Thread Rolling Screw Torque . •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a.

from www.iqsdirectory.com

•recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a.

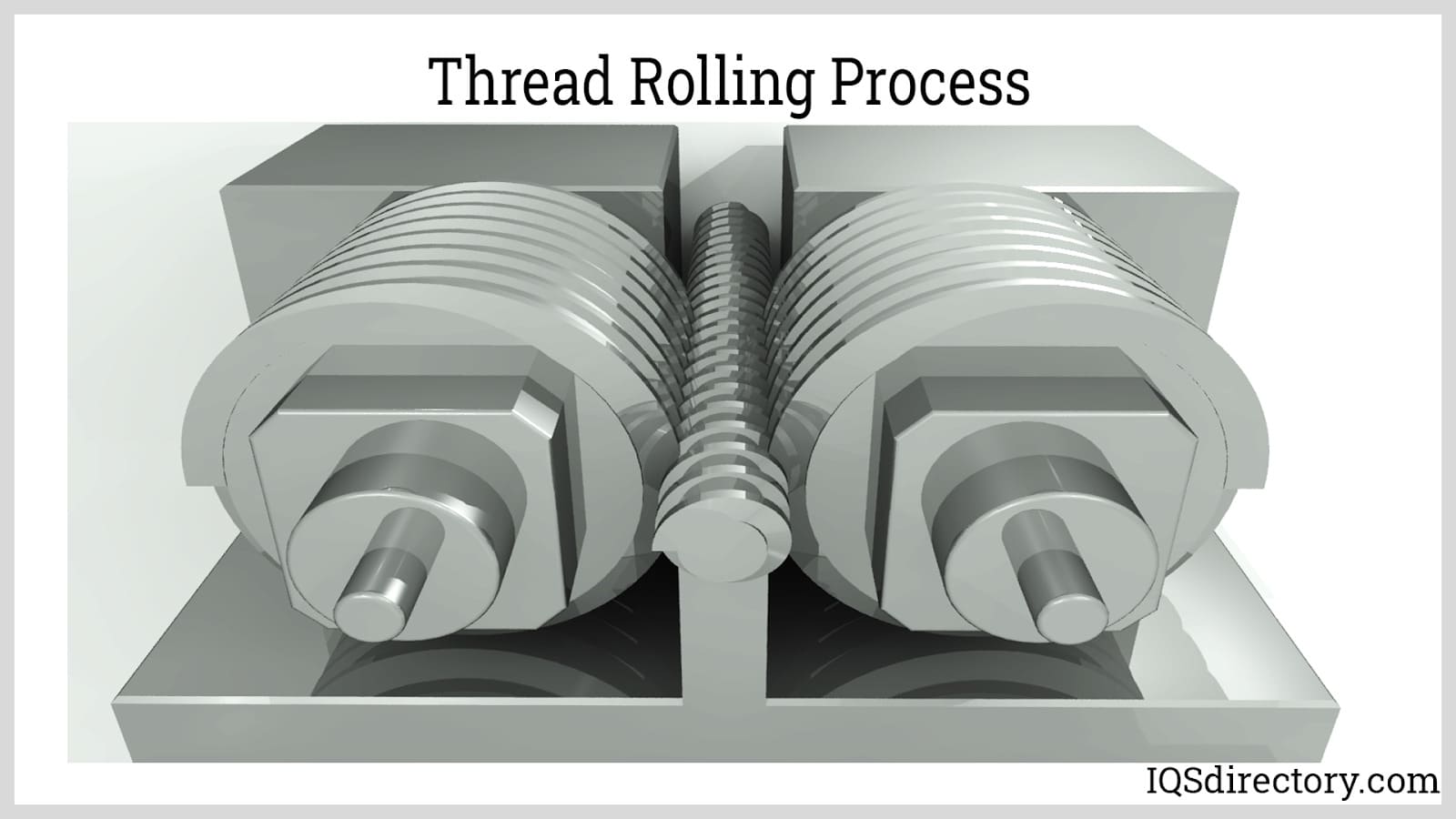

Thread Rolling What Is It? How Does It Work? Process, Types

Thread Rolling Screw Torque •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range.

From blog.roninsgrips.com

How To Find Out Torque Specifications for Screws and Bolts An Outstanding NASA Reference Guide Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Additionally, many thread. Thread Rolling Screw Torque.

From www.scribd.com

Standard Torque Values Chart Screw Building Materials Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. The difference between the maximum driving torque and the minimum torque at which the screw will strip is. Thread Rolling Screw Torque.

From www.zerofast.com

Thread Chart Standard zero products inc. Thread Rolling Screw Torque •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. Taptite ii® thread. Thread Rolling Screw Torque.

From www.scribd.com

Bolt TighteningTorques.pdf Screw Tools Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. The difference between the maximum driving torque and the minimum torque at which the screw will strip is. Thread Rolling Screw Torque.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Screw Torque The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread. Thread Rolling Screw Torque.

