Punch Tool Hardness . Harder tool surface finishes for. a2 steel is one of the most readily available and widely used tool steel grades. the three primary areas are: when it comes to punch performance, other key criteria include the following: drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. Most punch press tooling is. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. A2 tool steel’s composition provides excellent wear resistance, making it suitable for cutting and forming applications. It has deep hardening, low distortion and high heat treatment safety, high resistance to high temperature softening and medium resistance to decarburization. even though they are not necessarily the most exciting tool, punch tools are definitely a staple in the. pm tool steels can achieve higher hardness after heattreat than conventional tools steels. what is punch tool? It exhibits good toughness, allowing it to withstand impact and heavy loads. M2 tool steel is the most commonly used grade of the high speed category.

from www.modiantsolutions.com

For additional chipping resistance and wear resistance, powder metallurgy (pm) tool steels may offer a solution. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. achieving the correct die clearance is easy, once you understand the punching process. the three primary areas are: permanent bending of cutting edges, mushrooming of punch faces, or indenting of die surfaces (peening) all indicate. A2 tool steel’s composition provides excellent wear resistance, making it suitable for cutting and forming applications. pm tool steels can achieve higher hardness after heattreat than conventional tools steels. a2 steel is one of the most readily available and widely used tool steel grades. A punch is a tool used to indent or create a hole through a hard surface. Stiffness and toughness of the tool substrate for failure protection.

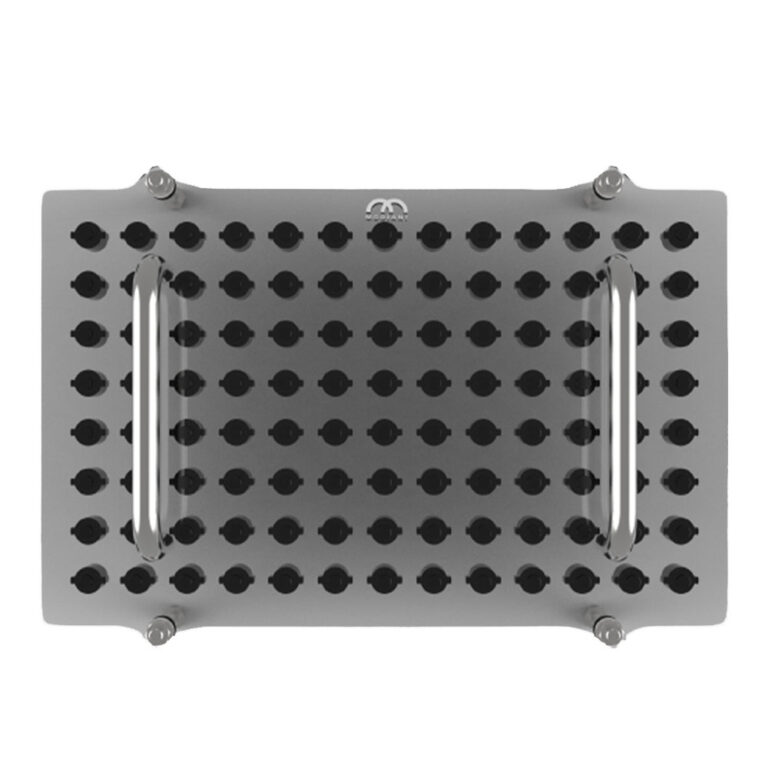

Punch Tool Modiant Solutions

Punch Tool Hardness Harder tool surface finishes for. the three primary areas are: s7 steel is primarily used for chisels, punches, rivet sets, stamps, screwdrivers and other applications that require high. pm tool steels can achieve higher hardness after heattreat than conventional tools steels. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. what is punch tool? even though they are not necessarily the most exciting tool, punch tools are definitely a staple in the. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. a punch is a tool used in order to cut and shape a block of material, which is usually made up of metal rods that are. achieving the correct die clearance is easy, once you understand the punching process. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. A punch is a tool used to indent or create a hole through a hard surface. For additional chipping resistance and wear resistance, powder metallurgy (pm) tool steels may offer a solution. a2 steel is one of the most readily available and widely used tool steel grades. Hardness is tested using the rockwell c scale. M2 tool steel is the most commonly used grade of the high speed category.

