Dry Plating Process . Emission and reduces thermal curing time from hours to minutes. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. First the powders of the active materials, additives and binders were blended in a dry. This process eliminates volatile org. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. The process of dry coating includes two essential steps. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. At the end stage, final vacuum.

from www.aitechnology.com

The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. This process eliminates volatile org. The process of dry coating includes two essential steps. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. At the end stage, final vacuum. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. First the powders of the active materials, additives and binders were blended in a dry. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. Emission and reduces thermal curing time from hours to minutes.

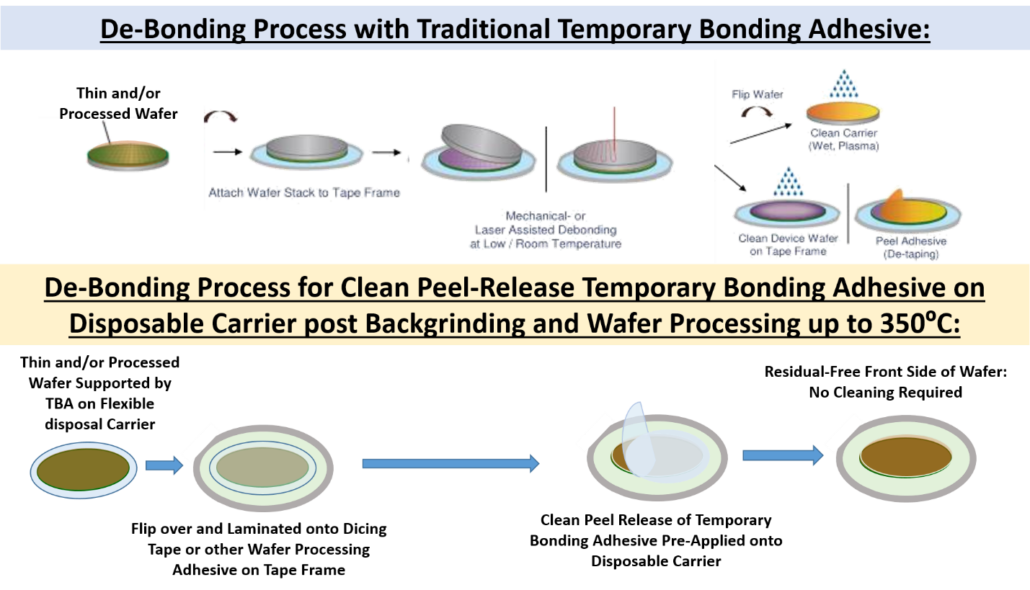

Wafer Processing Adhesives and Solutions AI Technology, Inc.

Dry Plating Process This process eliminates volatile org. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. At the end stage, final vacuum. First the powders of the active materials, additives and binders were blended in a dry. Emission and reduces thermal curing time from hours to minutes. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. The process of dry coating includes two essential steps. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. This process eliminates volatile org.

From www.researchgate.net

Generalized plating process current applied onto Mg alloys routes... Download Scientific Diagram Dry Plating Process Emission and reduces thermal curing time from hours to minutes. At the end stage, final vacuum. The process of dry coating includes two essential steps. First the powders of the active materials, additives and binders were blended in a dry. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. The dry process, which tesla. Dry Plating Process.

From www.kleinplating.com

Electroplating 101 Klein Plating Works Dry Plating Process The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. Emission and reduces thermal curing time from hours to minutes. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing,. Dry Plating Process.

From shincci-global.com

How to dry electroplating sludge Shincci Global Dry Plating Process This process eliminates volatile org. At the end stage, final vacuum. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery. Dry Plating Process.

From www.soseng.com

A Beginner's Guide to Understanding the Selective Plating Process Dry Plating Process The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. This process eliminates volatile org. At the end stage, final vacuum. The process of dry coating includes two essential steps. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods. Dry Plating Process.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Dry Plating Process Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Emission and reduces thermal curing time from hours to minutes. This process eliminates volatile org. The process of dry coating includes two essential steps. The dry process, which tesla obtained via its 2019. Dry Plating Process.

From sensorex.com

Electroplating The Process & Uses in Liquid Analysis Explained Sensorex Dry Plating Process Emission and reduces thermal curing time from hours to minutes. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. At the end stage, final vacuum. First the powders of the active materials, additives and binders were blended in a dry. The process of dry coating includes two essential steps. The dry process, which tesla obtained via its. Dry Plating Process.

