Atc Not In Zero Position . Example atc tool changer operation for a cnc. The atc map field will indicate if the tool selected is in the magazine, and its location. Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and. By dsuds in forum fadal. How do i get the fadal to show my zero position instead of its home position? Atc has not returned to its home position. I just brought a 83 vmc back to life. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Once there try a m06 in manual and see if it will recover. Enter the tool number (of the. Determine the sequence for an automatic tool change: The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. Z has to be zero to allow atc to work. Magazine reference ls not seen. Axes moves to tool change.

from www.aviationsafetymagazine.com

Once there try a m06 in manual and see if it will recover. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. Z has to be zero to allow atc to work. How do i get the fadal to show my zero position instead of its home position? Example atc tool changer operation for a cnc. Atc has not returned to its home position. I just brought a 83 vmc back to life. Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and. If there is no tool in the spindle, set the tool in spindle field to 0 (zero).

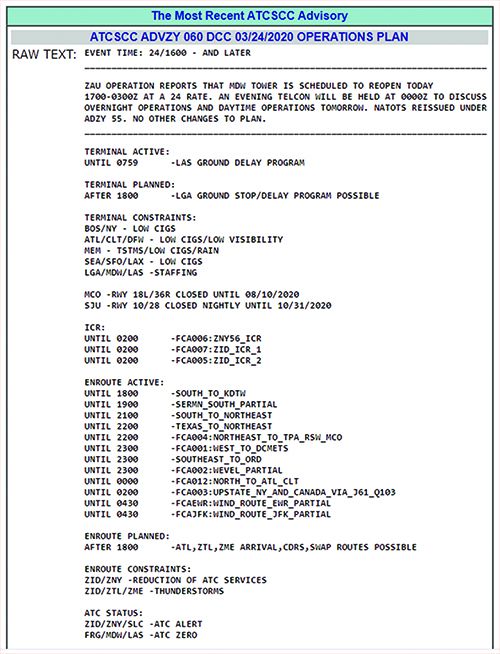

ATCZero Aviation Safety

Atc Not In Zero Position Example atc tool changer operation for a cnc. By dsuds in forum fadal. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Axes moves to tool change. I just brought a 83 vmc back to life. Magazine reference ls not seen. Enter the tool number (of the. Atc has not returned to its home position. How do i get the fadal to show my zero position instead of its home position? The atc map field will indicate if the tool selected is in the magazine, and its location. Once there try a m06 in manual and see if it will recover. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. Z has to be zero to allow atc to work. Determine the sequence for an automatic tool change: Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and. The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator.

From www.slideserve.com

PPT ECON111 PowerPoint Presentation, free download ID1366588 Atc Not In Zero Position Determine the sequence for an automatic tool change: If there is no tool in the spindle, set the tool in spindle field to 0 (zero). By dsuds in forum fadal. Once there try a m06 in manual and see if it will recover. I just brought a 83 vmc back to life. The atc map field will indicate if the. Atc Not In Zero Position.

From ops.group

Planning for “ATC Zero” events in Oceanic Airspace International Ops Atc Not In Zero Position Atc has not returned to its home position. I just brought a 83 vmc back to life. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Z has to be zero to allow atc to work. Axes moves to tool change. By dsuds in forum fadal. The loss of signals indicates either. Atc Not In Zero Position.

From www.aopa.org

Training Tip When ATC goes to zero AOPA Atc Not In Zero Position How do i get the fadal to show my zero position instead of its home position? The atc map field will indicate if the tool selected is in the magazine, and its location. Z has to be zero to allow atc to work. The reason is because the fanuc sets a bit in the ladder logic that will turn on. Atc Not In Zero Position.

From forum.vatsim.net

Clarifying the TopDown ATC figure New Member Orientation Pilot Atc Not In Zero Position Once there try a m06 in manual and see if it will recover. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). How do i get the fadal to show my zero position instead of its home position? Example atc tool changer operation for a cnc. Determine the sequence for an automatic. Atc Not In Zero Position.

From www.slideserve.com

PPT Air Defense Identification Zone (ADIZ) The Course PowerPoint Atc Not In Zero Position The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. Z has to be zero to allow atc to work. Example atc tool changer operation for a cnc. By dsuds in forum fadal. Atc has not returned to its home position. If there is no tool. Atc Not In Zero Position.

From forums.flightsimulator.com

Left vs. Right Downwind ATC Calls ATC, Traffic & NAVAIDs Microsoft Atc Not In Zero Position Axes moves to tool change. The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. Determine the sequence for an automatic tool change: Atc has not returned to its home position. The atc map field will indicate if the tool selected is in the magazine, and. Atc Not In Zero Position.

