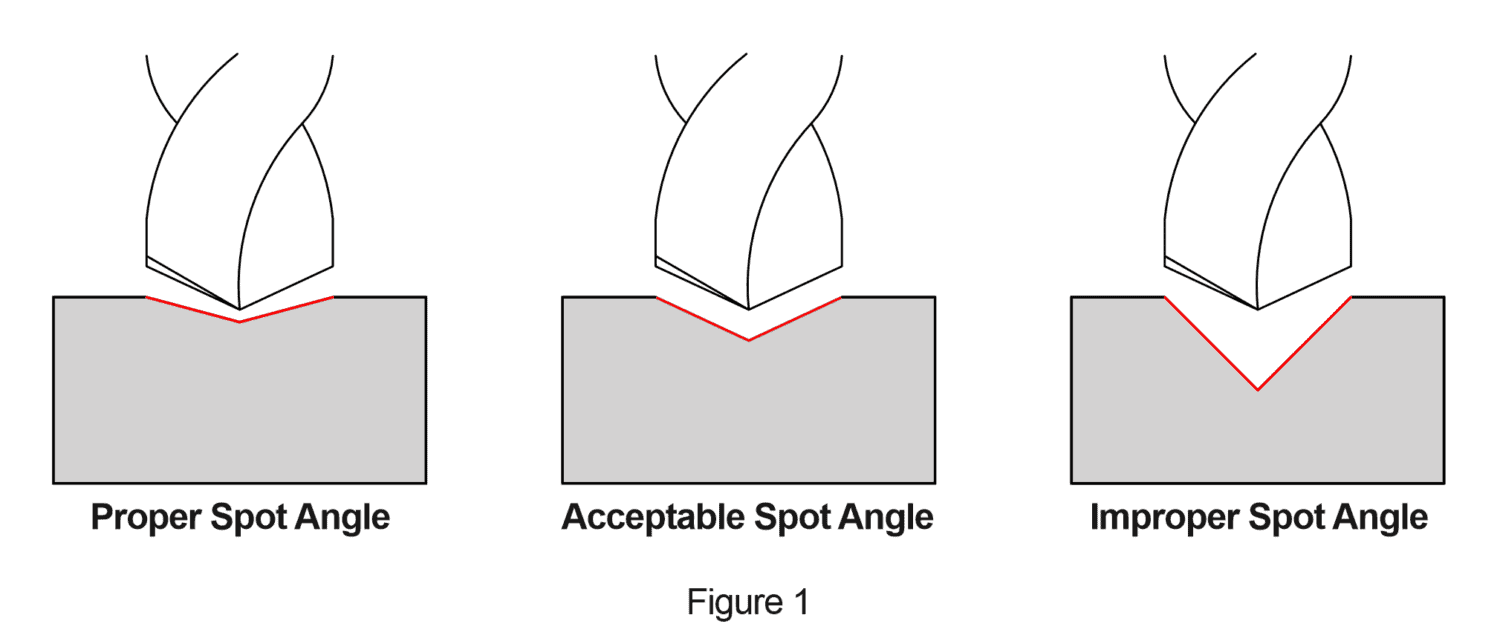

Spot Drill Feed And Speed . The selection of a suitable spot drill is critical for precision drilling success. how to use this calculator: Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. The ideal scenario involves the carbide drill’s tip making the first contact with the material — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. — selecting the perfect spot drill for superior outcomes: carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill.

from www.harveyperformance.com

Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. how to use this calculator: — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. The selection of a suitable spot drill is critical for precision drilling success. The ideal scenario involves the carbide drill’s tip making the first contact with the material feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. — selecting the perfect spot drill for superior outcomes: carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point.

Spot Drilling The First Step to Precision Drilling In The Loupe

Spot Drill Feed And Speed Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. — selecting the perfect spot drill for superior outcomes: The selection of a suitable spot drill is critical for precision drilling success. — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. The ideal scenario involves the carbide drill’s tip making the first contact with the material Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. how to use this calculator:

From www.youtube.com

Selecting Correct Speeds and Feeds for Drilling YouTube Spot Drill Feed And Speed — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. The ideal scenario. Spot Drill Feed And Speed.

