Milling Machine Procedure . Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Follow correct clam ping procedures to ensure work is secured to table. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Do not use this machine without completing appropriate induction / training. There are several basic operations that can be performed on a milling machine, including: Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. This operation involves cutting a flat surface on the. Remove all tools from the bed and slides of the machine.

from www.mechanicalbooster.com

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Follow correct clam ping procedures to ensure work is secured to table. This operation involves cutting a flat surface on the. There are several basic operations that can be performed on a milling machine, including: Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. Do not use this machine without completing appropriate induction / training. Remove all tools from the bed and slides of the machine.

What is Milling Machine Operation, Parts and Types. Mechanical Booster

Milling Machine Procedure There are several basic operations that can be performed on a milling machine, including: Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Remove all tools from the bed and slides of the machine. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. Follow correct clam ping procedures to ensure work is secured to table. This operation involves cutting a flat surface on the. There are several basic operations that can be performed on a milling machine, including: Do not use this machine without completing appropriate induction / training.

From www.researchgate.net

Operation Sheet for Machining Complex Part Download Table Milling Machine Procedure Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. There are several basic operations that can be performed on a milling machine, including: Follow correct clam ping procedures to ensure work is secured to table. This operation involves cutting a flat surface on the. Conventional milling (or “up milling”) has. Milling Machine Procedure.

From www.industrybuying.com

How to Use a Milling Machine Safely? Free Step by Step Guide Milling Machine Procedure Remove all tools from the bed and slides of the machine. Follow correct clam ping procedures to ensure work is secured to table. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Do not use this machine without completing appropriate induction. Milling Machine Procedure.

From mavink.com

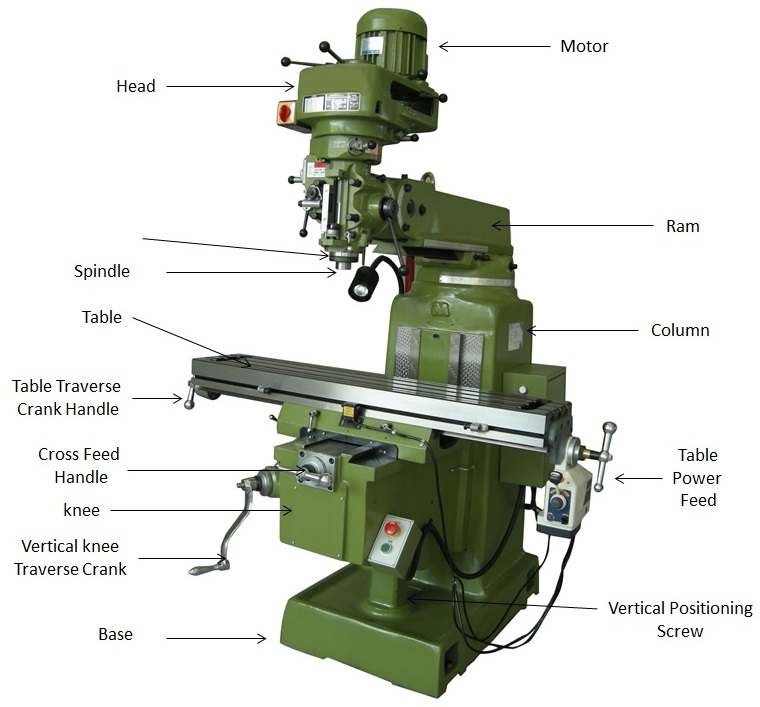

Milling Machine Labeled Diagram Milling Machine Procedure Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. There are several basic operations that can be performed on a milling machine,. Milling Machine Procedure.

From hubpages.com

Milling Machine Parts and their Function HubPages Milling Machine Procedure Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. This operation involves cutting a flat surface on the. There are several basic. Milling Machine Procedure.

From www.youtube.com

Cutting bevel gears on milling machinemanual indexing head YouTube Milling Machine Procedure This operation involves cutting a flat surface on the. Follow correct clam ping procedures to ensure work is secured to table. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Conventional milling (or “up milling”) has the cutting tool rotating in. Milling Machine Procedure.