From www.youtube.com

HOW TO RECOVER ATC ARM STOCK UP NHP8000 HORIZONTAL MACHINE YouTube Atc Not In Zero Position If there is no tool in the spindle, set the tool in spindle field to 0 (zero). How do i get the fadal to show my zero position instead of its home position? Magazine reference ls not seen. Determine the sequence for an automatic tool change: Next, turn the manual 1\0 slot on the o1585 valve from the 0 position. Atc Not In Zero Position.

From aviation.stackexchange.com

air traffic control What are the slides that ATCs use for tracking Atc Not In Zero Position Determine the sequence for an automatic tool change: Magazine reference ls not seen. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. I just brought a 83 vmc back to life. Example atc tool changer operation for a cnc. Axes moves. Atc Not In Zero Position.

From www.semanticscholar.org

[PDF] “Zeroposition” functional shoulder orthosis Semantic Scholar Atc Not In Zero Position By dsuds in forum fadal. The atc map field will indicate if the tool selected is in the magazine, and its location. How do i get the fadal to show my zero position instead of its home position? Example atc tool changer operation for a cnc. If there is no tool in the spindle, set the tool in spindle field. Atc Not In Zero Position.

From www.youtube.com

How ATC cnc router tool sensor work/ Z axis zero syntec controller Atc Not In Zero Position Magazine reference ls not seen. The atc map field will indicate if the tool selected is in the magazine, and its location. The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. If there is no tool in the spindle, set the tool in spindle field. Atc Not In Zero Position.

From www.aviator.zone

Miami Aviation School ATC Light Gun Signals Aviator Zone Academy, LLC Atc Not In Zero Position The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. Axes moves to tool change. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Z has to be zero to allow atc to work.. Atc Not In Zero Position.

From www.researchgate.net

general contract of the system The primary users of the ATC automation Atc Not In Zero Position Enter the tool number (of the. Once there try a m06 in manual and see if it will recover. The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. Atc has not returned to its home position. I just brought a 83 vmc back to life.. Atc Not In Zero Position.

From www.tele-radio.com

Enhancing Workplace Safety The Crucial Role of ZeroPosition Check on Atc Not In Zero Position I just brought a 83 vmc back to life. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Axes moves to tool change. The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. The reason is because the. Atc Not In Zero Position.

From community.infiniteflight.com

Reporting Position ATC Infinite Flight Community Atc Not In Zero Position How do i get the fadal to show my zero position instead of its home position? If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Z has to be zero to allow atc to work. The reason is because the fanuc sets a bit in the ladder logic that will turn on. Atc Not In Zero Position.

From www.youtube.com

XPlane 12, Flying along the Default ATC YouTube Atc Not In Zero Position Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. Z has to be. Atc Not In Zero Position.

From www.aviationsafetymagazine.com

ATCZero Aviation Safety Atc Not In Zero Position Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Axes moves to tool change. Enter the tool number (of the. How do i get. Atc Not In Zero Position.

From www.slideserve.com

PPT ATC TRANSPONDER SYSTEMS PowerPoint Presentation ID5403352 Atc Not In Zero Position By dsuds in forum fadal. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. Z has to be zero to allow atc to work. Example atc tool changer operation for a cnc. Axes moves to tool change. If there is no. Atc Not In Zero Position.

From www.youtube.com

ATC position tool for Stepcraft YouTube Atc Not In Zero Position Atc has not returned to its home position. Z has to be zero to allow atc to work. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright,. Atc Not In Zero Position.

From vimeopro.com

Operational Readiness Intro SYSOPS_D10 ATC ZERO on Vimeo Atc Not In Zero Position Once there try a m06 in manual and see if it will recover. Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and. The atc map field will indicate if the tool selected is in the magazine, and its location. Magazine reference. Atc Not In Zero Position.

From www.slideserve.com

PPT ATC TRANSPONDER SYSTEMS PowerPoint Presentation, free download Atc Not In Zero Position Magazine reference ls not seen. Z has to be zero to allow atc to work. Determine the sequence for an automatic tool change: The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. Axes moves to tool change. I just brought a. Atc Not In Zero Position.

From www.youtube.com

FSHud Air Traffic Control Demo Video 1 YouTube Atc Not In Zero Position Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and. Magazine reference ls not seen. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's. Atc Not In Zero Position.

From wtruib.ru

AIR TRAFFIC CONTROL (ATC) SYSTEM WTRUIB TRAINING Atc Not In Zero Position Enter the tool number (of the. Example atc tool changer operation for a cnc. Z has to be zero to allow atc to work. Determine the sequence for an automatic tool change: Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and.. Atc Not In Zero Position.

