Cleaning Procedures ( Industrial Cooking Laboratory) . • which equipment needs to have validated cleaning • the impact of sanitary design of. Their significance extends across various facets,. Dry cleaning is more appropriate for low moisture food processing. There are two main methods of cleaning in the food and beverage industry: Wet cleaning and dry cleaning. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Additionally, the article will touch on: The layout, design, construction, siting and size of. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Food premises are to be kept clean and maintained in good repair and condition. Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces.

from urstay.co.uk

There are two main methods of cleaning in the food and beverage industry: Dry cleaning is more appropriate for low moisture food processing. The layout, design, construction, siting and size of. Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Additionally, the article will touch on: As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Food premises are to be kept clean and maintained in good repair and condition. Wet cleaning and dry cleaning. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. • which equipment needs to have validated cleaning • the impact of sanitary design of.

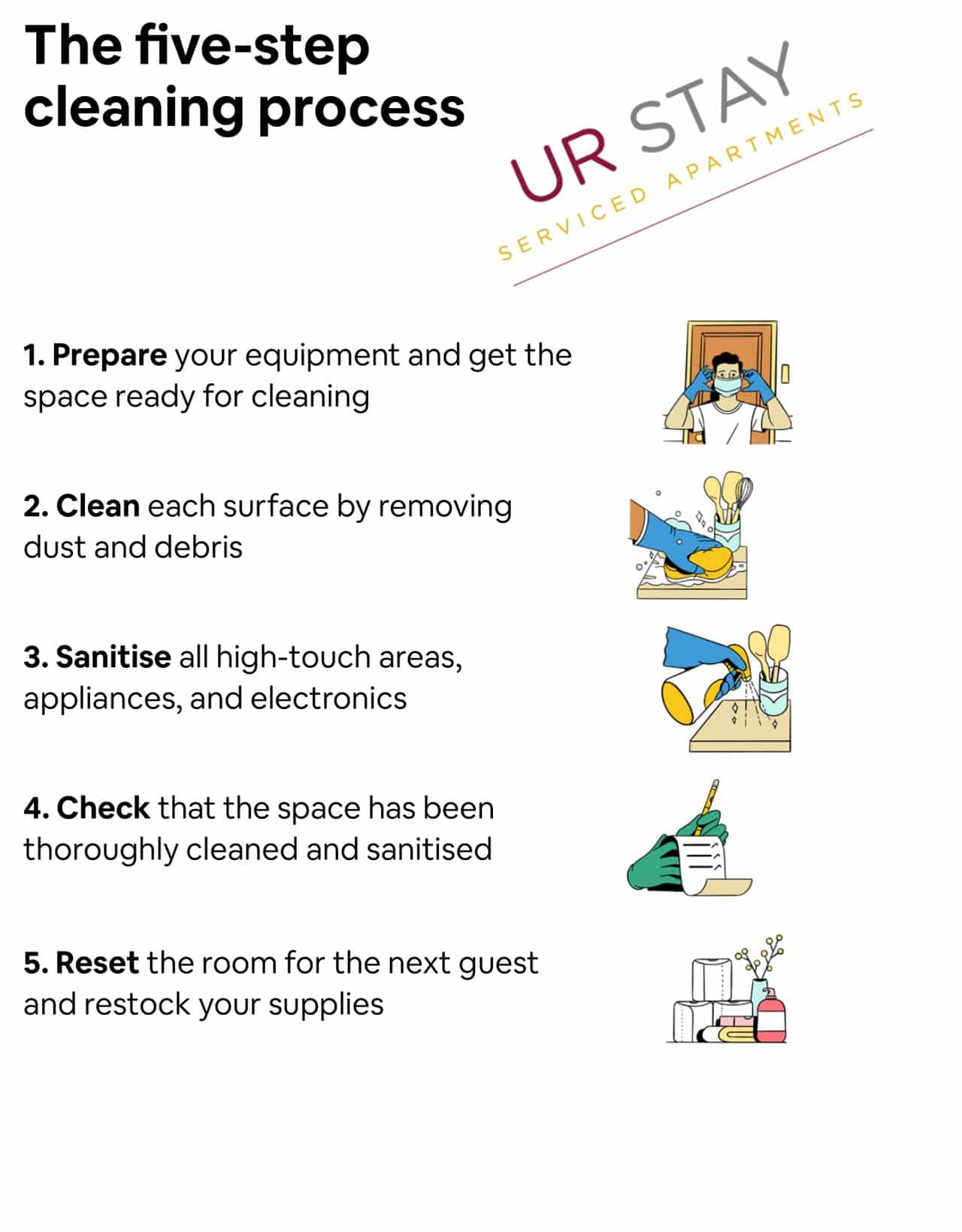

5 STEP CLEANING PROCESS UR STAY SERVICED APARTMENTS

Cleaning Procedures ( Industrial Cooking Laboratory) As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Food premises are to be kept clean and maintained in good repair and condition. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. • which equipment needs to have validated cleaning • the impact of sanitary design of. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. Additionally, the article will touch on: There are two main methods of cleaning in the food and beverage industry: Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. The layout, design, construction, siting and size of. Their significance extends across various facets,. Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Wet cleaning and dry cleaning. Dry cleaning is more appropriate for low moisture food processing.

From agriculture.vermont.gov

Produce Safety Bite Cleaning & Sanitizing Food Contact Surfaces Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Wet cleaning and dry cleaning. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Their significance extends across various facets,. There are two main methods of cleaning in the food and. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.highspeedtraining.co.uk

Six Stages of Cleaning Key Steps & Safety Factors Cleaning Procedures ( Industrial Cooking Laboratory) Dry cleaning is more appropriate for low moisture food processing. Their significance extends across various facets,. Wet cleaning and dry cleaning. There are two main methods of cleaning in the food and beverage industry: As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Food premises are to be kept clean. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.seton.co.uk

