Strain Extension Original Length . tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. The quantity that describes this deformation is called strain. Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. the following equation gives the relation for deformation in terms of the length of a solid: an object or medium under stress becomes deformed.

from www.chegg.com

deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. The quantity that describes this deformation is called strain. an object or medium under stress becomes deformed. the following equation gives the relation for deformation in terms of the length of a solid: Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l.

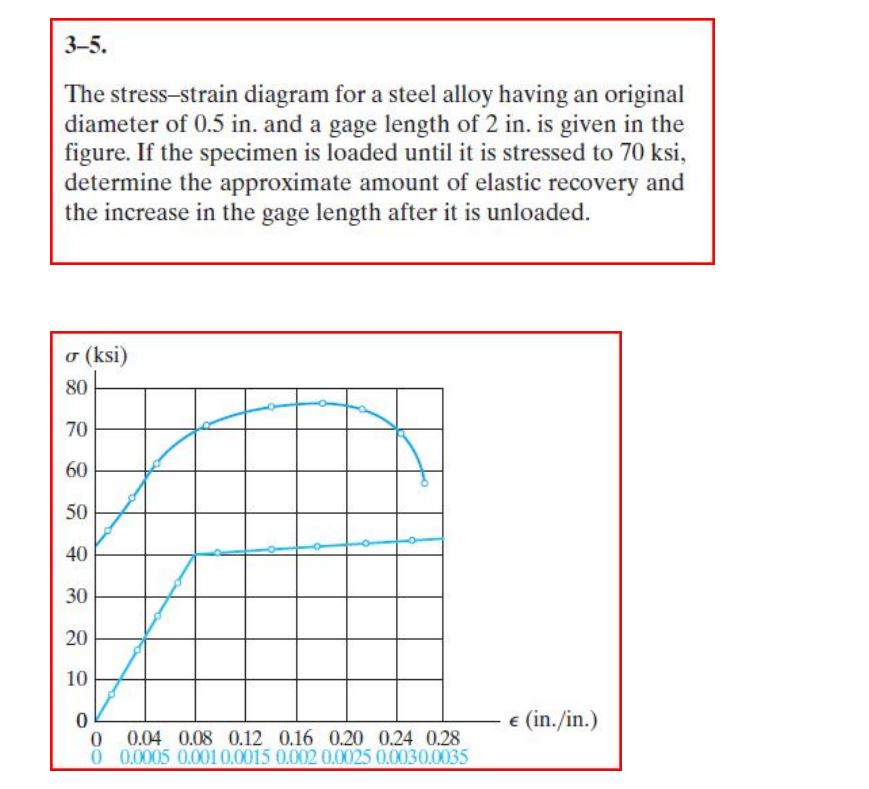

Solved 35. The stressstrain diagram for a steel alloy

Strain Extension Original Length the following equation gives the relation for deformation in terms of the length of a solid: Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. an object or medium under stress becomes deformed. The quantity that describes this deformation is called strain. the following equation gives the relation for deformation in terms of the length of a solid:

From www.researchgate.net

Extension to the stressstrain curves for strain rates v = 0.001 and Strain Extension Original Length The quantity that describes this deformation is called strain. the following equation gives the relation for deformation in terms of the length of a solid: Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε.. Strain Extension Original Length.

From www.piping-designer.com

Strain Strain Extension Original Length The quantity that describes this deformation is called strain. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. an object or medium under stress becomes deformed. the following equation gives the relation for deformation in terms of the length of a solid: Linear strain. Strain Extension Original Length.

From www.chegg.com

Solved *312. The stressstrain diagram for an aluminum Strain Extension Original Length The quantity that describes this deformation is called strain. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. the following equation gives the relation for deformation in. Strain Extension Original Length.

From www.researchgate.net

1. Experimental extension strain as a function of shear strain for Strain Extension Original Length an object or medium under stress becomes deformed. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. the following equation gives the relation for deformation in terms of the length of a solid: tensile stress and strain occur. Strain Extension Original Length.

From www.numerade.com

SOLVED Calculate the strain of a brass rod of length 250 mm which is Strain Extension Original Length tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. an object or medium under stress becomes deformed. The quantity that describes this deformation is called strain. deformation is a measure of how much an object is stretched, and strain is the ratio between the. Strain Extension Original Length.

From www.chegg.com

Solved The stressstrain diagram for a steel alloy having an Strain Extension Original Length the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. the following equation gives the relation for. Strain Extension Original Length.

From www.slideserve.com

PPT 1.2 STRENGTH OF MATERIALS PowerPoint Presentation, free download Strain Extension Original Length the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. an object or medium under stress becomes deformed. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original. Strain Extension Original Length.

From www.chegg.com

Solved 36. The stressstrain diagram for a steel alloy Strain Extension Original Length an object or medium under stress becomes deformed. Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. tensile stress and strain occur. Strain Extension Original Length.

From www.youtube.com

Problem 2 on Calculation of Change in Length and Change in Diameter Strain Extension Original Length the following equation gives the relation for deformation in terms of the length of a solid: The quantity that describes this deformation is called strain. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. an object or medium under. Strain Extension Original Length.

From ahssinsights.org

Total Elongation AHSS Guidelines Strain Extension Original Length an object or medium under stress becomes deformed. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the.. Strain Extension Original Length.

From engineeringdiscoveries.com

Stress And Strain Simple Explanation Engineering Discoveries Strain Extension Original Length an object or medium under stress becomes deformed. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. \ (\begin {array} {l}\epsilon. Strain Extension Original Length.

