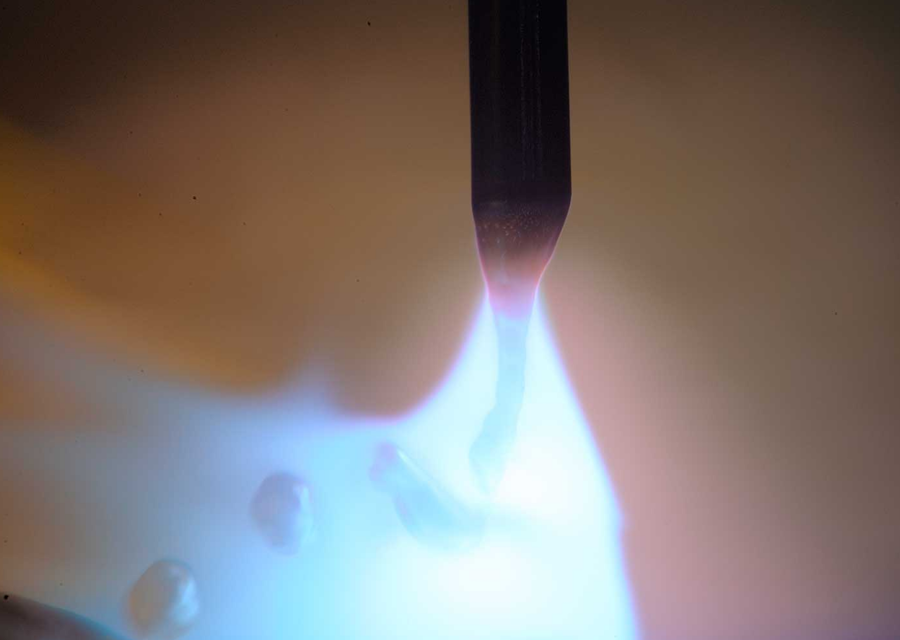

Undercut In Arc Welding . undercut in tig welding is caused by an improper weld bead width, an incorrect welding current setting, or welding in the wrong direction. It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away your base material. One reason is an amperage/voltage problem. The size and shape of the undercut depend on the welding speed, electrode size, and current. This excess heat takes away the material at the edges of the weld. This leaves a depression or groove shape along with the weld metal. undercut in welding refers to the groove melted into the base metal near the toe of the weld. what is undercut in welding? It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or a depression in the edge of the completed weld. undercut welding defects are caused when the welding arc moves faster than the weld metal can solidify. It refers to the depression or groove formed in the base metal part along the weld foot. It's a deviation from the desired weld profile and can. an undercut is a common welding defect that refers to the groove or depression along the edge of the weld,.

from houseandbeyond.org

It's a deviation from the desired weld profile and can. an undercut is a common welding defect that refers to the groove or depression along the edge of the weld,. This leaves a depression or groove shape along with the weld metal. undercut welding defects are caused when the welding arc moves faster than the weld metal can solidify. Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or a depression in the edge of the completed weld. If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away your base material. The size and shape of the undercut depend on the welding speed, electrode size, and current. It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. undercut in welding refers to the groove melted into the base metal near the toe of the weld. what is undercut in welding?

Welding Undercut Everything You Need to Know (Winter 2024)

Undercut In Arc Welding undercut welding defects are caused when the welding arc moves faster than the weld metal can solidify. undercut in tig welding is caused by an improper weld bead width, an incorrect welding current setting, or welding in the wrong direction. undercut is caused by several issues. undercut welding defects are caused when the welding arc moves faster than the weld metal can solidify. welding undercut is one of the most common defects encountered by welders. It refers to the depression or groove formed in the base metal part along the weld foot. Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or a depression in the edge of the completed weld. It's a deviation from the desired weld profile and can. If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away your base material. what is undercut in welding? It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. The size and shape of the undercut depend on the welding speed, electrode size, and current. This leaves a depression or groove shape along with the weld metal. It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. undercut in welding refers to the groove melted into the base metal near the toe of the weld. This excess heat takes away the material at the edges of the weld.

From materialwelding.com

Welding Undercut Causes & Remedies Tips You Must Know Undercut In Arc Welding undercut is caused by several issues. undercut in tig welding is caused by an improper weld bead width, an incorrect welding current setting, or welding in the wrong direction. It's a deviation from the desired weld profile and can. an undercut is a common welding defect that refers to the groove or depression along the edge of. Undercut In Arc Welding.

From weldingpros.net

Welding Terminology Basic Terms In Welding Trade Undercut In Arc Welding If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away your base material. It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. welding undercut is one of the most. Undercut In Arc Welding.

From www.arc-zone.com

What Is Undercut in Welding? Inc Undercut In Arc Welding It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. what is undercut in welding? undercut in welding refers to the groove melted into the base metal near the toe of the weld. welding undercut is one of the. Undercut In Arc Welding.

From blacksmithingart.com

What Is An Undercut In Welding? 5 Causes And How To Avoid It Undercut In Arc Welding It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. The size and shape of the undercut depend on the welding speed, electrode size, and current. This excess heat takes away the material at the edges of the weld. If your amperage is too high with stick and tig welding, the. Undercut In Arc Welding.

