Function Of Gearbox In Compressor . Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor.

from www.linkedin.com

The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor.

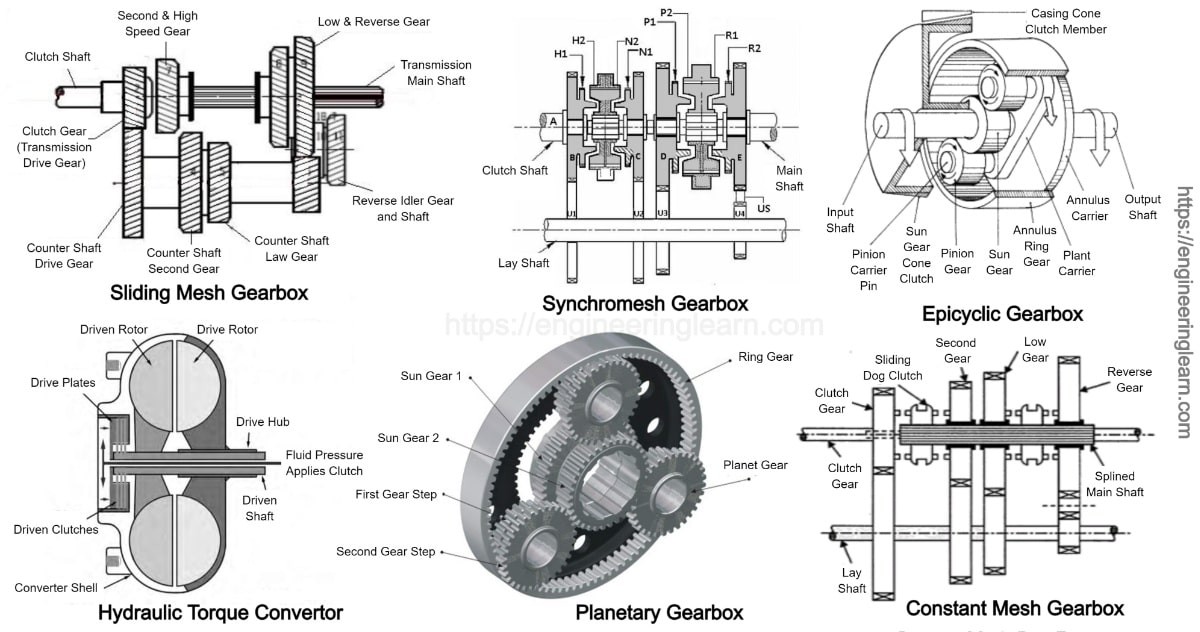

Types of Gearboxes and Their Applications

Function Of Gearbox In Compressor Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan.

From www.rasmech.com

Rotary Screw Air Compressor Basics Rasmussen Mechanical Function Of Gearbox In Compressor Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. A motor shaft is attached to one end. Function Of Gearbox In Compressor.

From www.sundyne.com

Sundyne LF 2X80 API 617 / ISO 10439 Base Mounted Integrally Geared Function Of Gearbox In Compressor A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. Gearboxes are devices for the transmission of movement (precisely torque. Function Of Gearbox In Compressor.

From www.bigrentz.com

How Air Compressors Work An Animated Guide BigRentz Function Of Gearbox In Compressor Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. The solution is to use a gearbox (rated between 16,000 and 32,000. Function Of Gearbox In Compressor.

From automationforum.co

Air compressor basics types & accessories Instrumentation and Function Of Gearbox In Compressor Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. A motor shaft is attached to one end of the gearbox and through the internal. Function Of Gearbox In Compressor.

From www.coursehero.com

Title Design of a gearbox for an Air Compressor Problem Details Function Of Gearbox In Compressor Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. Gearboxes are devices for the transmission of movement (precisely torque and speed) between two. Function Of Gearbox In Compressor.

From lubbil.com

6 Types of Gearbox The Ultimate Guide in 2021 Linquip (2024) Function Of Gearbox In Compressor The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. Gear units located next to the driver should be capable of continuously. Function Of Gearbox In Compressor.

From thepipingtalk.com

Centrifugal compressor parts & their function The piping talk Function Of Gearbox In Compressor Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. A motor shaft is attached to one end of the gearbox and. Function Of Gearbox In Compressor.

From mechanicalboost.com

Dynamic Compressor Working Principle, Types and Applications Function Of Gearbox In Compressor Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. The solution is to. Function Of Gearbox In Compressor.

From gas-turbines.weebly.com

Gear Boxes & Accessory Drives Function Of Gearbox In Compressor A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. Gearboxes are devices for the transmission of. Function Of Gearbox In Compressor.

From www.slideserve.com

PPT Compressors PowerPoint Presentation, free download ID6814077 Function Of Gearbox In Compressor The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. The solution is to use a gearbox (rated. Function Of Gearbox In Compressor.

From jetposting.com

What is a Dynamic Compressor? Jet Posting Function Of Gearbox In Compressor Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. A motor shaft is attached to one end of the gearbox and. Function Of Gearbox In Compressor.

From masptt.en.made-in-china.com

Gearbox of Two Stage Centrifugal Compressor Gear and Gearbox Function Of Gearbox In Compressor Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. Gear units located next to the driver should. Function Of Gearbox In Compressor.

From www.vrogue.co

How A Centrifugal Compressor Works vrogue.co Function Of Gearbox In Compressor The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gear units located next to the. Function Of Gearbox In Compressor.

