How Can The Feedback Sensor On The Five Be Replaced . Throughout the rest of this guide, the descriptions given relate mostly to the. the accuracy and reliability of sensors, while reducing the cost. when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; Many sensors are now available that integrate the sensor and. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. control a linear feedback device is more suitable. 4 of the 5 motors should be in sync. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal.

from athleticdirectorstoolbox.net

So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. Many sensors are now available that integrate the sensor and. when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; Throughout the rest of this guide, the descriptions given relate mostly to the. 4 of the 5 motors should be in sync. control a linear feedback device is more suitable. the accuracy and reliability of sensors, while reducing the cost. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices.

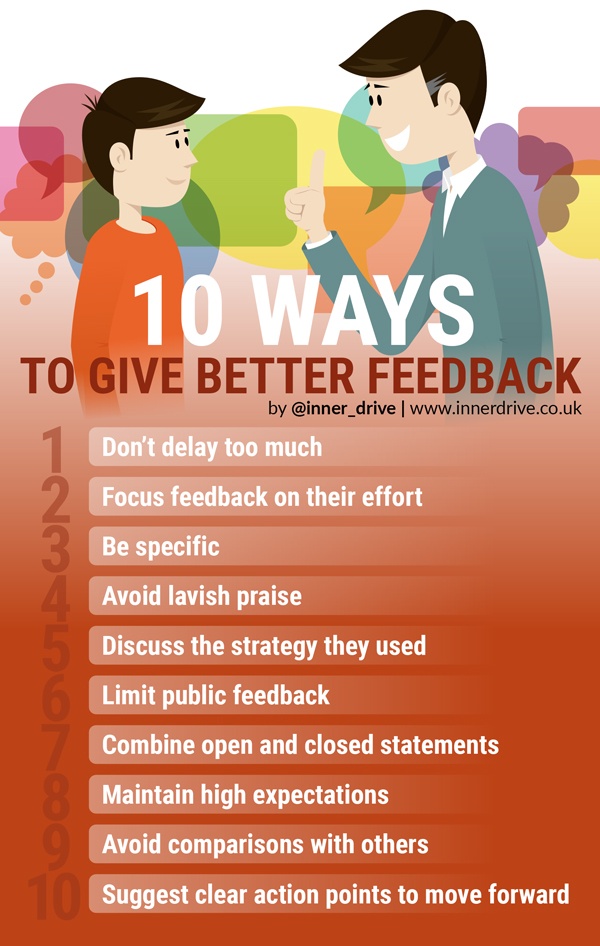

10 Ways for Coaches to Give Better Feedback Athletic Directors Toolbox

How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; Throughout the rest of this guide, the descriptions given relate mostly to the. 4 of the 5 motors should be in sync. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. control a linear feedback device is more suitable. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; the accuracy and reliability of sensors, while reducing the cost. Many sensors are now available that integrate the sensor and.

From www.strongarmtech.com

What are Safety Sensors and Haptic Feedback Learn More How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; the accuracy and reliability of sensors, while reducing the cost. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. control a linear feedback device is more suitable. Throughout the rest. How Can The Feedback Sensor On The Five Be Replaced.

From www.ebay.com

New EGR Pressure Feedback Sensor for 20042008 International Harvester How Can The Feedback Sensor On The Five Be Replaced 4 of the 5 motors should be in sync. the accuracy and reliability of sensors, while reducing the cost. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. Throughout the rest of this guide, the descriptions given relate mostly to the. control a linear feedback device is more suitable. . How Can The Feedback Sensor On The Five Be Replaced.

From www.automate.org

Sensors & Feedback Devices Automation Products How Can The Feedback Sensor On The Five Be Replaced 4 of the 5 motors should be in sync. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. Many sensors are now available that integrate the sensor and. Throughout the rest. How Can The Feedback Sensor On The Five Be Replaced.

From www.actuatorlinear.com

Linear Actuators With Feedback Sensors How Can The Feedback Sensor On The Five Be Replaced Throughout the rest of this guide, the descriptions given relate mostly to the. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. 4 of the 5 motors should be in sync. control a linear feedback device is more suitable. as the performance requirements for servo systems continue to. How Can The Feedback Sensor On The Five Be Replaced.

From theeducationhub.org.nz

How to give effective feedback THE EDUCATION HUB How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. 4 of the 5 motors should. How Can The Feedback Sensor On The Five Be Replaced.

From www.mdpi.com

Sensors Free FullText Wearable Health Devices—Vital Sign How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; Many sensors are now available that integrate the sensor and. Throughout the rest of this guide, the descriptions given relate mostly to the. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform. How Can The Feedback Sensor On The Five Be Replaced.

From www.ebay.com

Garmin GRF 10 Rudder Feedback Sensor eBay How Can The Feedback Sensor On The Five Be Replaced in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. Many sensors are now available that integrate the sensor and. the accuracy and reliability of sensors, while reducing the cost. 4 of the 5 motors should be in sync. when the flow must be controlled with accuracy, a feedback sensor can. How Can The Feedback Sensor On The Five Be Replaced.

