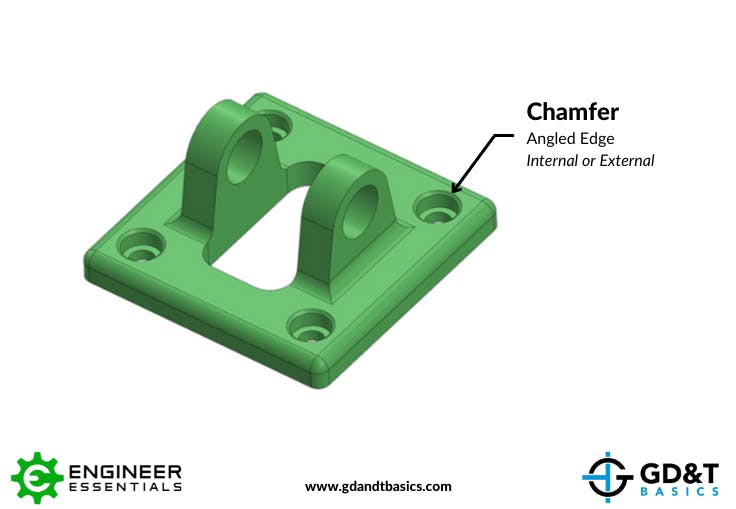

Chamfer At Joint . In the picture of a triangle below, the legs are the. A chamfer applies a flat at an angle to the edge. For example, a cube has 12 external edges. Additionally, chamfering is great for creating edges that can join seamlessly. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Also known as external edge chamfer. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. A bevel occurs when the flat is the. Depending on component size, this may seem like a. To address this, designs often incorporate chamfers to smooth or break those sharp edges.

from www.gdandtbasics.com

Additionally, chamfering is great for creating edges that can join seamlessly. A bevel occurs when the flat is the. In the picture of a triangle below, the legs are the. Depending on component size, this may seem like a. Also known as external edge chamfer. For example, a cube has 12 external edges. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. To address this, designs often incorporate chamfers to smooth or break those sharp edges. A chamfer applies a flat at an angle to the edge. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance.

Chamfer Dimensioning GD&T Basics

Chamfer At Joint A chamfer applies a flat at an angle to the edge. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Depending on component size, this may seem like a. A chamfer applies a flat at an angle to the edge. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. Also known as external edge chamfer. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. A bevel occurs when the flat is the. To address this, designs often incorporate chamfers to smooth or break those sharp edges. In the picture of a triangle below, the legs are the. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. For example, a cube has 12 external edges. Additionally, chamfering is great for creating edges that can join seamlessly.

From www.woodsmith.com

The Versatile Chamfer Woodsmith Chamfer At Joint In the picture of a triangle below, the legs are the. A bevel occurs when the flat is the. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating. Chamfer At Joint.

From www.woodsmith.com

The Versatile Chamfer Woodsmith Chamfer At Joint Additionally, chamfering is great for creating edges that can join seamlessly. Also known as external edge chamfer. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. For example, a cube has 12 external edges. The most common way to spec a chamfer is by. Chamfer At Joint.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria Chamfer At Joint This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. A bevel occurs when the flat is the. Additionally, chamfering is great for creating edges that can join seamlessly. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. In the. Chamfer At Joint.

From www.slideshare.net

Dimensioning standards Chamfer At Joint A bevel occurs when the flat is the. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Additionally, chamfering is great for creating edges that can join seamlessly. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. A chamfer. Chamfer At Joint.

From www.practicalmachinist.com

Understanding Chamfer and Chamfer Mills Practical Machinist Chamfer At Joint A bevel occurs when the flat is the. To address this, designs often incorporate chamfers to smooth or break those sharp edges. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. For example, a cube has 12 external edges. This particular type of edge makes it less susceptible to damage. Chamfer At Joint.

From www.coolenbearings.com

Chamfer dimensions Coolen Bearings Chamfer At Joint Also known as external edge chamfer. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. To address this, designs often incorporate chamfers to smooth or break those sharp edges. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and. Chamfer At Joint.

