Spot Welding Process Parameters . The specialized form of welding plays a pivotal role. Thus the electrode tip contact area usually define the weld nugget size. the form of the electrodes localized the current and the heat generation. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. spot welding (also known as resistance spot welding) is a resistance welding process. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. This welding process is used primarily for welding two or more metal sheets together. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication.

from weldingblos.netlify.app

spot welding (also known as resistance spot welding) is a resistance welding process. Thus the electrode tip contact area usually define the weld nugget size. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. This welding process is used primarily for welding two or more metal sheets together. the form of the electrodes localized the current and the heat generation. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. The specialized form of welding plays a pivotal role.

Spot Welding Force Calculation

Spot Welding Process Parameters Thus the electrode tip contact area usually define the weld nugget size. This welding process is used primarily for welding two or more metal sheets together. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. the form of the electrodes localized the current and the heat generation. Thus the electrode tip contact area usually define the weld nugget size. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. The specialized form of welding plays a pivotal role. spot welding (also known as resistance spot welding) is a resistance welding process. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication.

From www.mdpi.com

Metals Free FullText Resistance Spot Welding of Aluminum Alloy and Spot Welding Process Parameters Thus the electrode tip contact area usually define the weld nugget size. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. spot welding (also known as resistance spot welding) is a resistance welding process. learn how to select and adjust resistance spot welding (rsw). Spot Welding Process Parameters.

From woodlands.adventist.org

Appearance evolution diary spot welding parameters Petrify Railway Spot Welding Process Parameters learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. Thus the electrode tip contact area usually define the weld nugget size. The specialized form of welding plays a pivotal role. spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is. Spot Welding Process Parameters.

From qualityengineerstuff.com

What are the Spot welding Parameters / Resistance welding? Quality Assist Spot Welding Process Parameters learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. This welding process is used primarily for welding two or more metal sheets together. The specialized form of welding plays a pivotal role. Thus the electrode tip contact area usually define the weld nugget size. spot welding (rsw). Spot Welding Process Parameters.

From www.researchgate.net

Resistance spot welding processes. (a) Schematic of the electrode; (b Spot Welding Process Parameters spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. Thus the electrode tip contact area usually define the weld nugget size. the resistance spot welding (rsw) process is often used. Spot Welding Process Parameters.

From www.researchgate.net

(PDF) Predicting Parametric Influence of Resistance Spot Welding Spot Welding Process Parameters learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. the form of the electrodes localized the current and the heat generation. Thus the electrode tip contact area usually define the weld nugget size. spot welding (resistance welding) is a highly efficient metal joining process used in. Spot Welding Process Parameters.

From www.slideshare.net

Spot welding basic parameters setting basic calculations / equatio… Spot Welding Process Parameters This welding process is used primarily for welding two or more metal sheets together. Thus the electrode tip contact area usually define the weld nugget size. the form of the electrodes localized the current and the heat generation. The specialized form of welding plays a pivotal role. spot welding (rsw) is an electrical resistance welding process that joins. Spot Welding Process Parameters.

From infoweldings.blogspot.com

Projection Welding Parameters Info Welding Spot Welding Process Parameters spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal sheets together. The specialized form of welding plays a pivotal role. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes.. Spot Welding Process Parameters.

From www.mechstudies.com

Spot Welding How to Spot Welding? Types, Process, Stages www Spot Welding Process Parameters Thus the electrode tip contact area usually define the weld nugget size. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. This welding process is used primarily for welding two or more metal sheets together. learn how to select and adjust resistance spot welding (rsw). Spot Welding Process Parameters.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Spot Welding Process Parameters spot welding (also known as resistance spot welding) is a resistance welding process. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. This welding process is used primarily for welding two or more metal sheets together. Thus the electrode tip contact area usually define the weld nugget size. learn how. Spot Welding Process Parameters.

From www.researchgate.net

Laser microspot welding process parameters Download Scientific Diagram Spot Welding Process Parameters The specialized form of welding plays a pivotal role. Thus the electrode tip contact area usually define the weld nugget size. spot welding (also known as resistance spot welding) is a resistance welding process. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. spot welding (resistance. Spot Welding Process Parameters.

From cexvjvvg.blob.core.windows.net

Weld Parameter Calculator at Madeline Burwell blog Spot Welding Process Parameters the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. the form of the electrodes localized the current and the heat generation. This welding process is used primarily for welding two or more metal sheets together. The specialized form of welding plays a pivotal role. . Spot Welding Process Parameters.

From www.mdpi.com

Metals Free FullText Resistance Spot Welding of Aluminum Alloy and Spot Welding Process Parameters learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. spot welding (also known. Spot Welding Process Parameters.

From www.researchgate.net

(PDF) Study And Analysis Of Welding Process Parameters On Failure Load Spot Welding Process Parameters spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal sheets together. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. Thus the electrode tip contact area usually define the weld nugget size. The specialized form. Spot Welding Process Parameters.

