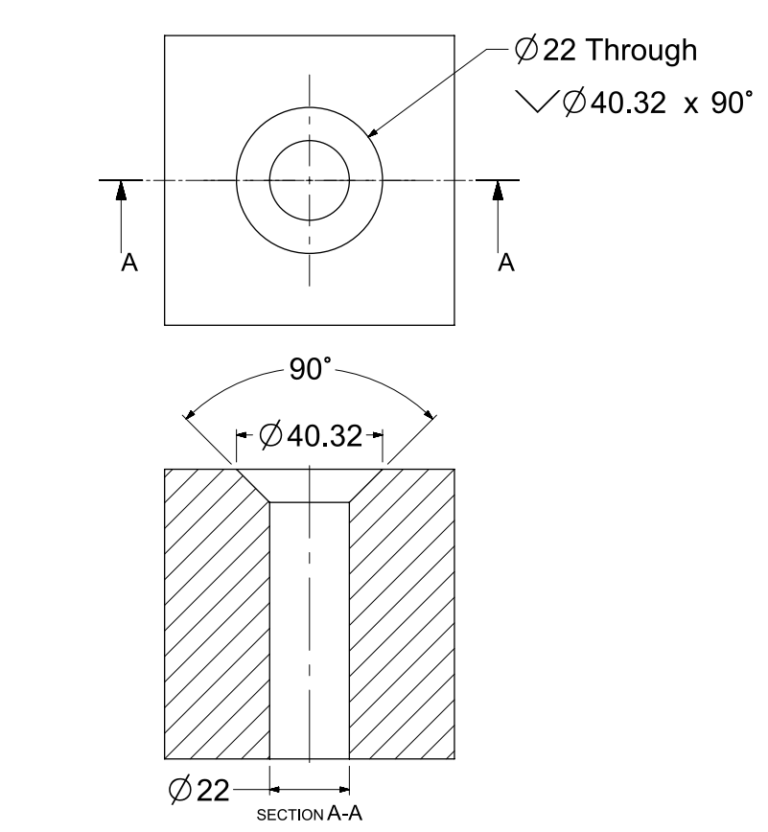

Countersunk Hole Annotation . 90 is the angle between the two edges of the cone shaped hole. this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. 17.30 is the theoretical edge for an m8 countersunk hole. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. I'm not entirely sure if the larger hole. adding hole callouts in a drawing. 1 create a 3.00 × 4.00 × 1.75 block. In this guide you’ll learn: on a technical drawing, countersink hole is read using the ‘ ’ callout. You can add hole callouts in standard drawing views and in section views. The different types of holes used in machining. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). This is a complete guide to the types of holes found in machining. The transition is usually shown at the same.

from dxoieatkz.blob.core.windows.net

on a technical drawing, countersink hole is read using the ‘ ’ callout. The different types of holes used in machining. adding hole callouts in a drawing. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. In this guide you’ll learn: To add a hole callout: this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). This is a complete guide to the types of holes found in machining. 17.30 is the theoretical edge for an m8 countersunk hole. 1 create a 3.00 × 4.00 × 1.75 block.

Countersink Solidworks Drawing at Jeremy Stewart blog

Countersunk Hole Annotation 90 is the angle between the two edges of the cone shaped hole. The transition is usually shown at the same. The different types of holes used in machining. 17.30 is the theoretical edge for an m8 countersunk hole. 2 click the hole wizard tool, click the counterbore option, and insert the counterbored hole that goes completely through. adding hole callouts in a drawing. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). 90 is the angle between the two edges of the cone shaped hole. To add a hole callout: This is a complete guide to the types of holes found in machining. In this guide you’ll learn: this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). on a technical drawing, countersink hole is read using the ‘ ’ callout. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. I'm not entirely sure if the larger hole. You can add hole callouts in standard drawing views and in section views.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersunk Hole Annotation This is a complete guide to the types of holes found in machining. I'm not entirely sure if the larger hole. on a technical drawing, countersink hole is read using the ‘ ’ callout. this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). 1 create a 3.00 × 4.00 ×. Countersunk Hole Annotation.