From mantavya.com

What Is Electroplating & How does it work 2021 Guide Mantavya Dry Plating Process The process of dry coating includes two essential steps. Emission and reduces thermal curing time from hours to minutes. First the powders of the active materials, additives and binders were blended in a dry. At the end stage, final vacuum. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. The dry process, which tesla. Dry Plating Process.

From pubs.acs.org

Solventborne Polymer Coatings Drying, Film Formation, Stress Evolution, and Failure Langmuir Dry Plating Process The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question. Dry Plating Process.

From www.youtube.com

Pattern Plating Multilayer PCB Manufacturing Process 08 YouTube Dry Plating Process The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. At the end stage, final vacuum. First the powders of the active materials, additives and binders were blended in a dry. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. The process. Dry Plating Process.

From hayden-bogspotcarrillo.blogspot.com

Wafer Fabrication Process Flow Dry Plating Process First the powders of the active materials, additives and binders were blended in a dry. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. The process of dry coating includes two essential steps. This process eliminates volatile org. At the end stage,. Dry Plating Process.

From bakereng.co.uk

Plating process flow diagram steps from pretreatment to plated Dry Plating Process The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Emission and reduces thermal curing time from hours. Dry Plating Process.

From capablemachining.com

How Electroplating Works and Where it is Used Capable Machining Dry Plating Process At the end stage, final vacuum. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. This process eliminates volatile org. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. The process of dry coating includes two essential steps. First the powders. Dry Plating Process.

From www.researchgate.net

7 Schematic illustration of physical vapor deposition (PVD) process.... Download Scientific Dry Plating Process At the end stage, final vacuum. The process of dry coating includes two essential steps. First the powders of the active materials, additives and binders were blended in a dry. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. The typical wet. Dry Plating Process.

From www.iqsdirectory.com

Electroless Nickel Plating Variations, Types, Applications, and Benefits Dry Plating Process The process of dry coating includes two essential steps. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. First the powders of the active materials, additives and binders were blended in a dry. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying,. Dry Plating Process.

From www.researchgate.net

Process schemes of copper pattern formation through a direct pattern... Download Scientific Dry Plating Process The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. This process eliminates volatile org. At the end stage, final vacuum. Emission and reduces thermal curing time from hours to minutes. First the powders of the active materials, additives and binders were blended. Dry Plating Process.

From mechanicalfinishersinc.blogspot.com

The Different Steps Involved In The Zinc Plating Process Dry Plating Process The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. Emission and reduces thermal curing time from hours to minutes. This process eliminates volatile org. First the powders of the active materials, additives and binders were blended in a dry. At the end. Dry Plating Process.

From www.semanticscholar.org

[PDF] NICKEL PLATING HANDBOOK Semantic Scholar Dry Plating Process Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. First the powders of the active materials, additives. Dry Plating Process.

From galvanizeit.org

Galvanizing Process American Galvanizers Association Dry Plating Process At the end stage, final vacuum. This process eliminates volatile org. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. Emission and reduces thermal curing time from hours to minutes. First the powders of the active materials, additives and binders were blended in a. Dry Plating Process.

From www.nidek-intl.com

Coating Method (Vacuum Deposition) Coating Technical Introduction NIDEK CO.,LTD. Dry Plating Process At the end stage, final vacuum. This process eliminates volatile org. First the powders of the active materials, additives and binders were blended in a dry. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. Emission and reduces thermal curing time from hours to minutes. Dry coating is an innovative process in battery cell production that is. Dry Plating Process.

From www.diyphotography.net

Remembering The Dead Discovering Dry Plate Photography Dry Plating Process The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. First the powders of the active materials, additives and binders were blended in a dry. This process eliminates volatile org. At the end stage, final vacuum. Emission and reduces thermal curing time from hours to minutes. The process of dry coating includes two essential steps.. Dry Plating Process.

From www.aitechnology.com

Wafer Processing Adhesives and Solutions AI Technology, Inc. Dry Plating Process The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. First the powders of the active materials, additives and binders were blended in a dry. At the end stage, final vacuum. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. The dry process, which tesla obtained via its 2019 acquisition of california. Dry Plating Process.

