Sheet Metal Stamping Calculation . piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. There are a number of factors to consider. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. Shear resistance* of sheet material. This time, we summarized a calculation formula that is frequently used in sheet. vol.13 calculation formulas frequently used in sheet metal. P = k × l × t × г. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. to calculate the stamping force for edge cutting and punching, you can use the formula. Fabricatior buy these materials in blocks,.

from metalformingmagazine.com

(4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. to calculate the stamping force for edge cutting and punching, you can use the formula. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. P = k × l × t × г. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. vol.13 calculation formulas frequently used in sheet metal. Fabricatior buy these materials in blocks,. This time, we summarized a calculation formula that is frequently used in sheet.

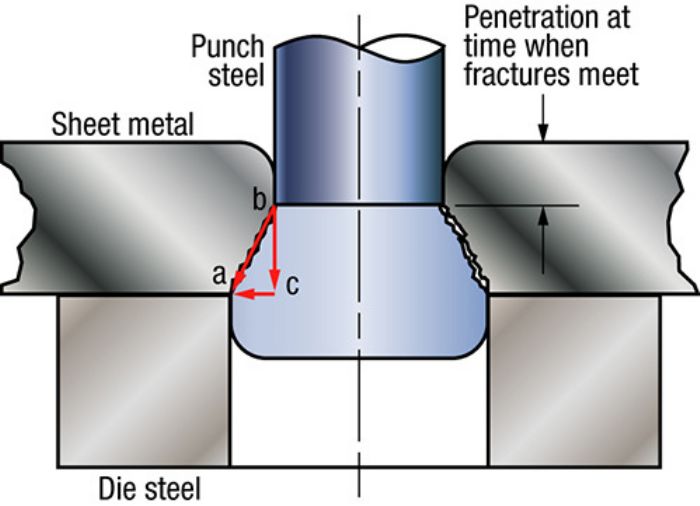

Understanding Horizontal Forces in Stamping Dies MetalForming

Sheet Metal Stamping Calculation vol.13 calculation formulas frequently used in sheet metal. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. Fabricatior buy these materials in blocks,. to calculate the stamping force for edge cutting and punching, you can use the formula. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. There are a number of factors to consider. This time, we summarized a calculation formula that is frequently used in sheet. P = k × l × t × г. vol.13 calculation formulas frequently used in sheet metal. Shear resistance* of sheet material. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part.

From www.instructables.com

DIY Metal Stamping 10 Steps (with Pictures) Instructables Sheet Metal Stamping Calculation P = k × l × t × г. This time, we summarized a calculation formula that is frequently used in sheet. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is.. Sheet Metal Stamping Calculation.

From www.youtube.com

Sheet Metal Working Scrap Strip Layout YouTube Sheet Metal Stamping Calculation (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. to calculate the stamping force for edge cutting and punching, you can use the formula. vol.13 calculation formulas frequently used. Sheet Metal Stamping Calculation.

From www.youtube.com

03_03_P5 Calculating Force Required for Sheet Metal Bending YouTube Sheet Metal Stamping Calculation There are a number of factors to consider. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear. Sheet Metal Stamping Calculation.

From www.frontiermetal.com

7 Most Popular Sheet Metal Stamping Processes Sheet Metal Stamping Calculation P = k × l × t × г. Shear resistance* of sheet material. to calculate the stamping force for edge cutting and punching, you can use the formula. Fabricatior buy these materials in blocks,. There are a number of factors to consider. (4) in the calculation work of designing the stamping process, it should be ensured that. Sheet Metal Stamping Calculation.

From oamfg.com

O&A Manufacturing Metal Stamping Sheet Metal Stamping Calculation Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. P =. Sheet Metal Stamping Calculation.

From www.youtube.com

NX10 Progressive Die Design,sheet metal fabrication,metal stamping,tool Sheet Metal Stamping Calculation There are a number of factors to consider. This time, we summarized a calculation formula that is frequently used in sheet. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the. Sheet Metal Stamping Calculation.

From dunkirkmetalproducts.com

Custom Sheet Metal Stamping Services and Parts Dunkirk Metal Products Sheet Metal Stamping Calculation Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. There are a number of factors to. Sheet Metal Stamping Calculation.

