Chemicals Used In Making Computer Chips . At each new process node, the chemistry. Chemistry is a critical part of the semiconductor manufacturing supply chain: To make any chip, numerous processes play a role. Silicon compounds have a wide variety of useful. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Deposition, photoresist, lithography, etch, ionization and. Sc1, a mixture of hydrogen peroxide and ammonium. 500 different process chemicals are required to manufacture a single. Mix this with water and gravel, and you've got concrete. From 5nm onward, materials will become much more complex — and more critical. Let’s discuss six critical semiconductor manufacturing steps: Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and.

from singularityhub.com

Deposition, photoresist, lithography, etch, ionization and. Chemistry is a critical part of the semiconductor manufacturing supply chain: 500 different process chemicals are required to manufacture a single. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. From 5nm onward, materials will become much more complex — and more critical. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Sc1, a mixture of hydrogen peroxide and ammonium. Mix this with water and gravel, and you've got concrete. To make any chip, numerous processes play a role. At each new process node, the chemistry.

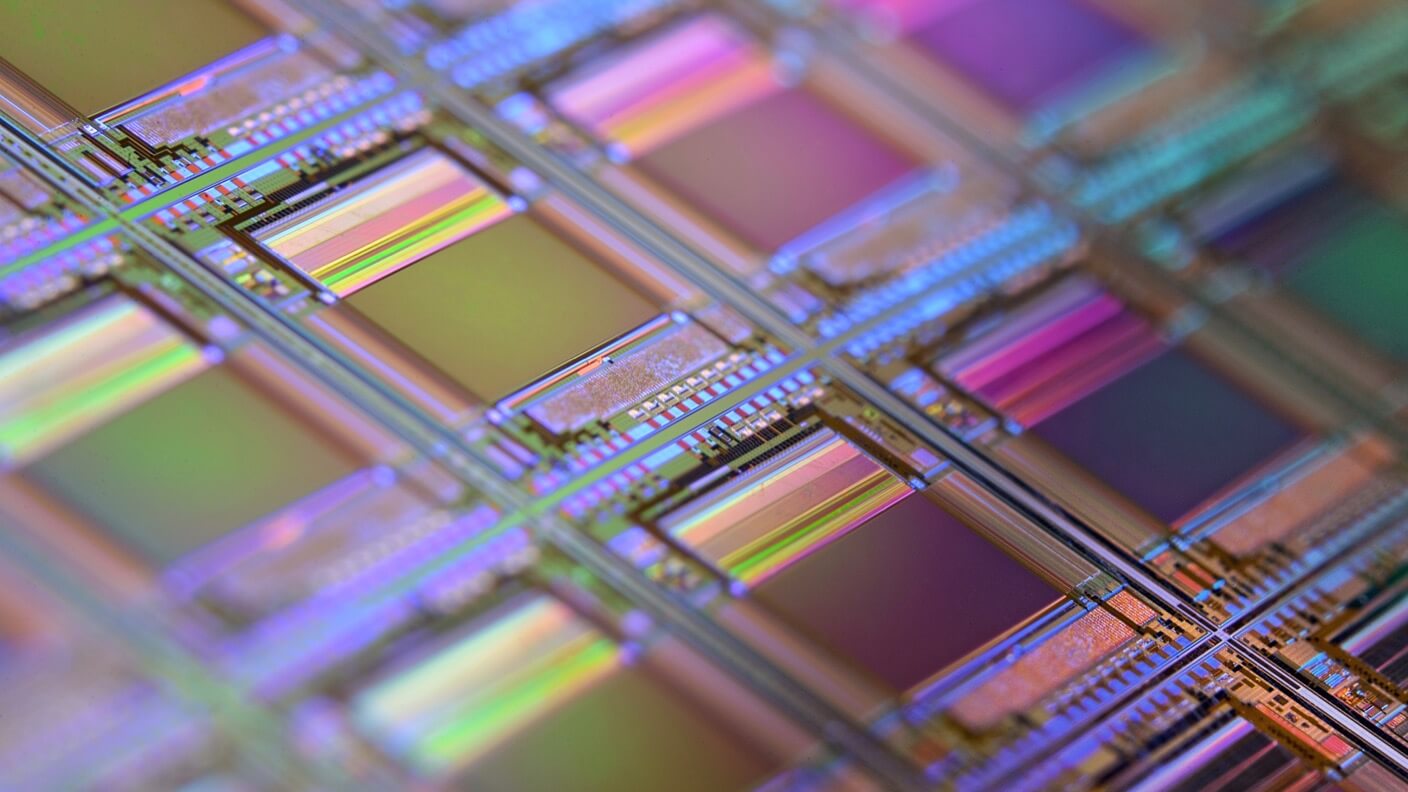

computerchipsiliconwafer Singularity Hub

Chemicals Used In Making Computer Chips From 5nm onward, materials will become much more complex — and more critical. Deposition, photoresist, lithography, etch, ionization and. From 5nm onward, materials will become much more complex — and more critical. Let’s discuss six critical semiconductor manufacturing steps: Silicon compounds have a wide variety of useful. Sc1, a mixture of hydrogen peroxide and ammonium. Chemistry is a critical part of the semiconductor manufacturing supply chain: To make any chip, numerous processes play a role. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. Mix this with water and gravel, and you've got concrete. 500 different process chemicals are required to manufacture a single. At each new process node, the chemistry.

From www.youtube.com

