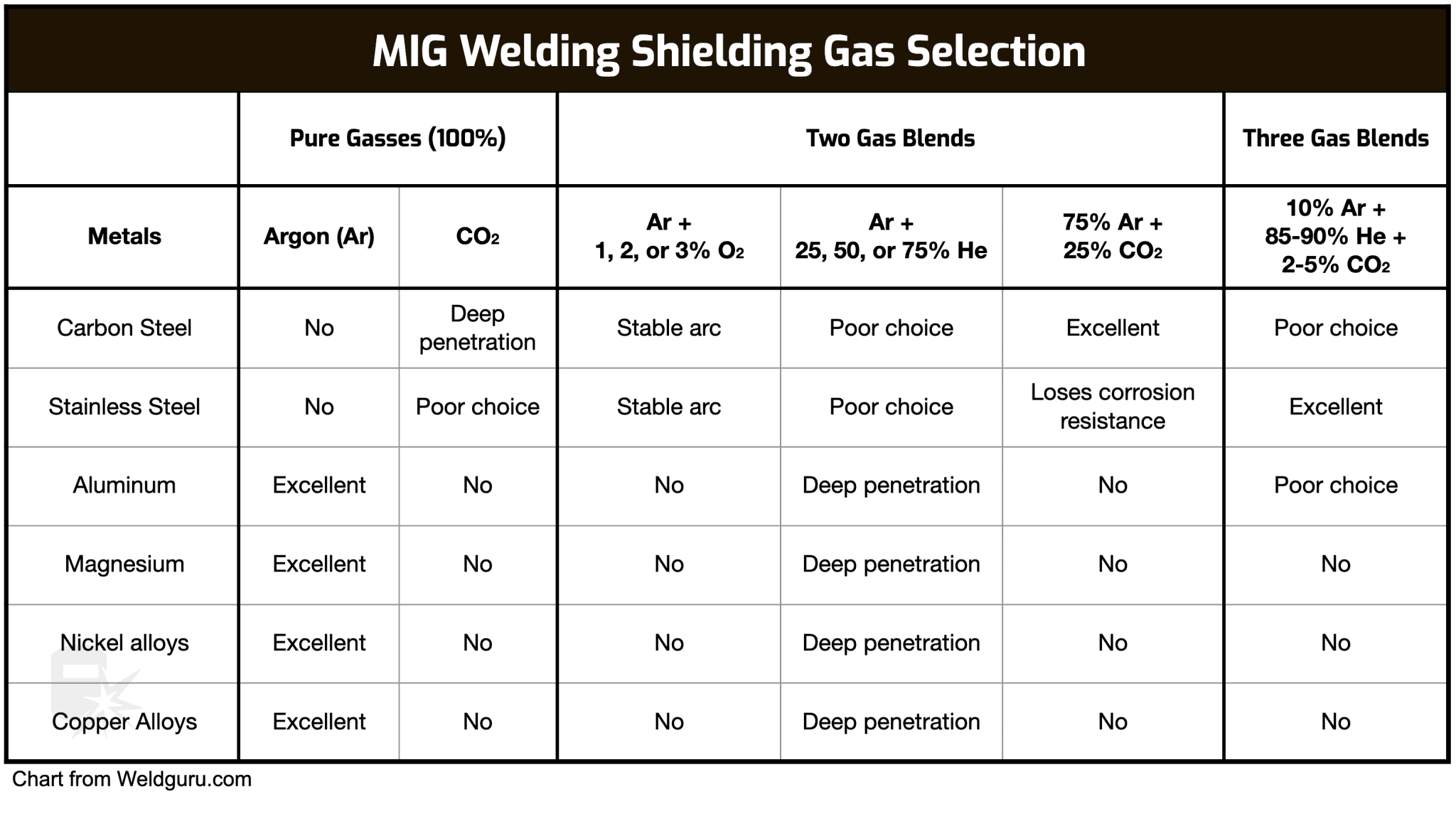

Best Gas for MIG Welding What to Use (with Chart)

