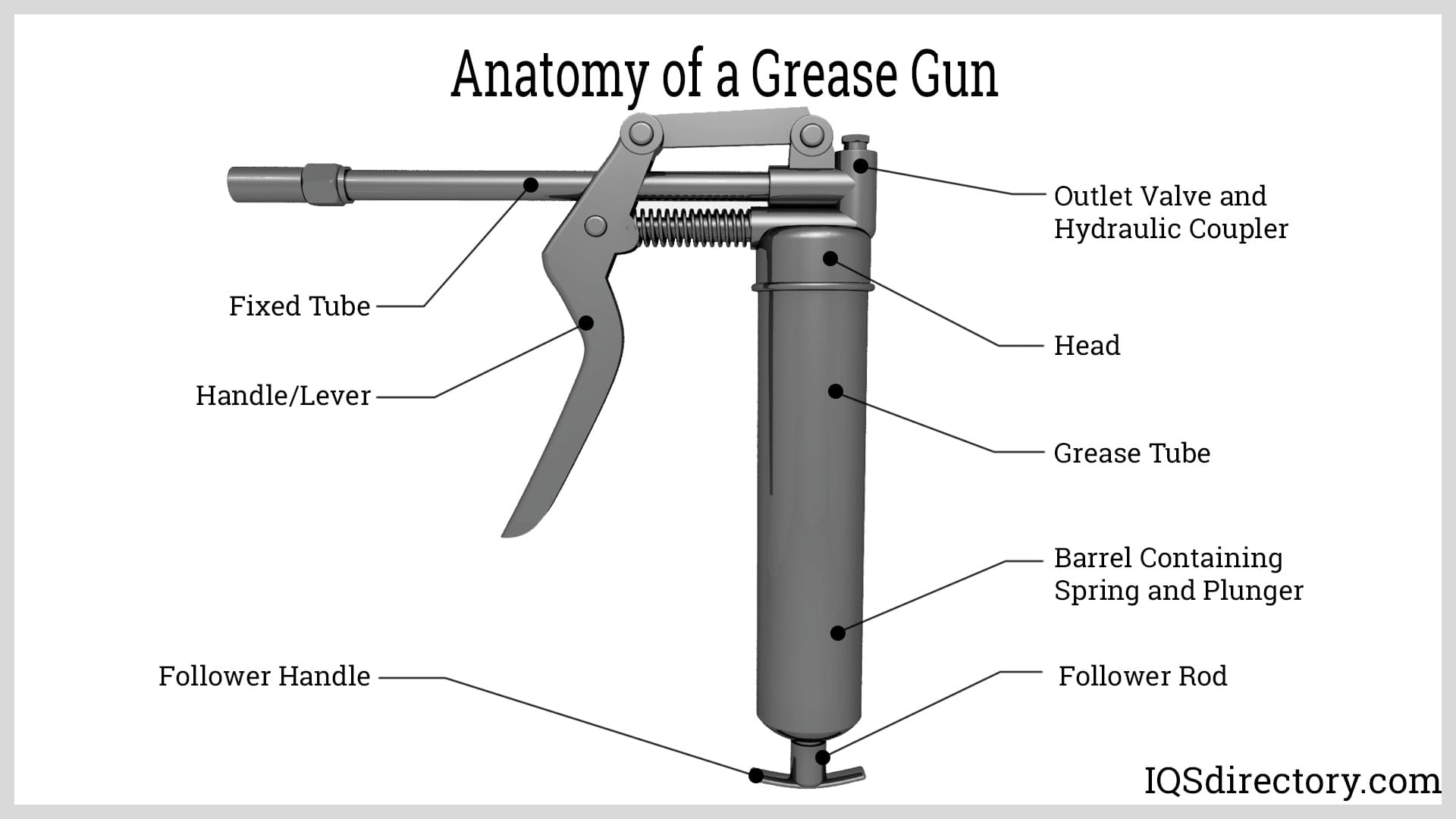

Grease Gun Head Assembly . Depending on the model, accessories can or must be fitted. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. The filler nipple is the injection point for grease from a filler pump. Check out our grease gun parts diagram to learn more! Because of operator responsibility, the following parts must be. For longer service life, efficient operation of the coupler, and to avoid. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. Assembly the grease gun is supplied fully assembled. (note that when the grease gun is in continuous use, pressing. How to reassemble a grease gun coupler. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. Remove head assembly from cylinder of the grease gun.

from www.lubricatingsystems.com

Because of operator responsibility, the following parts must be. How to reassemble a grease gun coupler. Depending on the model, accessories can or must be fitted. Remove head assembly from cylinder of the grease gun. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. (note that when the grease gun is in continuous use, pressing. The filler nipple is the injection point for grease from a filler pump. For longer service life, efficient operation of the coupler, and to avoid. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. Check out our grease gun parts diagram to learn more!