From forums.flightsimulator.com

Atc stops talking randomly? General Discussion Microsoft Flight Atc Not In Zero Position Enter the tool number (of the. Atc has not returned to its home position. Example atc tool changer operation for a cnc. How do i get the fadal to show my zero position instead of its home position? Once there try a m06 in manual and see if it will recover. Magazine reference ls not seen. The atc map field. Atc Not In Zero Position.

From www.youtube.com

How to set Position Zero Adjustment YouTube Atc Not In Zero Position Magazine reference ls not seen. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. Axes moves to tool change. Determine the sequence for an automatic tool change: Next, turn the manual 1\0 slot on the o1585 valve from the 0 position. Atc Not In Zero Position.

From ops.group

Planning for “ATC Zero” events in Oceanic Airspace International Ops Atc Not In Zero Position Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this should raise the spindle back to the upright, home position, and. Determine the sequence for an automatic tool change: By dsuds in forum fadal. Z has to be zero to allow atc to work. Atc has not returned to its home position. How. Atc Not In Zero Position.

From www.faa.gov

Airport Operations Atc Not In Zero Position I just brought a 83 vmc back to life. The atc map field will indicate if the tool selected is in the magazine, and its location. The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. Next, turn the manual 1\0 slot on the o1585 valve. Atc Not In Zero Position.

From www.grissom.afrc.af.mil

ATC Zero Grissom steps up, supports air traffic crisis > Grissom Air Atc Not In Zero Position The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. The atc map field will indicate if the tool selected is in the magazine, and its location. Magazine reference ls not seen. How do i get the fadal to show my zero position instead of its. Atc Not In Zero Position.

From community.infiniteflight.com

No ATC Position Infinite Flight Community Atc Not In Zero Position Example atc tool changer operation for a cnc. Atc has not returned to its home position. By dsuds in forum fadal. The atc map field will indicate if the tool selected is in the magazine, and its location. Magazine reference ls not seen. Z has to be zero to allow atc to work. The reason is because the fanuc sets. Atc Not In Zero Position.

From ops.group

ATC Zero in Class A Airspace Is It Dangerous? International Ops 2024 Atc Not In Zero Position Example atc tool changer operation for a cnc. I just brought a 83 vmc back to life. The loss of signals indicates either the arm is not getting to the 60 position or it is getting there but the position indicator. The atc map field will indicate if the tool selected is in the magazine, and its location. The reason. Atc Not In Zero Position.

From www.aopa.org

'ATC Zero' Inside the Chicago Center fire AOPA Atc Not In Zero Position Example atc tool changer operation for a cnc. I just brought a 83 vmc back to life. How do i get the fadal to show my zero position instead of its home position? Once there try a m06 in manual and see if it will recover. Next, turn the manual 1\0 slot on the o1585 valve from the 0 position. Atc Not In Zero Position.

From analystprep.com

Factors Affecting LongRun Equilibrium Example CFA Level 1 AnalystPrep Atc Not In Zero Position Z has to be zero to allow atc to work. By dsuds in forum fadal. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. Next, turn the manual 1\0 slot on the o1585 valve from the 0 position to 1, this. Atc Not In Zero Position.

From www.toppr.com

Two point charges ( + Q) and ( 2Q) are fixed on the X axis at Atc Not In Zero Position Determine the sequence for an automatic tool change: The atc map field will indicate if the tool selected is in the magazine, and its location. Z has to be zero to allow atc to work. If there is no tool in the spindle, set the tool in spindle field to 0 (zero). Atc has not returned to its home position.. Atc Not In Zero Position.

From www.semanticscholar.org

Figure 4 from “Zeroposition” functional shoulder orthosis Semantic Atc Not In Zero Position Z has to be zero to allow atc to work. Example atc tool changer operation for a cnc. Once there try a m06 in manual and see if it will recover. How do i get the fadal to show my zero position instead of its home position? Atc has not returned to its home position. If there is no tool. Atc Not In Zero Position.

From safeblog.org

Brief and Understand "ATC ZERO"! Aviation Ideas and Discussion! Atc Not In Zero Position Determine the sequence for an automatic tool change: Axes moves to tool change. By dsuds in forum fadal. Once there try a m06 in manual and see if it will recover. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. I. Atc Not In Zero Position.

From www.youtube.com

ATC position error YouTube Atc Not In Zero Position The atc map field will indicate if the tool selected is in the magazine, and its location. Axes moves to tool change. Example atc tool changer operation for a cnc. The reason is because the fanuc sets a bit in the ladder logic that will turn on the ref light when you g28 the axis to it's home. How do. Atc Not In Zero Position.