What Should The Gas Setting Be On A Mig Welder Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. How to set gas pressure on a mig welder; Setting the gas on your. Weld penetration and bead appearance. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). The ideal gas pressure range for mig welding should be three to eight psi; This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. The more heat needed, the higher the gas pressure you’ll use for welding. Some wire and gas combinations commonly seen with mig welding are: Different gasses used in mig welding; However, the exact pressure setting can vary depending on. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Many factors affect the gas pressure setting in mig welding processes;

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER What Should The Gas Setting Be On A Mig Welder Different gasses used in mig welding; This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). Some wire and gas combinations commonly seen with mig welding are: This, in. What Should The Gas Setting Be On A Mig Welder.

From www.youtube.com

Perfect Mig Welder Settings in 3 Easy Steps YouTube What Should The Gas Setting Be On A Mig Welder Setting the gas on your. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). The ideal gas pressure range for mig welding should be three to eight psi; Weld penetration and bead appearance. However, the exact pressure setting can vary depending on. This article will detail how to set the gas. What Should The Gas Setting Be On A Mig Welder.

From waterwelders.com

What Should My MIG Welding Gas Pressure Be? WaterWelders What Should The Gas Setting Be On A Mig Welder Many factors affect the gas pressure setting in mig welding processes; The more heat needed, the higher the gas pressure you’ll use for welding. How to set gas pressure on a mig welder; However, the exact pressure setting can vary depending on. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh).. What Should The Gas Setting Be On A Mig Welder.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Setting Be On A Mig Welder The ideal gas pressure range for mig welding should be three to eight psi; How to set gas pressure on a mig welder; Weld penetration and bead appearance. Many factors affect the gas pressure setting in mig welding processes; Setting the gas on your. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen,. What Should The Gas Setting Be On A Mig Welder.

From migweldingexpert.com

How to Set Gas the Flow on a MIG Welder? Mig Welding Expert What Should The Gas Setting Be On A Mig Welder Many factors affect the gas pressure setting in mig welding processes; Weld penetration and bead appearance. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). The more heat needed, the. What Should The Gas Setting Be On A Mig Welder.

From www.youtube.com

Mig Welding Gas Setup Made Simple YouTube What Should The Gas Setting Be On A Mig Welder Setting the gas on your. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. Some wire and gas combinations commonly seen with mig welding are: However, the exact pressure setting can vary depending on. This article will detail how to set the gas on a mig welding set, and what. What Should The Gas Setting Be On A Mig Welder.

From gowelding.org

How To Set Up a MIG Welder Welder Settings, Gasses and Electrodes What Should The Gas Setting Be On A Mig Welder Some wire and gas combinations commonly seen with mig welding are: However, the exact pressure setting can vary depending on. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Setting the gas on your. Weld penetration and bead appearance. The most common mig welding gas pressure. What Should The Gas Setting Be On A Mig Welder.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru What Should The Gas Setting Be On A Mig Welder Different gasses used in mig welding; The ideal gas pressure range for mig welding should be three to eight psi; This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. However, the exact pressure setting can vary depending on. This article will detail how to set the gas on a mig. What Should The Gas Setting Be On A Mig Welder.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs What Should The Gas Setting Be On A Mig Welder Weld penetration and bead appearance. However, the exact pressure setting can vary depending on. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). Setting the gas on your. Some wire and gas. What Should The Gas Setting Be On A Mig Welder.

From makemoneywelding.com

Important MIG Welder Settings You Need to Know (with Chart) What Should The Gas Setting Be On A Mig Welder Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. Many factors affect the gas pressure setting in mig welding processes; This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Setting the gas on your.. What Should The Gas Setting Be On A Mig Welder.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs What Should The Gas Setting Be On A Mig Welder However, the exact pressure setting can vary depending on. How to set gas pressure on a mig welder; Some wire and gas combinations commonly seen with mig welding are: Many factors affect the gas pressure setting in mig welding processes; This article will detail how to set the gas on a mig welding set, and what are the different types. What Should The Gas Setting Be On A Mig Welder.