Grease Gun Manufacturers Grease Gun Suppliers

Grease Gun Head Assembly (note that when the grease gun is in continuous use, pressing. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. Remove head assembly from cylinder of the grease gun. Because of operator responsibility, the following parts must be. The filler nipple is the injection point for grease from a filler pump. For longer service life, efficient operation of the coupler, and to avoid. How to reassemble a grease gun coupler. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. Depending on the model, accessories can or must be fitted. Check out our grease gun parts diagram to learn more! Assembly the grease gun is supplied fully assembled. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. (note that when the grease gun is in continuous use, pressing.

From www.homedepot.com

Lincoln 2 Way Loading Lever Action Grease Gun with 18 in. WhipLIN1133 Grease Gun Head Assembly The filler nipple is the injection point for grease from a filler pump. How to reassemble a grease gun coupler. Remove head assembly from cylinder of the grease gun. Because of operator responsibility, the following parts must be. (note that when the grease gun is in continuous use, pressing. Depending on the model, accessories can or must be fitted. Check. Grease Gun Head Assembly.

From www.alibaba.com

Syd946 1/827 Npt Button Head Brass Grease Gun Adapter For Grease Gun Grease Gun Head Assembly Because of operator responsibility, the following parts must be. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. Check out our grease gun parts diagram to learn more! The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel. Grease Gun Head Assembly.

From au.rs-online.com

A Guide to Grease Guns and Grease Nipples RS Grease Gun Head Assembly Assembly the grease gun is supplied fully assembled. Depending on the model, accessories can or must be fitted. Check out our grease gun parts diagram to learn more! (note that when the grease gun is in continuous use, pressing. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. Remove head assembly from cylinder of. Grease Gun Head Assembly.

From www.aliexpress.com

Transkoot Silver Heavy Duty Quick Release Grease Gun Filling Head Metal Grease Gun Head Assembly Check out our grease gun parts diagram to learn more! How to reassemble a grease gun coupler. Depending on the model, accessories can or must be fitted. Remove head assembly from cylinder of the grease gun. For longer service life, efficient operation of the coupler, and to avoid. The filler nipple is the injection point for grease from a filler. Grease Gun Head Assembly.

From globalgarage.org

10 Best Grease Guns Review and Buying Guide 2024 Grease Gun Head Assembly How to reassemble a grease gun coupler. For longer service life, efficient operation of the coupler, and to avoid. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. (note that when the grease gun is in continuous use, pressing. Remove. Grease Gun Head Assembly.

From mastrapumps.com

Grease gun with flexible and grease head Mastrapumps Grease Gun Head Assembly Remove head assembly from cylinder of the grease gun. For longer service life, efficient operation of the coupler, and to avoid. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. The filler nipple is the injection point for grease from. Grease Gun Head Assembly.

From kimlabenicio.blogspot.com

9+ lincoln grease gun parts diagram KimlaBenicio Grease Gun Head Assembly The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. (note that when the grease gun is in continuous use, pressing. Check out our grease gun. Grease Gun Head Assembly.

From www.northerntool.com

Plews Pistol Grip Grease Gun — 5000 PSI, Model 30300 Northern Tool Grease Gun Head Assembly The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. Remove head assembly from cylinder of the grease gun. Because of operator responsibility, the following parts must be. Assembly the grease gun is supplied fully assembled. Once all air bubbles are. Grease Gun Head Assembly.

From www.lazada.com.ph

5Pcs 70mm Grease Needle Nozzle Needle Nose Grease Gun Head for Grease Gun Head Assembly (note that when the grease gun is in continuous use, pressing. For longer service life, efficient operation of the coupler, and to avoid. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. Because of operator responsibility, the following parts must be. Remove head assembly from cylinder of the grease gun. Assembly the grease gun. Grease Gun Head Assembly.

