Countersink Example . Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. These holes are conical in shape and. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. Countersunk holes are used for applications where a countersunk bolt or screw is required. A countersink consists of a conical hole that is coaxial to a. To countersink in wood, use. But do you know that the countersink angle you choose can impact the strength and stability of the joint?

from www.theengineeringknowledge.com

In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Countersunk holes are used for applications where a countersunk bolt or screw is required. To countersink in wood, use. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. A countersink consists of a conical hole that is coaxial to a. These holes are conical in shape and. But do you know that the countersink angle you choose can impact the strength and stability of the joint?

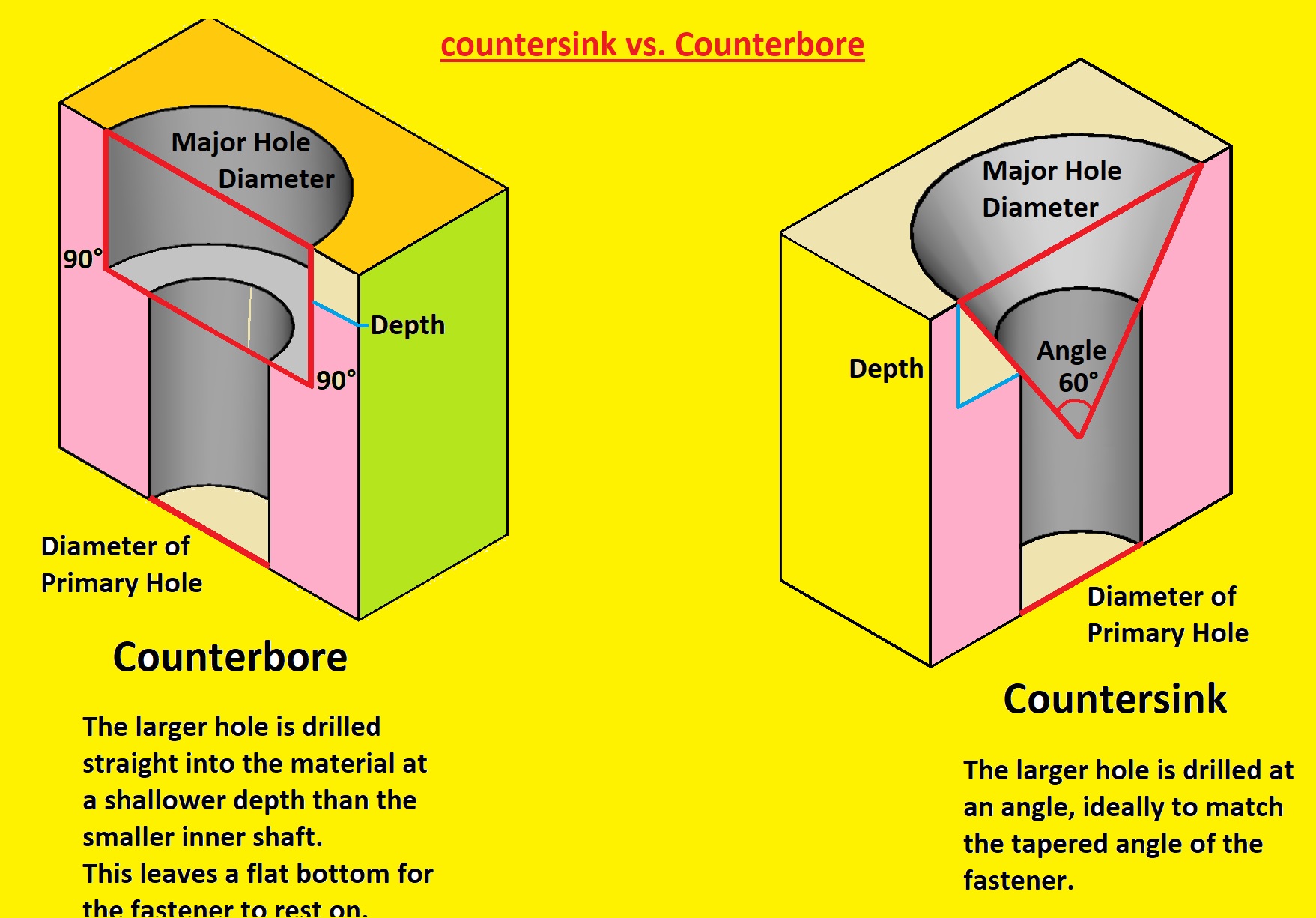

What is Countersink vs. Counterbore Holes in Machining The

Countersink Example Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. A countersink consists of a conical hole that is coaxial to a. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. To countersink in wood, use. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Countersunk holes are used for applications where a countersunk bolt or screw is required. But do you know that the countersink angle you choose can impact the strength and stability of the joint? These holes are conical in shape and. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or.

From www.youtube.com

🔩 How To Make Countersink And Counterbore Holes FreeCAD Hole Tutorial Countersink Example A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersunk holes are used for applications where a countersunk bolt or screw is required. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. These holes are conical in shape. Countersink Example.

From www.clevelandsteeltool.com

Countersink Tools Cleveland Steel Tool Countersink Example This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. The purpose of a countersink is to allow a fastener, typically. Countersink Example.

From www.wisc-online.com

Counterbore Example OER Countersink Example This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. These holes are conical in shape and. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. The purpose of a. Countersink Example.

From forums.autodesk.com

Countersink Diameter for Flat Head Screws too Small Autodesk Community Countersink Example To countersink in wood, use. A countersink consists of a conical hole that is coaxial to a. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. Countersunk holes are used for applications where a countersunk bolt or screw is required. These holes are conical in shape and. But do you know that the countersink angle. Countersink Example.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Example In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. These holes are conical in shape and. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. But do you know. Countersink Example.

From www.youtube.com

PLTW IED 5.5 Countersink in Fusion 360 YouTube Countersink Example Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. But do you know that the countersink angle you choose can impact the strength and stability of the joint? A countersink consists of a conical hole that is coaxial to a. A countersink is an angled taper applied to a hole that allows a fastener (usually. Countersink Example.