From sayyamfirst.blogspot.com

Define process and working in milling machine studycity Milling Machine Procedure There are several basic operations that can be performed on a milling machine, including: Remove all tools from the bed and slides of the machine. Do not use this machine without completing appropriate induction / training. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting. Milling Machine Procedure.

From www.mechanicalbooster.com

What is Milling Machine Operation, Parts and Types. Mechanical Booster Milling Machine Procedure Follow correct clam ping procedures to ensure work is secured to table. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Remove. Milling Machine Procedure.

From www.merchantsfabrication.com

CNC Machining 101 Milling and Turning Merchants Fabrication, Inc Milling Machine Procedure Follow correct clam ping procedures to ensure work is secured to table. There are several basic operations that can be performed on a milling machine, including: Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Remove all tools from the bed and slides of the machine. Milling is the most. Milling Machine Procedure.

From www.instructables.com

How to Use a Manual Milling Machine 7 Steps Instructables Milling Machine Procedure Do not use this machine without completing appropriate induction / training. This operation involves cutting a flat surface on the. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Follow correct clam ping procedures to ensure work is secured to table.. Milling Machine Procedure.

From www.iqsdirectory.com

CNC Machining What Is It? How Does It Work? Types, Codes Milling Machine Procedure Do not use this machine without completing appropriate induction / training. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool. Milling Machine Procedure.

From learnmech.com

Basic Lathe Operations Lathe operation Explained Milling Machine Procedure Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. There are several basic operations that can be performed on a milling machine, including: Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled. Milling Machine Procedure.

From fractory.com

CNC Milling a Complete Guide to Understand the Process Milling Machine Procedure Follow correct clam ping procedures to ensure work is secured to table. There are several basic operations that can be performed on a milling machine, including: Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. This operation involves cutting a flat. Milling Machine Procedure.

From www.scribd.com

OPENG038 Milling Machine Procedure PDF Milling Machine Procedure This operation involves cutting a flat surface on the. There are several basic operations that can be performed on a milling machine, including: Do not use this machine without completing appropriate induction / training. Follow correct clam ping procedures to ensure work is secured to table. Remove all tools from the bed and slides of the machine. Milling is a. Milling Machine Procedure.

From www.videoblocks.com

Working process of the milling and drilling machine at the factory Milling Machine Procedure This operation involves cutting a flat surface on the. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. There are several basic operations that can be performed on a milling machine, including: Do not use this machine without completing appropriate induction. Milling Machine Procedure.

From pepmfg.us

What is the Difference Between CNC Milling and Turning? PEP Mfg., Inc. Milling Machine Procedure This operation involves cutting a flat surface on the. Remove all tools from the bed and slides of the machine. There are several basic operations that can be performed on a milling machine, including: Follow correct clam ping procedures to ensure work is secured to table. Milling is the most common form of machining, a material removal process, which can. Milling Machine Procedure.

From www.pinterest.com

A Safety Guide to CNC Milling Machine Cnc milling machine, Safety Milling Machine Procedure This operation involves cutting a flat surface on the. Follow correct clam ping procedures to ensure work is secured to table. There are several basic operations that can be performed on a milling machine, including: Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away. Milling Machine Procedure.

From www.pinterest.com.au

Milling (machining) Wikipedia Milling machine projects, Metal Milling Machine Procedure There are several basic operations that can be performed on a milling machine, including: Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. Do not use this machine without completing appropriate induction / training. Follow correct clam ping procedures to ensure. Milling Machine Procedure.

From www.slideserve.com

PPT Milling Machines PowerPoint Presentation, free download ID2263507 Milling Machine Procedure This operation involves cutting a flat surface on the. There are several basic operations that can be performed on a milling machine, including: Remove all tools from the bed and slides of the machine. Follow correct clam ping procedures to ensure work is secured to table. Milling is the most common form of machining, a material removal process, which can. Milling Machine Procedure.

From www.theengineerspost.com

15 Different Types of Milling Machine Explained [with PDF] Milling Machine Procedure There are several basic operations that can be performed on a milling machine, including: Do not use this machine without completing appropriate induction / training. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Follow correct clam ping procedures to ensure. Milling Machine Procedure.

From www.mechanicaleducation.com

Milling Machine Operation, Types And Parts Of Milling Machine Milling Machine Procedure Do not use this machine without completing appropriate induction / training. Remove all tools from the bed and slides of the machine. This operation involves cutting a flat surface on the. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. Milling. Milling Machine Procedure.

