Aluminium Continuous Casting Process . Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Continuous casting and continuous rolling is the main process of aluminum rod production. Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Because of its many economic advantages,. Control continuous length, cut length, length verification and more for continuous quality. An oil or mould slag can. In 1948, the aluminum rod. Discover the aluminium casting processing in asm handbook volume 15: Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Learn about thermodynamics, alloys, furnaces, degassing, and more.

from www.mdpi.com

Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Continuous casting and continuous rolling is the main process of aluminum rod production. Because of its many economic advantages,. In 1948, the aluminum rod. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Learn about thermodynamics, alloys, furnaces, degassing, and more. Discover the aluminium casting processing in asm handbook volume 15: Control continuous length, cut length, length verification and more for continuous quality. An oil or mould slag can. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of.

MachineLearning Algorithms for Process Condition DataBased Inclusion

Aluminium Continuous Casting Process Continuous casting and continuous rolling is the main process of aluminum rod production. Control continuous length, cut length, length verification and more for continuous quality. Because of its many economic advantages,. In 1948, the aluminum rod. Learn about thermodynamics, alloys, furnaces, degassing, and more. Discover the aluminium casting processing in asm handbook volume 15: Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Continuous casting and continuous rolling is the main process of aluminum rod production. An oil or mould slag can. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of.

From www.syalons.com

Continuous Steel Casting with Syalon Break Rings Aluminium Continuous Casting Process Learn about thermodynamics, alloys, furnaces, degassing, and more. Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Discover the aluminium casting processing in asm handbook volume 15: In 1948, the aluminum rod. Control continuous length, cut length, length verification and more for continuous quality. An oil or mould slag can. Continuous. Aluminium Continuous Casting Process.

From www.youtube.com

Aluminum ingot horizontal continuous casting line YouTube Aluminium Continuous Casting Process Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. An oil or mould slag can. Because of its many economic advantages,. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Continuous casting process is initial solidification process at. Aluminium Continuous Casting Process.

From www.mdpi.com

Metals Free FullText Influence of Continuous Casting Speeds on Aluminium Continuous Casting Process Control continuous length, cut length, length verification and more for continuous quality. In 1948, the aluminum rod. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Because of its many economic advantages,. Learn about thermodynamics, alloys, furnaces, degassing, and more. Six of the most widely used aluminum continuous. Aluminium Continuous Casting Process.

From www.pdfprof.com

Billets from continuous casting SEMIFINISHED PRODUCT FOR Anciens Et Aluminium Continuous Casting Process In 1948, the aluminum rod. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Because of its many economic advantages,. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. An oil or mould slag can. Discover the aluminium. Aluminium Continuous Casting Process.

From www.versa-bar.com

Advantages of the Continuous Casting Process Benefits of Cast Iron Aluminium Continuous Casting Process Because of its many economic advantages,. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. An oil or mould slag can. In 1948, the aluminum rod. Learn about thermodynamics, alloys, furnaces, degassing, and more. Discover the aluminium casting processing in asm handbook volume 15: Continuous casting and continuous rolling is. Aluminium Continuous Casting Process.

From novelispae.com

Twinroll casting machine Novelis PAE Aluminium Continuous Casting Process Because of its many economic advantages,. Control continuous length, cut length, length verification and more for continuous quality. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Discover the aluminium casting processing in asm handbook volume 15: An oil or mould slag can. In 1948, the aluminum rod.. Aluminium Continuous Casting Process.