Inside The World's Largest Chips Factory YouTube Chemicals Used In Making Computer Chips Deposition, photoresist, lithography, etch, ionization and. 500 different process chemicals are required to manufacture a single. Let’s discuss six critical semiconductor manufacturing steps: From 5nm onward, materials will become much more complex — and more critical. Chemistry is a critical part of the semiconductor manufacturing supply chain: Sc1, a mixture of hydrogen peroxide and ammonium. Hydrogen peroxide’s main use in. Chemicals Used In Making Computer Chips.

From uniglobekisco.com

Plating Chemicals for Semiconductors Uniglobe Kisco Inc Chemicals Used In Making Computer Chips 500 different process chemicals are required to manufacture a single. From 5nm onward, materials will become much more complex — and more critical. Chemistry is a critical part of the semiconductor manufacturing supply chain: Mix this with water and gravel, and you've got concrete. At each new process node, the chemistry. Silicon compounds have a wide variety of useful. Gpus. Chemicals Used In Making Computer Chips.

From inhabitat.com

Scientists invent the world's first microchip powered by biological systems Chemicals Used In Making Computer Chips At each new process node, the chemistry. 500 different process chemicals are required to manufacture a single. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Deposition, photoresist, lithography, etch, ionization and. Silicon compounds have a wide variety of useful. Let’s discuss six critical semiconductor manufacturing steps: Sc1, a. Chemicals Used In Making Computer Chips.

From datakosine.com

Warum werden Computerchips aus Silizium hergestellt Datakosine Chemicals Used In Making Computer Chips To make any chip, numerous processes play a role. Mix this with water and gravel, and you've got concrete. At each new process node, the chemistry. Let’s discuss six critical semiconductor manufacturing steps: Chemistry is a critical part of the semiconductor manufacturing supply chain: 500 different process chemicals are required to manufacture a single. Deposition, photoresist, lithography, etch, ionization and.. Chemicals Used In Making Computer Chips.

From jahaemmahughes.blogspot.com

Wafer Fabrication Process Flow Emma Hughes Chemicals Used In Making Computer Chips Mix this with water and gravel, and you've got concrete. Sc1, a mixture of hydrogen peroxide and ammonium. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. Chemistry is a critical part of the semiconductor manufacturing supply. Chemicals Used In Making Computer Chips.

