Surface Defect . It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. The present review examines the different types of defects associated with surface coatings, their significant causes, and the.

from www.stahleisen.de

Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. The present review examines the different types of defects associated with surface coatings, their significant causes, and the.

Finding qualityrelevant surface defects stahleisen

Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic.

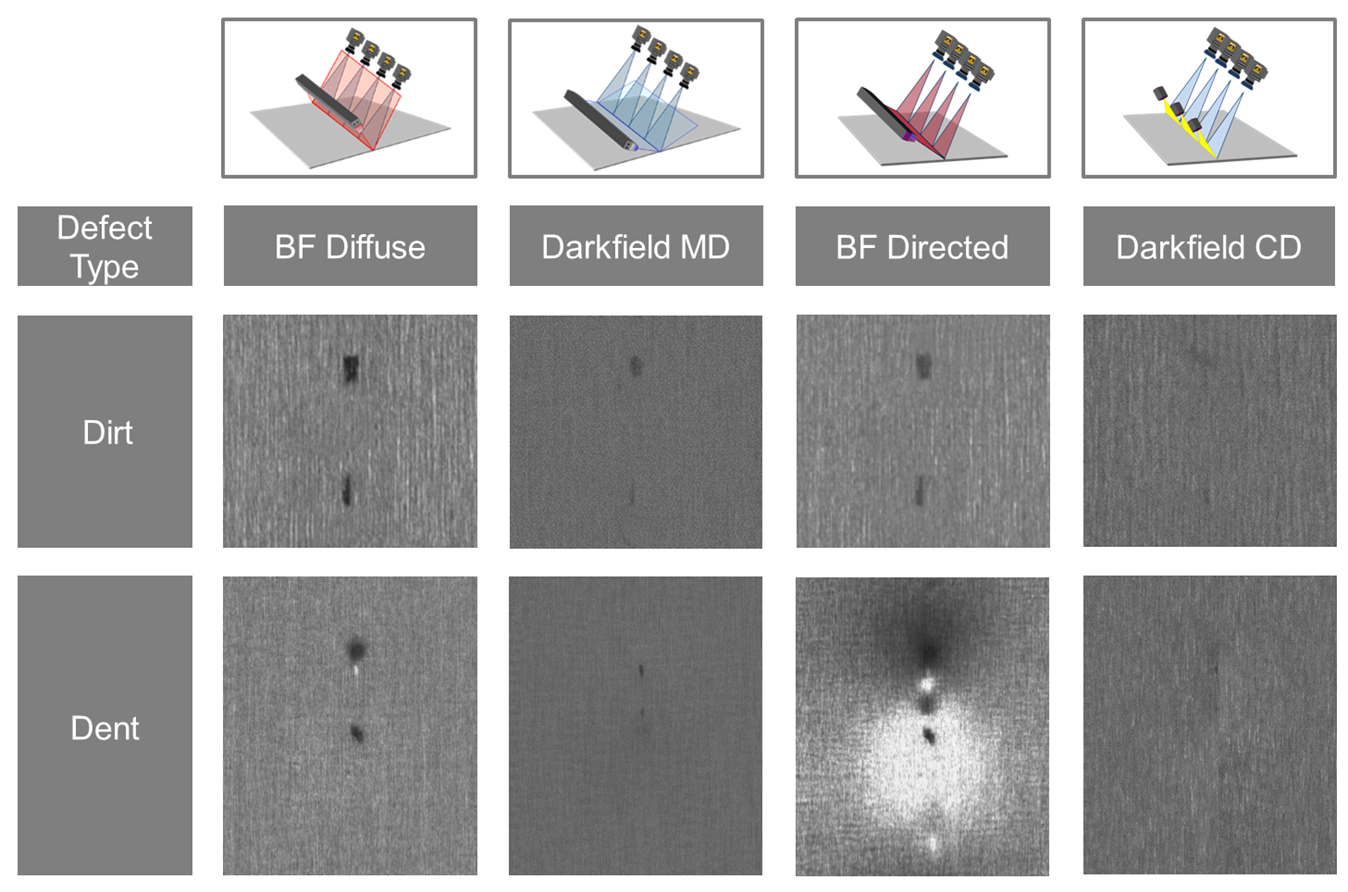

From metrology.news

Deep Learning Delivers Automated Surface Defect Detection Metrology Surface Defect The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour,. Surface Defect.

From www.youtube.com

Surface (Plane) Defects Defects in Solids Grain Boundary Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface quality is one of the most scrutinized specifications in the industry and, while its. Surface Defect.

From www.researchgate.net

15 Images of typical surface defects like scratches, inclusions (a Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a. Surface Defect.

From www.stahleisen.de

Finding qualityrelevant surface defects stahleisen Surface Defect The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour,. Surface Defect.

