Axle Bolt Tightening . Tighten bolt to 148 lb. Tightening torques on the front undercarriage. All of those factors are summarized in single. i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. you all know better than to use an impact wrench to tighten an axle nut, right? Axle nuts play an important role in the wheel. the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. No matter what your preference for bolt tightening, atlas copco have it covered. i've found conflicting information on the front axle bolt torque spec. Ft / 200 nm with. Tighten to 20% to 30% of target torque usind cross pattern. the gigant axle nut is an important axle component for securing the hub unit and to correctly set the pretension in the bearing. · the proper axial tightening force for a bolt should be calculated within an elasticity range up to 70% of the rated yield strength. you should screw your through axle according to the manufacturer's specified torque value range. pocket guide to tightening technique.

from www.youtube.com

there are several factors that affect the relationship between the applied bolt torque and the resulting bolt tension. i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. Check flange gap around circumference for uniformity. Ft / 200 nm with. pocket guide to tightening technique. you should screw your through axle according to the manufacturer's specified torque value range. vehicles with 12 point bolt without ribs on under side of bolt flange: I suppose this is the cv joint grease. when i removed the axle bolt, the threads were covered in grease. Shock and pivot bolts may be installed at any suspension position but bolts must only.

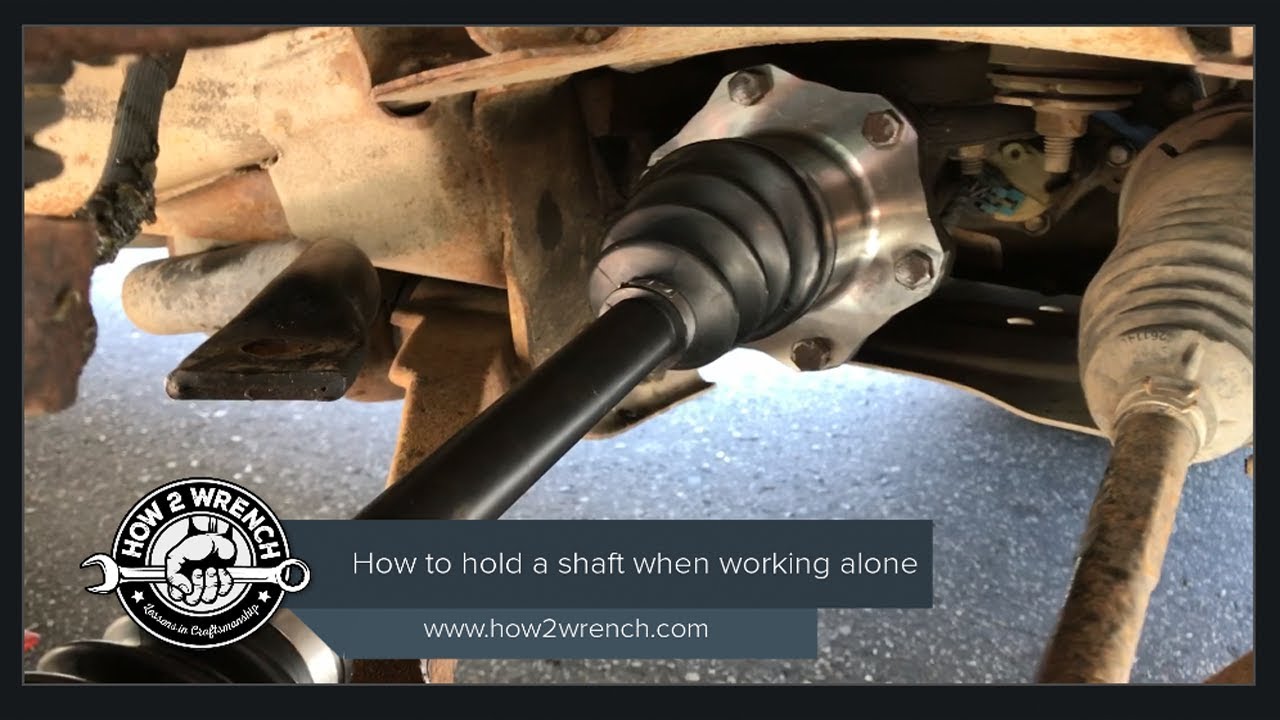

Chevy GMC Truck CV Axle Replacement Tip how to prevent shaft from turning while torquing the

Axle Bolt Tightening Ft / 200 nm with. too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to vibrations. shock & pivot bolt tightening: i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. No matter what your preference for bolt tightening, atlas copco have it covered. Ft / 200 nm with. vehicles with 12 point bolt without ribs on under side of bolt flange: there are several factors that affect the relationship between the applied bolt torque and the resulting bolt tension. i've found conflicting information on the front axle bolt torque spec. there's two different style bolts & each one has different torque specs: the gigant axle nut is an important axle component for securing the hub unit and to correctly set the pretension in the bearing. Tighten to 20% to 30% of target torque usind cross pattern. Check flange gap around circumference for uniformity. you all know better than to use an impact wrench to tighten an axle nut, right? Axle nuts play an important role in the wheel. One specs 50 nm and the second 35.