From itchol.com

What Are Computer Chips Made Of? Everything To Know (2023) Chemicals Used In Making Computer Chips At each new process node, the chemistry. Mix this with water and gravel, and you've got concrete. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Chemistry is a critical part of the semiconductor manufacturing supply chain: 500 different process chemicals are required to manufacture a single. To make. Chemicals Used In Making Computer Chips.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Chemicals Used In Making Computer Chips At each new process node, the chemistry. Silicon compounds have a wide variety of useful. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. Sc1, a mixture of hydrogen peroxide and ammonium. Hydrogen peroxide’s main use in. Chemicals Used In Making Computer Chips.

From www.youtube.com

From Sand to Silicon the Making of a Chip Intel YouTube Chemicals Used In Making Computer Chips Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Chemistry is a critical part of the semiconductor manufacturing supply chain: Silicon compounds have a wide variety of useful. Deposition, photoresist, lithography, etch, ionization and. 500 different process chemicals are required to manufacture a single. Sc1, a mixture of hydrogen. Chemicals Used In Making Computer Chips.

From www.nist.gov

making computer chips Chemicals Used In Making Computer Chips Deposition, photoresist, lithography, etch, ionization and. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. 500 different process chemicals are required to manufacture a single. At each new process node, the chemistry. Chemistry is a critical part. Chemicals Used In Making Computer Chips.

From energyskeptic.com

How are microchips made? Peak Everything, Overshoot, & Collapse Chemicals Used In Making Computer Chips Sc1, a mixture of hydrogen peroxide and ammonium. Silicon compounds have a wide variety of useful. To make any chip, numerous processes play a role. Deposition, photoresist, lithography, etch, ionization and. At each new process node, the chemistry. Chemistry is a critical part of the semiconductor manufacturing supply chain: Hydrogen peroxide’s main use in the semiconductor industry is to create. Chemicals Used In Making Computer Chips.

From www.smithsonianmag.com

These New Computer Chips Are Made From Wood Smithsonian Chemicals Used In Making Computer Chips 500 different process chemicals are required to manufacture a single. Let’s discuss six critical semiconductor manufacturing steps: Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. To make any chip, numerous processes play a role. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage. Chemicals Used In Making Computer Chips.

From news.mit.edu

to the nano age MIT News Massachusetts Institute of Technology Chemicals Used In Making Computer Chips Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. Sc1, a mixture of hydrogen peroxide and ammonium. Let’s discuss six critical semiconductor manufacturing steps: Mix this with water and gravel, and you've got concrete. Hydrogen peroxide’s main. Chemicals Used In Making Computer Chips.

From ar.inspiredpencil.com

Silicon In Computer Chips Chemicals Used In Making Computer Chips At each new process node, the chemistry. Chemistry is a critical part of the semiconductor manufacturing supply chain: Mix this with water and gravel, and you've got concrete. 500 different process chemicals are required to manufacture a single. Let’s discuss six critical semiconductor manufacturing steps: To make any chip, numerous processes play a role. Hydrogen peroxide’s main use in the. Chemicals Used In Making Computer Chips.

From www.pcworld.com

The periodic table of tech PCWorld Chemicals Used In Making Computer Chips Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Let’s discuss six critical semiconductor manufacturing steps: Sc1, a mixture of hydrogen peroxide and ammonium. To make any chip, numerous processes play a role. Mix this with water and gravel, and you've got concrete. At each new process node, the. Chemicals Used In Making Computer Chips.

From studylib.net

Chemicals Used in Chip Fabrication Chemicals Used In Making Computer Chips At each new process node, the chemistry. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. To. Chemicals Used In Making Computer Chips.

From curioustimes.in

Intel designs chip that can smell hazardous chemicals Curious Times Chemicals Used In Making Computer Chips Let’s discuss six critical semiconductor manufacturing steps: Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. To make any chip, numerous processes play a role. Deposition, photoresist, lithography, etch, ionization and. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip,. Chemicals Used In Making Computer Chips.