Kitchen Hygiene Poster (Photographic) Seton UK Cleaning Procedures ( Industrial Cooking Laboratory) As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. • which equipment needs to have validated cleaning • the impact of sanitary design of. Wet cleaning and dry cleaning. Dry cleaning is more appropriate for low moisture food processing. Their significance extends across various facets,. Food premises are to be. Cleaning Procedures ( Industrial Cooking Laboratory).

From proper-cooking.info

Lab Safety Poster Cleaning Procedures ( Industrial Cooking Laboratory) Dry cleaning is more appropriate for low moisture food processing. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. The layout, design, construction, siting and size of. Cleaning schedules are the written work instructions that detail precisely how the cleaning. Cleaning Procedures ( Industrial Cooking Laboratory).

From studylib.net

Laboratory Cleaning and Maintenance Cleaning Procedures ( Industrial Cooking Laboratory) Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. The layout, design, construction, siting and size of. Their significance extends across various. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.foodequipment.com.au

How to Maintain Your Commercial Kitchen Equipment Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. The layout, design, construction, siting and size of. • which equipment needs to. Cleaning Procedures ( Industrial Cooking Laboratory).

From thesafetyposter.com

Wear your Personal Protective Equipment Cook PPE Kitchen safety Cleaning Procedures ( Industrial Cooking Laboratory) There are two main methods of cleaning in the food and beverage industry: Their significance extends across various facets,. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. • which equipment needs to have validated cleaning • the impact of sanitary design of. Cleaning schedules are the written work instructions. Cleaning Procedures ( Industrial Cooking Laboratory).

From kaivac.com

The Best Commercial Kitchen Cleaning Hacks Kaivac, Inc. Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Additionally, the article will touch on: • which equipment needs to have validated cleaning • the impact of sanitary design of. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed. Cleaning Procedures ( Industrial Cooking Laboratory).

From guardianmed.net

Cleaning Stainless Steel in the Pharmacy & Lab Guardian Medical Systems Cleaning Procedures ( Industrial Cooking Laboratory) Food premises are to be kept clean and maintained in good repair and condition. Dry cleaning is more appropriate for low moisture food processing. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically. Cleaning Procedures ( Industrial Cooking Laboratory).