From www.researchgate.net

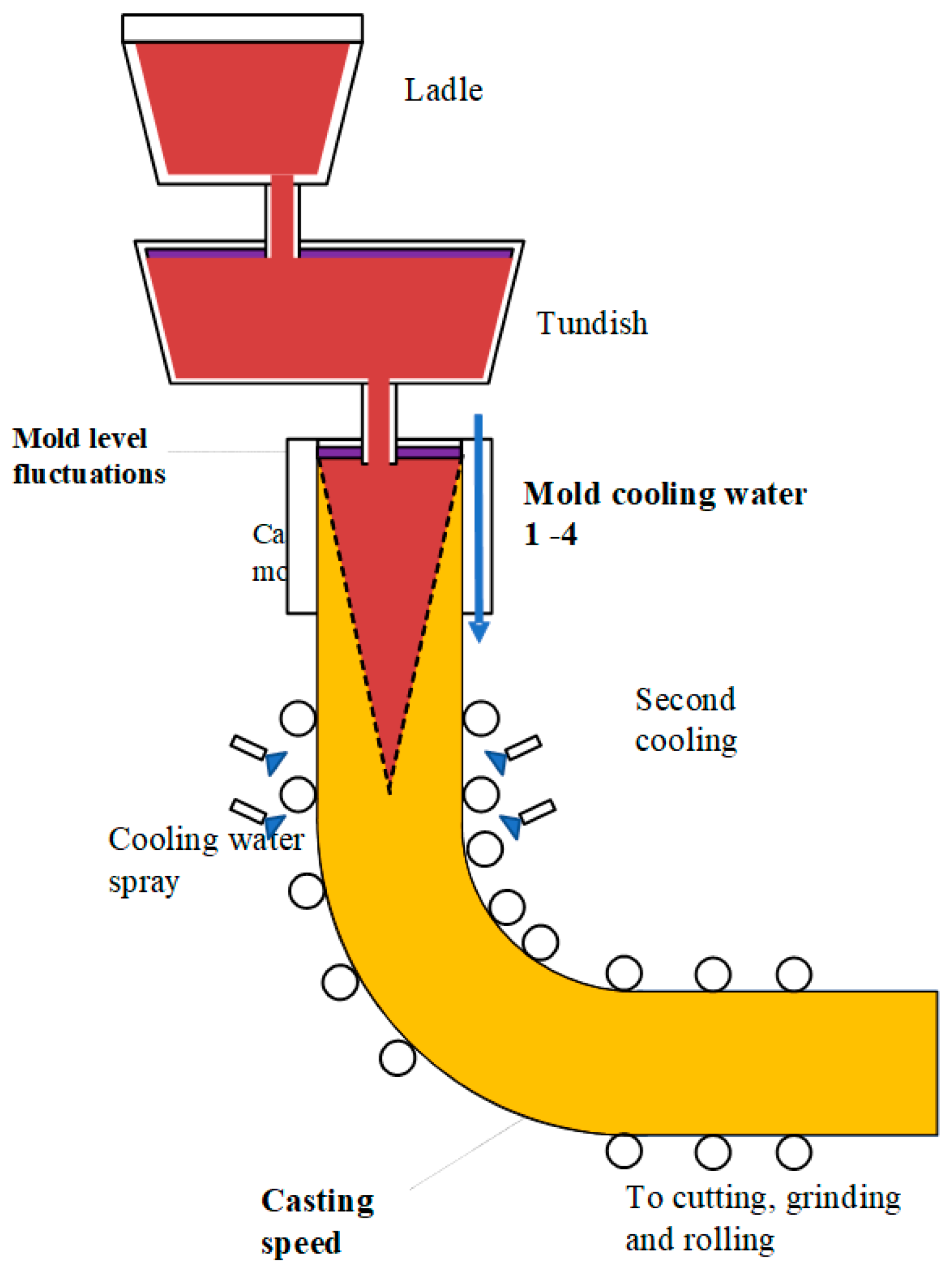

Schematic of continuous casting process Download Scientific Diagram Aluminium Continuous Casting Process Discover the aluminium casting processing in asm handbook volume 15: Control continuous length, cut length, length verification and more for continuous quality. An oil or mould slag can. Because of its many economic advantages,. In 1948, the aluminum rod. Continuous casting and continuous rolling is the main process of aluminum rod production. Learn about thermodynamics, alloys, furnaces, degassing, and more.. Aluminium Continuous Casting Process.

From aluminiumfurnace.com

Hot top aluminium billets casting platform a leading manufacturer of Aluminium Continuous Casting Process In 1948, the aluminum rod. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Continuous casting and continuous rolling is the main process of aluminum rod production. Learn about thermodynamics, alloys, furnaces, degassing, and more. Because of its many economic advantages,. Discover the aluminium casting processing in asm. Aluminium Continuous Casting Process.

From www.sistemteknik.com

Aluminium Melting & Holding Furnaces Sistem Teknik Aluminium Continuous Casting Process Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Learn about thermodynamics, alloys, furnaces, degassing, and more. An oil or mould slag can. Continuous casting and continuous rolling is the main process of aluminum rod production. Discover the aluminium casting processing in asm handbook volume 15: Because of. Aluminium Continuous Casting Process.

From www.ait.ac.at

Horizontal continuous casting plant AIT Austrian Institute Of Technology Aluminium Continuous Casting Process Learn about thermodynamics, alloys, furnaces, degassing, and more. Because of its many economic advantages,. Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Six of the most widely used aluminum. Aluminium Continuous Casting Process.