From www.joom.com

Buy 1.3in Firewood Drill Bit High Hardness Splitting Cone Reamer Punch Punch Tool Hardness A2 tool steel’s composition provides excellent wear resistance, making it suitable for cutting and forming applications. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. Stiffness and toughness of the tool substrate for failure protection. the three primary areas are: drawing back the punch head to. Punch Tool Hardness.

From www.aliexpress.com

Set Packing with 5 pieces High Hardness Steel Chisel Punch Fitter Punch Tool Hardness For additional chipping resistance and wear resistance, powder metallurgy (pm) tool steels may offer a solution. It has a tendency to retain austenite. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. a2 steel is one of the most readily available and widely used tool steel grades.. Punch Tool Hardness.

From www.joom.com

Buy 1.3in Firewood Drill Bit High Hardness Splitting Cone Reamer Punch Punch Tool Hardness Hardness is tested using the rockwell c scale. Harder tool surface finishes for. what is punch tool? It has deep hardening, low distortion and high heat treatment safety, high resistance to high temperature softening and medium resistance to decarburization. a punch is a tool used in order to cut and shape a block of material, which is usually. Punch Tool Hardness.

From www.walmart.com

2 Prong Leather Punch Tool, High Hardness Spacing Punches Tools 2Pcs Punch Tool Hardness It has a tendency to retain austenite. For additional chipping resistance and wear resistance, powder metallurgy (pm) tool steels may offer a solution. a2 steel is one of the most readily available and widely used tool steel grades. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and. Punch Tool Hardness.

From www.precision-mouldparts.com

Custom Oblong Die Punch Pins High Speed Tool Steel Material With 6062 Punch Tool Hardness what is punch tool? hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. a2 steel is one of the most readily available and widely used tool steel grades. the three primary areas are: Harder tool surface finishes for. M2 tool steel is the most commonly. Punch Tool Hardness.

From www.amazon.com

ABN Hollow Punch Kit Leather Punches Tools Hole Punch Set Gasket Punch Punch Tool Hardness For additional chipping resistance and wear resistance, powder metallurgy (pm) tool steels may offer a solution. Harder tool surface finishes for. permanent bending of cutting edges, mushrooming of punch faces, or indenting of die surfaces (peening) all indicate. A punch is a tool used to indent or create a hole through a hard surface. a punch is a. Punch Tool Hardness.

From www.canadianmetalworking.com

Improve punch tool organization for higher productivity Punch Tool Hardness achieving the correct die clearance is easy, once you understand the punching process. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. Most punch press tooling is. even though they are not necessarily the most exciting tool, punch tools are definitely a staple in. Punch Tool Hardness.

From www.tenyutool.com

Automatic Center Punch Tenyu Tool Punch Tool Hardness hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. Most punch press tooling is. A2 tool steel’s composition provides excellent wear resistance, making it suitable for cutting and forming applications. A punch is a tool used to indent or create a hole through a hard surface. pm. Punch Tool Hardness.

From www.walmart.com

Leather Craft Slot Punches Cutter Incisive High Hardness Word Knife Punch Tool Hardness It exhibits good toughness, allowing it to withstand impact and heavy loads. achieving the correct die clearance is easy, once you understand the punching process. what is punch tool? M2 tool steel is the most commonly used grade of the high speed category. s7 steel is primarily used for chisels, punches, rivet sets, stamps, screwdrivers and other. Punch Tool Hardness.

From engineeringlearn.com

14 Types of Punches (Tool) Applications, Precautions, Working Punch Tool Hardness the three primary areas are: Hardness is tested using the rockwell c scale. It exhibits good toughness, allowing it to withstand impact and heavy loads. what is punch tool? hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. Most punch press tooling is. a2 steel. Punch Tool Hardness.

From www.aliexpress.com

Automatic Center Punch Locator High Hardness Punch Breaker Automatic Punch Tool Hardness A punch is a tool used to indent or create a hole through a hard surface. what is punch tool? Most punch press tooling is. For additional chipping resistance and wear resistance, powder metallurgy (pm) tool steels may offer a solution. even though they are not necessarily the most exciting tool, punch tools are definitely a staple in. Punch Tool Hardness.

From www.mechstudies.com

What is Punch Tool? Types of Punch Tools Punch Tool Hardness pm tool steels can achieve higher hardness after heattreat than conventional tools steels. even though they are not necessarily the most exciting tool, punch tools are definitely a staple in the. a2 steel is one of the most readily available and widely used tool steel grades. For additional chipping resistance and wear resistance, powder metallurgy (pm) tool. Punch Tool Hardness.

