Emergency Stop Testing Procedure . ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. If you break the machine while testing the emergency stop system, count this as a failed test. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. After an individual activates it, the machinery must not be able to operate again until they reset the function. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system.

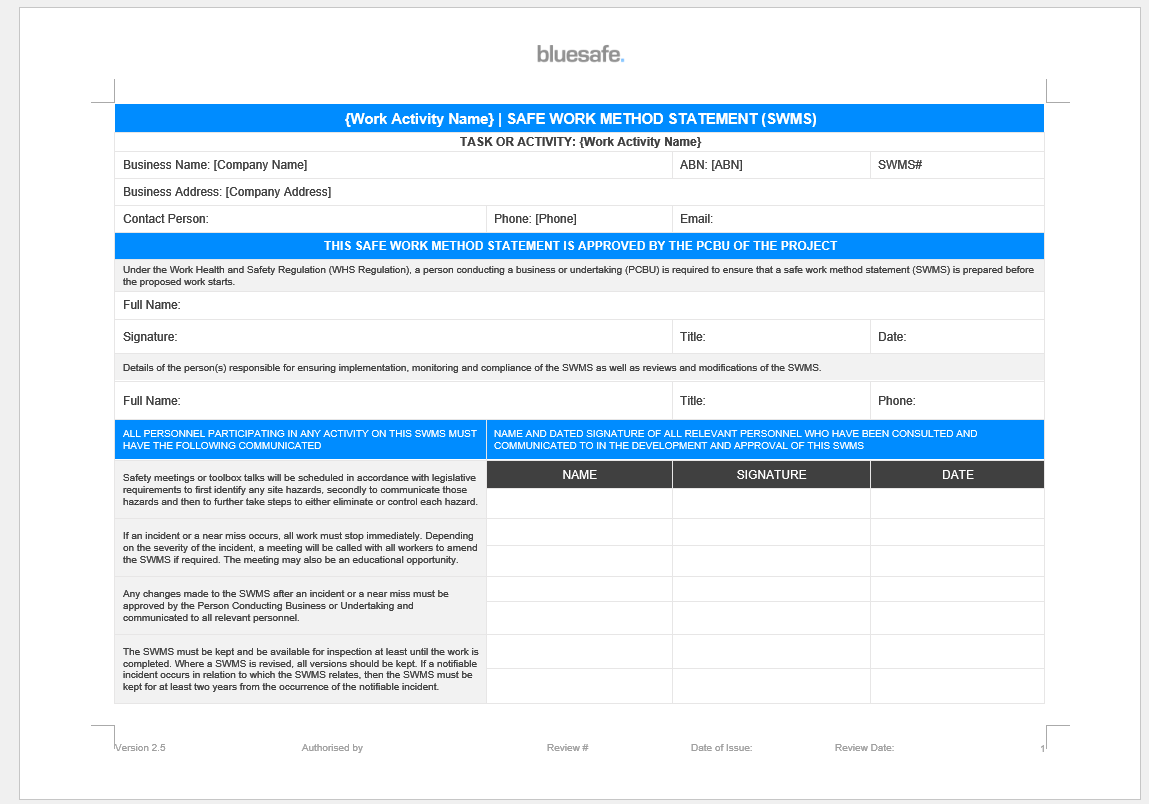

from bluesafe.net.au

If you break the machine while testing the emergency stop system, count this as a failed test. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. After an individual activates it, the machinery must not be able to operate again until they reset the function. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency.

Emergency Stop Testing Safe Work Method Statement (SWMS) Bluesafe.

Emergency Stop Testing Procedure Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. If you break the machine while testing the emergency stop system, count this as a failed test. After an individual activates it, the machinery must not be able to operate again until they reset the function.

From www.youtube.com

How To Do An Emergency Stop Driving Test 2021 YouTube Emergency Stop Testing Procedure It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. ‘emergency stop’ focuses on the procedure to quickly. Emergency Stop Testing Procedure.

From hsseworld.com

Photo of the day Chemical Spill Emergency Response HSSE WORLD Emergency Stop Testing Procedure Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial. Emergency Stop Testing Procedure.