From novelispae.com

Twinroll casting machine Novelis PAE Aluminium Continuous Casting Process Discover the aluminium casting processing in asm handbook volume 15: Control continuous length, cut length, length verification and more for continuous quality. In 1948, the aluminum rod. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Continuous casting and continuous rolling is the main process of aluminum rod production. Continuous. Aluminium Continuous Casting Process.

From www.mechgrace.com

Continuous Casting Working, Process, Diagram, Types, Continuous Aluminium Continuous Casting Process Control continuous length, cut length, length verification and more for continuous quality. In 1948, the aluminum rod. Continuous casting and continuous rolling is the main process of aluminum rod production. Because of its many economic advantages,. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Continuous casting processes have been. Aluminium Continuous Casting Process.

From ppcpinc.com

» PPCP Process Aluminium Continuous Casting Process Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. An oil or mould slag can. Discover the aluminium casting processing in asm handbook volume 15: Because of its many economic advantages,. Continuous casting and continuous rolling is the main process of aluminum rod production. Control continuous length, cut length, length verification. Aluminium Continuous Casting Process.

From www.researchgate.net

Show Illustration of Continuous Casting Process [6]. Download Aluminium Continuous Casting Process Continuous casting and continuous rolling is the main process of aluminum rod production. Discover the aluminium casting processing in asm handbook volume 15: Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Because of its many economic advantages,. Control continuous length, cut length, length verification and more for. Aluminium Continuous Casting Process.

From expomachinetools.com

Continous Casting Dies Manufacturers & Suppliers 100 Quality Aluminium Continuous Casting Process In 1948, the aluminum rod. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Continuous casting and continuous rolling is the main process of aluminum rod production. Learn about thermodynamics, alloys, furnaces,. Aluminium Continuous Casting Process.

From www.mdpi.com

Materials Free FullText Optimization of Continuous Casting for Aluminium Continuous Casting Process In 1948, the aluminum rod. Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. An oil or mould slag can. Continuous casting and continuous rolling is the main process of aluminum rod production. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing. Aluminium Continuous Casting Process.

From www.mdpi.com

Materials Free FullText A Novel Approach to Improve the Aluminium Continuous Casting Process Because of its many economic advantages,. Continuous casting and continuous rolling is the main process of aluminum rod production. An oil or mould slag can. In 1948, the aluminum rod. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Continuous casting process is initial solidification process at the. Aluminium Continuous Casting Process.

From www.vrogue.co

What Is Centrifugal Casting Centrifugal Casting Types vrogue.co Aluminium Continuous Casting Process Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Because of its many economic advantages,. Learn about thermodynamics, alloys, furnaces, degassing, and more. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Discover the aluminium casting processing in. Aluminium Continuous Casting Process.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Aluminium Continuous Casting Process In 1948, the aluminum rod. Because of its many economic advantages,. Continuous casting and continuous rolling is the main process of aluminum rod production. Discover the aluminium casting processing in asm handbook volume 15: Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Control continuous length, cut length,. Aluminium Continuous Casting Process.

From www.weld2cast.com

Sand Casting Weld2Cast Aluminium Continuous Casting Process An oil or mould slag can. Discover the aluminium casting processing in asm handbook volume 15: Because of its many economic advantages,. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. In 1948, the aluminum rod. Continuous casting processes have been used successfully for more than 50 years to reduce. Aluminium Continuous Casting Process.

From www.mdpi.com

Metals Free FullText Control of Upstream Austenite Grain Aluminium Continuous Casting Process Learn about thermodynamics, alloys, furnaces, degassing, and more. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Discover the aluminium casting processing in asm handbook volume 15: Because of its many economic advantages,. In 1948, the aluminum rod. Continuous casting process is initial solidification process at the meniscus,. Aluminium Continuous Casting Process.

From www.mdpi.com

MachineLearning Algorithms for Process Condition DataBased Inclusion Aluminium Continuous Casting Process An oil or mould slag can. Because of its many economic advantages,. Control continuous length, cut length, length verification and more for continuous quality. In 1948, the aluminum rod. Continuous casting and continuous rolling is the main process of aluminum rod production. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing. Aluminium Continuous Casting Process.

From www.researchgate.net

Schematic of continuous casting process [84]. Chen et al. [86] modelled Aluminium Continuous Casting Process Continuous casting and continuous rolling is the main process of aluminum rod production. Learn about thermodynamics, alloys, furnaces, degassing, and more. Discover the aluminium casting processing in asm handbook volume 15: Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. An oil or mould slag can. Six of the most widely. Aluminium Continuous Casting Process.