From engineersbible.com

Countersunk Hole Size for Flat Head Screws (ISO) The Engineer's Bible Countersunk Hole Annotation 90 is the angle between the two edges of the cone shaped hole. this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. This. Countersunk Hole Annotation.

From www.gdandtbasics.com

Countersink GD&T Basics Countersunk Hole Annotation The transition is usually shown at the same. when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. You can add hole callouts in standard drawing views and in section views. In this guide you’ll learn: This is a complete guide to the types of holes found in machining. 2 click the. Countersunk Hole Annotation.

From community.ptc.com

Counterbore/Countersink hole Notes on Drawing. PTC Community Countersunk Hole Annotation the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). 1 create a 3.00 × 4.00 × 1.75 block. adding hole callouts in a drawing. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone. Countersunk Hole Annotation.

From ar.inspiredpencil.com

Standard Countersink Hole Countersunk Hole Annotation adding hole callouts in a drawing. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. To add a hole callout: when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. 17.30. Countersunk Hole Annotation.

From www.educationalstuffs.in

ENGINEERING DRAWING Dimensioning Countersunk Hole Annotation 90 is the angle between the two edges of the cone shaped hole. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). I'm not entirely sure if the larger hole. when a larger hole has a conical transition to a smaller hole, this is called a. Countersunk Hole Annotation.

From dxojjaryn.blob.core.windows.net

How To Draw Countersink In Solidworks at Edith Arnold blog Countersunk Hole Annotation I'm not entirely sure if the larger hole. The transition is usually shown at the same. 17.30 is the theoretical edge for an m8 countersunk hole. You can add hole callouts in standard drawing views and in section views. 90 is the angle between the two edges of the cone shaped hole. 2 click the hole wizard tool, click the. Countersunk Hole Annotation.

From dobemy.com

Countersunk Holes vs. Counterbore Holes What's the Difference?DOBEMY Countersunk Hole Annotation 17.30 is the theoretical edge for an m8 countersunk hole. You can add hole callouts in standard drawing views and in section views. In this guide you’ll learn: when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. I'm not entirely sure if the larger hole. The different types of holes used. Countersunk Hole Annotation.

From forums.autodesk.com

Add hole type counterbored+countersunk Autodesk Community Countersunk Hole Annotation This is a complete guide to the types of holes found in machining. To add a hole callout: when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. 2 click the hole wizard tool, click the counterbore option, and insert the counterbored hole that goes completely through. the countersink will be. Countersunk Hole Annotation.

From www.scribd.com

Guidelines for Punching and Countersinking Holes for Various Screw Countersunk Hole Annotation 2 click the hole wizard tool, click the counterbore option, and insert the counterbored hole that goes completely through. I'm not entirely sure if the larger hole. adding hole callouts in a drawing. This is a complete guide to the types of holes found in machining. You can add hole callouts in standard drawing views and in section views.. Countersunk Hole Annotation.

From www.protoexpress.com

Countersink Holes in PCBs Sierra Circuits Countersunk Hole Annotation This is a complete guide to the types of holes found in machining. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). You can add hole callouts in standard drawing views and in section views. when a larger hole has a conical transition to a smaller. Countersunk Hole Annotation.

From www.youtube.com

How to Make Countersink Holes in SolidWorks using Hole Wizard Command Countersunk Hole Annotation The different types of holes used in machining. 17.30 is the theoretical edge for an m8 countersunk hole. on a technical drawing, countersink hole is read using the ‘ ’ callout. 1 create a 3.00 × 4.00 × 1.75 block. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the. Countersunk Hole Annotation.

From help.kubotekkosmos.com

KeyCreator Help Countersunk Hole Countersunk Hole Annotation In this guide you’ll learn: The transition is usually shown at the same. I'm not entirely sure if the larger hole. adding hole callouts in a drawing. 2 click the hole wizard tool, click the counterbore option, and insert the counterbored hole that goes completely through. 90 is the angle between the two edges of the cone shaped hole.. Countersunk Hole Annotation.