From www.mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Countersink Example Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. These holes are conical in shape and. To. Countersink Example.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Countersink Example In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with,. Countersink Example.

From cecztgns.blob.core.windows.net

Counterbore Solidworks at William Preciado blog Countersink Example The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. This article will explore what countersink holes are, their uses, and. Countersink Example.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Countersink Example The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. To countersink in wood, use. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. A countersink consists of a conical hole that is coaxial to a. Countersunk holes are used for applications. Countersink Example.

From mathscinotes.com

Measuring Countersink Angle Using Gage Balls Math Encounters Blog Countersink Example But do you know that the countersink angle you choose can impact the strength and stability of the joint? The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. These holes are conical in shape and. A countersink consists of a conical hole that is coaxial to. Countersink Example.

From www.wonkeedonkeetools.co.uk

Screw glossary Countersink Example A countersink consists of a conical hole that is coaxial to a. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in. Countersink Example.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Example The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. But do you know that the countersink angle you choose can impact the strength and stability of the joint? Countersunk holes are used for applications where a countersunk bolt or screw is required. To countersink in wood,. Countersink Example.

From www.youtube.com

Countersink and Counterbore YouTube Countersink Example Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. To countersink in wood, use. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersunk holes are. Countersink Example.

From www.gdandtbasics.com

Countersink GD&T Basics Countersink Example A countersink consists of a conical hole that is coaxial to a. To countersink in wood, use. But do you know that the countersink angle you choose can impact the strength and stability of the joint? A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even. Countersink Example.

From joigdeluq.blob.core.windows.net

Countersink Diameter For M4 at Richard Durham blog Countersink Example The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. But do you know that the countersink angle you choose can impact the strength. Countersink Example.

From mechheart.com

What is a Countersunk Screw? MECHHEART Countersink Example These holes are conical in shape and. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. A countersink consists of a conical hole that is coaxial to a. To countersink in wood, use. But do you know that the countersink angle you choose can impact the strength and stability of the joint? The purpose of a countersink. Countersink Example.