From allaboutweldingjobs.com

Undercut In Welding Top 5 Tips & Best Helpful Guide Types Undercut In Arc Welding Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or a depression in the edge of the completed weld. It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. This excess heat. Undercut In Arc Welding.

From www.mig-welding.co.uk

Arc (MMA) Welding Fillet Joints Undercut In Arc Welding what is undercut in welding? The size and shape of the undercut depend on the welding speed, electrode size, and current. an undercut is a common welding defect that refers to the groove or depression along the edge of the weld,. This leaves a depression or groove shape along with the weld metal. undercut in welding refers. Undercut In Arc Welding.

From welderplanet.com

How To Avoid Undercut In MIG Welding? Welder Undercut In Arc Welding One reason is an amperage/voltage problem. If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away your base material. It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. It's a. Undercut In Arc Welding.

From www.researchgate.net

(a) Cross section of typical undercut in a fiber laser/arc hybrid weld Undercut In Arc Welding It refers to the depression or groove formed in the base metal part along the weld foot. undercut is caused by several issues. It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. This leaves a depression or groove shape along. Undercut In Arc Welding.

From weldingtroop.com

How to Prevent Undercut in Stick Welding 12 Golden Tips Undercut In Arc Welding It's a deviation from the desired weld profile and can. Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or a depression in the edge of the completed weld. The size and shape of the undercut depend on the welding speed,. Undercut In Arc Welding.

From blacksmithingart.com

What Is An Undercut In Welding? 5 Causes And How To Avoid It Undercut In Arc Welding Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or a depression in the edge of the completed weld. welding undercut is one of the most common defects encountered by welders. undercut in tig welding is caused by an. Undercut In Arc Welding.

From waterwelders.com

What is Undercut in Welding (Causes & Possible Remedies) WaterWelders Undercut In Arc Welding This excess heat takes away the material at the edges of the weld. undercut in welding refers to the groove melted into the base metal near the toe of the weld. One reason is an amperage/voltage problem. undercut is caused by several issues. It can also be caused by an incorrect arc length, inadequate joint preparation, or an. Undercut In Arc Welding.

From allaboutweldingjobs.com

Undercut In Welding Top 5 Tips & Best Helpful Guide Types Undercut In Arc Welding what is undercut in welding? This leaves a depression or groove shape along with the weld metal. undercut is caused by several issues. One reason is an amperage/voltage problem. Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or. Undercut In Arc Welding.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Undercut In Arc Welding The size and shape of the undercut depend on the welding speed, electrode size, and current. It's a deviation from the desired weld profile and can. One reason is an amperage/voltage problem. what is undercut in welding? Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable. Undercut In Arc Welding.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Undercut In Arc Welding undercut in welding refers to the groove melted into the base metal near the toe of the weld. This leaves a depression or groove shape along with the weld metal. what is undercut in welding? The size and shape of the undercut depend on the welding speed, electrode size, and current. Welding undercut is a weld discontinuity that. Undercut In Arc Welding.

From welderstream.com

What is Undercutting in Welding? WelderStream Undercut In Arc Welding This excess heat takes away the material at the edges of the weld. undercut welding defects are caused when the welding arc moves faster than the weld metal can solidify. Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or. Undercut In Arc Welding.

From weldingclarity.com

What is Undercut in Welding, Causes and How to Avoid Them Undercut In Arc Welding undercut in welding refers to the groove melted into the base metal near the toe of the weld. It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. undercut in tig welding is caused by an improper weld bead width, an incorrect welding current setting, or welding in the. Undercut In Arc Welding.

From mavink.com

Fillet Weld Undercut Undercut In Arc Welding undercut is caused by several issues. This leaves a depression or groove shape along with the weld metal. welding undercut is one of the most common defects encountered by welders. undercut welding defects are caused when the welding arc moves faster than the weld metal can solidify. This excess heat takes away the material at the edges. Undercut In Arc Welding.

From yenaengineering.nl

What is Undercut? How To Avoid Undercut Defect in Welding? YENA Undercut In Arc Welding undercut is caused by several issues. It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. It refers to the depression or groove formed in the base metal part along the weld foot. undercut welding defects are caused when the welding arc moves faster than the weld metal can. Undercut In Arc Welding.

From gambrick.com

What Is Undercut In Welding? Undercut In Arc Welding It refers to the depression or groove formed in the base metal part along the weld foot. undercut is caused by several issues. It's a deviation from the desired weld profile and can. This excess heat takes away the material at the edges of the weld. Welding undercut is a weld discontinuity that occurs when the base metal has. Undercut In Arc Welding.

From weldguru.com

Undercut in Welding Causes & Prevention Weld Guru Undercut In Arc Welding It's a deviation from the desired weld profile and can. welding undercut is one of the most common defects encountered by welders. It refers to the depression or groove formed in the base metal part along the weld foot. This excess heat takes away the material at the edges of the weld. undercut in welding refers to the. Undercut In Arc Welding.