From urstay.co.uk

5 STEP CLEANING PROCESS UR STAY SERVICED APARTMENTS Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. There are two main methods of cleaning in the food and beverage industry: Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Dry cleaning is more appropriate for low moisture food processing.. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.youtube.com

Lesson 2 Fundamental Cleaning Procedures YouTube Cleaning Procedures ( Industrial Cooking Laboratory) • which equipment needs to have validated cleaning • the impact of sanitary design of. Wet cleaning and dry cleaning. The layout, design, construction, siting and size of. Additionally, the article will touch on: As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. There are two main methods of cleaning. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.fooddocs.com

Sanitation Standard Operating Procedures (SSOP) Free Download Cleaning Procedures ( Industrial Cooking Laboratory) Additionally, the article will touch on: Food premises are to be kept clean and maintained in good repair and condition. The layout, design, construction, siting and size of. Wet cleaning and dry cleaning. There are two main methods of cleaning in the food and beverage industry: Their significance extends across various facets,. Cip procedures describe the method by which a. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.cleanipedia.com

Guide to Cleaning and Sanitizing Kitchen Utensils Cleanipedia Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Dry cleaning is more appropriate for low moisture food processing. The layout, design, construction, siting and size of. Cip procedures describe the method. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.youtube.com

Cleaning Laboratory Glassware YouTube Cleaning Procedures ( Industrial Cooking Laboratory) Their significance extends across various facets,. • which equipment needs to have validated cleaning • the impact of sanitary design of. Additionally, the article will touch on: There are two main methods of cleaning in the food and beverage industry: Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.powershow.com

PPT Cleaning And Sanitation Procedures In Food Industry JBN Cleaning Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. • which equipment needs to have validated cleaning • the impact of sanitary design of. Their significance extends across various facets,. The layout, design, construction, siting and size of. Additionally, the article will touch on: Cleaning and sanitizing within food operations play. Cleaning Procedures ( Industrial Cooking Laboratory).

From sicweb.com

LAB EQUIPMENT CLEANING CALIBRATION AND REPAIRS Cleaning Procedures ( Industrial Cooking Laboratory) Wet cleaning and dry cleaning. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Their significance extends across various facets,. Dry cleaning is more appropriate for low moisture food processing. • which equipment needs to have validated cleaning • the impact of sanitary design of. There are two main methods. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.mjanitorial.com

Laboratory Cleaning Millennium Maintenance Systems Cleaning Procedures ( Industrial Cooking Laboratory) • which equipment needs to have validated cleaning • the impact of sanitary design of. Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Their significance extends across various facets,. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Food premises. Cleaning Procedures ( Industrial Cooking Laboratory).

From log10.com

Sanitation Standard Operating Procedures In Food Processing Cleaning Procedures ( Industrial Cooking Laboratory) Their significance extends across various facets,. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Additionally, the article will touch on: There are two main methods of cleaning in the food and beverage industry: The layout, design, construction, siting and size of. • which equipment needs to have validated cleaning. Cleaning Procedures ( Industrial Cooking Laboratory).

From ecolink.com

Parts Cleaning Processes Precision Cleaning Solvents Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Food premises are to be kept clean and maintained in good repair and condition. There are two main methods of cleaning in the food and beverage industry: • which equipment needs to have validated cleaning • the impact of sanitary design. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.cadexair.com

Cadexair IKECA — Commercial Kitchen Hood Cleaning Cleaning Procedures ( Industrial Cooking Laboratory) Wet cleaning and dry cleaning. Additionally, the article will touch on: • which equipment needs to have validated cleaning • the impact of sanitary design of. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. Food premises are to be. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.food-safety.com

The basics of cleaning and sanitation in food plants 20200115 Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. There are two main methods of cleaning in the food and beverage industry: As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Additionally, the article will touch on: Cip procedures describe the. Cleaning Procedures ( Industrial Cooking Laboratory).

From amphomag.com

Laboratory hazardous spills use Amphomag Cleaning Procedures ( Industrial Cooking Laboratory) As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Additionally, the article will touch on: Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.thehospitalityshop.co.uk

Kitchen Hygiene Poster The Hospitality Shop Cleaning Procedures ( Industrial Cooking Laboratory) As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. • which equipment needs to have validated cleaning • the impact of sanitary design of. Wet cleaning and dry cleaning. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through. Cleaning Procedures ( Industrial Cooking Laboratory).

