Material Requirements Schedule . a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). Use the master production schedule to gauge product demand and required objects to. — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. — estimate required materials: mrp is a system designed to plan manufacturing production. It identifies necessary materials, estimates quantities,.

from www.slideteam.net

mrp is a system designed to plan manufacturing production. It identifies necessary materials, estimates quantities,. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. — estimate required materials: Use the master production schedule to gauge product demand and required objects to.

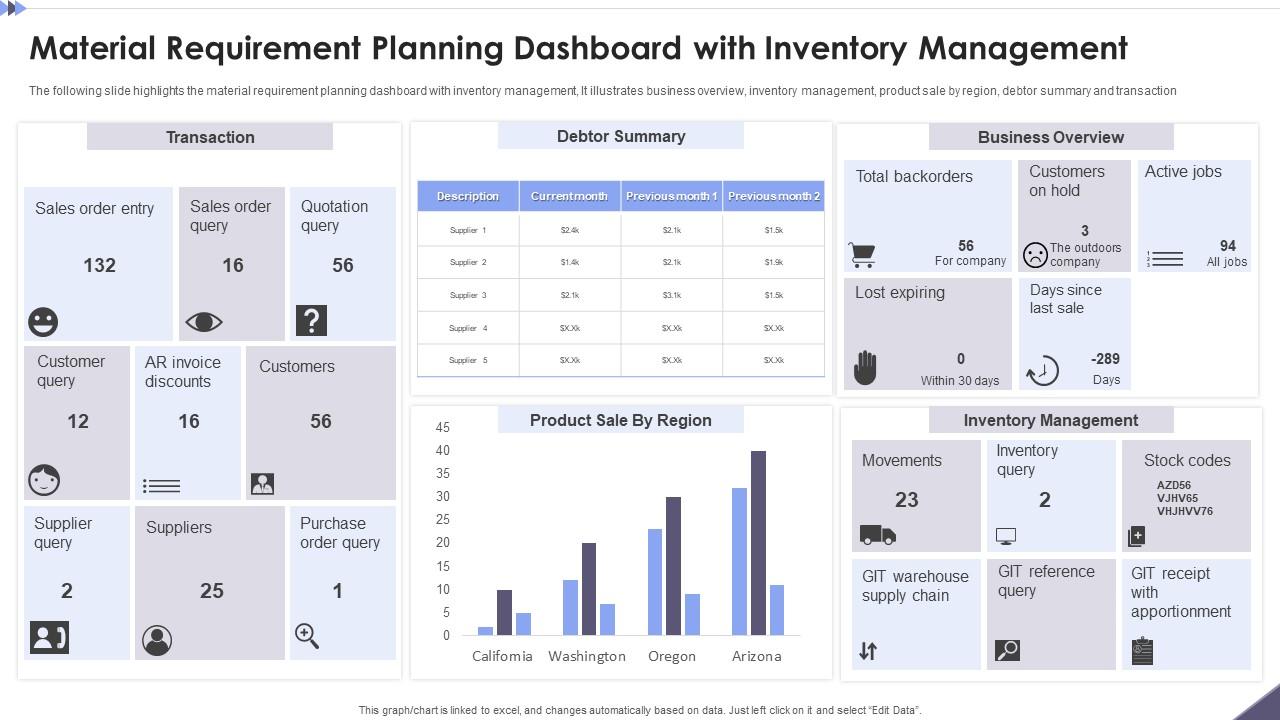

Material Requirement Planning Dashboard With Inventory Management

Material Requirements Schedule It identifies necessary materials, estimates quantities,. — estimate required materials: a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). mrp is a system designed to plan manufacturing production. — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. It identifies necessary materials, estimates quantities,. — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. Use the master production schedule to gauge product demand and required objects to.

From www.slideteam.net

Material Requirement Planning Dashboard With Inventory Management Material Requirements Schedule It identifies necessary materials, estimates quantities,. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — estimate required materials: Use the master production schedule to gauge product demand and required objects. Material Requirements Schedule.

From www.youtube.com

Concept of Material Requirements Planning (MRP) YouTube Material Requirements Schedule — estimate required materials: — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. Use the master production schedule to gauge product demand and required objects to. It identifies necessary materials, estimates quantities,. mrp is a system designed to plan manufacturing production. — by tracking exact materials requirements, you can identify. Material Requirements Schedule.