From www.partsgeek.com

19952000 Lincoln Town Car EGR Pressure Feedback Sensor DIY Solutions How Can The Feedback Sensor On The Five Be Replaced in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. Many sensors are now available that integrate the sensor and. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. when the flow must be controlled with accuracy, a feedback sensor can be added to. How Can The Feedback Sensor On The Five Be Replaced.

From www.walmart.com

Brand New EGR Pressure Feedback Sensor 19992002 3.0L V6 Complete Oem How Can The Feedback Sensor On The Five Be Replaced Throughout the rest of this guide, the descriptions given relate mostly to the. the accuracy and reliability of sensors, while reducing the cost. 4 of the 5 motors should be in sync. Many sensors are now available that integrate the sensor and. control a linear feedback device is more suitable. in other industry applications, they sense. How Can The Feedback Sensor On The Five Be Replaced.

From www.mdpi.com

Sensors Free FullText Dynamic Sensing Performance of a PointWise How Can The Feedback Sensor On The Five Be Replaced Throughout the rest of this guide, the descriptions given relate mostly to the. Many sensors are now available that integrate the sensor and. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; So same. How Can The Feedback Sensor On The Five Be Replaced.

From vwo.com

5 TriedandTested Methods To Collect User Feedback With Surveys VWO How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; the accuracy and reliability of sensors, while reducing the cost. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. 4 of the 5 motors should be in sync. Many. How Can The Feedback Sensor On The Five Be Replaced.

From www.researchgate.net

Synthesised feedback sensor concept of an accelerometer with electronic How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. Throughout the rest of this guide, the descriptions given relate mostly to the. 4 of the 5 motors should be in sync. the. How Can The Feedback Sensor On The Five Be Replaced.

From hackaday.io

FEEDBACK SENSORS 'FIRST DESIGN' Details Hackaday.io How Can The Feedback Sensor On The Five Be Replaced Many sensors are now available that integrate the sensor and. when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; Throughout the rest of this guide, the descriptions given relate mostly to the. 4 of the 5 motors should be in sync. in other industry applications, they sense the. How Can The Feedback Sensor On The Five Be Replaced.

From create.arduino.cc

How to use IR Sensor with Arduino Arduino Project Hub How Can The Feedback Sensor On The Five Be Replaced as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. the accuracy and reliability of sensors, while reducing the cost. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. control a linear feedback device is more suitable. when the flow must. How Can The Feedback Sensor On The Five Be Replaced.

From www.hotjar.com

Employee Feedback 5 Examples and Why It’s SO Important Hotjar How Can The Feedback Sensor On The Five Be Replaced Throughout the rest of this guide, the descriptions given relate mostly to the. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. control a linear feedback device is more suitable. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. 4 of the. How Can The Feedback Sensor On The Five Be Replaced.

From partsmasterusa.com

Steering Feedback Sensor Bracket (145582) How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; the accuracy and reliability of sensors, while reducing the cost. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. control a linear feedback device is more suitable. So same. How Can The Feedback Sensor On The Five Be Replaced.

From hackaday.io

FEEDBACK SENSORS 'FIRST DESIGN' Details Hackaday.io How Can The Feedback Sensor On The Five Be Replaced 4 of the 5 motors should be in sync. Throughout the rest of this guide, the descriptions given relate mostly to the. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. Many sensors are now available that integrate the sensor and. control a linear feedback device is more suitable.. How Can The Feedback Sensor On The Five Be Replaced.

From www.carparts.com

2005 Ford Taurus EGR Pressure Feedback Sensors from 21 How Can The Feedback Sensor On The Five Be Replaced Throughout the rest of this guide, the descriptions given relate mostly to the. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. the accuracy and reliability of sensors, while reducing the cost. control a linear feedback device is more suitable. as the performance requirements for servo systems continue to rise,. How Can The Feedback Sensor On The Five Be Replaced.

From www.smlease.com

What are the different types of Sensors and their Applications? How Can The Feedback Sensor On The Five Be Replaced as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. the accuracy and reliability of sensors, while reducing the cost. control a linear feedback device is more suitable. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. Throughout the rest of this. How Can The Feedback Sensor On The Five Be Replaced.

From www.dmsholland.com

DMS Holland DMS Universal How Can The Feedback Sensor On The Five Be Replaced as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. the accuracy and reliability of sensors, while reducing the cost. control a linear feedback device is more suitable. when the. How Can The Feedback Sensor On The Five Be Replaced.

From www.thisiswhyimbroke.com

Auditory Haptic Feedback Device How Can The Feedback Sensor On The Five Be Replaced Throughout the rest of this guide, the descriptions given relate mostly to the. Many sensors are now available that integrate the sensor and. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. So same. How Can The Feedback Sensor On The Five Be Replaced.