From protigwelder.com

What is Spot welding? And How Does It works? [PROTIGWELDER] Spot Welding Process Parameters learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. This welding process is used primarily for welding two or more metal sheets together. the form of the electrodes localized the current and the heat generation. spot welding (also known as resistance spot welding) is a resistance. Spot Welding Process Parameters.

From www.researchgate.net

(PDF) Optimization on Spot Weld Parameters in Resistance Spot Welding Spot Welding Process Parameters This welding process is used primarily for welding two or more metal sheets together. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. spot welding (resistance welding) is a highly. Spot Welding Process Parameters.

From ahssinsights.org

Spot Weld Strength Improvement by PWHT AHSS Guidelines Spot Welding Process Parameters the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high. Spot Welding Process Parameters.

From www.researchgate.net

Parameters used for spot welding. Download Table Spot Welding Process Parameters spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. This welding process is used primarily for welding two or more metal sheets together. the form of the electrodes localized the current and the heat generation. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two. Spot Welding Process Parameters.

From www.researchgate.net

Optimization of resistance spot welding process parameters and Spot Welding Process Parameters the form of the electrodes localized the current and the heat generation. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. Thus the electrode tip contact area usually define the weld nugget size. This welding process is used primarily for welding two or more metal. Spot Welding Process Parameters.

From www.semanticscholar.org

Table 2 from STUDY OF EFFECT OF PARAMETERS ON RESISTANCE SPOT WELD OF Spot Welding Process Parameters spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. Thus the electrode tip contact area usually define the weld nugget size. spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal sheets together. the form. Spot Welding Process Parameters.

From infoweldings.blogspot.com

Projection Welding Parameters Info Welding Spot Welding Process Parameters This welding process is used primarily for welding two or more metal sheets together. the form of the electrodes localized the current and the heat generation. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. The specialized form of welding plays a pivotal role. the resistance spot welding (rsw) process. Spot Welding Process Parameters.

From www.semanticscholar.org

[PDF] OPTIMIZATION OF SPOT WELDING PROCESS PARAMETERS FOR MAXIMUM Spot Welding Process Parameters spot welding (also known as resistance spot welding) is a resistance welding process. Thus the electrode tip contact area usually define the weld nugget size. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication.. Spot Welding Process Parameters.

From www.scribd.com

Spot Welding Parameters Welding Metals Spot Welding Process Parameters The specialized form of welding plays a pivotal role. the form of the electrodes localized the current and the heat generation. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes.. Spot Welding Process Parameters.

From www.researchgate.net

Optimization of resistance spot welding process parameters of Spot Welding Process Parameters learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. spot welding (also known as resistance spot welding) is a resistance welding process. the form of the electrodes localized the current and the heat generation. Thus the electrode tip contact area usually define the weld nugget size.. Spot Welding Process Parameters.

From www.academia.edu

(PDF) Analysis of Process Parameters for Resistance Spot Welding Spot Welding Process Parameters The specialized form of welding plays a pivotal role. spot welding (also known as resistance spot welding) is a resistance welding process. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. the form of the electrodes localized the current and the heat generation. . Spot Welding Process Parameters.

