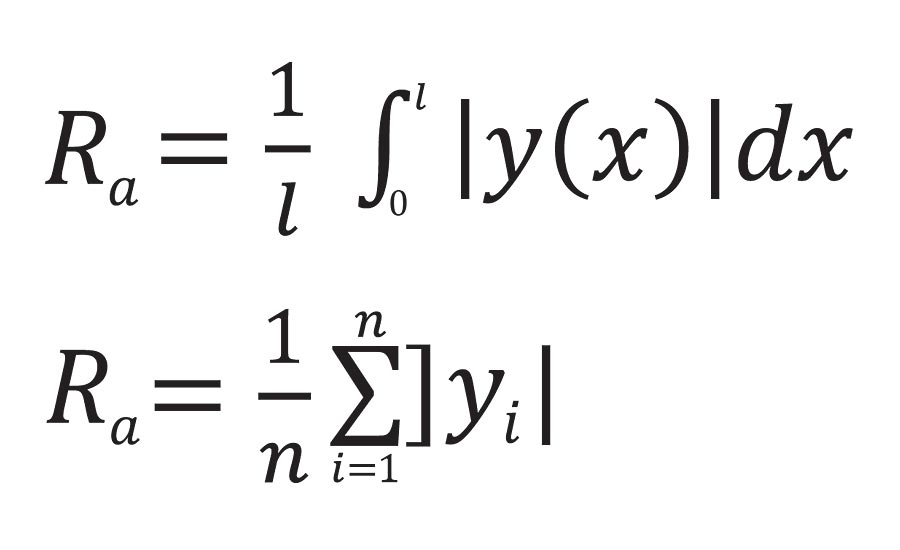

Surface Roughness Milling Formula . Here, “ra” represents the average roughness,. In addition to an overview of cutting tools, safety and precautions, information on calculation. Sr = (ra + rz) / 2. Root mean square (rms / rq / rs) can be calculated by: The measured profile is the profile resulting from scanning the. The formula for calculating surface roughness (sr) is: Surface roughness value, normally at right angles to the lay of the machining marks. This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. Detailed information on surface roughness. The ability of a manufacturing operation to produce a specific surface roughness depends on many. There are 3 main ways to acquire the surface roughness value:

from www.qualitymag.com

The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. The ability of a manufacturing operation to produce a specific surface roughness depends on many. In addition to an overview of cutting tools, safety and precautions, information on calculation. There are 3 main ways to acquire the surface roughness value: The measured profile is the profile resulting from scanning the. The formula for calculating surface roughness (sr) is: Root mean square (rms / rq / rs) can be calculated by: Detailed information on surface roughness. Here, “ra” represents the average roughness,.

How to Successfully Establish a Correlation between Contact and Optical

Surface Roughness Milling Formula This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. Detailed information on surface roughness. The formula for calculating surface roughness (sr) is: The measured profile is the profile resulting from scanning the. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. The ability of a manufacturing operation to produce a specific surface roughness depends on many. Sr = (ra + rz) / 2. Here, “ra” represents the average roughness,. There are 3 main ways to acquire the surface roughness value: In addition to an overview of cutting tools, safety and precautions, information on calculation. Surface roughness value, normally at right angles to the lay of the machining marks. Root mean square (rms / rq / rs) can be calculated by:

From www.qualitymag.com

How to Successfully Establish a Correlation between Contact and Optical Surface Roughness Milling Formula The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. The ability of a manufacturing operation to produce a specific surface roughness depends on many. Root mean square (rms / rq / rs) can be calculated by: Sr = (ra + rz) / 2. Surface roughness value, normally at right. Surface Roughness Milling Formula.

From moseys.com

Machining Surface Finish Chart & Specifications Moseys Production Surface Roughness Milling Formula The formula for calculating surface roughness (sr) is: The ability of a manufacturing operation to produce a specific surface roughness depends on many. Root mean square (rms / rq / rs) can be calculated by: This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard. Surface Roughness Milling Formula.