From bradleyabbott.z13.web.core.windows.net

Mig Weld Settings Chart What Should The Gas Setting Be On A Mig Welder Different gasses used in mig welding; However, the exact pressure setting can vary depending on. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. The more heat needed, the higher the gas pressure you’ll use for welding. This article will detail how to set the gas on a mig welding. What Should The Gas Setting Be On A Mig Welder.

From weldingpros.net

MIG welder settings explained Amperage & Wire Speed What Should The Gas Setting Be On A Mig Welder The more heat needed, the higher the gas pressure you’ll use for welding. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. Different gasses used. What Should The Gas Setting Be On A Mig Welder.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) What Should The Gas Setting Be On A Mig Welder The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). Some wire and gas combinations commonly seen with mig welding are: However, the exact pressure setting can vary depending on. Setting the gas on your. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and. What Should The Gas Setting Be On A Mig Welder.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs What Should The Gas Setting Be On A Mig Welder However, the exact pressure setting can vary depending on. This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. This article will show you. What Should The Gas Setting Be On A Mig Welder.

From beststudwelders.com

MIG Welding Gas Pressure Settings Complete Guide best stud welders What Should The Gas Setting Be On A Mig Welder This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). How to set gas pressure on a mig welder; Many factors affect the gas pressure setting in. What Should The Gas Setting Be On A Mig Welder.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) What Should The Gas Setting Be On A Mig Welder Setting the gas on your. Weld penetration and bead appearance. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. The more heat needed, the higher the gas pressure you’ll use for welding. Many factors affect the gas pressure setting in mig welding processes; This article will detail how to set. What Should The Gas Setting Be On A Mig Welder.

From gowelding.org

How To Set Up a MIG Welder Welder Settings, Gasses and Electrodes What Should The Gas Setting Be On A Mig Welder Weld penetration and bead appearance. Different gasses used in mig welding; The more heat needed, the higher the gas pressure you’ll use for welding. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). This article will detail how to set the gas on a mig welding set, and what are the. What Should The Gas Setting Be On A Mig Welder.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire What Should The Gas Setting Be On A Mig Welder The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). Weld penetration and bead appearance. However, the exact pressure setting can vary depending on. Setting the gas on your. This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases. What Should The Gas Setting Be On A Mig Welder.

From lessonzoneoster.z19.web.core.windows.net

Mig Welding Chart Settings And Guides What Should The Gas Setting Be On A Mig Welder This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. Some wire and gas combinations commonly seen with mig welding are: Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. How to set gas pressure on a mig welder;. What Should The Gas Setting Be On A Mig Welder.

From www.youtube.com

VIPER 185 Gasshielded and Gasless MIG Welding Setup Guide YouTube What Should The Gas Setting Be On A Mig Welder Many factors affect the gas pressure setting in mig welding processes; This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Some wire and gas combinations commonly seen with mig welding are: How to set gas pressure on a mig welder; Weld penetration and bead appearance. Different. What Should The Gas Setting Be On A Mig Welder.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Setting Be On A Mig Welder The ideal gas pressure range for mig welding should be three to eight psi; This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. However, the exact pressure setting can vary depending on. The most common mig welding gas pressure settings range from 20 to. What Should The Gas Setting Be On A Mig Welder.

From www.youtube.com

MIG Welder Safety 4 of 7 Turning on the shielding gas YouTube What Should The Gas Setting Be On A Mig Welder The more heat needed, the higher the gas pressure you’ll use for welding. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). The ideal gas pressure range for mig welding should be three to eight psi; However, the exact pressure setting can vary depending on. This, in turn, reduces the occurrence. What Should The Gas Setting Be On A Mig Welder.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Setting Be On A Mig Welder This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. Weld penetration and bead appearance. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. However, the exact pressure setting can vary depending on. Many factors. What Should The Gas Setting Be On A Mig Welder.