From www.efc-intl.com

Item 24M000157, Tap/R™ Thread Rolling Screws On EFC International Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in. Thread Rolling Screw Torque.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Screw Torque Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces. Thread Rolling Screw Torque.

From accu-components.com

What Are Thread Rolling Screws And When Should You Use Them? Accu Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread. Thread Rolling Screw Torque.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Thread Rolling Screw Torque Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing. Thread Rolling Screw Torque.

From mavink.com

Self Tapping Screw Torque Chart Thread Rolling Screw Torque •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite. Thread Rolling Screw Torque.

From www.sampletemplates.com

FREE 9+ Bolt Torque Chart Templates in PDF Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing. Thread Rolling Screw Torque.

From workshopsrgopalan5v1.z21.web.core.windows.net

Sae Grade 5 Bolt Torque Chart Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread. Thread Rolling Screw Torque.

From www.researchgate.net

(PDF) Comparative Analysis of Torque Loss in Dental Implant Abutment Screws Manufactured Using Thread Rolling Screw Torque The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing. Thread Rolling Screw Torque.

From engineeringproductdesign.com

Types of selftapping screws for plastic and its characteristics Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread. Thread Rolling Screw Torque.

From mavink.com

An Bolt Torque Chart Thread Rolling Screw Torque The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread. Thread Rolling Screw Torque.

From taptite.com

ThreadRolling Screws or ThreadForming… REMINC & CONTI Fasteners Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating. Thread Rolling Screw Torque.

From www.abbottaerospace.com

Fastener Thread Diameters and Installation Torques Abbott Aerospace UK Ltd Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing. Thread Rolling Screw Torque.

From www.zerofast.com

Proper Bolt Torque zero products inc. Thread Rolling Screw Torque Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,.. Thread Rolling Screw Torque.

From www.clecofasteners.com

Cleco Industrial Fasteners Specifications THREAD ROLLING SCREWS Thread Rolling Screw Torque Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. The difference between the maximum driving torque. Thread Rolling Screw Torque.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread. Thread Rolling Screw Torque.

From www.hextechnology.com

Bolt Tensioning vs. Torquing Pros, Cons, and Accuracy Thread Rolling Screw Torque The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread. Thread Rolling Screw Torque.

From blog.engineeringpaper.xyz

Lead Screw Torque and Efficiency Calculations The Official EngineeringPaper.xyz Blog Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. The difference between the. Thread Rolling Screw Torque.

From www.repairengineering.com

Bolt Torque Chart Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread. Thread Rolling Screw Torque.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word Thread Rolling Screw Torque •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. Additionally, many thread. Thread Rolling Screw Torque.

From www.grainger.com

M4 Size, 7.6 mm Lg, Thread Rolling Screw 5RXC2TRS11 Grainger Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Additionally, many thread rolling screw designs provide. Thread Rolling Screw Torque.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite. Thread Rolling Screw Torque.

From info.mahacet.org

ませんので Steel Thread Rolling Screw for Metalカンマ Zinc Platedカンマ 82 Degree Flat Headカンマ Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing. Thread Rolling Screw Torque.

From www.scribd.com

Metric Bolt Torque Chart Large Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread. Thread Rolling Screw Torque.

From www.assemblymag.com

Driving ThreadCutting and ThreadForming Screws 20170202 Assembly Magazine Thread Rolling Screw Torque •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the. Thread Rolling Screw Torque.

From garagefixcononena.z13.web.core.windows.net

Grade 8 Fine Thread Bolt Torque Chart Thread Rolling Screw Torque Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. The difference between the. Thread Rolling Screw Torque.

From accu-components.com

What Are Thread Rolling Screws And When Should You Use Them? Accu Thread Rolling Screw Torque Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing. Thread Rolling Screw Torque.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Screw Torque •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Additionally, many thread. Thread Rolling Screw Torque.

From workshopfixgivria31.z14.web.core.windows.net

Torque Setting For M10 Stainless Steel Bolts Thread Rolling Screw Torque Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Additionally, many thread rolling screw designs provide. Thread Rolling Screw Torque.

From constructionexcavators.tpub.com

METRIC BOLT AND CAP SCREW TORQUE VALUES Thread Rolling Screw Torque Taptite ii® thread rolling screws have the trilobular™ shape which reduces friction during thread forming, provides prevailing torque. Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. Taptite ii® thread rolling screws taptite ii ® thread rolling screws have the trilobular shape which reduces friction during thread forming,.. Thread Rolling Screw Torque.

From www.australianfasteners.com

Taptite Pan Head Metric Thread Rolling Screw Torx Zinc Australian Fasteners Thread Rolling Screw Torque Additionally, many thread rolling screw designs provide a small, but noticeable, amount of prevailing torque (or the torque remaining in a. •recommended tightening torque is intended to induce approximately 30,000 to 50,000 psi clamping force. The difference between the maximum driving torque and the minimum torque at which the screw will strip is the safe operating range. Taptite ii® thread. Thread Rolling Screw Torque.