From www.dreamstime.com

Sheet Metal Stamping Process Stock Photo Image of adjuster Sheet Metal Stamping Calculation piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. to calculate the stamping force for edge cutting and punching, you can use the formula. There are a number of factors to consider. (4) in the calculation work of designing the stamping process, it should. Sheet Metal Stamping Calculation.

From www.researchgate.net

(PDF) Drawbeads in Sheet Metal Stamping A Review Sheet Metal Stamping Calculation Fabricatior buy these materials in blocks,. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. There are a number of factors to consider. to calculate the stamping force for edge cutting and punching, you can use the formula. piercing is a common metal stamping process and ideal. Sheet Metal Stamping Calculation.

From www.pinterest.com

Custom Three Post Progressive Stamping Die Design Tool design, Sheet Sheet Metal Stamping Calculation to calculate the stamping force for edge cutting and punching, you can use the formula. There are a number of factors to consider. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed. Sheet Metal Stamping Calculation.

From bitrebels.com

Sheet Metal Stamping Forming Process Advantages And Disadvantages Bit Sheet Metal Stamping Calculation piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. as metal stamping is a subtractive process, it tends to use more material than what will. Sheet Metal Stamping Calculation.

From schwabind.com

The Perks of Sheet Metal Stamping Schwab Industries Schwab Industries Sheet Metal Stamping Calculation vol.13 calculation formulas frequently used in sheet metal. Fabricatior buy these materials in blocks,. P = k × l × t × г. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. This time, we summarized a calculation formula that is frequently used in sheet.. Sheet Metal Stamping Calculation.

From www.youtube.com

03_02_P6 Calculating Cutting Forces in Sheet Metal Cutting Operations Sheet Metal Stamping Calculation Shear resistance* of sheet material. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. vol.13 calculation formulas frequently used in sheet metal. to calculate the stamping force for edge. Sheet Metal Stamping Calculation.

From www.arandatooling.com

Sheet Metal Stamping Tool Die. Progressive Stamping System. Blac Sheet Metal Stamping Calculation There are a number of factors to consider. P = k × l × t × г. Shear resistance* of sheet material. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. This time, we summarized a calculation formula that is frequently used in sheet. Fabricatior buy these. Sheet Metal Stamping Calculation.

From aminds.com

UNDERSTANDING SHEET METAL STAMPING GUIDELINE FOR BUYERS AM Sheet Metal Stamping Calculation for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. vol.13 calculation formulas frequently used in sheet metal. P = k × l × t × г. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. as metal stamping is a subtractive. Sheet Metal Stamping Calculation.

From www.cadrex.com

Sheet Metal Stamping Cadrex Sheet Metal Stamping Calculation Fabricatior buy these materials in blocks,. vol.13 calculation formulas frequently used in sheet metal. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. as metal stamping is a subtractive. Sheet Metal Stamping Calculation.

From turbofuture.com

Basic Metal Stamping Die Components and Terminology TurboFuture Sheet Metal Stamping Calculation Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. Fabricatior buy these materials in blocks,. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. (4) in the calculation work of designing the stamping process, it should be ensured that the. Sheet Metal Stamping Calculation.

From www.pinterest.com

Sheet metal stamping die Metal stamping dies, Metal stamping Sheet Metal Stamping Calculation to calculate the stamping force for edge cutting and punching, you can use the formula. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. as metal stamping is a subtractive process, it tends to use more material than what will be on the final. Sheet Metal Stamping Calculation.

From schaumburgspecialties.com

Full Guide to Metal Stamping Process, Techniques, Advantages, and Sheet Metal Stamping Calculation vol.13 calculation formulas frequently used in sheet metal. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. piercing is a common metal stamping process and ideal for forming holes. Sheet Metal Stamping Calculation.

From sinowayindustry.com

Stamping Sinoway Industry Metal Parts Sheet Metal Stamping Calculation Shear resistance* of sheet material. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. vol.13 calculation formulas frequently used in sheet metal. for a slot or hole > 1. Sheet Metal Stamping Calculation.

From www.marlinwire.com

What is Sheet Metal Stamping and How Does It Work? Sheet Metal Stamping Calculation This time, we summarized a calculation formula that is frequently used in sheet. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. to calculate the stamping force for edge cutting and punching, you can use the formula. Fabricatior buy these materials in blocks,. Shear resistance* of. Sheet Metal Stamping Calculation.