From www.diecuttingcreasingmatrix.com

48 HRC Hardness Die Cutting Accessories Hole Punch Side Ejection ODM Punch Tool Hardness the three primary areas are: Harder tool surface finishes for. M2 tool steel is the most commonly used grade of the high speed category. Stiffness and toughness of the tool substrate for failure protection. pm tool steels can achieve higher hardness after heattreat than conventional tools steels. Hardness is tested using the rockwell c scale. achieving the. Punch Tool Hardness.

From www.walmart.com

TALENT High Hardness Punching Galvanized Tool Device Leather Hollow Punch Tool Hardness It exhibits good toughness, allowing it to withstand impact and heavy loads. permanent bending of cutting edges, mushrooming of punch faces, or indenting of die surfaces (peening) all indicate. It has a tendency to retain austenite. Stiffness and toughness of the tool substrate for failure protection. s7 steel is primarily used for chisels, punches, rivet sets, stamps, screwdrivers. Punch Tool Hardness.

From www.modiantsolutions.com

Punch Tool Modiant Solutions Punch Tool Hardness pm tool steels can achieve higher hardness after heattreat than conventional tools steels. the three primary areas are: s7 steel is primarily used for chisels, punches, rivet sets, stamps, screwdrivers and other applications that require high. permanent bending of cutting edges, mushrooming of punch faces, or indenting of die surfaces (peening) all indicate. Harder tool surface. Punch Tool Hardness.

From www.desertcart.com.my

Buy VOLTZ SYK 151 Hydraulic Knockout Punches tools Professional 22mm Punch Tool Hardness drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. a2 steel is one of the most readily available and widely used tool steel grades. pm tool steels can achieve higher hardness after heattreat than conventional tools steels. Harder tool surface finishes for. what. Punch Tool Hardness.

From www.amazon.co.uk

6 Pcs Leather Hole Punch Tools, Belt Hole Puncher for Steel Hollow Punch Tool Hardness permanent bending of cutting edges, mushrooming of punch faces, or indenting of die surfaces (peening) all indicate. M2 tool steel is the most commonly used grade of the high speed category. what is punch tool? drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to.. Punch Tool Hardness.

From whiteoutpress.com

Top 10 Advantages For Metal Punches and Die WhiteOut Press Punch Tool Hardness M2 tool steel is the most commonly used grade of the high speed category. s7 steel is primarily used for chisels, punches, rivet sets, stamps, screwdrivers and other applications that require high. when it comes to punch performance, other key criteria include the following: pm tool steels can achieve higher hardness after heattreat than conventional tools steels.. Punch Tool Hardness.

From www.walmart.com

2 Prong Leather Punch Tool, High Hardness Spacing Punches Tools Fine Punch Tool Hardness a2 steel is one of the most readily available and widely used tool steel grades. It has a tendency to retain austenite. A2 tool steel’s composition provides excellent wear resistance, making it suitable for cutting and forming applications. M2 tool steel is the most commonly used grade of the high speed category. the three primary areas are: . Punch Tool Hardness.

From www.joom.com

Buy 1.3in Firewood Drill Bit High Hardness Splitting Cone Reamer Punch Punch Tool Hardness a punch is a tool used in order to cut and shape a block of material, which is usually made up of metal rods that are. pm tool steels can achieve higher hardness after heattreat than conventional tools steels. Most punch press tooling is. s7 steel is primarily used for chisels, punches, rivet sets, stamps, screwdrivers and. Punch Tool Hardness.

From store.pipeman.com

Punch Tool ¯5mm Punch Tool Hardness what is punch tool? hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. A punch is a tool used to indent or create a hole through a hard surface. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it. Punch Tool Hardness.

From megahardwarett.com

Worksite 12 INCH Pointed Concrete Cold Chisel Punches. High hardness Punch Tool Hardness A2 tool steel’s composition provides excellent wear resistance, making it suitable for cutting and forming applications. M2 tool steel is the most commonly used grade of the high speed category. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. even though they are not necessarily. Punch Tool Hardness.

From www.walmart.com

2 Prong Leather Punch Tool, High Hardness Spacing Punches Tools Fine Punch Tool Hardness permanent bending of cutting edges, mushrooming of punch faces, or indenting of die surfaces (peening) all indicate. Harder tool surface finishes for. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. a punch is a tool used in order to cut and shape a block of. Punch Tool Hardness.