From www.protoexpress.com

Wet PCB Etching Using Acidic & Alkaline Sierra Circuits Dry Plating Process The process of dry coating includes two essential steps. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. At the end stage, final vacuum. First the powders of the active materials, additives and binders were blended in a dry. This process eliminates. Dry Plating Process.

From www.researchgate.net

(PDF) Direct Copper Pattern Plating on Glass and Ceramic Substrates Using an AlDoped ZnO as an Dry Plating Process The process of dry coating includes two essential steps. At the end stage, final vacuum. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. This process eliminates volatile org. The dry process, which tesla obtained via its 2019 acquisition of california startup. Dry Plating Process.

From www.mdpi.com

Processes Free FullText Spray FreezeDrying as a Solution to Continuous Manufacturing of Dry Plating Process The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. At the end stage, final vacuum. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. This process eliminates volatile org. Emission and reduces thermal curing time from hours to. Dry Plating Process.

From www.daelyuk.com

DAELYUK CO,.Ltd Dry Plating Process Emission and reduces thermal curing time from hours to minutes. The process of dry coating includes two essential steps. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. First the powders of the active materials, additives and binders were blended in a dry. At. Dry Plating Process.

From www.researchgate.net

a Schematic diagram of the electroless plating process of CuSnAg... Download Scientific Diagram Dry Plating Process The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. This process eliminates volatile org. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. At the end. Dry Plating Process.

From eureka-patsnap-com.libproxy1.nus.edu.sg

Method for implementing semidry plating on surface of plastic substrate Eureka Patsnap Dry Plating Process The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. This process eliminates volatile org. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. First the powders of the active materials, additives and binders were blended in a dry.. Dry Plating Process.

From ecoreprap.com

Surface Finishes Electroplating ECOREPRAP S Dry Plating Process The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. Emission and reduces thermal curing time from hours to minutes. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question. Dry Plating Process.

From www.mdpi.com

Coatings Free FullText Controlled Electroplating of Noble Metals on IIIV Semiconductor Dry Plating Process The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. Emission and reduces thermal curing time from hours to minutes. This process eliminates volatile org. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. The industrial electrode manufacturing processes. Dry Plating Process.

From www.researchgate.net

Generalized plating process current applied onto Mg alloys routes... Download Scientific Diagram Dry Plating Process The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated step of battery manufacturing that involves. At the end stage, final vacuum. Emission and. Dry Plating Process.

From www.iqsdirectory.com

Industrial Coatings Types, Applications, Benefits, and Techniques Dry Plating Process The process of dry coating includes two essential steps. At the end stage, final vacuum. This process eliminates volatile org. Emission and reduces thermal curing time from hours to minutes. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. First the powders of the active materials, additives and binders were blended in a dry. Dry coating is. Dry Plating Process.

From suntronicinc.com

PCB Plating Process for PCB Manufacturing, PCB Plating Methods Suntronic Inc. Dry Plating Process Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. At the end stage, final vacuum. The industrial electrode manufacturing processes include slurry preparation, blade coating, drying, solvent. This process eliminates volatile org. The typical wet process involves slurry mixing, coating, drying (including. Dry Plating Process.

From www.mdpi.com

Materials Free FullText Optimization of Plating Process on Inner Wall of Metal Pipe and Dry Plating Process Emission and reduces thermal curing time from hours to minutes. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. The industrial electrode manufacturing processes include slurry preparation,. Dry Plating Process.

From sun-glo.com

Zinc Rack/Barrel Plating Zinc Electroplating Services Sun Glo Dry Plating Process At the end stage, final vacuum. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. First the powders of the active materials, additives and binders were blended in a dry. This process eliminates volatile org. The dry process, which tesla obtained via its 2019 acquisition of california startup maxwell technologies, replaces a traditional, complicated. Dry Plating Process.

From www.youtube.com

Metal Plating Process A Complete Guide To Its Types And Technique. YouTube Dry Plating Process First the powders of the active materials, additives and binders were blended in a dry. At the end stage, final vacuum. The process of dry coating includes two essential steps. Emission and reduces thermal curing time from hours to minutes. The typical wet process involves slurry mixing, coating, drying (including solvent recovery), pressing, and slitting. The industrial electrode manufacturing processes. Dry Plating Process.