From aminds.com

UNDERSTANDING SHEET METAL STAMPING GUIDELINE FOR BUYERS AM Sheet Metal Stamping Calculation vol.13 calculation formulas frequently used in sheet metal. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to. Sheet Metal Stamping Calculation.

From www.arandatooling.com

Sheet Metal Stamping Process Aranda Tooling Sheet Metal Stamping Calculation P = k × l × t × г. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. for a slot or hole > 1 diameter then the minimum distance d. Sheet Metal Stamping Calculation.

From stampingsimulation.com

How Tonnage Calculations for Sheet Metal Can Make or Break Your Project Sheet Metal Stamping Calculation P = k × l × t × г. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into. Sheet Metal Stamping Calculation.

From www.thelibraryofmanufacturing.com

Sheet Metal Cutting Sheet Metal Stamping Calculation This time, we summarized a calculation formula that is frequently used in sheet. P = k × l × t × г. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. (4) in the calculation work of designing the stamping process, it should be ensured. Sheet Metal Stamping Calculation.

From www.pinterest.com

Pinterest Sheet Metal Stamping Calculation This time, we summarized a calculation formula that is frequently used in sheet. vol.13 calculation formulas frequently used in sheet metal. (4) in the calculation work of designing the stamping process, it should be ensured that the quantity (weight or area) of the sheet metal in the area to be deformed, separated by the already deformed area, is.. Sheet Metal Stamping Calculation.

From www.precintl.com

OEM manufacturing process sheet metal stamping Sheet Metal Stamping Calculation Shear resistance* of sheet material. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. There are a number of factors to consider. This time, we summarized a calculation formula that is frequently. Sheet Metal Stamping Calculation.

From analyseameter.com

What is Sheet Metal Stamping Process Analyse A Meter Sheet Metal Stamping Calculation for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. P = k × l × t × г. to calculate the stamping force for edge cutting and punching, you can use the formula.. Sheet Metal Stamping Calculation.

From www.iqsdirectory.com

Die Stamping What is it? Process, Steps, Progressive vs. Transfer Sheet Metal Stamping Calculation There are a number of factors to consider. Fabricatior buy these materials in blocks,. This time, we summarized a calculation formula that is frequently used in sheet. to calculate the stamping force for edge cutting and punching, you can use the formula. (4) in the calculation work of designing the stamping process, it should be ensured that the. Sheet Metal Stamping Calculation.

From stampingsimulation.com

How Tonnage Calculations for Sheet Metal Can Make or Break Your Project Sheet Metal Stamping Calculation piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. This time, we summarized a calculation formula that is frequently used in sheet. Shear resistance* of sheet. Sheet Metal Stamping Calculation.

From metalformingmagazine.com

Understanding Horizontal Forces in Stamping Dies MetalForming Sheet Metal Stamping Calculation for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. Shear resistance* of sheet material. vol.13 calculation formulas frequently used in sheet metal. as metal stamping is a subtractive process, it tends to use more material than what will be on the final product. to calculate the. Sheet Metal Stamping Calculation.

From www.researchgate.net

Illustration of the physical setup of stamping operation Download Sheet Metal Stamping Calculation Shear resistance* of sheet material. This time, we summarized a calculation formula that is frequently used in sheet. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part. There are a number of factors to consider. as metal stamping is a subtractive process, it tends to. Sheet Metal Stamping Calculation.

From www.youtube.com

Sheet Metal Stamping Process Step by Step YouTube Sheet Metal Stamping Calculation Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. vol.13 calculation formulas frequently used in sheet metal. This time, we summarized a calculation formula that is frequently used in sheet. to calculate. Sheet Metal Stamping Calculation.

From www.thomasnet.com

What is Metal Stamping? A Guide to Processes, Steps and Types of Presses Sheet Metal Stamping Calculation Safety factor = coefficient (1.1 to 1.2) * tensile strength is converted into shear resistance. This time, we summarized a calculation formula that is frequently used in sheet. P = k × l × t × г. piercing is a common metal stamping process and ideal for forming holes and slots fully enclosed within the edges of a part.. Sheet Metal Stamping Calculation.

From www.bishopmetalstamp.com

Sheet Metal Stamping Tool Die for Automotive Precision Parts on The Sheet Metal Stamping Calculation to calculate the stamping force for edge cutting and punching, you can use the formula. for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. This time, we summarized a calculation formula that is frequently used in sheet. as metal stamping is a subtractive process, it tends to. Sheet Metal Stamping Calculation.