From exooeycjx.blob.core.windows.net

Speeds And Feeds For Spot Drills at Elliott Carlson blog Spot Drill Feed And Speed — selecting the perfect spot drill for superior outcomes: Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008,. Spot Drill Feed And Speed.

From www.scribd.com

Carbide End Mill Feeds and Speeds TuffCut XR 177 Metric Cast Iron Steel Spot Drill Feed And Speed how to use this calculator: — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. — selecting the perfect spot drill for superior outcomes: carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the. Spot Drill Feed And Speed.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Spot Drill Feed And Speed — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. how to use this calculator: carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater. Spot Drill Feed And Speed.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter Spot Drill Feed And Speed feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and. Spot Drill Feed And Speed.

From museumhead.com

Milling Tools for use with Speed Tiger NC Spot Drill Tool SPEED TIGER Spot Drill Feed And Speed 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. —. Spot Drill Feed And Speed.

From mungfali.com

Drill Feed Speed Chart Spot Drill Feed And Speed — selecting the perfect spot drill for superior outcomes: 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. The ideal scenario involves the carbide drill’s tip making. Spot Drill Feed And Speed.

From www.formsbank.com

Top 5 Drill Speed Charts free to download in PDF format Spot Drill Feed And Speed how to use this calculator: feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. — selecting the. Spot Drill Feed And Speed.

From exooeycjx.blob.core.windows.net

Speeds And Feeds For Spot Drills at Elliott Carlson blog Spot Drill Feed And Speed Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. The selection of a suitable spot drill is critical for precision drilling success. how to use this calculator: — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. carbide drill selecting the correct spotting drill. Spot Drill Feed And Speed.

From www.cnccookbook.com

Carbide Drill Speeds and Feeds [Plus Tips and Techniques] Spot Drill Feed And Speed — selecting the perfect spot drill for superior outcomes: 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. carbide drill selecting the correct spotting drill select. Spot Drill Feed And Speed.

From mungfali.com

Drill Feed Speed Chart Spot Drill Feed And Speed The selection of a suitable spot drill is critical for precision drilling success. carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. . Spot Drill Feed And Speed.

From www.youtube.com

DRILL CUTTING SPEED FEED AND TIME CALCULATION IN TAMIL YouTube Spot Drill Feed And Speed The selection of a suitable spot drill is critical for precision drilling success. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. — proper. Spot Drill Feed And Speed.

From www.engineering.com

Spot Drill Tip Calculator Spot Drill Feed And Speed — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness. Spot Drill Feed And Speed.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Spot Drill Feed And Speed The selection of a suitable spot drill is critical for precision drilling success. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. carbide drill selecting the correct spotting drill select a spotting drill with a. Spot Drill Feed And Speed.

From annularcutterbitsharpening.com

Metal Drill Feeds and Speeds JR Machinery Online Store Spot Drill Feed And Speed feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material. Spot Drill Feed And Speed.

From www.slideserve.com

PPT ME 350 Lecture 4 Chapter 22 PowerPoint Presentation, free Spot Drill Feed And Speed 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. The selection of a suitable spot drill is critical for precision drilling success. — selecting the perfect spot drill for superior outcomes: The ideal scenario involves the. Spot Drill Feed And Speed.

From mungfali.com

Drilling Speed Chart Spot Drill Feed And Speed carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. —. Spot Drill Feed And Speed.

From exooeycjx.blob.core.windows.net

Speeds And Feeds For Spot Drills at Elliott Carlson blog Spot Drill Feed And Speed 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. — selecting the perfect spot drill for superior outcomes: The selection of a suitable spot drill is critical. Spot Drill Feed And Speed.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Spot Drill Feed And Speed The selection of a suitable spot drill is critical for precision drilling success. — selecting the perfect spot drill for superior outcomes: carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. how to use this calculator: Choose a type of operation. Spot Drill Feed And Speed.

From protocutter.com

Drilling and Reaming Speeds and Feed Rates by Material and Hardness Spot Drill Feed And Speed — selecting the perfect spot drill for superior outcomes: how to use this calculator: — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. Choose a. Spot Drill Feed And Speed.