From ansi.ph

6 Benefits Material Requirement Planning Brings to Manufacturers Material Requirements Schedule mrp is a system designed to plan manufacturing production. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — by tracking exact materials requirements, you can identify economic order quantities,. Material Requirements Schedule.

From www.wallstreetmojo.com

Material Requirement Planning (MRP) Examples, Pros, Cons Material Requirements Schedule — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). mrp is a system designed. Material Requirements Schedule.

From www.slideserve.com

PPT Material Requirements Planning PowerPoint Presentation ID443125 Material Requirements Schedule mrp is a system designed to plan manufacturing production. — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. It identifies necessary materials, estimates quantities,. a material requirements planning (mrp) system accelerates the manufacturing production. Material Requirements Schedule.

From www.slideserve.com

PPT Chapter 14 PowerPoint Presentation, free download ID507185 Material Requirements Schedule mrp is a system designed to plan manufacturing production. Use the master production schedule to gauge product demand and required objects to. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom).. Material Requirements Schedule.

From www.erp-information.com

Material Requirements Planning (MRP) A Comprehensive Guide Material Requirements Schedule mrp is a system designed to plan manufacturing production. — estimate required materials: a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — material requirements planning (mrp) in manufacturing. Material Requirements Schedule.

From www.erp-information.com

Material Requirements Planning (MRP) A Comprehensive Guide Material Requirements Schedule — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. Use the master production schedule to gauge product demand and required objects to. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on. Material Requirements Schedule.

From www.researchgate.net

Material Requirements Planning System Download Scientific Diagram Material Requirements Schedule a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — estimate required materials: — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. . Material Requirements Schedule.

From www.slideserve.com

PPT CHAPTER 5 OPERATIONS MANAGEMENT PowerPoint Presentation, free Material Requirements Schedule mrp is a system designed to plan manufacturing production. It identifies necessary materials, estimates quantities,. — estimate required materials: a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). Use the. Material Requirements Schedule.

From studylib.net

Material Requirements Planning Defined Material Requirements Schedule It identifies necessary materials, estimates quantities,. — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). . Material Requirements Schedule.

From www.smartsheet.com

Everything You Need to Know About Material Requirements Planning (MRP Material Requirements Schedule — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. It identifies necessary materials, estimates quantities,. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). . Material Requirements Schedule.

From www.vrogue.co

What Is Material Requirements Planning And Manufactur vrogue.co Material Requirements Schedule — estimate required materials: Use the master production schedule to gauge product demand and required objects to. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). It identifies necessary materials, estimates. Material Requirements Schedule.

From www.slideserve.com

PPT Material Requirements Planning PowerPoint Presentation ID443125 Material Requirements Schedule a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. Use the master production schedule to gauge. Material Requirements Schedule.

From www.engineeringbooks.me

Estimate of Requirement of Material Excel Sheet Engineering Books Material Requirements Schedule mrp is a system designed to plan manufacturing production. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — estimate required materials: It identifies necessary materials, estimates quantities,. —. Material Requirements Schedule.

From www.batchmaster.com

Material Requirement Planning (MRP) ERP Software Material Requirements Schedule a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). It identifies necessary materials, estimates quantities,. mrp is a system designed to plan manufacturing production. — by tracking exact materials requirements,. Material Requirements Schedule.

From corporatefinanceinstitute.com

Material Requirements Planning (MRP) How it Works Material Requirements Schedule It identifies necessary materials, estimates quantities,. mrp is a system designed to plan manufacturing production. Use the master production schedule to gauge product demand and required objects to. — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. — estimate required materials: — material requirements planning (mrp) in manufacturing is. Material Requirements Schedule.

From efinancemanagement.com

Material Requirements Planning (MRP) All You Need To Know Material Requirements Schedule — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. — estimate required materials: Use the master production schedule to gauge product demand and required objects to. mrp is a system designed to plan manufacturing production. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw. Material Requirements Schedule.

From www.slideshare.net

Material requirement planning presentation Material Requirements Schedule — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — estimate required materials: Use. Material Requirements Schedule.