From www.slideserve.com

PPT Holes PowerPoint Presentation, free download ID2107959 Countersunk Hole Annotation You can add hole callouts in standard drawing views and in section views. this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). 90 is the angle between the two edges of the cone shaped hole. when a larger hole has a conical transition to a smaller hole, this is called a. Countersunk Hole Annotation.

From mechheart.com

What is a Countersunk Screw? MECHHEART Countersunk Hole Annotation The different types of holes used in machining. 1 create a 3.00 × 4.00 × 1.75 block. 90 is the angle between the two edges of the cone shaped hole. You can add hole callouts in standard drawing views and in section views. on a technical drawing, countersink hole is read using the ‘ ’ callout. To add. Countersunk Hole Annotation.

From www.engineersrule.com

Tips and Tricks for Defining and Organizing Hole Callouts in SOLIDWORKS Countersunk Hole Annotation on a technical drawing, countersink hole is read using the ‘ ’ callout. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. adding hole callouts in a drawing. 1 create a 3.00 × 4.00 × 1.75 block.. Countersunk Hole Annotation.

From www.bestpcbs.com

What’s the Countersink and counter bore on a PCB drawing? PCB & MCPCB Countersunk Hole Annotation I'm not entirely sure if the larger hole. 90 is the angle between the two edges of the cone shaped hole. In this guide you’ll learn: You can add hole callouts in standard drawing views and in section views. The transition is usually shown at the same. the countersink will be an additional 0.030 at 45 degrees from the. Countersunk Hole Annotation.

From www.youtube.com

Two easy ways to make counterbore holes in AutoCAD YouTube Countersunk Hole Annotation You can add hole callouts in standard drawing views and in section views. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). I'm not entirely sure if the larger hole.. Countersunk Hole Annotation.

From www.altium.com

Working with a Counter Hole View Object on a Draftsman Document in Countersunk Hole Annotation on a technical drawing, countersink hole is read using the ‘ ’ callout. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). 17.30 is the theoretical edge for an m8 countersunk hole. In this guide you’ll learn: I'm not entirely sure if the larger hole. The. Countersunk Hole Annotation.

From www.magnet4sale.com

Countersunk Hole Rectangle Countersunk Hole Annotation This is a complete guide to the types of holes found in machining. The different types of holes used in machining. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). 17.30 is the theoretical edge for an m8 countersunk hole. In this guide you’ll learn: To add. Countersunk Hole Annotation.

From forum.onshape.com

How to create a countersunk hole? — Onshape Countersunk Hole Annotation I'm not entirely sure if the larger hole. In this guide you’ll learn: 1 create a 3.00 × 4.00 × 1.75 block. 90 is the angle between the two edges of the cone shaped hole. This is a complete guide to the types of holes found in machining. To add a hole callout: when a larger hole has. Countersunk Hole Annotation.

From engineersbible.com

Countersunk Hole Size for Socket Flat Head (ANSI Metric) Countersunk Hole Annotation This is a complete guide to the types of holes found in machining. I'm not entirely sure if the larger hole. 1 create a 3.00 × 4.00 × 1.75 block. 90 is the angle between the two edges of the cone shaped hole. 17.30 is the theoretical edge for an m8 countersunk hole. You can add hole callouts in. Countersunk Hole Annotation.

From www.innova-systems.co.uk

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems Countersunk Hole Annotation The transition is usually shown at the same. on a technical drawing, countersink hole is read using the ‘ ’ callout. adding hole callouts in a drawing. when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. this handout will focus on the standards of annotation for fasteners, and. Countersunk Hole Annotation.

