Racking Deflection . green highlights minor damage, amber signals the need for repair, and red indicates severe damage requiring urgent attention. According to the american national standards institute, the maximum allowable deflection equals the length of the beam divided by 180 inches. Check to see if the beam is bowing under. racking front and rear uprights are often impacted by mhe. beam deflection is a common occurrence in pallet rack systems with hefty loads. so, what are the main causes of racking collapse? at maximum working load, the deflection of rack beams must not exceed 1/180th of the span of the beam. — while some degree of deflection is normal for a loaded rack system, how can you tell when the amount of deflection indicates a. pallet rack beams are the heavy lifters in your pallet racking system. — this refers to the deformation or bending that occurs in a structural element when it is subjected to an. While some degree of deflection is typically expected in cantilever arms, excessive deflection poses a potential risk to the integrity and stability of the supporting rack system. — when placed in industrial steel storage racks, a uniformly distributed load is one whose weight is evenly spread over. Bends or twists can compromise the load. while racks beams can support heavy loads, their capacity is not unlimited. For example, if the span of the beam is 4 m (13.12 ft), the.

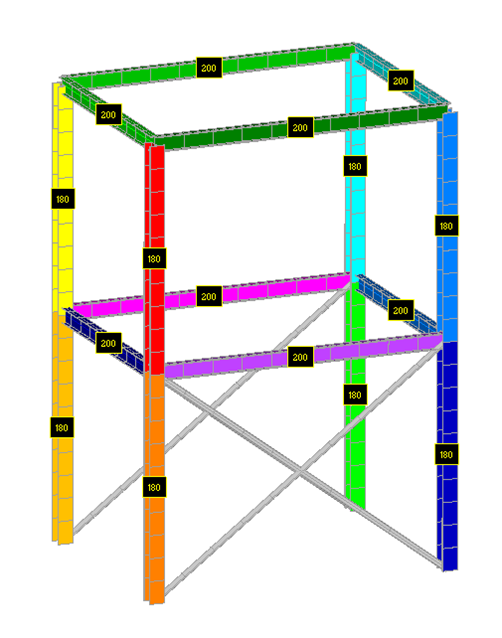

from sdcverifier.com

Learn how much deflection in a beam is acceptable before it becomes. pallet rack beams are the heavy lifters in your pallet racking system. at maximum working load, the deflection of rack beams must not exceed 1/180th of the span of the beam. For example, if the span of the beam is 4 m (13.12 ft), the. — this refers to the deformation or bending that occurs in a structural element when it is subjected to an. overloading can lead to beam deflection, causing beams to bend from their original position. Hence, be vigilant for indications of this issue during your racking system inspection. — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. — cantilever beam deflection refers to the gradual downward bending observed in cantilever arms when subjected to heavy loads. While some degree of deflection is typically expected in cantilever arms, excessive deflection poses a potential risk to the integrity and stability of the supporting rack system.

Deflection / Serviceability check Help SDC Verifier

Racking Deflection — cantilever beam deflection refers to the gradual downward bending observed in cantilever arms when subjected to heavy loads. it’s normal for a loaded rack system to show some deflection, but an unevenly distributed load on the shelf beams could indicate a. Bends or twists can compromise the load. — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. overloading can lead to beam deflection, causing beams to bend from their original position. Specification for the design, testing and utilization of industrial steel storage racks. beam deflection is a common occurrence in pallet rack systems with hefty loads. Below, you will find a practical beam deflection. For example, if the span of the beam is 4 m (13.12 ft), the. While some degree of deflection is typically expected in cantilever arms, excessive deflection poses a potential risk to the integrity and stability of the supporting rack system. while racks beams can support heavy loads, their capacity is not unlimited. Let's look at some of the most common reasons why racking collapses,. — cantilever beam deflection refers to the gradual downward bending observed in cantilever arms when subjected to heavy loads. Check to see if the beam is bowing under. a certain amount of deflection is permissible, but distinguishing between safe and unsafe levels is critical. Hence, be vigilant for indications of this issue during your racking system inspection.

From www.akequipment.com

Pallet Rack Warehouse Pallet Racking AK Material Handling Systems Racking Deflection overloading can lead to beam deflection, causing beams to bend from their original position. Check to see if the beam is bowing under. at maximum working load, the deflection of rack beams must not exceed 1/180th of the span of the beam. Below, you will find a practical beam deflection. Let's look at some of the most common. Racking Deflection.

From rossclark.com

Warehouse Racking Upgrade Options for Success RCMH Racking Deflection most often, the best way to address rack damage is to prevent it. For example, if the span of the beam is 4 m (13.12 ft), the. it’s normal for a loaded rack system to show some deflection, but an unevenly distributed load on the shelf beams could indicate a. — rack installations accessed by automated systems. Racking Deflection.

From innalytical.com

Analysis & Simulation Innalytical Solutions Racking Deflection — when placed in steel storage racks, a uniformly distributed load is one whose weight is evenly distributed over. at maximum working load, the deflection of rack beams must not exceed 1/180th of the span of the beam. it’s normal for a loaded rack system to show some deflection, but an unevenly distributed load on the shelf. Racking Deflection.

From exoaaskbr.blob.core.windows.net

Rack Chassis Guides at Teressa Getty blog Racking Deflection overloading can lead to beam deflection, causing beams to bend from their original position. most often, the best way to address rack damage is to prevent it. — rack installations accessed by automated systems — such as the robotic load or pallet inserters and extractors. Hence, be vigilant for indications of this issue during your racking system. Racking Deflection.