From repairfixziffernrp.z22.web.core.windows.net

Engine Torque Specification Chart Axle Bolt Tightening I suppose this is the cv joint grease. you should screw your through axle according to the manufacturer's specified torque value range. Ft / 200 nm with. you all know better than to use an impact wrench to tighten an axle nut, right? All of those factors are summarized in single. Check flange gap around circumference for uniformity.. Axle Bolt Tightening.

From bagnolatijs7fixengine.z13.web.core.windows.net

Chevy Silverado Rear Differential Chart Axle Bolt Tightening there's two different style bolts & each one has different torque specs: i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. shock & pivot bolt tightening: I suppose this is the cv joint grease. when i removed the axle bolt, the threads were covered in grease.. Axle Bolt Tightening.

From hxezogmyz.blob.core.windows.net

Wheel Axle Bolt Nut at Mark Howell blog Axle Bolt Tightening Axle nuts play an important role in the wheel. there's two different style bolts & each one has different torque specs: Shock and pivot bolts may be installed at any suspension position but bolts must only. when i removed the axle bolt, the threads were covered in grease. vehicles with 12 point bolt without ribs on under. Axle Bolt Tightening.

From www.aiophotoz.com

Metric Bolt Tightening Torque Chart Images With Images Metric Bolt Images and Photos finder Axle Bolt Tightening Tightening torques on the front undercarriage. shock & pivot bolt tightening: No matter what your preference for bolt tightening, atlas copco have it covered. you all know better than to use an impact wrench to tighten an axle nut, right? #1 · sep 3, 2020 (edited) tightening torques (nm)* engine tightening torques. Ft / 200 nm with.. Axle Bolt Tightening.

From repairfixmenyeid50.z4.web.core.windows.net

Torque Settings For Bolts Chart Axle Bolt Tightening there's two different style bolts & each one has different torque specs: Tighten to 20% to 30% of target torque usind cross pattern. the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. I suppose this is the cv joint grease. you should screw your through axle. Axle Bolt Tightening.

From exovjhchb.blob.core.windows.net

Ford Axle Flange Bolt Pattern at Esther Nieto blog Axle Bolt Tightening the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. there are several factors that affect the relationship between the applied bolt torque and the resulting bolt tension. shock & pivot bolt tightening: No matter what your preference for bolt tightening, atlas copco have it covered. . Axle Bolt Tightening.

From psiquicaavafixengine.z13.web.core.windows.net

2003 Chevy Silverado Front Wheel Bearing Axle Bolt Tightening i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. Tightening torques on the front undercarriage. I suppose this is the cv joint grease. when i removed the. Axle Bolt Tightening.

From repairfixjongbyrd.z22.web.core.windows.net

F 150 U Bolt Torque Spec Axle Bolt Tightening vehicles with 12 point bolt without ribs on under side of bolt flange: Ft / 200 nm with. Tighten bolt to 148 lb. One specs 50 nm and the second 35. I suppose this is the cv joint grease. too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to. Axle Bolt Tightening.

From hxemztldg.blob.core.windows.net

H22 Head Bolt Torque Sequence at Proctor blog Axle Bolt Tightening the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. you should screw your through axle according to the manufacturer's specified torque value range. i've found conflicting information on the front axle bolt torque spec. All of those factors are summarized in single. vehicles with 12. Axle Bolt Tightening.

From repairfixmenyeid50.z4.web.core.windows.net

Flange Torque Specs Chart Axle Bolt Tightening i've found conflicting information on the front axle bolt torque spec. i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. vehicles with 12 point bolt without ribs on under side of bolt flange: I suppose this is the cv joint grease. Axle nuts play an important role. Axle Bolt Tightening.

From www.orangetractortalks.com

rear axle housing bolt torque OrangeTractorTalks Everything Kubota Axle Bolt Tightening Shock and pivot bolts may be installed at any suspension position but bolts must only. the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. · the proper axial tightening force for a bolt should be calculated within an elasticity range up to 70% of the rated yield. Axle Bolt Tightening.

