What Is A 45 Degree Chamfer . chamfering is the process in developing that edge and what one could argue, a unique yet very common application. If an angle other than 45. the most common chamfer angle is 45 degrees. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. A chamfer edge is made up. Sometimes defined as a form of. chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. Depending on the part geometry, different tools can be used to.

from www.kitplanes.com

A chamfer edge is made up. chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. the most common chamfer angle is 45 degrees. Sometimes defined as a form of. Depending on the part geometry, different tools can be used to. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. If an angle other than 45.

Chamfers and Tapers KITPLANES

What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Depending on the part geometry, different tools can be used to. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. A chamfer edge is made up. chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. If an angle other than 45. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. the most common chamfer angle is 45 degrees. Sometimes defined as a form of. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the.

From www.desertcart.co.za

Buy 2in1 Mini Air Chamfer Tool for Chamfering and Round Cornor on What Is A 45 Degree Chamfer If an angle other than 45. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Sometimes defined as a form of. the most common chamfer angle is 45 degrees. chamfers are a key feature in machining, essential for removing sharp edges and facilitating. What Is A 45 Degree Chamfer.

From www.amanatool.com

49404 Carbide Tipped Chamfer 45 Degree x 131/32 Inch Dia x 3/4 x 1/2 Shank What Is A 45 Degree Chamfer A chamfer edge is made up. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. the most common chamfer. What Is A 45 Degree Chamfer.

From www.youtube.com

Mastercam Tip Chamfer any angle with a 45° Chamfering Tool YouTube What Is A 45 Degree Chamfer If an angle other than 45. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. chamfers can be dimensioned in two ways, either. What Is A 45 Degree Chamfer.

From uquid.com

BEYOND TCM 45 Degree Chamfering Cutter Milling 12 16 20 25mm C1620110 What Is A 45 Degree Chamfer chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. Sometimes defined as a form of. the most common chamfer angle. What Is A 45 Degree Chamfer.