From www.researchgate.net

Streaks due to extrusion surface defects. (a) Profile of an anodized Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a. Surface Defect.

From www.researchgate.net

Diagram outlining the common surface defects that occurred during Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination,. Surface Defect.

From www.semanticscholar.org

Metal Inspection for Surface defect Detection by Image Thresholding Surface Defect The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect. Surface Defect.

From www.researchgate.net

Schematic Diagram of Surface Defects Formed During Solidification in Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination,. Surface Defect.

From www.vrogue.co

Surface Defect Classification In Silicon Wafer Manufa vrogue.co Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface quality is one of the most scrutinized specifications in the industry and, while its. Surface Defect.

From www.researchgate.net

Surface defects of steel plate. Download Scientific Diagram Surface Defect The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour,. Surface Defect.

From www.constructioncivil.com

Causes, Prevention And Repair Of Concrete Surface Defects Surface Defect Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the. Surface Defect.

From mavink.com

Defect Types Surface Defect Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding,. Surface Defect.

From www.youtube.com

Surface Defects Grain Boundaries and Stacking Fault 2D Surface Defect Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding,. Surface Defect.

From civil4m.com

Types of surface defects occurs in concrete at construction project Surface Defect Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. The present review examines the different. Surface Defect.

From www.researchgate.net

Typical surface defect samples in the NEUDET dataset. Download Surface Defect Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. The present review examines the different. Surface Defect.

From www.researchgate.net

Typical examples of 5 wafer surface defect classes (a) Cluster, (b Surface Defect Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. It addresses a number of defects. Surface Defect.

From www.silcotek.com

Identify and Fix Common Stainless Steel Surface Defects Surface Defect Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect. Surface Defect.

From gitplanet.com

Alternatives and detailed information of Surface Defect Detection Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. The present review examines the different types of defects associated with surface coatings,. Surface Defect.

From www.researchgate.net

Process of surface defect classification methods based on image Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. Surface defect detection refers to the detection of scratches, defects, foreign body shielding,. Surface Defect.

From www.researchgate.net

Surface defects of the parts produced from stainless steel 12X18Н10Т Surface Defect Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. The present review examines the different. Surface Defect.

From mungfali.com

Metal Surface Defects Surface Defect The present review examines the different types of defects associated with surface coatings, their significant causes, and the. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface quality is one of the most scrutinized specifications in the industry and, while its. Surface Defect.

From www.researchgate.net

Threedimensional computer graphics analysis of surface defects. (a Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a. Surface Defect.

From www.constructioncivil.com

Causes, Prevention And Repair Of Concrete Surface Defects Surface Defect Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect. Surface Defect.

From www.researchgate.net

SEM photographs of the surface defects. af The 1st, 30th, 60th, 90th Surface Defect Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. The present review examines the different. Surface Defect.

From www.researchgate.net

Some samples of Metallic surface defects. (a) Crazing. (b) Inclusion Surface Defect Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings,. Surface Defect.

From www.researchgate.net

The pictures of surface defects in heavy and medium plate. Download Surface Defect The present review examines the different types of defects associated with surface coatings, their significant causes, and the. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination,. Surface Defect.

From www.frontiersin.org

Frontiers Multilevel semantic information guided image generation Surface Defect The present review examines the different types of defects associated with surface coatings, their significant causes, and the. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface quality is one of the most scrutinized specifications in the industry and, while its. Surface Defect.

From debuggercafe.com

Steel Surface Defect Detection using Object Detection Surface Defect The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect. Surface Defect.

From www.vrogue.co

Classification Of Defects In Steel Structures Downloa vrogue.co Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination,. Surface Defect.

From materean.com

Names of coating/surface defects Paul Wu's Blog Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface quality is one of the most scrutinized specifications in the industry and, while its. Surface Defect.

From www.arck-sensor.com

Surface defect inspection system Arck Sensor Surface Defect Surface quality is one of the most scrutinized specifications in the industry and, while its significance to any given optic. It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding,. Surface Defect.

From www.researchgate.net

Samples of six kinds of typical surface defects on NEU surface defect Surface Defect Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. The present review examines the different. Surface Defect.

From engineeringdiscoveries.com

Types Of Defects Observed In Plastering Engineering Discoveries Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination,. Surface Defect.

From www.slideshare.net

Surface defects in crystals Surface Defect Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a series of relevant information such as the category, contour, location, and size of surface defects of the sample to be tested. The present review examines the different. Surface Defect.

From www.researchgate.net

Examples of the industrial surface defect detection using the proposed Surface Defect It addresses a number of defects and their causes, including craters and other surface tension related defects, dirt (the most common defect of all), popping, and flow. Surface defect detection refers to the detection of scratches, defects, foreign body shielding, color contamination, holes, and other defects on the surface of the sample to be tested, so as to obtain a. Surface Defect.