From www.myxxgirl.com

D Steel Surface Roughness Values Of Conventional Helical Milling My Surface Roughness Milling Formula The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. Detailed information on surface roughness. Here, “ra” represents the average roughness,. The formula for calculating surface roughness (sr) is: The measured profile is the profile resulting from scanning the. This resource will share ways to measure and compare surface roughness. Surface Roughness Milling Formula.

From www.manufacturingguide.com

Surface roughness Find suppliers, processes & material Surface Roughness Milling Formula Surface roughness value, normally at right angles to the lay of the machining marks. There are 3 main ways to acquire the surface roughness value: Detailed information on surface roughness. This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. Here, “ra” represents the. Surface Roughness Milling Formula.

From www.youtube.com

Surface Roughness Measurement 10 point Rz method YouTube Surface Roughness Milling Formula The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. Detailed information on surface roughness. Root mean square (rms / rq / rs) can. Surface Roughness Milling Formula.

From www.pcb-hero.com

How To Distinguish CNC machining Surface Roughness Between 6.3 And 0.8 Surface Roughness Milling Formula The formula for calculating surface roughness (sr) is: The measured profile is the profile resulting from scanning the. Surface roughness value, normally at right angles to the lay of the machining marks. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. There are 3 main ways to acquire the. Surface Roughness Milling Formula.

From www.researchgate.net

Surface roughness during helical milling for various cutting speeds and Surface Roughness Milling Formula The formula for calculating surface roughness (sr) is: In addition to an overview of cutting tools, safety and precautions, information on calculation. Here, “ra” represents the average roughness,. Root mean square (rms / rq / rs) can be calculated by: This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d. Surface Roughness Milling Formula.

From www.myxxgirl.com

Metric Surface Finish Symbols My XXX Hot Girl Surface Roughness Milling Formula Sr = (ra + rz) / 2. Here, “ra” represents the average roughness,. Detailed information on surface roughness. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. There are 3 main ways to acquire the surface roughness value: This resource will share ways to measure and compare surface roughness. Surface Roughness Milling Formula.

From www.myxxgirl.com

Surface Roughness Equation My XXX Hot Girl Surface Roughness Milling Formula The ability of a manufacturing operation to produce a specific surface roughness depends on many. Sr = (ra + rz) / 2. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. In addition to an overview of cutting tools, safety and precautions, information on calculation. Root mean square (rms. Surface Roughness Milling Formula.

From www.desertcart.ae

Buy Digital Surface Roughness Tester Meter Gauge LCD Display 4 Surface Roughness Milling Formula Here, “ra” represents the average roughness,. The formula for calculating surface roughness (sr) is: In addition to an overview of cutting tools, safety and precautions, information on calculation. The measured profile is the profile resulting from scanning the. The ability of a manufacturing operation to produce a specific surface roughness depends on many. Detailed information on surface roughness. The most. Surface Roughness Milling Formula.

From patagonik.cl

curve son Defeated casting surface finish chart Strait thong provide before Surface Roughness Milling Formula The formula for calculating surface roughness (sr) is: This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. Here, “ra” represents the average roughness,. Sr = (ra + rz) / 2. The measured profile is the profile resulting from scanning the. In addition to. Surface Roughness Milling Formula.

From www.edmundoptics.com

Understanding Surface Roughness Edmund Optics Surface Roughness Milling Formula Here, “ra” represents the average roughness,. In addition to an overview of cutting tools, safety and precautions, information on calculation. Root mean square (rms / rq / rs) can be calculated by: Surface roughness value, normally at right angles to the lay of the machining marks. The measured profile is the profile resulting from scanning the. This resource will share. Surface Roughness Milling Formula.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Surface Roughness Milling Formula This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. Detailed information on surface roughness. The measured profile is the profile resulting from scanning the. There are 3 main ways to acquire the surface roughness value: The most common method is to scan the. Surface Roughness Milling Formula.

From picclick.co.uk

MACHINING QUALITY CONTROL Surface Roughness Comparator Gauges Sample Surface Roughness Milling Formula Detailed information on surface roughness. Root mean square (rms / rq / rs) can be calculated by: Sr = (ra + rz) / 2. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. The measured profile is the profile resulting from scanning the. There are 3 main ways to. Surface Roughness Milling Formula.