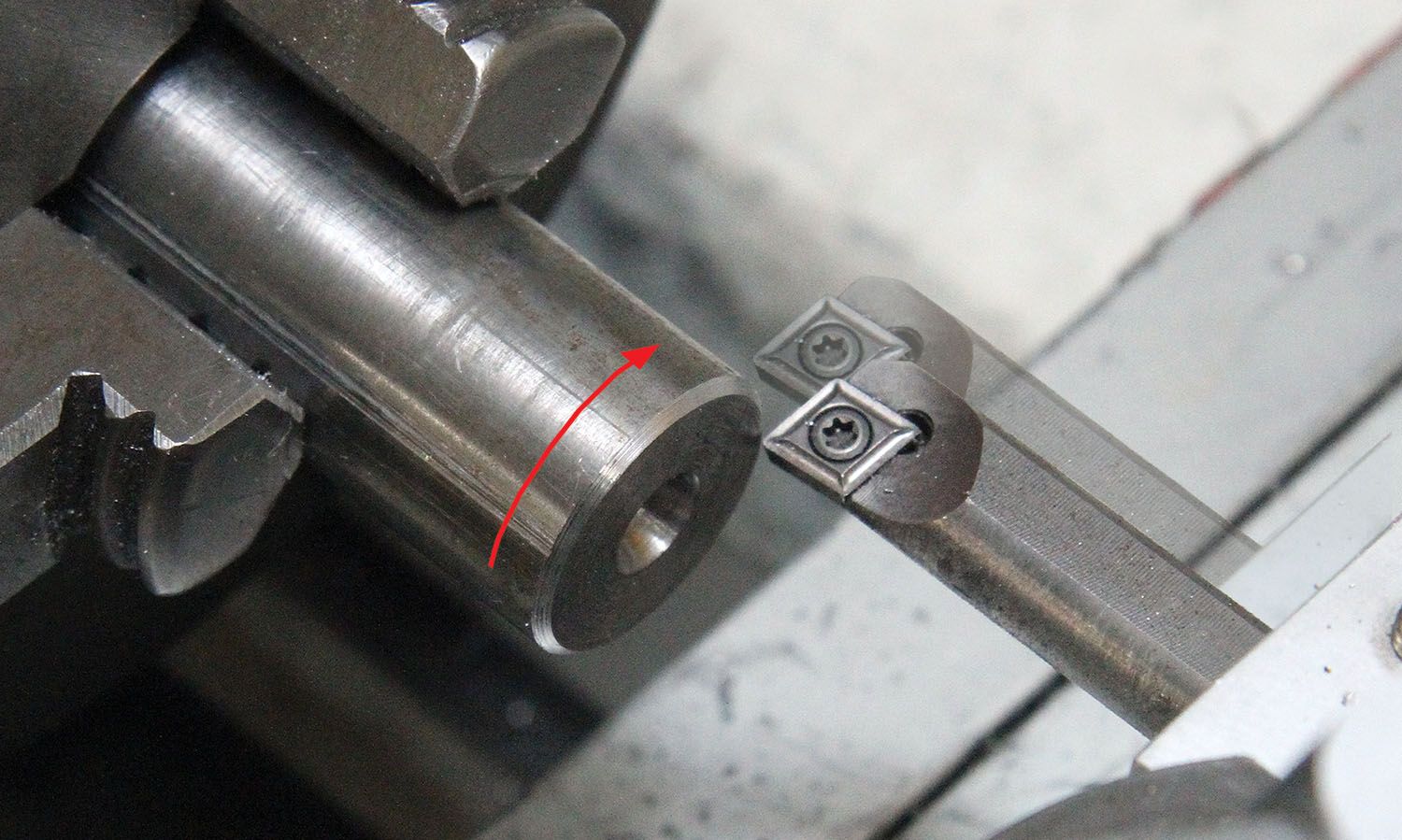

From rsvautomotive.co.uk

chamfering Tool makes It a Workhorse Facing New Lathe 45 Degree Turning What Is A 45 Degree Chamfer chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. chamfering is the process in developing that edge and what one. What Is A 45 Degree Chamfer.

From www.levelenginc.com

Measuring Chamfers Level Engineering, Inc. What Is A 45 Degree Chamfer The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. Sometimes defined as a form of. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer edge is made up. the most common. What Is A 45 Degree Chamfer.

From www.cutwel.co.uk

45 Degree Indexable Chamfer Multi Mill CEC45 Series (Korloy) Cutwel What Is A 45 Degree Chamfer the most common chamfer angle is 45 degrees. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. chamfers can be dimensioned in. What Is A 45 Degree Chamfer.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer edge is made up. Depending on the part geometry, different tools can be used to. the most common chamfer angle is 45 degrees. chamfers are a key feature in machining, essential for removing sharp edges and. What Is A 45 Degree Chamfer.

From advancedcarbidetooling.co.uk

Nine9 45 degree Chamfer Mill 20mm dia shank x 32max. Advanced What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. chamfers are a key feature in machining, essential for removing sharp edges and facilitating part. What Is A 45 Degree Chamfer.

From www.kitplanes.com

Chamfers and Tapers KITPLANES What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Sometimes defined as a form of. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. A chamfer edge is made up. The purpose of chamfering is. What Is A 45 Degree Chamfer.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is A 45 Degree Chamfer Depending on the part geometry, different tools can be used to. A chamfer edge is made up. chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. the most common chamfer angle is 45 degrees. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as. What Is A 45 Degree Chamfer.

From vibadirect.com

Dimension Guidelines ViBaDirect What Is A 45 Degree Chamfer Sometimes defined as a form of. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer edge is made up. the most common chamfer angle is 45 degrees. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out. What Is A 45 Degree Chamfer.

From www.aliexpress.com

45degrees Digital Chamfer Gauge Stainless steel Chamfering vernier What Is A 45 Degree Chamfer A chamfer edge is made up. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. chamfers can be dimensioned in two ways, either by. What Is A 45 Degree Chamfer.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics What Is A 45 Degree Chamfer A chamfer edge is made up. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. Sometimes defined as a form of. If an angle. What Is A 45 Degree Chamfer.

From www.youtube.com

Dimensioning Chamfers YouTube What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. the most common chamfer angle is 45 degrees. If an angle other than 45. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. chamfers. What Is A 45 Degree Chamfer.

From www.practicalmachinist.com

Understanding Chamfer and Chamfer Mills Practical Machinist What Is A 45 Degree Chamfer Sometimes defined as a form of. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Depending on the part geometry, different tools can be used to. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between. What Is A 45 Degree Chamfer.

From www.researchgate.net

Cutting edge chamfer. Chamfer width w, and chamfer angle γ Download What Is A 45 Degree Chamfer chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. If an angle other than 45. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Sometimes defined as a form of. the most common chamfer angle is 45 degrees. A chamfer. What Is A 45 Degree Chamfer.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is A 45 Degree Chamfer chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. A chamfer edge is made up. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. If an angle other than 45. Depending on the part geometry, different tools can be used to.. What Is A 45 Degree Chamfer.

From werk24.io

Symbols used in Technical Drawings What Is A 45 Degree Chamfer Sometimes defined as a form of. Depending on the part geometry, different tools can be used to. A chamfer edge is made up. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. chamfers can be dimensioned in two ways, either by calling out the length by angle, or. What Is A 45 Degree Chamfer.

