Crankshaft Journal Inspection . A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. In the case of a new crankshaft, check for dimensions and runout. Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Proper crankshaft inspection is the foundation of effective maintenance. Here’s what you need to know: Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft.

from repairmachineenisle.z5.web.core.windows.net

With a previously used crankshaft, you’ll also need to check for flaws (cracks). In the case of a new crankshaft, check for dimensions and runout. Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Here’s what you need to know: Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. Proper crankshaft inspection is the foundation of effective maintenance.

Ls Engine Bearing Clearance Chart

Crankshaft Journal Inspection Here’s what you need to know: Proper crankshaft inspection is the foundation of effective maintenance. Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Here’s what you need to know: Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. In the case of a new crankshaft, check for dimensions and runout.

From www.youtube.com

Crankshaft True Roundness Inspection Machine +Vantage Metrology Crankshaft Journal Inspection Here’s what you need to know: Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new. Crankshaft Journal Inspection.

From www.hotrod.com

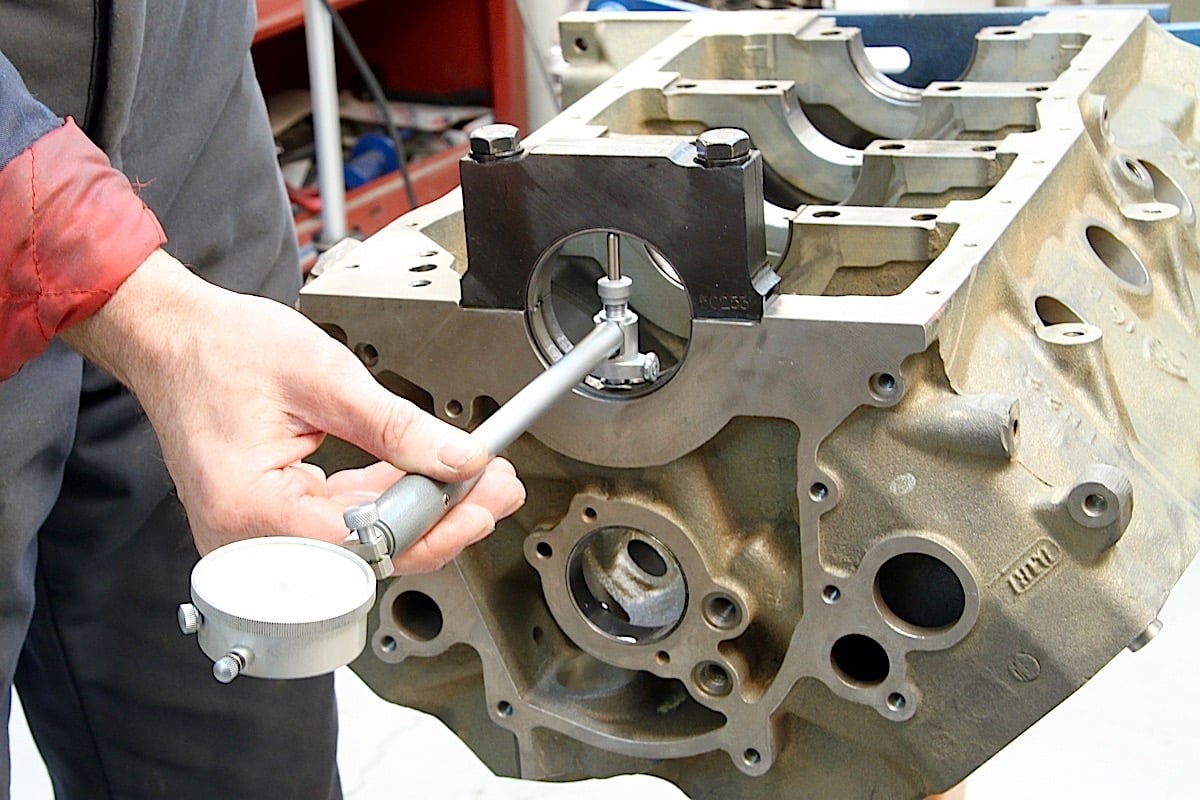

How to Measure Bottom End Clearance Hot Rod Network Crankshaft Journal Inspection Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. Proper crankshaft inspection is the foundation of effective maintenance. Here’s what you need to know: In the case of a new crankshaft, check for dimensions and runout. A noticeable decrease in engine power, accompanied by a rough idle, can point to. Crankshaft Journal Inspection.

From www.youtube.com

Crankshaft Dimensional Inspection YouTube Crankshaft Journal Inspection Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Here’s what you need. Crankshaft Journal Inspection.