From thecustomizewindows.com

Material Requirements Planning (MRP) Basics Material Requirements Schedule — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. — estimate required materials: a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). . Material Requirements Schedule.

From www.slideshare.net

Material requirements planning & erp ppt bec doms Material Requirements Schedule Use the master production schedule to gauge product demand and required objects to. It identifies necessary materials, estimates quantities,. — estimate required materials: a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials. Material Requirements Schedule.

From www.slideserve.com

PPT Materials Requirement Planning (MRP) PowerPoint Presentation Material Requirements Schedule Use the master production schedule to gauge product demand and required objects to. It identifies necessary materials, estimates quantities,. — estimate required materials: mrp is a system designed to plan manufacturing production. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble. Material Requirements Schedule.

From www.slideserve.com

PPT Chapter 18. Materials Requirements Planning PowerPoint Material Requirements Schedule It identifies necessary materials, estimates quantities,. — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. mrp is a system designed to plan manufacturing production. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished. Material Requirements Schedule.

From www.etsy.com

Excel Material Requirements Planning MRP Template Etsy Material Requirements Schedule a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — estimate required materials: — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. It identifies. Material Requirements Schedule.

From www.financestrategists.com

Material Requirements Planning (MRP) Definition & Process Material Requirements Schedule — estimate required materials: — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. It identifies necessary materials, estimates quantities,. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and. Material Requirements Schedule.

From www.slideteam.net

Elements Of Material Requirement Planning System Presentation Material Requirements Schedule mrp is a system designed to plan manufacturing production. — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. Use the master production schedule to gauge product demand and required objects to. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are. Material Requirements Schedule.

From theinvestorsbook.com

What is Material Requirements Planning (MRP)? Process, Example The Material Requirements Schedule It identifies necessary materials, estimates quantities,. Use the master production schedule to gauge product demand and required objects to. mrp is a system designed to plan manufacturing production. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on. Material Requirements Schedule.

From www.toppers4u.com

Material Requirement Planning (MRP) Definition, Objectives, System Material Requirements Schedule a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. mrp is a system designed. Material Requirements Schedule.

From www.slideserve.com

PPT Material Requirements Planning (MRP) and ERP PowerPoint Material Requirements Schedule — estimate required materials: a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials (bom). mrp is a system designed to plan manufacturing production. — by tracking exact materials requirements, you. Material Requirements Schedule.

From old.sermitsiaq.ag

Material Requirement Planning Excel Template Material Requirements Schedule — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. mrp is a system designed to plan manufacturing production. Use the master production schedule to gauge product demand and required objects to. It identifies necessary materials, estimates quantities,. — estimate required materials: a material requirements planning (mrp) system accelerates the. Material Requirements Schedule.

From slidesdocs.com

Material Requirements Planning Table Excel Template And Google Sheets Material Requirements Schedule — estimate required materials: — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. It identifies necessary materials, estimates quantities,. mrp is a system designed to plan manufacturing production. — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. a material requirements planning (mrp). Material Requirements Schedule.

From www.wallstreetmojo.com

Material Requirement Planning (MRP) Examples, Pros, Cons Material Requirements Schedule mrp is a system designed to plan manufacturing production. — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. — estimate required materials: a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished. Material Requirements Schedule.

From excelguider.com

Material Requirement Planning Excel Template — Material Requirements Schedule — estimate required materials: It identifies necessary materials, estimates quantities,. Use the master production schedule to gauge product demand and required objects to. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand and bill of materials. Material Requirements Schedule.

From www.slideteam.net

Key Features Of Material Requirement Planning System Presentation Material Requirements Schedule — estimate required materials: — by tracking exact materials requirements, you can identify economic order quantities, or the specific volume. It identifies necessary materials, estimates quantities,. — material requirements planning (mrp) in manufacturing is a production planning, scheduling, and inventory control. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw. Material Requirements Schedule.

From www.slideserve.com

PPT Material Requirements Planning (MRP) PowerPoint Presentation Material Requirements Schedule — estimate required materials: mrp is a system designed to plan manufacturing production. Use the master production schedule to gauge product demand and required objects to. a material requirements planning (mrp) system accelerates the manufacturing production process by determining what raw materials, components and subassemblies are needed, and when to assemble the finished goods, based on demand. Material Requirements Schedule.