From exooeycjx.blob.core.windows.net

Speeds And Feeds For Spot Drills at Elliott Carlson blog Spot Drill Feed And Speed Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. how. Spot Drill Feed And Speed.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Spot Drill Feed And Speed — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. — selecting the perfect spot drill for superior outcomes: how to use this calculator: The selection of a suitable spot drill is critical for precision drilling success. — proper speed and feed settings can prevent tool. Spot Drill Feed And Speed.

From arturowbryant.github.io

Drill Bit Speed Chart Spot Drill Feed And Speed 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. The selection of a suitable spot drill is critical for precision drilling success. how to. Spot Drill Feed And Speed.

From www.harveyperformance.com

Spot Drilling The First Step to Precision Drilling In The Loupe Spot Drill Feed And Speed — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. how to use this calculator: The ideal scenario involves the carbide drill’s. Spot Drill Feed And Speed.

From exomlutrb.blob.core.windows.net

Morse Carbide Drill Speeds And Feeds at Jose Fierro blog Spot Drill Feed And Speed how to use this calculator: Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. The ideal scenario involves the carbide drill’s tip making the first contact with the material — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. 13 rows — spot &. Spot Drill Feed And Speed.

From www.scribd.com

HSS Drill Speeds and Feeds Cast Iron Steel Spot Drill Feed And Speed feed rate, ipr (inch per revolution) material low carbon steel up to 30 250 1006, 1008, 1018, 1020, 1022, 1025, 1117, 1140, 1215,. — selecting the perfect spot drill for superior outcomes: how to use this calculator: carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or >. Spot Drill Feed And Speed.

From www.slideserve.com

PPT Basic Guide to Speeds & Feeds PowerPoint Presentation, free Spot Drill Feed And Speed 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. — selecting the perfect spot drill for superior outcomes: — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. feed rate, ipr (inch per revolution) material low. Spot Drill Feed And Speed.

From www.slideserve.com

PPT Speeds and Feeds PowerPoint Presentation, free download ID6311492 Spot Drill Feed And Speed — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. how to use this calculator: carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. The selection of a suitable spot drill. Spot Drill Feed And Speed.

From woodworkadvice.com

Drill Press Speed Chart Your 2021 Guide Woodwork Advice Spot Drill Feed And Speed — selecting the perfect spot drill for superior outcomes: how to use this calculator: Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. The ideal scenario involves the carbide. Spot Drill Feed And Speed.

From peacecommission.kdsg.gov.ng

U Drill Speeds And Feeds Chart Spot Drill Feed And Speed — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. The selection of a suitable spot drill is critical for precision drilling success. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group iso hardness sfm ipr. The ideal scenario involves the carbide. Spot Drill Feed And Speed.

From www.slideserve.com

PPT Speeds and Feeds PowerPoint Presentation, free download ID6311492 Spot Drill Feed And Speed — selecting the perfect spot drill for superior outcomes: The ideal scenario involves the carbide drill’s tip making the first contact with the material carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. 13 rows — spot & spade drills recommended. Spot Drill Feed And Speed.

From mungfali.com

Drill Feed Speed Chart Spot Drill Feed And Speed The ideal scenario involves the carbide drill’s tip making the first contact with the material — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final. Spot Drill Feed And Speed.

From quoteimg.com

drill press speed chart Quotes Spot Drill Feed And Speed Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab. The selection of a suitable spot drill is critical for precision drilling success. — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece. Spot Drill Feed And Speed.

From tubingchina.com

Speeds and Feeds for Drilling and Reaming Stainless Steel Spot Drill Feed And Speed carbide drill selecting the correct spotting drill select a spotting drill with a point angle = to or > greater than the final drill point. — as a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill. how to use this calculator: 13 rows — spot & spade. Spot Drill Feed And Speed.

From www.youtube.com

60° 90° 120° ACE Spot Drill High rigidity, high performance cutting Spot Drill Feed And Speed The selection of a suitable spot drill is critical for precision drilling success. — selecting the perfect spot drill for superior outcomes: — proper speed and feed settings can prevent tool breakage, achieve a clean cut, and enhance the overall efficiency of. 13 rows — spot & spade drills recommended cutting parameters drill diameter workpiece material group. Spot Drill Feed And Speed.