From www.youtube.com

6.1b Graphs of StressStrain and ForceExtension AS Deformation Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. an object or medium under stress becomes deformed. the following equation. Strain Extension Original Length.

From www.answersarena.com

[Solved] *312. The stressstrain diagram for a steel allo Strain Extension Original Length tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. the following equation gives the relation for deformation in terms of the length of a solid: an object or medium under stress becomes deformed. Linear strain a straight bar will change in length when loaded. Strain Extension Original Length.

From www.comsol.com

What Is Structural Mechanics? An Introductory Guide Strain Extension Original Length an object or medium under stress becomes deformed. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. the following equation gives the relation for deformation in terms of the length of a solid: the engineering measures of stress and strain, denoted in this. Strain Extension Original Length.

From www.chegg.com

Solved The stressstrain diagram for an aluminum alloy Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. the following equation gives the relation for. Strain Extension Original Length.

From www.chegg.com

Solved 35. The stressstrain diagram for a steel alloy Strain Extension Original Length tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. an object or medium under stress becomes deformed. The quantity that describes this deformation is called strain. the following equation gives the relation for deformation in terms of the length of a solid: Linear strain. Strain Extension Original Length.

From www.researchgate.net

Loadextensiontime paths for tensile tests. (a) Constant rate of Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. the following equation gives the relation for deformation in terms of the length of a solid: The quantity that describes this deformation is called strain. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array}. Strain Extension Original Length.

From www.researchgate.net

Straincontrolled biaxial loading extension in principal fiber Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. the engineering measures of stress and strain, denoted in this module as. Strain Extension Original Length.

From www.piping-designer.com

Strain Length Change Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. an object or medium under stress becomes deformed. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. The quantity that describes this deformation is called strain. the engineering measures of. Strain Extension Original Length.

From www.chegg.com

Solved The stressstrain diagram for an aluminum alloy Strain Extension Original Length \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length. Strain Extension Original Length.

From www.youtube.com

Calculating Strain and Change in Area due to 2D Complex Loading YouTube Strain Extension Original Length Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. an object or medium under stress becomes deformed. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. \ (\begin. Strain Extension Original Length.

From www.researchgate.net

a Load versus extension, b Eng. stress versus eng. strain, c true Strain Extension Original Length The quantity that describes this deformation is called strain. an object or medium under stress becomes deformed. Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. the following equation gives the relation for. Strain Extension Original Length.

From material-properties.org

What is Ultimate Tensile Strength UTS Definition Material Properties Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. an. Strain Extension Original Length.

From www.chegg.com

35) The stressstrain diagram for a steel alloy Strain Extension Original Length an object or medium under stress becomes deformed. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. The quantity that describes this deformation is called strain. the following equation gives the relation for deformation in terms of the length of a solid: . Strain Extension Original Length.

From www.chegg.com

Solved 36. The stressstrain diagram for a steel alloy Strain Extension Original Length The quantity that describes this deformation is called strain. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. the following equation gives the relation for deformation in terms of the length of a solid: Linear strain a straight bar will change in length when loaded. Strain Extension Original Length.

From www.chegg.com

Solved The stressstrain diagram for a steel alloy having an Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. the following equation gives the relation for deformation in terms of the length of. Strain Extension Original Length.

From nigerianscholars.com

Changes in Length—Tension and Compression Elastic Modulus Friction Strain Extension Original Length the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \). Strain Extension Original Length.

From www.chegg.com

Solved 4 The stress strain diagram for a steel alloy having Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. tensile stress and strain occur when the. Strain Extension Original Length.

From www.researchgate.net

(a) The stress vs. strain curves for original PE thin films. (b) The Strain Extension Original Length tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. The quantity that describes this deformation is called strain. Linear strain a straight. Strain Extension Original Length.

From www.researchgate.net

Extension strain versus shear strain Download Scientific Diagram Strain Extension Original Length The quantity that describes this deformation is called strain. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. the following equation gives the relation for deformation in terms of the length of a solid: an object or medium under stress becomes deformed. deformation. Strain Extension Original Length.

From www.chegg.com

Solved The rigid beam AC is supported by a smooth pin A and Strain Extension Original Length deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in. the engineering measures of stress and strain, denoted in this module as σe and. Strain Extension Original Length.

From www.chegg.com

Solved The stressstrain diagram for a metal alloy having an Strain Extension Original Length an object or medium under stress becomes deformed. The quantity that describes this deformation is called strain. tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. deformation is a measure of how much an object is stretched, and strain is the ratio between the. Strain Extension Original Length.

From keytometals.com

Engineering Stressstrain Curve Total Materia Article Strain Extension Original Length The quantity that describes this deformation is called strain. the following equation gives the relation for deformation in terms of the length of a solid: \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε. Linear strain a straight bar will change in length when loaded axially, becoming longer when in tension and shorter when in.. Strain Extension Original Length.

From www.researchgate.net

Stressstrain diagram illustrating the determination of both the Proof Strain Extension Original Length tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change δl δ l. deformation is a measure of how much an object is stretched, and strain is the ratio between the deformation and the original length. \ (\begin {array} {l}\epsilon = \frac {\delta l} {l}\end {array} \) where ε.. Strain Extension Original Length.

From www.researchgate.net

Loadextension graph of the fabric. Download Scientific Diagram Strain Extension Original Length The quantity that describes this deformation is called strain. the engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the. the following equation gives the relation for deformation in terms of the length of a solid: deformation is a measure of. Strain Extension Original Length.