From dxojptbcg.blob.core.windows.net

Exhaust Bolt Tightening at Michael Rogers blog Axle Bolt Tightening · the proper axial tightening force for a bolt should be calculated within an elasticity range up to 70% of the rated yield strength. All of those factors are summarized in single. the gigant axle nut is an important axle component for securing the hub unit and to correctly set the pretension in the bearing. vehicles with. Axle Bolt Tightening.

From flugbrandijyfixengine.z13.web.core.windows.net

Gm Differential Identification Numbers Axle Bolt Tightening the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. pocket guide to tightening technique. Check flange gap around circumference for uniformity. there's two different style bolts & each one has different torque specs: you should screw your through axle according to the manufacturer's specified torque. Axle Bolt Tightening.

From fixengineukusniju88.z22.web.core.windows.net

Torque Specifications For Bolts Axle Bolt Tightening you all know better than to use an impact wrench to tighten an axle nut, right? No matter what your preference for bolt tightening, atlas copco have it covered. i've found conflicting information on the front axle bolt torque spec. Ft / 200 nm with. Tightening torques on the front undercarriage. there are several factors that affect. Axle Bolt Tightening.

From fixmachineochraceous.z14.web.core.windows.net

Hub Pilot Wheel Lug Nut Torque Axle Bolt Tightening No matter what your preference for bolt tightening, atlas copco have it covered. All of those factors are summarized in single. i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. Tightening torques on the front undercarriage. i've found conflicting information on the front axle bolt torque spec. . Axle Bolt Tightening.

From garagefixwidgies.z14.web.core.windows.net

Torque Spec For Front Axle Nut Axle Bolt Tightening when i removed the axle bolt, the threads were covered in grease. i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. · the proper axial tightening force for a bolt should be calculated within an elasticity range up to 70% of the rated yield strength. too. Axle Bolt Tightening.

From hxecdujsq.blob.core.windows.net

Bolt Axle Wrench at Janis Robbins blog Axle Bolt Tightening Tightening torques on the front undercarriage. Shock and pivot bolts may be installed at any suspension position but bolts must only. Axle nuts play an important role in the wheel. · the proper axial tightening force for a bolt should be calculated within an elasticity range up to 70% of the rated yield strength. Tighten to 20% to 30%. Axle Bolt Tightening.

From www.2carpros.com

What Are the Front and Rear Axle Torque Specs? Axle Bolt Tightening pocket guide to tightening technique. the gigant axle nut is an important axle component for securing the hub unit and to correctly set the pretension in the bearing. you should screw your through axle according to the manufacturer's specified torque value range. I suppose this is the cv joint grease. No matter what your preference for bolt. Axle Bolt Tightening.

From www.facebook.com

Restoration Garage S07 E03 Fire Fighting Heritage ('21 International ST509 fire truck, '62 Axle Bolt Tightening Ft / 200 nm with. you all know better than to use an impact wrench to tighten an axle nut, right? · the proper axial tightening force for a bolt should be calculated within an elasticity range up to 70% of the rated yield strength. Tighten to 20% to 30% of target torque usind cross pattern. there's. Axle Bolt Tightening.

From repairfixmenyeid50.z4.web.core.windows.net

Sae Bolt Torque Specs Axle Bolt Tightening you all know better than to use an impact wrench to tighten an axle nut, right? Check flange gap around circumference for uniformity. too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to vibrations. pocket guide to tightening technique. there's two different style bolts & each one. Axle Bolt Tightening.

From exovjhchb.blob.core.windows.net

Ford Axle Flange Bolt Pattern at Esther Nieto blog Axle Bolt Tightening i've found conflicting information on the front axle bolt torque spec. i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. Tighten bolt to 148 lb. too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to vibrations. there's. Axle Bolt Tightening.

From hxedzyggj.blob.core.windows.net

Truck Axle U Bolt Torque at Betty Keaton blog Axle Bolt Tightening you should screw your through axle according to the manufacturer's specified torque value range. Tighten to 20% to 30% of target torque usind cross pattern. the gigant axle nut is an important axle component for securing the hub unit and to correctly set the pretension in the bearing. Axle nuts play an important role in the wheel. . Axle Bolt Tightening.

From giofqafcs.blob.core.windows.net

Bmw F10 Axle Bolt Torque at Gilbert Rogers blog Axle Bolt Tightening Tighten bolt to 148 lb. i constantly rotate the wheel by hand in between lining up the calipers, tightening the caliper bolts, tightening the. I suppose this is the cv joint grease. the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. there's two different style bolts. Axle Bolt Tightening.