From www.youtube.com

Emergency Stop Driving Lesson and ABS explained Pass your Driving Test Series YouTube Emergency Stop Testing Procedure Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. If you break the machine while testing the emergency stop system, count this as a failed test. The emergency stop function is activated by. Emergency Stop Testing Procedure.

From ehsdailyadvisor.blr.com

Infographic Drug Testing Procedures EHS Daily Advisor Emergency Stop Testing Procedure ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. After an individual activates it, the machinery must not be able. Emergency Stop Testing Procedure.

From bluesafe.net.au

Emergency Stop Testing Safe Work Method Statement (SWMS) Bluesafe. Emergency Stop Testing Procedure After an individual activates it, the machinery must not be able to operate again until they reset the function. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can. Emergency Stop Testing Procedure.

From constructandcommission.com

NFPA 79 & OSHA Emergency Stop Requirements With Checklist Emergency Stop Testing Procedure It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators. Emergency Stop Testing Procedure.

From www.youtube.com

Emergency Stop Driving Test Report Explained DTCUK Driving Test UK YouTube Emergency Stop Testing Procedure ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. If you break the machine while testing the emergency stop system, count this as a failed test. After an individual activates it, the machinery must not be able to operate again until they reset the function. The key. Emergency Stop Testing Procedure.

From elecdiags.com

How to Properly Wire an Emergency Stop Contactor A StepbyStep Diagram Guide Emergency Stop Testing Procedure The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. After an individual activates it, the machinery must not be able to operate again until they reset the function. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an. Emergency Stop Testing Procedure.

From motioncontrolsrobotics.com

Types of EStops and How to Use Them Motion Controls Robotics Certified FANUC System Integrator Emergency Stop Testing Procedure If you break the machine while testing the emergency stop system, count this as a failed test. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. After an individual activates it, the machinery must not be able to operate again until they reset the function. It is an easily accessible button or switch. Emergency Stop Testing Procedure.

From www.alamy.com

Button emergency stop on cnc machine tool Stock Photo Alamy Emergency Stop Testing Procedure The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or. Emergency Stop Testing Procedure.

From www.controldesign.com

What is an emergency stop? Control Design Emergency Stop Testing Procedure After an individual activates it, the machinery must not be able to operate again until they reset the function. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. If you break the machine while testing the emergency stop system, count this as a failed test. It is. Emergency Stop Testing Procedure.

From machinerysafety101.com

Checking Emergency Stop Systems Emergency Stop Testing Procedure The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. If you break the machine while testing the emergency stop system, count this as a. Emergency Stop Testing Procedure.

From nutronusa.com

Emergency Stop Control Labels for Corporate Safety Emergency Stop Testing Procedure If you break the machine while testing the emergency stop system, count this as a failed test. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. The key function of an emergency stop system is to provide the user with a backup to the. Emergency Stop Testing Procedure.

From constructandcommission.com

NFPA 79 & OSHA Emergency Stop Requirements With Checklist Emergency Stop Testing Procedure The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. Iso 13850 defines the emergency stop function requirements. Emergency Stop Testing Procedure.

From www.slideserve.com

PPT HAZWOPER First Responder PowerPoint Presentation, free download ID1789727 Emergency Stop Testing Procedure Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. If you break the machine while testing the emergency stop system, count this as a failed test. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. After an. Emergency Stop Testing Procedure.

From www.driving-lessons-kettering.co.uk

What Happens if You're Asked To Do an Emergency Stop In a Driving Test? Emergency Stop Testing Procedure After an individual activates it, the machinery must not be able to operate again until they reset the function. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. If you break the machine while testing the emergency stop system, count this as. Emergency Stop Testing Procedure.

From www.interestingreality.com

Emergency Stop Switches Ensuring Safety and Preventing Catastrophes Interesting Facts Emergency Stop Testing Procedure ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. After an individual activates it, the machinery must not be able. Emergency Stop Testing Procedure.

From toolsweek.com

How to Wire an Emergency Stop Button Diagram (Walkthrough and Steps) Emergency Stop Testing Procedure The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. After an individual activates it, the machinery must not be able. Emergency Stop Testing Procedure.

From www.youtube.com

The Emergency Stop Driving Test YouTube Emergency Stop Testing Procedure The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. If you break the machine while testing the emergency stop system, count this as a failed test. The key function of an emergency stop system is to provide the user with a backup. Emergency Stop Testing Procedure.