From www.grizzly.com

HeavyDuty Grease Gun with Flex Nozzle Grizzly Industrial Grease Gun Head Assembly For longer service life, efficient operation of the coupler, and to avoid. Assembly the grease gun is supplied fully assembled. How to reassemble a grease gun coupler. Remove head assembly from cylinder of the grease gun. Depending on the model, accessories can or must be fitted. (note that when the grease gun is in continuous use, pressing. Because of operator. Grease Gun Head Assembly.

From www.alibaba.com

Syd946 1/827 Npt Button Head Brass Grease Gun Adapter For Grease Gun Grease Gun Head Assembly How to reassemble a grease gun coupler. Check out our grease gun parts diagram to learn more! Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. Assembly the grease gun is supplied fully assembled. (note that when the grease gun is in continuous use, pressing. The filler nipple is the. Grease Gun Head Assembly.

From shopee.ph

Needle grease gun head grease nozzle grease gun accessories sealed Grease Gun Head Assembly Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. The filler nipple is the injection point for grease from a filler pump. How to reassemble a grease gun coupler. Depending on the model, accessories can. Grease Gun Head Assembly.

From sayalimpex.com

PISTOL TYPE GREASE GUN EXTENDED HANDLE [ Model No S1013 ] Grease Gun Head Assembly Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. For longer service life, efficient operation of the coupler, and to avoid. (note that when the grease gun is in continuous use, pressing. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. Because of operator. Grease Gun Head Assembly.

From fyosdbycj.blob.core.windows.net

How To Put Grease In Lucas Grease Gun at Eric Kurtz blog Grease Gun Head Assembly Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. Because of operator responsibility, the following parts must be. The filler nipple is the injection point for grease from a filler pump. (note that when the grease gun is in continuous use, pressing. Once all air bubbles are removed, fully tighten. Grease Gun Head Assembly.

From shopee.com.my

Kobei Heavy Duty Grease Gun Head Nozzle / Grease Gun Coupler Shopee Grease Gun Head Assembly For longer service life, efficient operation of the coupler, and to avoid. (note that when the grease gun is in continuous use, pressing. Check out our grease gun parts diagram to learn more! The filler nipple is the injection point for grease from a filler pump. How to reassemble a grease gun coupler. Remove head assembly from cylinder of the. Grease Gun Head Assembly.

From www.lowes.com

Heavy duty aluminum die cast head; Metal body Air Grease Guns at Grease Gun Head Assembly Because of operator responsibility, the following parts must be. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. (note that when the grease gun is. Grease Gun Head Assembly.

From wileyequipment.com

Alemite 3255402 High Pressure Lever Grease Gun w/ Hose Assembly Grease Gun Head Assembly The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. (note that when the grease gun is in continuous use, pressing. Remove head assembly from cylinder of the grease gun. For longer service life, efficient operation of the coupler, and to. Grease Gun Head Assembly.

From www.amazon.in

Isc Multi Purpose Use Grease Gun Nozzle Set 11Piece Accessory Kit Grease Gun Head Assembly Because of operator responsibility, the following parts must be. Check out our grease gun parts diagram to learn more! For longer service life, efficient operation of the coupler, and to avoid. Remove head assembly from cylinder of the grease gun. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. How. Grease Gun Head Assembly.

From www.toolsource.com

Grease Tube Head Gun Assembly IngersollRand Parts GTH1 Grease Gun Head Assembly Remove head assembly from cylinder of the grease gun. How to reassemble a grease gun coupler. Assembly the grease gun is supplied fully assembled. Depending on the model, accessories can or must be fitted. (note that when the grease gun is in continuous use, pressing. The filler nipple is the injection point for grease from a filler pump. Because of. Grease Gun Head Assembly.

From wonderfulengineering.com

10 Best Grease Guns Grease Gun Head Assembly Depending on the model, accessories can or must be fitted. Because of operator responsibility, the following parts must be. Check out our grease gun parts diagram to learn more! Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. Remove head assembly from cylinder of the grease gun. (note that when the grease gun is. Grease Gun Head Assembly.