From www.youtube.com

setting up MIG welder and info for beginners LINCOLN 180 PRO MIG for What Should The Gas Setting Be On A Mig Welder Some wire and gas combinations commonly seen with mig welding are: Weld penetration and bead appearance. This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds.. What Should The Gas Setting Be On A Mig Welder.

From weldingmastermind.com

MIG Gas Settings How to Set Gas on MIG Welder Welding Mastermind What Should The Gas Setting Be On A Mig Welder Many factors affect the gas pressure setting in mig welding processes; Setting the gas on your. Some wire and gas combinations commonly seen with mig welding are: This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Adequate gas pressure creates a protective barrier that prevents atmospheric. What Should The Gas Setting Be On A Mig Welder.

From weldingzilla.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Setting Be On A Mig Welder This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. However, the exact pressure setting can vary depending on. How to set gas pressure on a mig welder; The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). Some. What Should The Gas Setting Be On A Mig Welder.

From gowelding.org

MIG Welding Gases Choices and Options for Most Metals What Should The Gas Setting Be On A Mig Welder Setting the gas on your. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). Weld penetration and bead appearance. Some wire and gas combinations commonly seen with mig. What Should The Gas Setting Be On A Mig Welder.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Setting Be On A Mig Welder This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. The more heat needed, the higher the gas pressure you’ll use for welding. The most common mig welding gas pressure settings range from 20 to 30 cubic feet per hour (cfh). Different gasses used in mig welding;. What Should The Gas Setting Be On A Mig Welder.

From informacionpublica.svet.gob.gt

MIG Gas Settings How To Set Gas On MIG Welder Welding What Should The Gas Setting Be On A Mig Welder The more heat needed, the higher the gas pressure you’ll use for welding. Weld penetration and bead appearance. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. The ideal gas pressure range for mig welding should be three to eight psi; This, in turn, reduces the occurrence of. What Should The Gas Setting Be On A Mig Welder.

From brandonkss.github.io

Mig Welding Settings Chart What Should The Gas Setting Be On A Mig Welder The more heat needed, the higher the gas pressure you’ll use for welding. Many factors affect the gas pressure setting in mig welding processes; This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. However, the exact pressure setting can vary depending on. This article will detail how to set the. What Should The Gas Setting Be On A Mig Welder.

From informacionpublica.svet.gob.gt

MIG Gas Settings How To Set Gas On MIG Welder Welding What Should The Gas Setting Be On A Mig Welder Many factors affect the gas pressure setting in mig welding processes; The more heat needed, the higher the gas pressure you’ll use for welding. This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination,. What Should The Gas Setting Be On A Mig Welder.

From www.youtube.com

Gas Flow Settings for MIG & TIG Welding YouTube What Should The Gas Setting Be On A Mig Welder Different gasses used in mig welding; This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. How to set gas pressure on a mig welder; Some. What Should The Gas Setting Be On A Mig Welder.

From weldingpros.net

MIG welder settings explained Amperage & Wire Speed What Should The Gas Setting Be On A Mig Welder This article will detail how to set the gas on a mig welding set, and what are the different types of shield gases to use. The more heat needed, the higher the gas pressure you’ll use for welding. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. Setting. What Should The Gas Setting Be On A Mig Welder.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Your Ultimate What Should The Gas Setting Be On A Mig Welder The more heat needed, the higher the gas pressure you’ll use for welding. This, in turn, reduces the occurrence of porosity (tiny holes) and minimizes spatter, resulting in cleaner and stronger welds. Adequate gas pressure creates a protective barrier that prevents atmospheric contamination, such as oxygen and nitrogen, from entering the weld pool. Weld penetration and bead appearance. The most. What Should The Gas Setting Be On A Mig Welder.