From cervlcoj.blob.core.windows.net

Solidworks How To Chamfer at Jose Margolis blog Chamfer At Joint To address this, designs often incorporate chamfers to smooth or break those sharp edges. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. Depending on component size, this may seem like a. A chamfer applies a flat at an angle to the edge. Also. Chamfer At Joint.

From klaatucee.blob.core.windows.net

What Is A Chamfer Hole at McBride blog Chamfer At Joint Also known as external edge chamfer. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. To address this, designs often incorporate chamfers to smooth or break those sharp edges. In the picture of a triangle below, the legs are the. For example, a cube. Chamfer At Joint.

From learnweldingsymbols.com

how is chamfering indicated in a welding symbol learnweldingsymbols Chamfer At Joint A bevel occurs when the flat is the. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. In the picture of a triangle below, the legs are the. For example, a cube has 12 external edges. Also known as external edge chamfer. The most common way to spec a. Chamfer At Joint.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Chamfer At Joint A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Additionally, chamfering is great for creating edges that can join seamlessly. For example, a cube has 12 external edges. To address this, designs often incorporate chamfers to smooth or break those sharp edges. This particular type of edge makes it less susceptible. Chamfer At Joint.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics Chamfer At Joint In the picture of a triangle below, the legs are the. Depending on component size, this may seem like a. A chamfer applies a flat at an angle to the edge. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. A chamfer edge improves visual properties, but it is. Chamfer At Joint.

From leadrp.net

Fillet Vs Chamfer What's The Difference? LEADRP Rapid Prototyping Chamfer At Joint The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. This particular type of edge makes it less susceptible to damage and is sturdier than a. Chamfer At Joint.

From www.researchgate.net

Details of the chamfer. Download Scientific Diagram Chamfer At Joint Also known as external edge chamfer. A bevel occurs when the flat is the. A chamfer applies a flat at an angle to the edge. To address this, designs often incorporate chamfers to smooth or break those sharp edges. Depending on component size, this may seem like a. A chamfer edge improves visual properties, but it is also a practical. Chamfer At Joint.

From www.pinterest.com

Miter joint and chamfer details at ceiling frame Daizen Joinery Work Chamfer At Joint This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. In the picture of a triangle below, the legs are the. Also known as external edge chamfer. A chamfer edge improves. Chamfer At Joint.

From support.ptc.com

About Trimming Chamfer Geometry Chamfer At Joint A chamfer applies a flat at an angle to the edge. Depending on component size, this may seem like a. To address this, designs often incorporate chamfers to smooth or break those sharp edges. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. In the picture of a triangle below, the. Chamfer At Joint.

From www.researchgate.net

Schematic illustration of (a) bolted joint, (b) nut chamfer at nut Chamfer At Joint For example, a cube has 12 external edges. Depending on component size, this may seem like a. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. Additionally, chamfering is great for creating edges that can join seamlessly. Also known as external edge chamfer. This. Chamfer At Joint.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Chamfer At Joint A chamfer applies a flat at an angle to the edge. Additionally, chamfering is great for creating edges that can join seamlessly. For example, a cube has 12 external edges. In the picture of a triangle below, the legs are the. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them,. Chamfer At Joint.

From www.emseal.com

What’s New at Expansion Joint Tools and News EMSEAL Chamfer At Joint Additionally, chamfering is great for creating edges that can join seamlessly. For example, a cube has 12 external edges. A bevel occurs when the flat is the. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. To address this, designs often incorporate chamfers to. Chamfer At Joint.

From www.woodworkingarchive.biz

Knuckle Joint MachineCut Joint Woodworking Archive Chamfer At Joint In the picture of a triangle below, the legs are the. To address this, designs often incorporate chamfers to smooth or break those sharp edges. Also known as external edge chamfer. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Additionally, chamfering is great for creating edges that can join seamlessly.. Chamfer At Joint.

From www.researchgate.net

Chamfer at bearing joint face. Download Scientific Diagram Chamfer At Joint A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Depending on component size, this may seem like a. To address this, designs often incorporate chamfers to smooth or break those sharp edges. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle.. Chamfer At Joint.

From docs.bentley.com

Beam Column End Plate Connection Plate Chamfer tab Chamfer At Joint To address this, designs often incorporate chamfers to smooth or break those sharp edges. In the picture of a triangle below, the legs are the. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. A chamfer edge improves visual properties, but it is also a practical option for reasons other. Chamfer At Joint.