From mail.freeasestudyguides.com

Engine Crankshaft Journal Bearings Inspection Crankshaft Journal Inspection With a previously used crankshaft, you’ll also need to check for flaws (cracks). Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Here’s what you need to know: In the case of a new crankshaft, check for dimensions and runout. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a. Crankshaft Journal Inspection.

From dieselgenerators.tpub.com

Figure 941. Crankshaft Journal Measurements Crankshaft Journal Inspection It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Proper crankshaft inspection is the foundation of. Crankshaft Journal Inspection.

From exodmwchw.blob.core.windows.net

How To Measure Crankshaft Journal Diameter at Derek Wheeler blog Crankshaft Journal Inspection Proper crankshaft inspection is the foundation of effective maintenance. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe. Crankshaft Journal Inspection.

From www.ebay.com

Snap Gage Air 2 1/4" 3 1/2" Crankshaft Shaft Bearing Journal Inspection Crankshaft Journal Inspection Proper crankshaft inspection is the foundation of effective maintenance. Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. Regular inspection of crankshafts is essential for maintaining optimal. Crankshaft Journal Inspection.

From www.howacarworks.com

How the crankshaft works All the details How a Car Works Crankshaft Journal Inspection Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. In the case of a new crankshaft, check for dimensions and runout. Proper crankshaft inspection is the foundation. Crankshaft Journal Inspection.

From www.youtube.com

Crankshaft Main Bearing Journal Measurements YouTube Crankshaft Journal Inspection With a previously used crankshaft, you’ll also need to check for flaws (cracks). Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. A noticeable decrease in engine power, accompanied by a rough idle, can point. Crankshaft Journal Inspection.

From dieselgenerators.tpub.com

Figure 942. Inspection of Crankshaft Crankshaft Journal Inspection Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. Here’s what you need to know: Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. It has to spin, plunge, accelerate and. Crankshaft Journal Inspection.

From www.youtube.com

Crankshaft Journal Measuring YouTube Crankshaft Journal Inspection Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect. Crankshaft Journal Inspection.

From www.youtube.com

Measuring Crankshaft Journals & How to use a Micrometer YouTube Crankshaft Journal Inspection A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. Proper crankshaft inspection is the foundation of effective maintenance. Regardless of which crank you choose to use during a customer’s engine rebuild or. Crankshaft Journal Inspection.

From www.enginelabs.com

EngineLabs’ Tool Of The Month Goodson Crankshaft Inspection Stand Crankshaft Journal Inspection Here’s what you need to know: With a previously used crankshaft, you’ll also need to check for flaws (cracks). Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. In the case of a new crankshaft, check for dimensions and runout. A noticeable decrease in engine power, accompanied by a rough idle, can point to a. Crankshaft Journal Inspection.

From www.youtube.com

Crankshaft Inspection Machine क्रैंकशाफ्ट निरीक्षण मशीन YouTube Crankshaft Journal Inspection It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Here’s what you need to know: Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Regardless of which crank you choose to. Crankshaft Journal Inspection.

From rapower.medium.com

Crankshaft inspection procedure crankshaftgrindingrepair RA Power Crankshaft Journal Inspection It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. A noticeable decrease in engine power, accompanied. Crankshaft Journal Inspection.

From mcgrp.ru

Tohatsu MFS 25 [165/319] Inspection of crankshaft Crankshaft Journal Inspection Here’s what you need to know: With a previously used crankshaft, you’ll also need to check for flaws (cracks). Proper crankshaft inspection is the foundation of effective maintenance. Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. In the case of a new crankshaft, check for dimensions and runout. Regardless of which crank you choose. Crankshaft Journal Inspection.

From www.megacarss.com

Bearing Damage Reference Wall Chart RMS Ltd, 54 OFF Crankshaft Journal Inspection A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. With a previously used crankshaft, you’ll also need to. Crankshaft Journal Inspection.

From ruichautoparts.com

The Grinding of Crankshaft Main Journal and conrod Journal Crankshaft Journal Inspection With a previously used crankshaft, you’ll also need to check for flaws (cracks). A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. It has to spin, plunge,. Crankshaft Journal Inspection.

From www.youtube.com

B18c TypeR Crankshaft Inspection journal runout, end play YouTube Crankshaft Journal Inspection It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Here’s what you need to know: Regular inspection of crankshafts is essential for maintaining optimal engine performance. Crankshaft Journal Inspection.

