Metal Finishes Product Design . Anodizing creates corrosion resistance and adds. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Here are some reasons why surface roughness and. Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they affect the appearance and durability of metals. Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Choosing the right metal finishing technique for a new product design involves a nuanced approach. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear.

from www.metal-city.com

Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Here are some reasons why surface roughness and. Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they affect the appearance and durability of metals. Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. Anodizing creates corrosion resistance and adds. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or.

Decorative Stainless Steel Metals Products Metal City

Metal Finishes Product Design Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Anodizing creates corrosion resistance and adds. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Choosing the right metal finishing technique for a new product design involves a nuanced approach. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Here are some reasons why surface roughness and. See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they affect the appearance and durability of metals. Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina.

From caitlinwilson.com

Design 101 Mixing Metal Finishes Caitlin Wilson Metal Finishes Product Design Here are some reasons why surface roughness and. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they affect the appearance and durability of metals. See. Metal Finishes Product Design.

From rustica.com

Metal Finishes Samples Stainless Steel & Brushed Metal Rustica Metal Finishes Product Design Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Here are some reasons why surface roughness and. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Common metal finishes include anodizing, electroplating, powder coating, brushing, and. Metal Finishes Product Design.

From blog.thepipingmart.com

Overview of Stainless Steel Surface Finishes ThePipingMart Blog Metal Finishes Product Design See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Learn about different types of metal finishes, such as paints, powder coating, patina,. Metal Finishes Product Design.

From www.ecfinc.com

What Metal Finishing Option Is Best For Your Product? Metal Finishes Product Design Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. See how ea craftworks applies their expertise. Metal Finishes Product Design.

From gallerymetalworks.com

Metal Finishes Gallery Metal Works Gallery Metalworks Metal Finishes Product Design Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Choosing the right metal finishing technique for a new product design involves a nuanced approach. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds,. Metal Finishes Product Design.

From www.americanmetalfinishing.com

American Metal Finishing — Vista, California Metal Finishes Product Design To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Learn about different metal finishing techniques,. Metal Finishes Product Design.

From www.mcloone.com

Metal Finishes for Product Identification by McLoone Metal Finishes Product Design Here are some reasons why surface roughness and. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Choosing the right metal finishing technique for a new product design involves a nuanced approach. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal. Metal Finishes Product Design.

From www.metalswarehouse.co.uk

Stainless Steel and Aluminium Finishes The Metals Warehouse Metal Finishes Product Design Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Learn about. Metal Finishes Product Design.

From www.steelartco.com

Metal Finishes — Steel Art Company Metal Finishes Product Design Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Here are some reasons why surface roughness and. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Consider transforming. Metal Finishes Product Design.

From blog.thepipingmart.com

7 Types of Metal Finishes and Their Uses Metal Finishes Product Design Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they affect. Metal Finishes Product Design.

From www.ulbrich.com

The Ultimate Guide to Stainless Steel Surface Finishes Ulbrich Metal Finishes Product Design Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Here are some reasons why surface roughness and. Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. To help. Metal Finishes Product Design.

From www.pinterest.com

Astor Metal Finishes Electroplating, Sydney Australia Polished Metal Finishes Product Design Anodizing creates corrosion resistance and adds. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they affect the appearance and durability of metals. Choosing the right metal finishing technique for a new product design involves a nuanced approach. Surface finish is essential in product design because it can significantly impact the parts’ performance,. Metal Finishes Product Design.

From mindfuldesignconsulting.com

Metal Finishes that Glam Up Your Interior Design Mindful Design Metal Finishes Product Design Here are some reasons why surface roughness and. Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Anodizing creates corrosion resistance and adds. To help demystify the. Metal Finishes Product Design.

From onlinemetalsupply.com

Guide to Stainless Steel Sheet Finishes Mill, Polished, Brushed Metal Finishes Product Design Here are some reasons why surface roughness and. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Learn about. Metal Finishes Product Design.

From digthisdesign.net

Embrace Metal Finishes Unveiling the Latest Metal Trends in Home Metal Finishes Product Design Here are some reasons why surface roughness and. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Anodizing creates corrosion resistance and adds. Choosing the right metal finishing technique for a new product design involves a nuanced approach.. Metal Finishes Product Design.

From furphyfoundry.com.au

A quick guide to common metal finishes Furphy Foundry Street Metal Finishes Product Design Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Anodizing creates corrosion resistance and adds. Choosing the right metal finishing technique for a new product design involves a nuanced approach. See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. Learn about different types of metal finishes, such as paints, powder coating,. Metal Finishes Product Design.

From www.dmdesignfabrication.co.uk

Metal Finishing Services D&M Design & Fabrication Ltd Metal Finishes Product Design Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Anodizing creates corrosion resistance and adds. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. Common metal. Metal Finishes Product Design.

From www.archdaily.com

Anodized Aluminum Stainless Steel Finishes from Lorin Industries Metal Finishes Product Design Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Choosing the right. Metal Finishes Product Design.

From www.huyett.com

Types of Metal Finishes for Fasteners Metal Finishes Product Design Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Here are some reasons why surface roughness and. Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. Surface finish is essential in product. Metal Finishes Product Design.

From www.kikukawa.com

Stainless Steel Finish Samples|KIKUKAWA Metal Finishes Product Design Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. Anodizing creates corrosion resistance and adds. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Consider transforming entire façades with shimmering metal finishes, creating. Metal Finishes Product Design.