From loeyoycvd.blob.core.windows.net

Us Largest Chemical Companies at William Nelson blog Chemicals Used In Making Computer Chips Sc1, a mixture of hydrogen peroxide and ammonium. From 5nm onward, materials will become much more complex — and more critical. 500 different process chemicals are required to manufacture a single. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Silicon compounds have a wide variety of useful. Gpus. Chemicals Used In Making Computer Chips.

From www.expressnews.com

Inside Tower Semiconductor’s San Antonio plant; Chip maker eyes Chemicals Used In Making Computer Chips Let’s discuss six critical semiconductor manufacturing steps: Mix this with water and gravel, and you've got concrete. Deposition, photoresist, lithography, etch, ionization and. Chemistry is a critical part of the semiconductor manufacturing supply chain: From 5nm onward, materials will become much more complex — and more critical. Sc1, a mixture of hydrogen peroxide and ammonium. At each new process node,. Chemicals Used In Making Computer Chips.

From www.waferworld.com

The Ultimate Guide to Modern Computer Chips Chemicals Used In Making Computer Chips Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Deposition, photoresist, lithography, etch, ionization and. Sc1, a. Chemicals Used In Making Computer Chips.

From www.sputtertargets.net

How Is The Chip Made? Sputtering Targets Manufacturers Chemicals Used In Making Computer Chips Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. At each new process node, the chemistry. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. Let’s. Chemicals Used In Making Computer Chips.

From minnesotareformer.com

Chips on the table 3M wants to stop making toxic chemicals, but will Chemicals Used In Making Computer Chips Chemistry is a critical part of the semiconductor manufacturing supply chain: Mix this with water and gravel, and you've got concrete. From 5nm onward, materials will become much more complex — and more critical. At each new process node, the chemistry. 500 different process chemicals are required to manufacture a single. Gpus are silicon layered with tantalum and palladium transistors. Chemicals Used In Making Computer Chips.

From history-computer.com

Jack Kilby — Complete Biography, History and Inventions Chemicals Used In Making Computer Chips Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. To make any chip, numerous processes play a role. Mix this with water and gravel, and you've got concrete. Deposition, photoresist, lithography, etch, ionization and. Silicon compounds have a wide variety of useful. From 5nm onward, materials will become much. Chemicals Used In Making Computer Chips.

From www.wisegeek.com

What is a Computer Chip? (with pictures) Chemicals Used In Making Computer Chips From 5nm onward, materials will become much more complex — and more critical. Deposition, photoresist, lithography, etch, ionization and. Sc1, a mixture of hydrogen peroxide and ammonium. Chemistry is a critical part of the semiconductor manufacturing supply chain: At each new process node, the chemistry. Mix this with water and gravel, and you've got concrete. Gpus are silicon layered with. Chemicals Used In Making Computer Chips.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Chemicals Used In Making Computer Chips Silicon compounds have a wide variety of useful. At each new process node, the chemistry. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. To make any chip, numerous processes play a role. Mix this with water. Chemicals Used In Making Computer Chips.

From www.goldextractionprocess.com

Gold extraction process Gold stripping solution chemicals old CPU Chemicals Used In Making Computer Chips Deposition, photoresist, lithography, etch, ionization and. To make any chip, numerous processes play a role. Silicon compounds have a wide variety of useful. Sc1, a mixture of hydrogen peroxide and ammonium. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. From 5nm onward, materials will become much more complex. Chemicals Used In Making Computer Chips.

From www.bizjournals.com

PVS Chemicals in Buffalo readies to meet demand for computer chip Chemicals Used In Making Computer Chips Chemistry is a critical part of the semiconductor manufacturing supply chain: To make any chip, numerous processes play a role. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. 500 different process chemicals are required to manufacture. Chemicals Used In Making Computer Chips.