From www.youtube.com

Crankshaft main journal and connecting rod journal measurements YouTube Crankshaft Journal Inspection Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. Here’s what you need to know: Proper crankshaft inspection is the foundation of effective. Crankshaft Journal Inspection.

From www.youtube.com

SBC crankshaft identification YouTube Crankshaft Journal Inspection A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Proper crankshaft inspection is the foundation of effective maintenance. Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Careful. Crankshaft Journal Inspection.

From inchbyinch.de

INCH Technical English crankshaft Crankshaft Journal Inspection A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. In the case of a new crankshaft, check for dimensions and runout. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Regardless of which crank you. Crankshaft Journal Inspection.

From www.enginelabs.com

EngineLabs’ Tool Of The Month Goodson Crankshaft Inspection Stand Crankshaft Journal Inspection Regular inspection and measurement of crankshaft journals are essential for maintaining engine performance and. Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. In the case of a new crankshaft, check for dimensions and runout. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Regardless of which crank you choose to. Crankshaft Journal Inspection.

From www.crankshaftgrindingrepair.com

Crankshaft Journal Repair And Crankpin Journal Repair Crankshaft Journal Inspection It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Proper crankshaft inspection is the foundation of effective maintenance. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. Here’s what you need to know: In the case of a new. Crankshaft Journal Inspection.

From www.youtube.com

Crankshaft Inspection // True Run to main bearing journal with Crankshaft Journal Inspection In the case of a new crankshaft, check for dimensions and runout. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Regular inspection of crankshafts is. Crankshaft Journal Inspection.

From motsmachining.com

Crankshaft Rebuilding Mots Machining Crankshaft Journal Inspection Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Regular inspection and measurement of crankshaft journals are essential for maintaining engine. Crankshaft Journal Inspection.

From hybridengineering.org

Crankshaft Inspection Machine Hybrid Engineering Crankshaft Journal Inspection Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Careful inspection and judgement of the crankpin journals must be carried out whenever. Crankshaft Journal Inspection.

From www.gl1800riders.com

Crankshaft Direction GL1800Riders Forums Crankshaft Journal Inspection Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed.. Crankshaft Journal Inspection.

From www.vrogue.co

What Is Crankshaft Deflection And Its Reasons Marineg vrogue.co Crankshaft Journal Inspection Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. Proper crankshaft inspection is the foundation of effective maintenance. Here’s what you need to know: It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Regular inspection of crankshafts is essential. Crankshaft Journal Inspection.

From www.youtube.com

DD15 engine crankshaft inspection movement to discovery the damage to Crankshaft Journal Inspection In the case of a new crankshaft, check for dimensions and runout. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. Regular inspection of crankshafts is essential for maintaining optimal engine performance and preventing costly. Here’s what you need to know: It has to spin, plunge, accelerate and decelerate, twist. Crankshaft Journal Inspection.

From www.autozone.com

Repair Guides Engine Mechanical Crankshaft And Main Bearings Crankshaft Journal Inspection Proper crankshaft inspection is the foundation of effective maintenance. A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed. It has to spin, plunge, accelerate and decelerate, twist. Crankshaft Journal Inspection.

From cgkgage.com

Camshaft and Crankshaft Inspection CGK Gage Group LLC Crankshaft Journal Inspection It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Here’s what you need to know: With a previously used crankshaft, you’ll also need to check for flaws (cracks). A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as. Crankshaft Journal Inspection.

From www.ebay.com

Snap Gage Air 2 1/4" 3 1/2" Crankshaft Shaft Bearing Journal Inspection Crankshaft Journal Inspection Regardless of which crank you choose to use during a customer’s engine rebuild or fresh build (used oe or new aftermarket), take the time to inspect the crankshaft. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Careful inspection and judgement of the crankpin journals must be carried out. Crankshaft Journal Inspection.

From repairmachineenisle.z5.web.core.windows.net

Ls Engine Bearing Clearance Chart Crankshaft Journal Inspection A noticeable decrease in engine power, accompanied by a rough idle, can point to a problem with the crankshaft, such as a bent. It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. With a previously used crankshaft, you’ll also need to check for flaws (cracks). Regular inspection and measurement. Crankshaft Journal Inspection.

From www.youtube.com

Crankshaft Rod & Main Journal Measurement YouTube Crankshaft Journal Inspection With a previously used crankshaft, you’ll also need to check for flaws (cracks). It has to spin, plunge, accelerate and decelerate, twist and untwist hundreds of times a minute, depending on its application. Here’s what you need to know: In the case of a new crankshaft, check for dimensions and runout. Regular inspection and measurement of crankshaft journals are essential. Crankshaft Journal Inspection.