From www.beaverdrillstore.com

Vertical Milling Surface Roughness Comparator 6 Specimens Beaver Surface Roughness Milling Formula There are 3 main ways to acquire the surface roughness value: Here, “ra” represents the average roughness,. The measured profile is the profile resulting from scanning the. Sr = (ra + rz) / 2. Detailed information on surface roughness. Surface roughness value, normally at right angles to the lay of the machining marks. This resource will share ways to measure. Surface Roughness Milling Formula.

From www.suginocorp.com

Surface Roughness for Lathe Turning Surface Roughness Milling Formula The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. The ability of a manufacturing operation to produce a specific surface roughness depends on many. Here, “ra” represents the average roughness,. There are 3 main ways to acquire the surface roughness value: Sr = (ra + rz) / 2. The. Surface Roughness Milling Formula.

From imagesee.biz

Machined Surface Roughness Charts For Kids IMAGESEE Surface Roughness Milling Formula Surface roughness value, normally at right angles to the lay of the machining marks. The measured profile is the profile resulting from scanning the. Root mean square (rms / rq / rs) can be calculated by: The ability of a manufacturing operation to produce a specific surface roughness depends on many. The formula for calculating surface roughness (sr) is: There. Surface Roughness Milling Formula.

From imagesee.biz

Surface Roughness Explained IMAGESEE Surface Roughness Milling Formula In addition to an overview of cutting tools, safety and precautions, information on calculation. Sr = (ra + rz) / 2. Here, “ra” represents the average roughness,. Surface roughness value, normally at right angles to the lay of the machining marks. The ability of a manufacturing operation to produce a specific surface roughness depends on many. Root mean square (rms. Surface Roughness Milling Formula.

From www.minaprem.com

Surface Roughness Formulas for Conventional Machining Surface Roughness Milling Formula This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. The measured profile is the profile resulting from scanning the. The formula for calculating surface roughness (sr) is: Surface roughness value, normally at right angles to the lay of the machining marks. Sr =. Surface Roughness Milling Formula.

From www.desertcart.in

Buy KOLWAY Combined 32 Block Surface Roughness Comparison Sample Surface Roughness Milling Formula The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. The measured profile is the profile resulting from scanning the. The formula for calculating surface roughness (sr) is: Sr = (ra + rz) / 2. Surface roughness value, normally at right angles to the lay of the machining marks. In. Surface Roughness Milling Formula.

From eureka.patsnap.com

Polarization correlation imaging scheme for detecting metal surface Surface Roughness Milling Formula Surface roughness value, normally at right angles to the lay of the machining marks. Here, “ra” represents the average roughness,. Root mean square (rms / rq / rs) can be calculated by: Sr = (ra + rz) / 2. The measured profile is the profile resulting from scanning the. The most common method is to scan the surface with a. Surface Roughness Milling Formula.

From www.pinterest.com

Surface Roughness Unit, Chart, and Measurement in 2021 Surface Surface Roughness Milling Formula Sr = (ra + rz) / 2. The measured profile is the profile resulting from scanning the. Surface roughness value, normally at right angles to the lay of the machining marks. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. This resource will share ways to measure and compare. Surface Roughness Milling Formula.

From www.researchgate.net

Surface roughness during drilling for various cutting speeds and feed Surface Roughness Milling Formula The formula for calculating surface roughness (sr) is: Sr = (ra + rz) / 2. This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. Detailed information on surface roughness. The most common method is to scan the surface with a needle that records. Surface Roughness Milling Formula.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Milling Formula The ability of a manufacturing operation to produce a specific surface roughness depends on many. There are 3 main ways to acquire the surface roughness value: The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. The measured profile is the profile resulting from scanning the. Root mean square (rms. Surface Roughness Milling Formula.

From www.semanticscholar.org

ANALYSIS OF SURFACE ROUGHNESS ON MACHINING OF AL5CU ALLOY IN CNC LATHE Surface Roughness Milling Formula Detailed information on surface roughness. Root mean square (rms / rq / rs) can be calculated by: In addition to an overview of cutting tools, safety and precautions, information on calculation. The formula for calculating surface roughness (sr) is: Here, “ra” represents the average roughness,. Surface roughness value, normally at right angles to the lay of the machining marks. The. Surface Roughness Milling Formula.