From www.researchgate.net

Process flowchart of aluminium extrusion. a Conventional. b Direct Aluminium Continuous Casting Process Learn about thermodynamics, alloys, furnaces, degassing, and more. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. An oil or mould slag can. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Continuous casting process is initial solidification. Aluminium Continuous Casting Process.

From www.mdpi.com

Metals Free FullText Continuous Casting Practices for Steel Past Aluminium Continuous Casting Process Because of its many economic advantages,. Control continuous length, cut length, length verification and more for continuous quality. An oil or mould slag can. Continuous casting and continuous rolling is the main process of aluminum rod production. Discover the aluminium casting processing in asm handbook volume 15: Continuous casting process is initial solidification process at the meniscus, where the surface. Aluminium Continuous Casting Process.

From substech.com

Horizontal continuous casting in graphite mold [SubsTech] Aluminium Continuous Casting Process Continuous casting and continuous rolling is the main process of aluminum rod production. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Discover the aluminium casting processing in asm handbook volume 15: Six of the most widely used aluminum continuous casting processes are here described, along with their. Aluminium Continuous Casting Process.

From www.danieli.com

Products › Aluminium and NonFerrous Metals › Aluminium Continuous Aluminium Continuous Casting Process Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Continuous casting and continuous rolling is the main process of aluminum rod production. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Continuous casting process is initial solidification process. Aluminium Continuous Casting Process.

From www.mdpi.com

Metals Free FullText Comparison of OptimizationRegulation Aluminium Continuous Casting Process Discover the aluminium casting processing in asm handbook volume 15: Learn about thermodynamics, alloys, furnaces, degassing, and more. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. In 1948, the aluminum rod. An oil or mould slag can. Continuous casting process is initial solidification process at the meniscus, where the. Aluminium Continuous Casting Process.

From www.vrogue.co

Process Flowchart Of Aluminium Extrusion A Convention vrogue.co Aluminium Continuous Casting Process Learn about thermodynamics, alloys, furnaces, degassing, and more. In 1948, the aluminum rod. Discover the aluminium casting processing in asm handbook volume 15: Continuous casting and continuous rolling is the main process of aluminum rod production. Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Control continuous length, cut length, length. Aluminium Continuous Casting Process.

From www.victoriana.com

Fülle Und auf Besichtigungstour gehen continuous casting and rolling Aluminium Continuous Casting Process Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Learn about thermodynamics, alloys, furnaces, degassing, and more. An oil or mould slag can. Control continuous length, cut length, length verification and more for continuous quality. Six of the most widely used aluminum continuous casting processes are here described,. Aluminium Continuous Casting Process.

From encyclopedia.pub

Continuous Casting Practices for Steel Encyclopedia MDPI Aluminium Continuous Casting Process Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Because of its many economic advantages,. Six of the most widely used aluminum continuous casting processes are here described, along with. Aluminium Continuous Casting Process.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Aluminium Continuous Casting Process Continuous casting process is initial solidification process at the meniscus, where the surface of the final mould produced. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. An oil or mould slag can. In 1948, the aluminum rod. Learn about thermodynamics, alloys, furnaces, degassing, and more. Six of. Aluminium Continuous Casting Process.

From www.youtube.com

Aluminium Billet Casting Process Alüminyum Billet Döküm YouTube Aluminium Continuous Casting Process Control continuous length, cut length, length verification and more for continuous quality. Six of the most widely used aluminum continuous casting processes are here described, along with their potentialities and drawbacks. Discover the aluminium casting processing in asm handbook volume 15: In 1948, the aluminum rod. Continuous casting process is initial solidification process at the meniscus, where the surface of. Aluminium Continuous Casting Process.

From www.researchgate.net

Semi continuous casting processes Download Scientific Diagram Aluminium Continuous Casting Process Discover the aluminium casting processing in asm handbook volume 15: Control continuous length, cut length, length verification and more for continuous quality. Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Continuous casting and continuous rolling is the main process of aluminum rod production. Six of the most. Aluminium Continuous Casting Process.

From www.comsol.com

Optimizing the Continuous Casting Process with Simulation COMSOL Blog Aluminium Continuous Casting Process Continuous casting processes have been used successfully for more than 50 years to reduce the cost of manufacturing a variety of. Control continuous length, cut length, length verification and more for continuous quality. Because of its many economic advantages,. Discover the aluminium casting processing in asm handbook volume 15: In 1948, the aluminum rod. Six of the most widely used. Aluminium Continuous Casting Process.