From www.youtube.com

What are Counterbore and Countersink? PCB Knowledge YouTube Countersink Example But do you know that the countersink angle you choose can impact the strength and stability of the joint? This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below. Countersink Example.

From www.youtube.com

How to Make Countersink Holes in SolidWorks using Hole Wizard Command Countersink Example A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. To countersink in wood, use. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. These holes are. Countersink Example.

From www.cartertools.com

5 Doing it — Countersinking 1 documentation Countersink Example Countersunk holes are used for applications where a countersunk bolt or screw is required. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. These holes are conical in shape and. A countersink consists of a conical hole that is coaxial to a. But do you know. Countersink Example.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Countersink Example A countersink consists of a conical hole that is coaxial to a. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Countersunk holes are used for applications where a countersunk bolt or screw is required. Like counterbore holes, countersink holes ensure the bolt or screw sit. Countersink Example.

From www.mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Countersink Example The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. These holes are conical in shape and. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. A countersink is an angled taper applied. Countersink Example.

From exywuesdi.blob.core.windows.net

Countersunk Screw Sizes Metric at Betty Dixon blog Countersink Example A countersink consists of a conical hole that is coaxial to a. But do you know that the countersink angle you choose can impact the strength and stability of the joint? This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. These holes are conical in shape. Countersink Example.

From klanninay.blob.core.windows.net

Countersink Symbol Autocad at Kevin Owens blog Countersink Example Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. A countersink consists of a conical hole that is coaxial to a. But do you know that the countersink angle you choose can impact the strength and stability of the joint? The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersink Example.

From www.wisc-online.com

Countersink Example OER Countersink Example This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. These holes are conical in shape and. But do you know that the countersink angle you choose can impact the strength and stability of the. Countersink Example.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Example A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. A countersink consists of a conical hole that is coaxial to a. But do you know that the countersink angle you choose can impact the strength and stability of the joint? Like counterbore holes,. Countersink Example.

From exofsrxty.blob.core.windows.net

Countersunk Hole For M12 at Jeanne Moore blog Countersink Example Countersunk holes are used for applications where a countersunk bolt or screw is required. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. But do you know that the countersink angle you choose can impact the strength and stability of the joint? These holes are conical in shape and. A countersink is an angled taper. Countersink Example.

From www.madearia.com

Spotface Vs. Counterbore in Machining Parts Countersink Example A countersink consists of a conical hole that is coaxial to a. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Countersunk holes. Countersink Example.

From www.gdandtbasics.com

Countersink GD&T Basics Countersink Example These holes are conical in shape and. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. But do you know that the countersink angle you choose can impact the strength and stability of the joint? To countersink in wood, use. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersink Example.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam Countersink Example These holes are conical in shape and. To countersink in wood, use. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. A countersink consists of a conical hole that is coaxial to a. Countersunk. Countersink Example.

From www.finepowertools.com

Counterbore vs Countersink. Differences, Strength & Uses Countersink Example Countersunk holes are used for applications where a countersunk bolt or screw is required. These holes are conical in shape and. To countersink in wood, use. A countersink consists of a conical hole that is coaxial to a. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. This article will explore what countersink holes are, their uses,. Countersink Example.

From www.differencebetween.net

Difference Between Counterbore and Countersink Difference Between Countersink Example But do you know that the countersink angle you choose can impact the strength and stability of the joint? To countersink in wood, use. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Like. Countersink Example.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersink Example The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. This article will explore what countersink holes are, their uses, and how to apply ansi standards to create precise, flush finishes in manufacturing. But do you know that the countersink angle you choose can impact the strength. Countersink Example.

From www.wikihow.com

How to Countersink 13 Steps (with Pictures) wikiHow Countersink Example A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. But do you know that the countersink angle you choose can impact the strength and stability of the joint? A countersink consists. Countersink Example.

From unipunch.com

Countersinking Solutions for Metal Fabrication UniPunch Countersink Example In woodworking, countersinking is essential for achieving flush and aesthetically pleasing surfaces. Like counterbore holes, countersink holes ensure the bolt or screw sit below the surface. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. A countersink consists of a conical hole that. Countersink Example.