From allaboutweldingjobs.com

Undercut In Welding Top 5 Tips & Best Helpful Guide Types Undercut In Arc Welding undercut is caused by several issues. If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away your base material. what is undercut in welding? One reason is an amperage/voltage problem. welding undercut is one of the most common defects encountered by welders. undercut in welding. Undercut In Arc Welding.

From slidingmotion.com

What is undercut in welding? Types Causes slidingmotion Undercut In Arc Welding an undercut is a common welding defect that refers to the groove or depression along the edge of the weld,. It's a deviation from the desired weld profile and can. what is undercut in welding? One reason is an amperage/voltage problem. It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten. Undercut In Arc Welding.

From www.researchgate.net

(a) Cross section of typical undercut in a fiber laser/arc hybrid weld Undercut In Arc Welding One reason is an amperage/voltage problem. This leaves a depression or groove shape along with the weld metal. welding undercut is one of the most common defects encountered by welders. This excess heat takes away the material at the edges of the weld. what is undercut in welding? It is the space left by the arc that is. Undercut In Arc Welding.

From houseandbeyond.org

Welding Undercut Everything You Need to Know (Winter 2024) Undercut In Arc Welding It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. It refers to the depression or groove formed in the base metal part along the weld foot. undercut is caused by several issues. This leaves a depression or groove shape along with the weld metal. This excess heat takes away. Undercut In Arc Welding.

From weldingofwelders.com

Undercut in Welding Welding of Welders Undercut In Arc Welding undercut is caused by several issues. It's a deviation from the desired weld profile and can. welding undercut is one of the most common defects encountered by welders. Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or a. Undercut In Arc Welding.

From www.arc-zone.com

What Is Undercut in Welding? Inc Undercut In Arc Welding It refers to the depression or groove formed in the base metal part along the weld foot. It can also be caused by an incorrect arc length, inadequate joint preparation, or an incorrect tungsten electrode size. If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away your base material.. Undercut In Arc Welding.

From waterwelders.com

What is Undercut in Welding (Causes & Possible Remedies) WaterWelders Undercut In Arc Welding undercut in tig welding is caused by an improper weld bead width, an incorrect welding current setting, or welding in the wrong direction. an undercut is a common welding defect that refers to the groove or depression along the edge of the weld,. what is undercut in welding? This leaves a depression or groove shape along with. Undercut In Arc Welding.

From houseandbeyond.org

Welding Undercut Everything You Need to Know (Winter 2024) Undercut In Arc Welding undercut in welding refers to the groove melted into the base metal near the toe of the weld. Welding undercut is a weld discontinuity that occurs when the base metal has not been adequately filled back in from the applicable welding process and leaves a groove or a depression in the edge of the completed weld. The size and. Undercut In Arc Welding.

From www.mig-welding.co.uk

Arc (MMA) Welding Fillet Joints Undercut In Arc Welding undercut welding defects are caused when the welding arc moves faster than the weld metal can solidify. If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away your base material. undercut is caused by several issues. This excess heat takes away the material at the edges of. Undercut In Arc Welding.

From welderstream.com

What is Undercutting in Welding? WelderStream Undercut In Arc Welding It refers to the depression or groove formed in the base metal part along the weld foot. It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. an undercut is a common welding defect that refers to the groove or depression. Undercut In Arc Welding.

From weldersmanual.com

Welding Undercut What Is It? And How to Avoid It! Welders Manual Undercut In Arc Welding This leaves a depression or groove shape along with the weld metal. It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. undercut is caused by several issues. It's a deviation from the desired weld profile and can. an undercut. Undercut In Arc Welding.

From www.youtube.com

Undercut on welds what it is and how to avoid it YouTube Undercut In Arc Welding This excess heat takes away the material at the edges of the weld. It's a deviation from the desired weld profile and can. The size and shape of the undercut depend on the welding speed, electrode size, and current. If your amperage is too high with stick and tig welding, the welding arc is too hot and it burns away. Undercut In Arc Welding.

From allaboutweldingjobs.com

Undercut In Welding Top 5 Tips & Best Helpful Guide Types Undercut In Arc Welding what is undercut in welding? It refers to the depression or groove formed in the base metal part along the weld foot. undercut in tig welding is caused by an improper weld bead width, an incorrect welding current setting, or welding in the wrong direction. This leaves a depression or groove shape along with the weld metal. . Undercut In Arc Welding.

From blacksmithingart.com

What Is An Undercut In Welding? 5 Causes And How To Avoid It Undercut In Arc Welding undercut in welding refers to the groove melted into the base metal near the toe of the weld. One reason is an amperage/voltage problem. undercut welding defects are caused when the welding arc moves faster than the weld metal can solidify. The size and shape of the undercut depend on the welding speed, electrode size, and current. This. Undercut In Arc Welding.

From blacksmithingart.com

What Is An Undercut In Welding? 5 Causes And How To Avoid It Undercut In Arc Welding It refers to the depression or groove formed in the base metal part along the weld foot. It is the space left by the arc that is not fully completed by the metal deposited after the base metal melts at the edge of the weld. welding undercut is one of the most common defects encountered by welders. This excess. Undercut In Arc Welding.