From www.suginocorp.com

Surface Roughness for Lathe Turning Surface Roughness Milling Formula Surface roughness value, normally at right angles to the lay of the machining marks. There are 3 main ways to acquire the surface roughness value: The measured profile is the profile resulting from scanning the. Detailed information on surface roughness. The formula for calculating surface roughness (sr) is: The most common method is to scan the surface with a needle. Surface Roughness Milling Formula.

From xometry.pro

Selecting Right Surface Roughness for CNC Machining Xometry Pro Surface Roughness Milling Formula The ability of a manufacturing operation to produce a specific surface roughness depends on many. Detailed information on surface roughness. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. The measured profile is the profile resulting from scanning the. Root mean square (rms / rq / rs) can be. Surface Roughness Milling Formula.

From www.empireabrasives.com

How Can You Reduce Surface Roughness when Milling Metal? Empire Abrasives Surface Roughness Milling Formula The ability of a manufacturing operation to produce a specific surface roughness depends on many. In addition to an overview of cutting tools, safety and precautions, information on calculation. Detailed information on surface roughness. The measured profile is the profile resulting from scanning the. The most common method is to scan the surface with a needle that records the micro. Surface Roughness Milling Formula.

From www.manufacturingguide.com

Surface finish when milling Find suppliers, processes & material Surface Roughness Milling Formula The measured profile is the profile resulting from scanning the. Root mean square (rms / rq / rs) can be calculated by: The formula for calculating surface roughness (sr) is: Detailed information on surface roughness. Surface roughness value, normally at right angles to the lay of the machining marks. Sr = (ra + rz) / 2. The most common method. Surface Roughness Milling Formula.

From www.aliexpress.com

Surface Roughness Milling Formula In addition to an overview of cutting tools, safety and precautions, information on calculation. The ability of a manufacturing operation to produce a specific surface roughness depends on many. Sr = (ra + rz) / 2. Root mean square (rms / rq / rs) can be calculated by: Detailed information on surface roughness. The measured profile is the profile resulting. Surface Roughness Milling Formula.

From xometry.com.tr

Selecting right surface roughness for CNC machining Xometry TR Surface Roughness Milling Formula Surface roughness value, normally at right angles to the lay of the machining marks. Sr = (ra + rz) / 2. The formula for calculating surface roughness (sr) is: Here, “ra” represents the average roughness,. Root mean square (rms / rq / rs) can be calculated by: The ability of a manufacturing operation to produce a specific surface roughness depends. Surface Roughness Milling Formula.

From picclick.co.uk

SURFACE ROUGHNESS COMPARISON Sample Block for Precision Machining Surface Roughness Milling Formula The ability of a manufacturing operation to produce a specific surface roughness depends on many. Sr = (ra + rz) / 2. The measured profile is the profile resulting from scanning the. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. Root mean square (rms / rq / rs). Surface Roughness Milling Formula.

From www.amazon.com

30PCS Roughness Test Block, Surface Roughness Comparison Surface Roughness Milling Formula Here, “ra” represents the average roughness,. The formula for calculating surface roughness (sr) is: Detailed information on surface roughness. The most common method is to scan the surface with a needle that records the micro “hills ” and “valleys”. There are 3 main ways to acquire the surface roughness value: This resource will share ways to measure and compare surface. Surface Roughness Milling Formula.

From gbu-taganskij.ru

Statistical Parameter Estimation Examples In SQL Server And, 57 OFF Surface Roughness Milling Formula This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. Here, “ra” represents the average roughness,. The measured profile is the profile resulting from scanning the. In addition to an overview of cutting tools, safety and precautions, information on calculation. The ability of a. Surface Roughness Milling Formula.

From www.dahometertester.com

KR210 Surface Roughness Tester, Surface Roughness Measuring Device Surface Roughness Milling Formula Root mean square (rms / rq / rs) can be calculated by: This resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface. The formula for calculating surface roughness (sr) is: The measured profile is the profile resulting from scanning the. In addition to an. Surface Roughness Milling Formula.