From samhakes.com

Types of Holes The Complete Guide The Engineer's Bible (2023) Countersunk Hole Annotation To add a hole callout: when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. 1 create a 3.00 × 4.00 × 1.75 block. 90 is the angle between the two edges of the cone shaped hole. adding hole callouts in a drawing. on a technical drawing, countersink hole. Countersunk Hole Annotation.

From www.youtube.com

PLTW IED 5.5 Countersink in Fusion 360 YouTube Countersunk Hole Annotation I'm not entirely sure if the larger hole. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. 17.30 is the theoretical edge for an m8 countersunk hole. 90 is the angle between the two edges of the cone shaped hole.. Countersunk Hole Annotation.

From www.villageinframe.com

1 4 20 Countersunk Hole Dimensions A Pictures Of Hole 2018 Countersunk Hole Annotation on a technical drawing, countersink hole is read using the ‘ ’ callout. adding hole callouts in a drawing. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. 2 click the hole wizard tool, click the counterbore option,. Countersunk Hole Annotation.

From www.youtube.com

🔩 How To Make Countersink And Counterbore Holes FreeCAD Hole Tutorial Countersunk Hole Annotation the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). 2 click the hole wizard tool, click the counterbore option, and insert the counterbored hole that goes completely through. 90 is the angle between the two edges of the cone shaped hole. this handout will focus on. Countersunk Hole Annotation.

From dxoieatkz.blob.core.windows.net

Countersink Solidworks Drawing at Jeremy Stewart blog Countersunk Hole Annotation a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. The transition is usually shown at the same. 17.30 is the theoretical edge for an m8 countersunk hole. The different types of holes used in machining. You can add hole callouts. Countersunk Hole Annotation.

From classlibrarymoses.z4.web.core.windows.net

Countersunk Hole Drawing Symbol Countersunk Hole Annotation 2 click the hole wizard tool, click the counterbore option, and insert the counterbored hole that goes completely through. I'm not entirely sure if the larger hole. To add a hole callout: In this guide you’ll learn: adding hole callouts in a drawing. this handout will focus on the standards of annotation for fasteners, and hole callouts (local. Countersunk Hole Annotation.

From celtdcnl.blob.core.windows.net

Countersink Dimension Callout at Alberto King blog Countersunk Hole Annotation 1 create a 3.00 × 4.00 × 1.75 block. when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. To add a. Countersunk Hole Annotation.

From www.engineersrule.com

Call out Multiple Features Together with a Single Annotation Countersunk Hole Annotation adding hole callouts in a drawing. this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). 90 is the angle between the two edges of the cone shaped hole. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). . Countersunk Hole Annotation.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk Hole Annotation adding hole callouts in a drawing. The different types of holes used in machining. The transition is usually shown at the same. This is a complete guide to the types of holes found in machining. this handout will focus on the standards of annotation for fasteners, and hole callouts (local notes). when a larger hole has a. Countersunk Hole Annotation.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk Hole Annotation when a larger hole has a conical transition to a smaller hole, this is called a counterdrill. the countersink will be an additional 0.030 at 45 degrees from the thru hole values (since the countersink won't be thru). 1 create a 3.00 × 4.00 × 1.75 block. 2 click the hole wizard tool, click the counterbore option,. Countersunk Hole Annotation.

From www.gdandtbasics.com

Countersink GD&T Basics Countersunk Hole Annotation In this guide you’ll learn: 1 create a 3.00 × 4.00 × 1.75 block. I'm not entirely sure if the larger hole. You can add hole callouts in standard drawing views and in section views. 2 click the hole wizard tool, click the counterbore option, and insert the counterbored hole that goes completely through. on a technical drawing,. Countersunk Hole Annotation.

From ceguixyw.blob.core.windows.net

Countersunk Holes Tekla at Xavier Thornton blog Countersunk Hole Annotation adding hole callouts in a drawing. 90 is the angle between the two edges of the cone shaped hole. The transition is usually shown at the same. You can add hole callouts in standard drawing views and in section views. I'm not entirely sure if the larger hole. on a technical drawing, countersink hole is read using the. Countersunk Hole Annotation.