From klarqaqxa.blob.core.windows.net

What Is Chamfering Operation In Lathe Machine at Ryan Stewart blog Chamfer At Joint A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. For example, a cube has 12 external edges. To address this, designs often incorporate chamfers to smooth or break those sharp edges.. Chamfer At Joint.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics Chamfer At Joint To address this, designs often incorporate chamfers to smooth or break those sharp edges. A chamfer applies a flat at an angle to the edge. Also known as external edge chamfer. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. A chamfer edge improves visual properties, but it is. Chamfer At Joint.

From toolnotes.com

Thread Terminology ToolNotes Chamfer At Joint This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. Also known as external edge chamfer. Depending on component size, this may seem like a. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. A chamfer applies a flat at. Chamfer At Joint.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Chamfer At Joint The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. A bevel occurs when the flat is the. Depending on component size, this may seem like a. A chamfer applies a. Chamfer At Joint.

From www.3qmachining.com

Difference Between a Fillet and Chamfer, Everything You Need To Know Chamfer At Joint The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. A bevel occurs when the flat is the. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. For example, a cube has 12 external edges. Also known as external edge. Chamfer At Joint.

From thefuturedentistry.com

Fixed Partial Dentures Part1 Focus Dentistry Chamfer At Joint This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. Depending on component size, this may seem like a. To address this, designs often incorporate chamfers to smooth or break those sharp edges. A bevel occurs when the flat is the. Also known as external edge chamfer. This article comprehensively. Chamfer At Joint.

From www.woodworkingarchive.biz

Knuckle Joint MachineCut Joint Woodworking Archive Chamfer At Joint A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. A chamfer applies a flat at an angle to the edge. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. To address this, designs often incorporate chamfers to smooth or break those. Chamfer At Joint.

From steinkebrothers.com

Chamforcor CFC Steinke Brothers Inc. Chamfer At Joint For example, a cube has 12 external edges. To address this, designs often incorporate chamfers to smooth or break those sharp edges. Additionally, chamfering is great for creating edges that can join seamlessly. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Depending on component size, this may seem like. Chamfer At Joint.

From www.mdpi.com

Applied Sciences Free FullText Finite Element Analysis of the Chamfer At Joint Depending on component size, this may seem like a. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Also known as external edge chamfer. In the picture of a triangle below, the legs are the. For example, a cube has 12 external edges. A chamfer applies a flat at an. Chamfer At Joint.

From www.researchgate.net

View of damaged rivet in joint with 0 mm chamfer (a, b) and with 0.5 Chamfer At Joint A bevel occurs when the flat is the. Depending on component size, this may seem like a. This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. A chamfer applies a flat at an angle to the edge. To address this, designs often incorporate chamfers. Chamfer At Joint.

From loeocnsoy.blob.core.windows.net

Chamfer At Corner at Brian Sawyer blog Chamfer At Joint This article comprehensively explains the concept of chamfer, covering its types, advantages, limitations, when and how to use them, and methods for creating chamfered edges. Additionally, chamfering is great for creating edges that can join seamlessly. This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. Also known as external. Chamfer At Joint.

From www.youtube.com

How to cut a 3way chamfer joint YouTube Chamfer At Joint A bevel occurs when the flat is the. Additionally, chamfering is great for creating edges that can join seamlessly. For example, a cube has 12 external edges. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Also known as external edge chamfer. This particular type of edge makes it less. Chamfer At Joint.

From www.youtube.com

Planing a chamfer/bevel on a jointer YouTube Chamfer At Joint Also known as external edge chamfer. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. For example, a cube has 12 external edges. To address this, designs often incorporate chamfers to smooth or break those sharp edges. A chamfer applies a flat at an angle to the edge. A bevel occurs. Chamfer At Joint.

From www.fictiv.com

Guide to Foamcore Joining Techniques Chamfer At Joint This particular type of edge makes it less susceptible to damage and is sturdier than a filet and bevel edge. Additionally, chamfering is great for creating edges that can join seamlessly. Also known as external edge chamfer. To address this, designs often incorporate chamfers to smooth or break those sharp edges. This article comprehensively explains the concept of chamfer, covering. Chamfer At Joint.