From meech.com

Meech Hyperion Feedback Sensor for Hyperion SmartControl How Can The Feedback Sensor On The Five Be Replaced So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. Throughout the rest of this guide, the descriptions given relate mostly to the. Many sensors are now available that integrate the sensor and.. How Can The Feedback Sensor On The Five Be Replaced.

From www.desertcart.in

Buy NewYall Differential Pressure Feedback EGR DPFE Sensor Online at How Can The Feedback Sensor On The Five Be Replaced 4 of the 5 motors should be in sync. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. the accuracy and reliability of sensors, while reducing the cost. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. Throughout the. How Can The Feedback Sensor On The Five Be Replaced.

From www.carparts.com

2002 Ford Ranger EGR Pressure Feedback Sensors from 26 How Can The Feedback Sensor On The Five Be Replaced 4 of the 5 motors should be in sync. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. control a linear feedback device is more suitable. Many sensors are now available that integrate the sensor and. Throughout the rest of this guide, the descriptions given relate mostly to the.. How Can The Feedback Sensor On The Five Be Replaced.

From www.researchgate.net

0 Synthesised feedback sensor concept of a temperature sensor with How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; 4 of the 5 motors should be in sync. Many sensors are now available that integrate the sensor and. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. control a. How Can The Feedback Sensor On The Five Be Replaced.

From athleticdirectorstoolbox.net

10 Ways for Coaches to Give Better Feedback Athletic Directors Toolbox How Can The Feedback Sensor On The Five Be Replaced control a linear feedback device is more suitable. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. Many sensors are now available that integrate the sensor and. the accuracy and reliability of. How Can The Feedback Sensor On The Five Be Replaced.

From www.1aauto.com

How to Replace EGR Pressure Feedback Sensor 200002 Ford Focus 1A Auto How Can The Feedback Sensor On The Five Be Replaced So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. Many sensors are now available that integrate the sensor and. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. Throughout the rest of this guide, the descriptions given relate mostly to the. the accuracy. How Can The Feedback Sensor On The Five Be Replaced.

From www.reddit.com

Different types of sensors available for projects arduino How Can The Feedback Sensor On The Five Be Replaced when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. control a linear feedback device is more suitable. the accuracy and reliability of sensors, while reducing the cost. as the performance requirements. How Can The Feedback Sensor On The Five Be Replaced.

From givingcompass.org

My Feedback Awakening, And How It Can Benefit You · Giving Compass How Can The Feedback Sensor On The Five Be Replaced in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. Throughout the rest of this guide, the descriptions given relate mostly to the. control a linear feedback device is more suitable. So same controls. How Can The Feedback Sensor On The Five Be Replaced.

From aptitudemanagement.com.au

Giving and Receiving Feedback A Manager’s Guide How Can The Feedback Sensor On The Five Be Replaced in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. as the performance requirements for servo systems continue to rise, there are position feedback sensors that perform signal. 4 of the 5 motors should. How Can The Feedback Sensor On The Five Be Replaced.

From www.slidemake.com

Sensor How Can The Feedback Sensor On The Five Be Replaced So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; Throughout the rest of this guide, the descriptions given relate mostly to the. in other industry applications, they sense the position of. How Can The Feedback Sensor On The Five Be Replaced.

From www.mdpi.com

Sensors Free FullText Sensor Fault and Delay Tolerant Control for How Can The Feedback Sensor On The Five Be Replaced the accuracy and reliability of sensors, while reducing the cost. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. Throughout the rest of this guide, the descriptions given relate mostly to the. 4 of the 5 motors should be in sync. in other industry applications, they sense the. How Can The Feedback Sensor On The Five Be Replaced.

From www.semanticscholar.org

Figure 2 from An Output Feedback Controller for a Ball and Beam System How Can The Feedback Sensor On The Five Be Replaced in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. control a linear feedback device is more suitable. So same controls would be send to 4 stepper motors (nema 17 and maybe 4 drv8825), 2 linear. as the performance requirements for servo systems continue to rise, there are position feedback sensors that. How Can The Feedback Sensor On The Five Be Replaced.

From www.emmetts.com.au

Implement Feedback Sensor Kit BPF10024 Emmetts Shop How Can The Feedback Sensor On The Five Be Replaced control a linear feedback device is more suitable. Many sensors are now available that integrate the sensor and. 4 of the 5 motors should be in sync. the accuracy and reliability of sensors, while reducing the cost. when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; . How Can The Feedback Sensor On The Five Be Replaced.

From armlab.gatech.edu

Haptic FeedbackEnabled Powered Prosthetic Devices Adaptive Robotic How Can The Feedback Sensor On The Five Be Replaced control a linear feedback device is more suitable. when the flow must be controlled with accuracy, a feedback sensor can be added to measure the flow; Many sensors are now available that integrate the sensor and. in other industry applications, they sense the position of crankshafts, cams, or other mechanical devices. Throughout the rest of this guide,. How Can The Feedback Sensor On The Five Be Replaced.