From www.toptechdiamond.com

What is Punch and Die Special Carbide and Diamond Tools Punch Tool Hardness It has deep hardening, low distortion and high heat treatment safety, high resistance to high temperature softening and medium resistance to decarburization. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. a2 steel is one of the most readily available and widely used tool steel grades. Most. Punch Tool Hardness.

From www.joom.com

Acquista 1.3in Firewood Drill Bit High Hardness Splitting Cone Reamer Punch Tool Hardness achieving the correct die clearance is easy, once you understand the punching process. Most punch press tooling is. A2 tool steel’s composition provides excellent wear resistance, making it suitable for cutting and forming applications. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. For additional chipping resistance. Punch Tool Hardness.

From www.modiantsolutions.com

Punch Tool Modiant Solutions Punch Tool Hardness It exhibits good toughness, allowing it to withstand impact and heavy loads. Most punch press tooling is. M2 tool steel is the most commonly used grade of the high speed category. It has a tendency to retain austenite. even though they are not necessarily the most exciting tool, punch tools are definitely a staple in the. A2 tool steel’s. Punch Tool Hardness.

From www.theengineerspost.com

The Engineers Post Punch Tool Hardness when it comes to punch performance, other key criteria include the following: a2 steel is one of the most readily available and widely used tool steel grades. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. the three primary areas are: drawing back the. Punch Tool Hardness.

From www.joom.com

Buy 1.3in Firewood Drill Bit High Hardness Splitting Cone Reamer Punch Punch Tool Hardness drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. what is punch tool? Harder tool surface finishes for. For additional chipping resistance and wear resistance, powder metallurgy (pm) tool steels may offer a solution. A punch is a tool used to indent or create a. Punch Tool Hardness.

From www.acscoating.com

Punches, Dies and Forming Tools Advanced Coating Service Punch Tool Hardness drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. It exhibits good toughness, allowing it to withstand impact and heavy loads. when it comes to punch performance, other key criteria include the following: achieving the correct die clearance is easy, once you understand the. Punch Tool Hardness.

From www.lazada.com.ph

2 Prong Leather Punch Tool, Fine Polishing High Hardness Integral Punch Tool Hardness It exhibits good toughness, allowing it to withstand impact and heavy loads. It has deep hardening, low distortion and high heat treatment safety, high resistance to high temperature softening and medium resistance to decarburization. A punch is a tool used to indent or create a hole through a hard surface. the three primary areas are: Most punch press tooling. Punch Tool Hardness.

From www.amazon.in

Hole Punch Tool Set, High Hardness Straight Round Hole Punch Tool 0.5 Punch Tool Hardness a2 steel is one of the most readily available and widely used tool steel grades. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. pm tool steels can achieve higher hardness after heattreat than conventional tools steels. A punch is a tool used to. Punch Tool Hardness.

From www.amazon.com

Wokesi 5/32"(4mm) High Hardness Carbon Steel Lowercase Punch Tool Hardness the three primary areas are: a punch is a tool used in order to cut and shape a block of material, which is usually made up of metal rods that are. Most punch press tooling is. It has deep hardening, low distortion and high heat treatment safety, high resistance to high temperature softening and medium resistance to decarburization.. Punch Tool Hardness.

From exoiggbzc.blob.core.windows.net

Hardest Punch On Punching Machine at Laura McDonald blog Punch Tool Hardness even though they are not necessarily the most exciting tool, punch tools are definitely a staple in the. drawing back the punch head to a consistent 40 to 45 rockwell hardness c (hrc) makes it less brittle and prone to. the three primary areas are: permanent bending of cutting edges, mushrooming of punch faces, or indenting. Punch Tool Hardness.

From www.amazon.ca

Super Strong Automatic Center Punch 5 inch Black Steel Spring Loaded Punch Tool Hardness It has deep hardening, low distortion and high heat treatment safety, high resistance to high temperature softening and medium resistance to decarburization. even though they are not necessarily the most exciting tool, punch tools are definitely a staple in the. Harder tool surface finishes for. hardness must be high enough to resist plastic deformation but not too high. Punch Tool Hardness.

From www.reddit.com

Types of Punch Tools r/coolguides Punch Tool Hardness permanent bending of cutting edges, mushrooming of punch faces, or indenting of die surfaces (peening) all indicate. A punch is a tool used to indent or create a hole through a hard surface. hardness must be high enough to resist plastic deformation but not too high as to cause premature chipping or cracking. pm tool steels can. Punch Tool Hardness.