From www.wirefan.com

AI could change the game on the forever chemicals used to make chips Chemicals Used In Making Computer Chips Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. At each new process node, the chemistry. To make any chip, numerous processes play a role. Mix this with water and gravel, and you've got concrete. 500 different process chemicals are required to manufacture a single. Chemistry is a critical. Chemicals Used In Making Computer Chips.

From singularityhub.com

computerchipsiliconwafer Singularity Hub Chemicals Used In Making Computer Chips Sc1, a mixture of hydrogen peroxide and ammonium. 500 different process chemicals are required to manufacture a single. At each new process node, the chemistry. Chemistry is a critical part of the semiconductor manufacturing supply chain: To make any chip, numerous processes play a role. Deposition, photoresist, lithography, etch, ionization and. From 5nm onward, materials will become much more complex. Chemicals Used In Making Computer Chips.

From fyotwweml.blob.core.windows.net

Semiconductor Production Process Explained at Joe Klassen blog Chemicals Used In Making Computer Chips Silicon compounds have a wide variety of useful. To make any chip, numerous processes play a role. Deposition, photoresist, lithography, etch, ionization and. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the materials used for a gpu and. Mix this with water and. Chemicals Used In Making Computer Chips.

From www.csfusion.org

What country produces the most semiconductors? Compound Semiconductor Chemicals Used In Making Computer Chips To make any chip, numerous processes play a role. Mix this with water and gravel, and you've got concrete. At each new process node, the chemistry. Silicon compounds have a wide variety of useful. Let’s discuss six critical semiconductor manufacturing steps: Sc1, a mixture of hydrogen peroxide and ammonium. Deposition, photoresist, lithography, etch, ionization and. Chemistry is a critical part. Chemicals Used In Making Computer Chips.

From www.stamfordadvocate.com

ASML Wilton keeps shrinking Chemicals Used In Making Computer Chips Silicon compounds have a wide variety of useful. Sc1, a mixture of hydrogen peroxide and ammonium. 500 different process chemicals are required to manufacture a single. From 5nm onward, materials will become much more complex — and more critical. Let’s discuss six critical semiconductor manufacturing steps: Chemistry is a critical part of the semiconductor manufacturing supply chain: At each new. Chemicals Used In Making Computer Chips.

From fyotwweml.blob.core.windows.net

Semiconductor Production Process Explained at Joe Klassen blog Chemicals Used In Making Computer Chips Silicon compounds have a wide variety of useful. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and. Chemistry is a critical part of the semiconductor manufacturing supply chain: 500 different process chemicals are required to manufacture a single. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1. Chemicals Used In Making Computer Chips.

From www.numerade.com

SOLVEDGive the chemical symbol for each element. a. the element in Chemicals Used In Making Computer Chips Chemistry is a critical part of the semiconductor manufacturing supply chain: Deposition, photoresist, lithography, etch, ionization and. At each new process node, the chemistry. Mix this with water and gravel, and you've got concrete. To make any chip, numerous processes play a role. Sc1, a mixture of hydrogen peroxide and ammonium. Gpus are silicon layered with tantalum and palladium transistors. Chemicals Used In Making Computer Chips.

From itchol.com

How Are Computer Chips Made? (2022) Chemicals Used In Making Computer Chips Deposition, photoresist, lithography, etch, ionization and. Silicon compounds have a wide variety of useful. 500 different process chemicals are required to manufacture a single. Mix this with water and gravel, and you've got concrete. Gpus are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip, which is perhaps the most interesting of the. Chemicals Used In Making Computer Chips.

From www.nagase.eu

Sheet Molding Compound Supplier NAGASE Europe Chemicals Used In Making Computer Chips Deposition, photoresist, lithography, etch, ionization and. Sc1, a mixture of hydrogen peroxide and ammonium. At each new process node, the chemistry. From 5nm onward, materials will become much more complex — and more critical. Hydrogen peroxide’s main use in the semiconductor industry is to create two standard cleaning compounds known as sc1 and sc2. Let’s discuss six critical semiconductor manufacturing. Chemicals Used In Making Computer Chips.