From www.mcnichols.com

5SM Designer Metal Stainless R8000002 McNICHOLS® Metal Finishes Product Design Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to. Metal Finishes Product Design.

From www.steelartco.com

Metal Finishes — Steel Art Company Metal Finishes Product Design Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Here are some reasons why surface roughness and. Learn about different types of metal finishes, such as paints,. Metal Finishes Product Design.

From www.deccaeurope.com

Luxury metal furniture finishes bespoke service Decca London Metal Finishes Product Design Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate. Metal Finishes Product Design.

From www.pinterest.com

Pin by Yeng on Finishes Metal furniture, Furniture finishes, Luxury Metal Finishes Product Design Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. Common. Metal Finishes Product Design.

From www.homestratosphere.com

12 Different Types of Metal Finishes Metal Finishes Product Design Choosing the right metal finishing technique for a new product design involves a nuanced approach. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, steelscape. Start by understanding the product’s specific needs, such as how it will perform under. Metal Finishes Product Design.

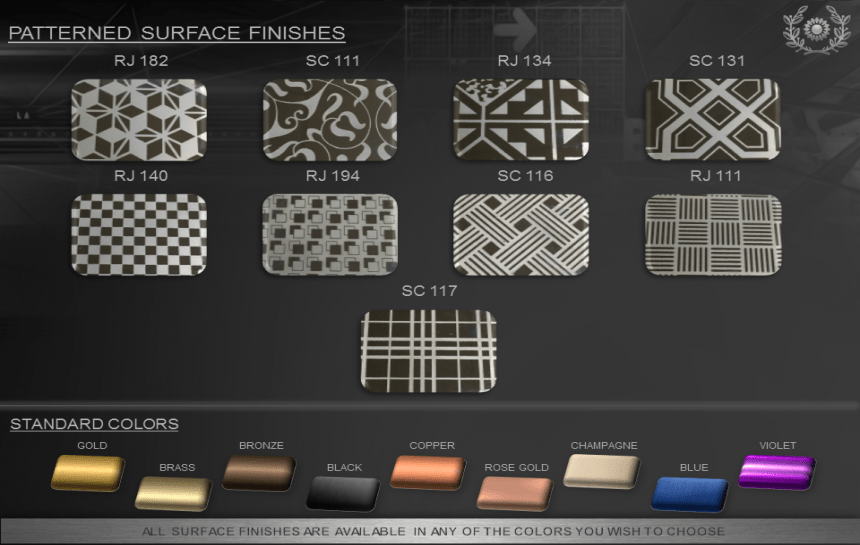

From www.optima.co.uk

Patterend Finishes Optima Metal Services Metal Finishes Product Design Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish,. Metal Finishes Product Design.

From www.kikukawa.com

Aluminium Finish Samples KIKUKAWA Metal Finishes Product Design Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how. Metal Finishes Product Design.

From www.verometal.com

Overview of our liquid design metals and finishes VeroMetal® Metal Finishes Product Design See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. Choosing the right metal finishing technique for a new product design involves a nuanced approach. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating,. Metal Finishes Product Design.

From www.topsonmetal.com

10 Best Stainless Steel Finishes You Must Know in 2024 Metal Finishes Product Design Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Anodizing creates corrosion resistance and adds. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. To. Metal Finishes Product Design.

From www.timelesstube.com

Metals and Finishes Metal Finishes Product Design Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Here are some reasons why surface roughness and. Choosing the right metal finishing technique for a new product design involves a nuanced approach. Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. To help demystify the different elements of a painted metal. Metal Finishes Product Design.

From bellemeadesignature.com

Metal Finish Options Belle Meade Signature Metal Finishes Product Design Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of metal products. See how ea craftworks applies their expertise and creativity to custom metal finishing projects for clients. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they affect. Metal Finishes Product Design.

From shengenfab.com

Metal Surface Finishes Achieving Excellence in Surface Treatment Metal Finishes Product Design Common metal finishes include anodizing, electroplating, powder coating, brushing, and patina. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Anodizing creates corrosion resistance and adds. Learn about different types of metal finishes, such as paints, powder coating, patina, and etching, and how they enhance the aesthetics and durability of. Metal Finishes Product Design.

From www.pinterest.com

Premier Metal Plating House design, Metal, Plating Metal Finishes Product Design Here are some reasons why surface roughness and. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they affect the appearance and durability of metals. Start by understanding the product’s specific needs, such as how it will. Metal Finishes Product Design.

From www.metal-city.com

Decorative Stainless Steel Metals Products Metal City Metal Finishes Product Design Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Here are some reasons why surface roughness and. Choosing the right metal finishing technique for a new product design involves a nuanced approach. Consider transforming entire façades with shimmering metal finishes, creating interactive displays with brushed metal surrounds, or. See how. Metal Finishes Product Design.

From www.verometal.com

Design with Nickel Silver VeroMetal® metal design coating Metal Finishes Product Design Learn about the diverse metal finishing processes, such as electroplating, anodizing, powder coating, and more, and how they enhance surface. Start by understanding the product’s specific needs, such as how it will perform under conditions like exposure to moisture, chemicals, or heavy wear. Learn about different metal finishing techniques, such as electroplating, anodizing, powder coating, and brushing, and how they. Metal Finishes Product Design.