From www.researchgate.net

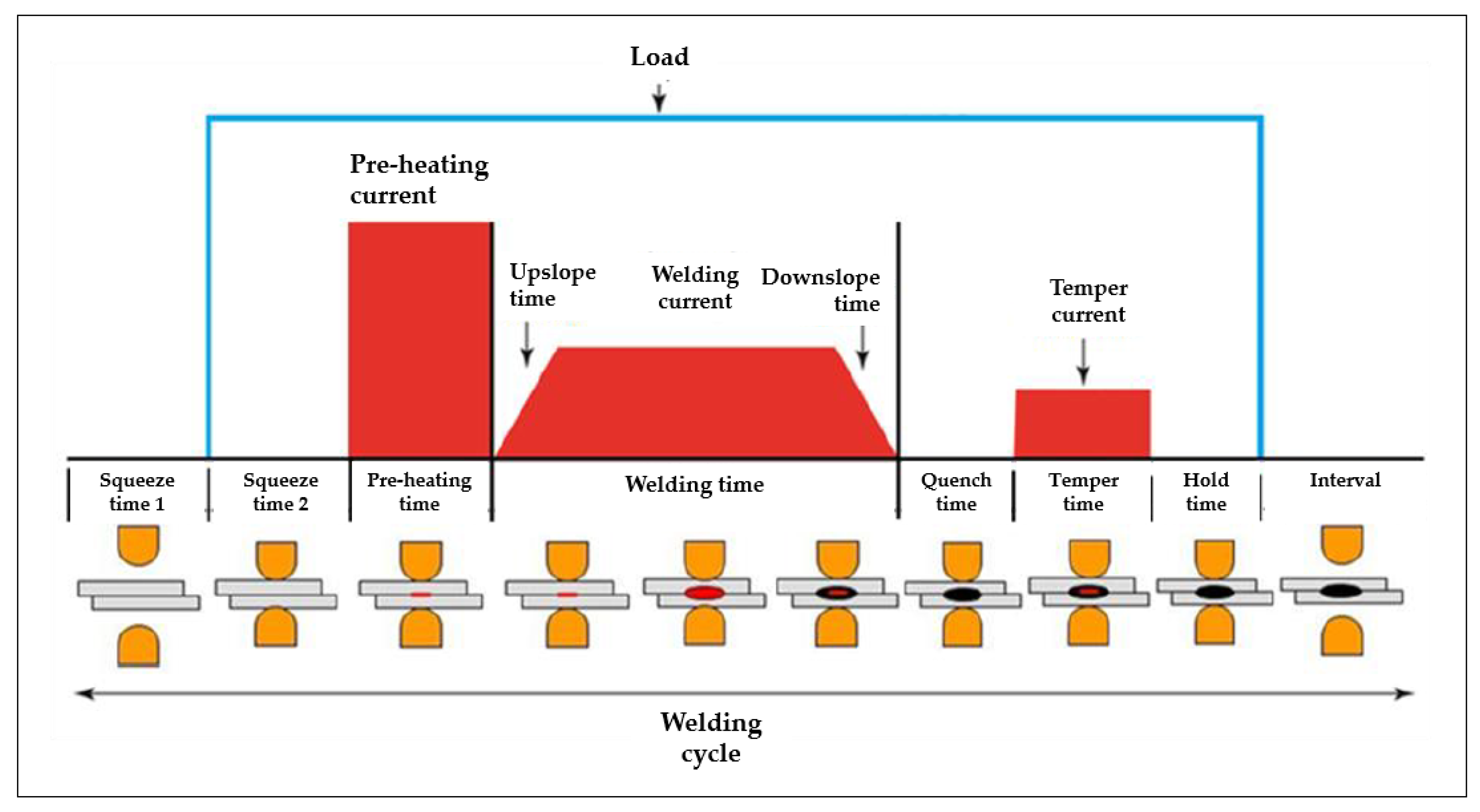

Welding process parameters for resistance spot welding (RSW) scheme Spot Welding Process Parameters the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and. Spot Welding Process Parameters.

From www.semanticscholar.org

Optimization of resistance spot welding parameters using differential Spot Welding Process Parameters spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. The specialized form of welding plays a pivotal role. Thus the electrode tip contact area usually define the weld nugget size. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. learn how to select. Spot Welding Process Parameters.

From weldingblos.netlify.app

Spot Welding Force Calculation Spot Welding Process Parameters spot welding (also known as resistance spot welding) is a resistance welding process. spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. the form of the electrodes localized the current and the heat generation. This welding process is used primarily for welding two or more metal sheets together. the. Spot Welding Process Parameters.

From www.researchgate.net

(PDF) Optimization and Modelling of Resistance Spot Welding Process Spot Welding Process Parameters Thus the electrode tip contact area usually define the weld nugget size. the form of the electrodes localized the current and the heat generation. This welding process is used primarily for welding two or more metal sheets together. spot welding (also known as resistance spot welding) is a resistance welding process. spot welding (resistance welding) is a. Spot Welding Process Parameters.

From www.semanticscholar.org

Figure 1 from Optimization of process parameters for Resistance Spot Spot Welding Process Parameters the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal sheets together. the form of the electrodes localized the current. Spot Welding Process Parameters.

From www.researchgate.net

Schematic of the spotwelding process. Download Scientific Diagram Spot Welding Process Parameters This welding process is used primarily for welding two or more metal sheets together. the form of the electrodes localized the current and the heat generation. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. spot welding (also known as resistance spot welding) is a resistance welding process. learn. Spot Welding Process Parameters.

From www.slideshare.net

Spot welding basic parameters setting basic calculations / equatio… Spot Welding Process Parameters the form of the electrodes localized the current and the heat generation. This welding process is used primarily for welding two or more metal sheets together. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. learn how to select and adjust resistance spot welding. Spot Welding Process Parameters.

From circuitsofizam5m.z21.web.core.windows.net

Spot Welding Parameters Calculations Pdf Spot Welding Process Parameters spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high. Spot Welding Process Parameters.

From www.mechstudies.com

Spot Welding How to Spot Welding? Types, Process, Stages www Spot Welding Process Parameters spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. This welding process is used. Spot Welding Process Parameters.

From punchlistzero.com

Explaining Spot Welding Process How It Works Spot Welding Process Parameters spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. spot welding (also known as resistance spot welding) is a resistance welding process. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. learn how to select and. Spot Welding Process Parameters.

From www.semanticscholar.org

Figure 1 from Optimization of Resistance Spot Welding Process Parameter Spot Welding Process Parameters spot welding (resistance welding) is a highly efficient metal joining process used in manufacturing and fabrication. Thus the electrode tip contact area usually define the weld nugget size. spot welding (rsw) is an electrical resistance welding process that joins overlapping metals between two electrodes. the resistance spot welding (rsw) process is often used as a model to. Spot Welding Process Parameters.