From www.routertooling.co.uk

Chamfer TCT 45° x 41mm x 1/2 Shank F What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. A chamfer edge is made up. Depending on the part geometry, different tools can be used to.. What Is A 45 Degree Chamfer.

From www.youtube.com

AutoCAD Tutorial Using the CHAMFER Command YouTube What Is A 45 Degree Chamfer The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. A chamfer edge is made up. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. chamfers are a key. What Is A 45 Degree Chamfer.

From www.trendproductsonline.co.uk

C197X1/2TC Bearing guided chamfer angle=45 degrees Trend Products What Is A 45 Degree Chamfer Sometimes defined as a form of. chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. If an angle other than 45. the most common chamfer angle is 45 degrees. Depending on the part geometry, different tools can be used to. chamfers are usually designated by their angle, such as 45. What Is A 45 Degree Chamfer.

From eziil.com

Chamfering 101 Types, Dimensions & Callout What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. If an angle other than 45. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. chamfers can be dimensioned in two ways, either by. What Is A 45 Degree Chamfer.

From www.cutwel.co.uk

29mm x 60mm 45 Degree Indexable Chamfer Multi Mill Korloy Cutwel What Is A 45 Degree Chamfer Sometimes defined as a form of. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. the most common chamfer angle is 45 degrees. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two. What Is A 45 Degree Chamfer.

From www.aliexpress.com

SSP 20 20 130 45 Degree Insertable Face Chamfer Mill for TCMT16T308 OR What Is A 45 Degree Chamfer chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Depending on the part geometry, different tools can be used to. If an angle other than 45.. What Is A 45 Degree Chamfer.

From www.kitplanes.com

Chamfers and Tapers KITPLANES What Is A 45 Degree Chamfer chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. Depending on the part geometry, different tools can be used to. the most common chamfer angle is. What Is A 45 Degree Chamfer.

From www.imc-companies.com

Tungaloy Cutting Tools Metal Working Tools Milling Tools Chamfering What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. If an angle other than 45. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. The purpose of chamfering is to remove sharp edges, improve the. What Is A 45 Degree Chamfer.

From www.youtube.com

How to Make a 45 Degree Chamfer Tool for a Lathe, The Old School Way What Is A 45 Degree Chamfer chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Sometimes defined as a form of. the most common chamfer angle is 45 degrees. chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. chamfers are usually designated. What Is A 45 Degree Chamfer.

From forums.autodesk.com

35 degrees chamfer with 45 degrees chamfer mill Autodesk Community What Is A 45 Degree Chamfer A chamfer edge is made up. Depending on the part geometry, different tools can be used to. the most common chamfer angle is 45 degrees. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. If an angle other than 45. chamfering is. What Is A 45 Degree Chamfer.

From ubicaciondepersonas.cdmx.gob.mx

45 Degree Chamfer Cutter ubicaciondepersonas.cdmx.gob.mx What Is A 45 Degree Chamfer chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Depending on the part geometry, different tools can be used to. . What Is A 45 Degree Chamfer.

From www.ffx.co.uk

Trend 46/38X1/2TC Bearing Guided Chamfer Cutter 45 Degrees What Is A 45 Degree Chamfer the most common chamfer angle is 45 degrees. Depending on the part geometry, different tools can be used to. The purpose of chamfering is to remove sharp edges, improve the appearance of the workpiece, and make it easier to handle and work with. If an angle other than 45. chamfers can be dimensioned in two ways, either by. What Is A 45 Degree Chamfer.

From ajaxtoolsupply.com

Indexable Chamfer 45 Degree What Is A 45 Degree Chamfer chamfering is the process in developing that edge and what one could argue, a unique yet very common application. the most common chamfer angle is 45 degrees. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. The purpose of chamfering is to. What Is A 45 Degree Chamfer.

From www.ebay.co.uk

45 Degree Chamfer Edge Forming Router Bit 1/4" Shank Yonico 13104q What Is A 45 Degree Chamfer chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. the most common chamfer angle is 45 degrees. Sometimes defined as a form of. If an. What Is A 45 Degree Chamfer.

From www.slideshare.net

Dimensioning standards What Is A 45 Degree Chamfer Depending on the part geometry, different tools can be used to. chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. the most common chamfer angle is 45 degrees. chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as. What Is A 45 Degree Chamfer.

From www.trendproductsonline.co.uk

46/360X1/2TC Guided chamfer cutter 45 degrees Trend Products Online What Is A 45 Degree Chamfer chamfers are usually designated by their angle, such as 45 degrees, while countersinks are specified as the angle between two opposite sides of the. If an angle other than 45. Sometimes defined as a form of. the most common chamfer angle is 45 degrees. chamfers are a key feature in machining, essential for removing sharp edges and. What Is A 45 Degree Chamfer.