From www.imaginemarine.com

Needle Nose Grease Gun Head Grease Dispenser Nozzles Adaptor Accessorie Grease Gun Head Assembly Remove head assembly from cylinder of the grease gun. Assembly the grease gun is supplied fully assembled. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. How to reassemble a grease gun coupler. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the. Grease Gun Head Assembly.

From www.suspension.com

How to Load a Grease Gun Grease Gun Head Assembly Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. How to reassemble a grease gun coupler. Depending on the model, accessories can or must be fitted. Remove head assembly from cylinder of the grease gun. For longer service life, efficient operation of the coupler, and to avoid. The filler nipple. Grease Gun Head Assembly.

From www.alba-tool.com

Mini Injection Head Grease Gun Kit Set Hand Grease Gun LUBRICATION Grease Gun Head Assembly Because of operator responsibility, the following parts must be. Depending on the model, accessories can or must be fitted. Remove head assembly from cylinder of the grease gun. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. How to reassemble. Grease Gun Head Assembly.

From hydraulicmegastore.com

LUMATIC INDUSTRIAL ONE HANDED GREASE GUN Hydraulic Megastore Grease Gun Head Assembly For longer service life, efficient operation of the coupler, and to avoid. The filler nipple is the injection point for grease from a filler pump. Because of operator responsibility, the following parts must be. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. Once all air bubbles are removed, fully. Grease Gun Head Assembly.

From www.bricoutensili.com

Straight Head for Grease Gun 11633 Grease Gun Head Assembly The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. For longer service life, efficient operation of the coupler, and to avoid. How to reassemble a grease gun coupler. Check out our grease gun parts diagram to learn more! Grease gun. Grease Gun Head Assembly.

From fhisbusiness.com

Factory Direct Grease Gun Pneumatic High Pressure Grease Gun Grease Grease Gun Head Assembly Depending on the model, accessories can or must be fitted. The filler nipple is the injection point for grease from a filler pump. Remove head assembly from cylinder of the grease gun. How to reassemble a grease gun coupler. Grease gun parts and anatomy must be understood in order to use the components of a grease gun correctly. The head. Grease Gun Head Assembly.

From www.liveauctionworld.com

pistol grip grease gun and pump grease gun head Grease Gun Head Assembly Because of operator responsibility, the following parts must be. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. The filler nipple is the injection point. Grease Gun Head Assembly.

From www.lubricatingsystems.com

Grease Gun Manufacturers Grease Gun Suppliers Grease Gun Head Assembly How to reassemble a grease gun coupler. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. Because of operator responsibility, the following parts must be.. Grease Gun Head Assembly.

From www.alba-tool.com

Grease Gun Injection Head w/ Nylon Grease Brush Hand Grease Gun Grease Gun Head Assembly Because of operator responsibility, the following parts must be. Remove head assembly from cylinder of the grease gun. The filler nipple is the injection point for grease from a filler pump. Once all air bubbles are removed, fully tighten the grease gun head onto the barrel. Assembly the grease gun is supplied fully assembled. Check out our grease gun parts. Grease Gun Head Assembly.

From www.homedepot.com

Lincoln Fully Automatic Pneumatic Grease GunLIN1162 The Home Depot Grease Gun Head Assembly Check out our grease gun parts diagram to learn more! (note that when the grease gun is in continuous use, pressing. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. Depending on the model, accessories can or must be fitted.. Grease Gun Head Assembly.

From www.lowes.com

STP Mini Manual Grease Gun at Grease Gun Head Assembly The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. (note that when the grease gun is in continuous use, pressing. For longer service life, efficient operation of the coupler, and to avoid. Depending on the model, accessories can or must. Grease Gun Head Assembly.

From www.fowkes.co.za

GREASE GUN LEVER TYPE GROZ DIE CAST HEAD Fowkes Bros Grease Gun Head Assembly How to reassemble a grease gun coupler. Remove head assembly from cylinder of the grease gun. (note that when the grease gun is in continuous use, pressing. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. For longer service life,. Grease Gun Head Assembly.

From www.graco.com

Heavy Duty Grease Guns Manual & Pneumatic Grease Gun Head Assembly For longer service life, efficient operation of the coupler, and to avoid. The head of the grease gun contains grease pathways and valves that allow the pumping of grease to travel from the barrel into the flexible hose or fixed tube. (note that when the grease gun is in continuous use, pressing. Check out our grease gun parts diagram to. Grease Gun Head Assembly.