From www.youtube.com

MERCEDES EMERGENCY STOP TEST 80km/h Automatic Breaking YouTube Emergency Stop Testing Procedure Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial. Emergency Stop Testing Procedure.

From www.youtube.com

160⚡ On board VLGC. Shunt Trip and Undervoltage Trip. Emergency Stop test. YouTube Emergency Stop Testing Procedure ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. If you break the machine while testing the emergency stop system, count this as a failed test. The emergency stop function is activated by a single human action and should be available and operational at all times for. Emergency Stop Testing Procedure.

From www.drivingtesttips.biz

Emergency Stop Driving Test Emergency Stop Testing Procedure The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial. Emergency Stop Testing Procedure.

From www.pinterest.com

Tips for Fire Action Emergency Health and safety poster, Workplace safety and health, Fire Emergency Stop Testing Procedure It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. If you break the machine while testing the emergency stop system, count this. Emergency Stop Testing Procedure.

From toolsweek.com

How to Wire an Emergency Stop Button Diagram (Walkthrough and Steps) Emergency Stop Testing Procedure The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. If you break the machine while testing the. Emergency Stop Testing Procedure.

From machinerysafety101.com

Testing Emergency Stop Systems Emergency Stop Testing Procedure It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. After an individual activates it, the machinery must not be able to operate. Emergency Stop Testing Procedure.

From k53master.co.za

K53 emergency stop procedure Emergency Stop Testing Procedure Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. The emergency. Emergency Stop Testing Procedure.

From www.youtube.com

How to an emergency stop on your driving test an emergency stopDriving Test tipsUK driving Emergency Stop Testing Procedure ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. After an individual activates it, the machinery must not be able to operate again until they reset the function. The emergency stop function is activated by a single human action and should be available and operational at all. Emergency Stop Testing Procedure.

From professionaleducation.blood.ca

Pretransfusion testing Professional Education Emergency Stop Testing Procedure It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. If you break the machine while testing the emergency stop system, count this as a failed test. The emergency. Emergency Stop Testing Procedure.

From blog.testlodge.com

When to Stop Testing TestLodge Blog Emergency Stop Testing Procedure ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. If you break the machine while testing the emergency stop system, count this as a failed test. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. It is an easily accessible. Emergency Stop Testing Procedure.

From www.reddrivingschool.com

How to Pass Your Practical Test Part One RED Driving School Emergency Stop Testing Procedure The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. After an individual activates it, the machinery must not be able to operate again until. Emergency Stop Testing Procedure.

From www.youtube.com

How to do an EMERGENCY STOP Road Test Tips Toronto Drivers YouTube Emergency Stop Testing Procedure The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. If you break the machine while testing the emergency stop system, count this. Emergency Stop Testing Procedure.

From elecschem.com

Understanding the Basics of an Emergency Stop Circuit Diagram Emergency Stop Testing Procedure ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. The key function of an emergency stop system is to provide the user with a backup to the primary safeguards. If you break the machine while testing the emergency stop system, count this as a failed test. After. Emergency Stop Testing Procedure.

From www.youtube.com

How to Emergency stop Practical Driving Test YouTube Emergency Stop Testing Procedure If you break the machine while testing the emergency stop system, count this as a failed test. Iso 13850 defines the emergency stop function requirements for machinery, ensuring that operators can halt machine. It is an easily accessible button or switch that, when pressed or activated, immediately halts the operation of a machine or an entire industrial system. After an. Emergency Stop Testing Procedure.

From mungfali.com

Emergency Flow Chart Emergency Stop Testing Procedure The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. After an individual activates it, the machinery must not be able to operate again until they reset the function. ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine. Emergency Stop Testing Procedure.

From www.oceanproperty.co.th

NFPA 79 OSHA Emergency Stop Requirements With Checklist , 48 OFF Emergency Stop Testing Procedure ‘emergency stop’ focuses on the procedure to quickly and safely shut down a machine or system in the event of an emergency. The emergency stop function is activated by a single human action and should be available and operational at all times for quick access to instantly eliminate hazards. After an individual activates it, the machinery must not be able. Emergency Stop Testing Procedure.