From giofqafcs.blob.core.windows.net

Bmw F10 Axle Bolt Torque at Gilbert Rogers blog Axle Bolt Tightening shock & pivot bolt tightening: too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to vibrations. the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. you all know better than to use an impact wrench to. Axle Bolt Tightening.

From dxoredljm.blob.core.windows.net

Torquing A Bolt at Nicole Miller blog Axle Bolt Tightening vehicles with 12 point bolt without ribs on under side of bolt flange: shock & pivot bolt tightening: too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to vibrations. Ft / 200 nm with. there are several factors that affect the relationship between the applied bolt torque. Axle Bolt Tightening.

From workshopdraftees.z13.web.core.windows.net

Dodge Ram 1500 Limited Slip Differential Axle Bolt Tightening One specs 50 nm and the second 35. too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to vibrations. Check flange gap around circumference for uniformity. · the proper axial tightening force for a bolt should be calculated within an elasticity range up to 70% of the rated yield. Axle Bolt Tightening.

From www.decathlon.com.kh

Crank Arm Tightening Bolts Decathlon Axle Bolt Tightening i've found conflicting information on the front axle bolt torque spec. the gigant axle nut is an important axle component for securing the hub unit and to correctly set the pretension in the bearing. #1 · sep 3, 2020 (edited) tightening torques (nm)* engine tightening torques. All of those factors are summarized in single. when i. Axle Bolt Tightening.

From www.youtube.com

Bolt Tensioning vs. Torquing, Compared YouTube Axle Bolt Tightening Tighten to 20% to 30% of target torque usind cross pattern. Ft / 200 nm with. #1 · sep 3, 2020 (edited) tightening torques (nm)* engine tightening torques. No matter what your preference for bolt tightening, atlas copco have it covered. I suppose this is the cv joint grease. pocket guide to tightening technique. i've found conflicting. Axle Bolt Tightening.

From www.youtube.com

Chevy GMC Truck CV Axle Replacement Tip how to prevent shaft from turning while torquing the Axle Bolt Tightening Tightening torques on the front undercarriage. the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. you all know better than to use an impact wrench to tighten an axle nut, right? One specs 50 nm and the second 35. shock & pivot bolt tightening: the. Axle Bolt Tightening.

From repairmachineondiskc.z22.web.core.windows.net

2009 Chevy Silverado 1500 Rear Differential Axle Bolt Tightening All of those factors are summarized in single. vehicles with 12 point bolt without ribs on under side of bolt flange: you should screw your through axle according to the manufacturer's specified torque value range. there's two different style bolts & each one has different torque specs: Tightening torques on the front undercarriage. Ft / 200 nm. Axle Bolt Tightening.

From giofqafcs.blob.core.windows.net

Bmw F10 Axle Bolt Torque at Gilbert Rogers blog Axle Bolt Tightening i've found conflicting information on the front axle bolt torque spec. I suppose this is the cv joint grease. All of those factors are summarized in single. Check flange gap around circumference for uniformity. the gigant axle nut is an important axle component for securing the hub unit and to correctly set the pretension in the bearing. . Axle Bolt Tightening.

From www.decathlon.com.kh

Crank Arm Tightening Bolts Decathlon Axle Bolt Tightening All of those factors are summarized in single. the calculator below can be used to calculate the torque required to achieve a given axial bolt force or load. there's two different style bolts & each one has different torque specs: No matter what your preference for bolt tightening, atlas copco have it covered. vehicles with 12 point. Axle Bolt Tightening.

From elchoroukhost.net

Bolt Tightening Torque Table In N M Pdf Elcho Table Axle Bolt Tightening shock & pivot bolt tightening: Ft / 200 nm with. Shock and pivot bolts may be installed at any suspension position but bolts must only. #1 · sep 3, 2020 (edited) tightening torques (nm)* engine tightening torques. Axle nuts play an important role in the wheel. · the proper axial tightening force for a bolt should be. Axle Bolt Tightening.

From www.decathlon.com.kh

Crank Arm Tightening Bolts Decathlon Axle Bolt Tightening Tightening torques on the front undercarriage. · the proper axial tightening force for a bolt should be calculated within an elasticity range up to 70% of the rated yield strength. No matter what your preference for bolt tightening, atlas copco have it covered. One specs 50 nm and the second 35. the gigant axle nut is an important. Axle Bolt Tightening.

From garagefixrosetasku.z13.web.core.windows.net

Jeep Jk Lug Nut Torque Spec Axle Bolt Tightening there are several factors that affect the relationship between the applied bolt torque and the resulting bolt tension. All of those factors are summarized in single. Axle nuts play an important role in the wheel. too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to vibrations. vehicles with. Axle Bolt Tightening.