From safetyskills.com

Cleaning and Sanitizing in Food Manufacturing SafetySkills Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Additionally, the article will touch on: Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Their significance extends across various facets,. Food premises are to be kept clean and maintained in good. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.laboratory-supply.net

Basic Cleanroom Gowning Procedures Cleaning Procedures ( Industrial Cooking Laboratory) Food premises are to be kept clean and maintained in good repair and condition. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. The layout, design, construction, siting and size of. Dry cleaning is more appropriate for low moisture food processing. Additionally, the article will touch on: Wet cleaning and. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.tion.co.uk

What’s the Best Cleaning Solution for Your Lab? (Automated vs Chemical) Cleaning Procedures ( Industrial Cooking Laboratory) Dry cleaning is more appropriate for low moisture food processing. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. The layout,. Cleaning Procedures ( Industrial Cooking Laboratory).

From cleanhero.com.my

Hard Floor Cleaning Process CleanHero Cleaning Procedures ( Industrial Cooking Laboratory) There are two main methods of cleaning in the food and beverage industry: As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. The layout, design, construction, siting and size of. • which equipment needs to have validated cleaning • the impact of sanitary design of. Food premises are to be. Cleaning Procedures ( Industrial Cooking Laboratory).

From safetyware.com

CHEMICAL SPILL CLEAN UP PROCEDURE Safetyware Sdn Bhd Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. • which equipment needs to have validated cleaning • the impact of. Cleaning Procedures ( Industrial Cooking Laboratory).

From extension.umaine.edu

Lesson 2 Personal Hygiene and Handwashing Cooperative Extension Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Dry cleaning is more appropriate for low moisture food processing. Wet cleaning and dry cleaning. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. There are two main methods of cleaning. Cleaning Procedures ( Industrial Cooking Laboratory).

From budgetbranders.com

Restaurant Cleaning Procedures & Cleaning Checklist Cleaning Procedures ( Industrial Cooking Laboratory) Dry cleaning is more appropriate for low moisture food processing. Their significance extends across various facets,. The layout, design, construction, siting and size of. Food premises are to be kept clean and maintained in good repair and condition. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. As with any. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.microlit.com

A Quick Guide to Lab Equipment Decontamination Microlit Cleaning Procedures ( Industrial Cooking Laboratory) Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. Dry cleaning is more appropriate for low moisture food processing. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. The layout,. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.scribd.com

QMR 044 Drain Cleaning Procedure Housekeeping Industrial Processes Cleaning Procedures ( Industrial Cooking Laboratory) Cleaning schedules are the written work instructions that detail precisely how the cleaning and disinfection procedures for each. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Food premises are to be kept clean and maintained in good repair and condition. Wet cleaning and dry cleaning. Their significance extends across. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.ipcol.com

Biotechnology and Pharmaceutical Industry Cleaning Products Cleaning Procedures ( Industrial Cooking Laboratory) The layout, design, construction, siting and size of. Their significance extends across various facets,. Wet cleaning and dry cleaning. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. Food premises are to be kept clean and maintained in good repair and condition. Cip procedures describe the method by which a. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.youtube.com

Standard Cleaning Procedure YouTube Cleaning Procedures ( Industrial Cooking Laboratory) Additionally, the article will touch on: • which equipment needs to have validated cleaning • the impact of sanitary design of. Cip procedures describe the method by which a detergent solution, water rinse, and sanitizing solution is mechanically circulated or passed through a piece of equipment and across its surfaces. Cleaning schedules are the written work instructions that detail precisely. Cleaning Procedures ( Industrial Cooking Laboratory).

From www.sepsservices.com

Lab Equipment Decontamination BSC, Incubator, & Centrifuge Cleaning Procedures ( Industrial Cooking Laboratory) • which equipment needs to have validated cleaning • the impact of sanitary design of. Cleaning and sanitizing within food operations play a pivotal role in guaranteeing the safety and excellence of food products. As with any process, cip procedures need to be validated by the experts involved with an operation’s food safety. The layout, design, construction, siting and size. Cleaning Procedures ( Industrial Cooking Laboratory).