From www.sundyne.com

How Do Centrifugal Compressors Work? Sundyne Function Of Gearbox In Compressor A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. In industry, gearboxes are used to transform the speeds and. Function Of Gearbox In Compressor.

From me-resetsg.blogspot.com

Mechanical Engineering Compressor Parts Function Of Gearbox In Compressor The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. In industry, gearboxes are used to transform the speeds and torques produced by the prime. Function Of Gearbox In Compressor.

From alemdaroglumakina.com

Functions and Parts of a Gear Box Alemdaroğlu Makina EN Alemdaroğlu Function Of Gearbox In Compressor Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a. Function Of Gearbox In Compressor.

From innovationdiscoveries.space

What are the Main Components of the Gear Box? Function Of Gearbox In Compressor In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. Gear units located next to the driver should be capable of continuously. Function Of Gearbox In Compressor.

From apadimaksud.com

Apa saja komponen di dalam gearbox beserta fungsinya? Function Of Gearbox In Compressor The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. A motor shaft is attached to one end of the gearbox and. Function Of Gearbox In Compressor.

From www.bigrentz.com

How Air Compressors Work An Animated Guide BigRentz Function Of Gearbox In Compressor The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. Gear units located next to the driver should be capable of. Function Of Gearbox In Compressor.

From www.youtube.com

Air Compressor Working Principle YouTube Function Of Gearbox In Compressor Gearboxes are devices for the transmission of movement (precisely torque and speed) between two shafts, those shafts can have axis parallel, perpendicular, or cross to each other. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. The gearbox is the. Function Of Gearbox In Compressor.

From www.youtube.com

3D animation of integrally geared centrifugal compressor YouTube Function Of Gearbox In Compressor In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. Gear units located next to the driver should be capable of continuously. Function Of Gearbox In Compressor.

From www.researchgate.net

(PDF) Numerical Simulations of Flow in Axial Compressor System Function Of Gearbox In Compressor The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. A motor shaft is attached to one end of the gearbox. Function Of Gearbox In Compressor.

From www.howacarworks.com

How manual gearboxes work How a Car Works Function Of Gearbox In Compressor The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. In industry, gearboxes are used to transform the speeds and torques produced by the. Function Of Gearbox In Compressor.

From www.linkedin.com

Types of Gearboxes and Their Applications Function Of Gearbox In Compressor In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gearboxes are devices for the transmission of. Function Of Gearbox In Compressor.

From diagramlibrarychapess.z13.web.core.windows.net

Diagram Of A Gearbox Function Of Gearbox In Compressor A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. In industry, gearboxes are used to transform the speeds and. Function Of Gearbox In Compressor.

From www.comsol.com

How to Model Gearbox Vibration and Noise in COMSOL Multiphysics Function Of Gearbox In Compressor A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. The solution is to use a gearbox. Function Of Gearbox In Compressor.

From www.linquip.com

Gearbox Components and Parts Everything You Need to Know Industrial Function Of Gearbox In Compressor A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. Gearboxes are devices for the transmission. Function Of Gearbox In Compressor.

From www.linquip.com

Gearbox Components and Parts Everything You Need to Know Industrial Function Of Gearbox In Compressor In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gear units located next to the driver. Function Of Gearbox In Compressor.

From www.mecholic.com

Centrifugal Compressor Parts and Its Function With PressureVelocity Function Of Gearbox In Compressor The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gear units located next to the driver. Function Of Gearbox In Compressor.

From compressedairducation.com

Compressed Air Compressedairducation Function Of Gearbox In Compressor The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. A motor shaft is attached to one end of the gearbox and. Function Of Gearbox In Compressor.

From mechreaders1.blogspot.com

Types of gearbox, Function,working Advantage or disadvantage Function Of Gearbox In Compressor A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. In industry, gearboxes are used to transform the speeds and. Function Of Gearbox In Compressor.

From www.pipingengineer.org

Reciprocating Compressors Introduction The Piping Engineering World Function Of Gearbox In Compressor Gear units located next to the driver should be capable of continuously transmitting the rated driver power, multiplied by an application. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. The solution is to use a gearbox (rated between 16,000. Function Of Gearbox In Compressor.

From www.lhevaporator.com

Centrifugal Turbo Compressor Gearbox Type Steam Turbo Compressor LH Function Of Gearbox In Compressor The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. Gearboxes are devices for the transmission of movement (precisely torque and. Function Of Gearbox In Compressor.

From electricalworkbook.com

What is Sliding Mesh Gearbox? Construction, Diagram & Working Function Of Gearbox In Compressor In industry, gearboxes are used to transform the speeds and torques produced by the prime mover to ensure they are appropriate to the machine. A motor shaft is attached to one end of the gearbox and through the internal gearbox configuration, empowers an output torque and the speed determined by the given ratio. Gear units located next to the driver. Function Of Gearbox In Compressor.

From www.youtube.com

What is gearbox? Functions of gearbox Applications of gearbox YouTube Function Of Gearbox In Compressor The gearbox is the process of transmitting energy in a mechanical engine to increase the output torque or to change the speed of a motor. The solution is to use a gearbox (rated between 16,000 and 32,000 hp with a ratio of 3:1) between the turbine and the fan. Gearboxes are devices for the transmission of movement (precisely torque and. Function Of Gearbox In Compressor.