From www.lathemastery.com

What Is Milling Machine? Parts, Operation & Working... Milling Machine Procedure Do not use this machine without completing appropriate induction / training. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. Follow correct clam ping procedures to ensure work is secured to table. There are several basic operations that can be performed. Milling Machine Procedure.

From www.lathematters.com

Parts of Milling Machine — Different Types and Operations Milling Machine Procedure Remove all tools from the bed and slides of the machine. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Do not. Milling Machine Procedure.

From engineeringlearn.com

Operation of Milling Machine Engineering Learn Milling Machine Procedure This operation involves cutting a flat surface on the. Remove all tools from the bed and slides of the machine. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Do not use this machine without completing appropriate induction / training. Conventional milling (or “up milling”) has the cutting tool rotating. Milling Machine Procedure.

From www.ctemag.com

Boring with a milling machine Cutting Tool Engineering Milling Machine Procedure Follow correct clam ping procedures to ensure work is secured to table. There are several basic operations that can be performed on a milling machine, including: Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. This operation involves cutting a flat surface on the. Do not use this machine without. Milling Machine Procedure.

From studylib.net

for MANUAL MILLING MACHINES STANDARD OPERATING PROCEDURES TABLE OF CONTENTS Milling Machine Procedure Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. Do not use this machine without completing appropriate induction / training. Remove all tools from the bed and slides of the machine. Follow correct clam ping procedures to ensure work is secured. Milling Machine Procedure.

From cncmachiningworks.com

The Ultimate Guide to Purchasing The Best Milling Machine [2022 Guide Milling Machine Procedure There are several basic operations that can be performed on a milling machine, including: Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted. Milling Machine Procedure.

From www.scribd.com

CNC Milling Machine Procedure PDF Numerical Control Personal Milling Machine Procedure This operation involves cutting a flat surface on the. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. Milling is the most. Milling Machine Procedure.

From safetydocs.safetyculture.com

Milling Machine SOP SafetyDocs PDF & Word Templates Milling Machine Procedure Remove all tools from the bed and slides of the machine. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Follow correct clam ping procedures to ensure work is secured to table. Milling is a machining operation in which a revolving. Milling Machine Procedure.

From www.researchgate.net

Vertical Milling Machine Download Scientific Diagram Milling Machine Procedure Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Follow correct clam ping procedures to ensure work is secured to table. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. There. Milling Machine Procedure.

From www.thomasnet.com

Understanding CNC Milling Milling Machine Procedure Do not use this machine without completing appropriate induction / training. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. There are several basic operations that can be performed on a milling machine, including: This operation involves cutting a flat surface. Milling Machine Procedure.

From g3machining.com

G3 Machining Machining Milling Machine Procedure This operation involves cutting a flat surface on the. Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Remove all tools from the bed and slides of the machine. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool. Milling Machine Procedure.

From mellowpine.com

Parts of a CNC Milling Machine Visual Guide MellowPine Milling Machine Procedure There are several basic operations that can be performed on a milling machine, including: Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. Follow correct clam ping procedures to ensure work is secured to table. This operation involves cutting a flat surface on the. Conventional milling (or “up milling”) has. Milling Machine Procedure.

From www.mechanicalbooster.com

What is Milling Machine Operation, Parts and Types. Mechanical Booster Milling Machine Procedure This operation involves cutting a flat surface on the. Remove all tools from the bed and slides of the machine. Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. Conventional milling (or “up milling”) has the cutting tool rotating in the. Milling Machine Procedure.

From www.mechical.com

Parts of Milling Machine and Their Types,Operation Milling Machine Procedure There are several basic operations that can be performed on a milling machine, including: Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the. Milling is the most common form of machining, a material removal process, which can create a variety of. Milling Machine Procedure.

From cncfirst.com

CNC Milling Its Definition, Machines, And Operations CNCFIRST Milling Machine Procedure This operation involves cutting a flat surface on the. There are several basic operations that can be performed on a milling machine, including: Do not use this machine without completing appropriate induction / training. Follow correct clam ping procedures to ensure work is secured to table. Conventional milling (or “up milling”) has the cutting tool rotating in the same direction. Milling Machine Procedure.