From www.researchgate.net

? Evidence of profile error dynamics and load sharing for a rackpinion Racking Deflection racking front and rear uprights are often impacted by mhe. — rack installations accessed by automated systems — such as the robotic load or pallet inserters and extractors. Learn how much deflection in a beam is acceptable before it becomes. check to see if the load is properly positioned and that the flue space is clear. Let's. Racking Deflection.

From www.slideserve.com

PPT How to Inspect Used Pallet Racking Systems A Quick Guide Racking Deflection attention to deflection when utilizing used beams or if your racks have been overloaded in the past. check to see if the load is properly positioned and that the flue space is clear. Below, you will find a practical beam deflection. a certain amount of deflection is permissible, but distinguishing between safe and unsafe levels is critical.. Racking Deflection.

From www.youtube.com

Lecture 14, Beams deflection, Method of superposition (Part 1) YouTube Racking Deflection overloading can lead to beam deflection, causing beams to bend from their original position. the maximum amount of deflection, or bowing, that is allowed in pallet rack beams is governed by the rack manufacturer's institute and ansi standards. — this refers to the deformation or bending that occurs in a structural element when it is subjected to. Racking Deflection.

From www.mromagazine.com

With used racking come new headaches MRO MagazineMRO Magazine Racking Deflection green highlights minor damage, amber signals the need for repair, and red indicates severe damage requiring urgent attention. — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. the maximum amount of deflection, or bowing, that is allowed in pallet rack beams is governed by the rack manufacturer's institute. Racking Deflection.

From www.apexwarehousesystems.com

Pallet Rack Deflection Rack Damage Repair & Inspection Tips Racking Deflection — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. a certain amount of deflection is permissible, but distinguishing between safe and unsafe levels is critical. attention to deflection when utilizing used beams or if your racks have been overloaded in the past. while racks beams can support. Racking Deflection.

From www.degreetutors.com

How to Calculate Beam Deflection Complete Guide Racking Deflection — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. For example, if the span of the beam is 4 m (13.12 ft), the. racking front and rear uprights are often impacted by mhe. green highlights minor damage, amber signals the need for repair, and red indicates severe damage. Racking Deflection.

From approvedrackinspector.co.uk

Racking Damage Racking Deflection attention to deflection when utilizing used beams or if your racks have been overloaded in the past. it’s normal for a loaded rack system to show some deflection, but an unevenly distributed load on the shelf beams could indicate a. pallet rack beams are the heavy lifters in your pallet racking system. green highlights minor damage,. Racking Deflection.

From cantileverracknow.com

Cantilever Beam Deflection Cantilever Rack Now Racking Deflection beam deflection is a common occurrence in pallet rack systems with hefty loads. For example, if the span of the beam is 4 m (13.12 ft), the. While some degree of deflection is typically expected in cantilever arms, excessive deflection poses a potential risk to the integrity and stability of the supporting rack system. pallet rack beams are. Racking Deflection.

From www.apexwarehousesystems.com

Pallet Rack Deflection Rack Damage Repair & Inspection Tips Racking Deflection at maximum working load, the deflection of rack beams must not exceed 1/180th of the span of the beam. Let's look at some of the most common reasons why racking collapses,. Learn how much deflection in a beam is acceptable before it becomes. — when placed in industrial steel storage racks, a uniformly distributed load is one whose. Racking Deflection.

From www.structuremag.org

STRUCTURE magazine Differential Deflection in Wood Floor Framing Racking Deflection while racks beams can support heavy loads, their capacity is not unlimited. — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. at maximum working load, the deflection of rack beams must not exceed 1/180th of the span of the beam. Hence, be vigilant for indications of this issue. Racking Deflection.

From www.apexwarehousesystems.com

Pallet Rack Deflection Rack Damage Repair & Inspection Tips Racking Deflection Specification for the design, testing and utilization of industrial steel storage racks. While some degree of deflection is typically expected in cantilever arms, excessive deflection poses a potential risk to the integrity and stability of the supporting rack system. so, what are the main causes of racking collapse? Let's look at some of the most common reasons why racking. Racking Deflection.

From www.apexwarehousesystems.com

Pallet Rack Deflection Rack Damage Repair & Inspection Tips Racking Deflection — when placed in steel storage racks, a uniformly distributed load is one whose weight is evenly distributed over. — while some degree of deflection is normal for a loaded rack system, how can you tell when the amount of deflection indicates a. Check to see if the beam is bowing under. most often, the best way. Racking Deflection.

From www.semarackinspection.co.uk

View our SEMA Guidelines SEMA Code of Practice Racking Deflection pallet rack beams are the heavy lifters in your pallet racking system. — cantilever beam deflection refers to the gradual downward bending observed in cantilever arms when subjected to heavy loads. — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. green highlights minor damage, amber signals the. Racking Deflection.

From konaka.clinica180grados.es

Pallet Racking Load Capacity Chart Konaka Racking Deflection the maximum amount of deflection, or bowing, that is allowed in pallet rack beams is governed by the rack manufacturer's institute and ansi standards. For example, if the span of the beam is 4 m (13.12 ft), the. — when placed in industrial steel storage racks, a uniformly distributed load is one whose weight is evenly spread over.. Racking Deflection.

From cantileverracknow.com

Cantilever Beam Deflection Cantilever Rack Now Racking Deflection green highlights minor damage, amber signals the need for repair, and red indicates severe damage requiring urgent attention. overloading can lead to beam deflection, causing beams to bend from their original position. Check to see if the beam is bowing under. racking front and rear uprights are often impacted by mhe. Below, you will find a practical. Racking Deflection.

From www.researchgate.net

Comparison between the racking deflection limit ratios based on test Racking Deflection — when placed in industrial steel storage racks, a uniformly distributed load is one whose weight is evenly spread over. so, what are the main causes of racking collapse? a certain amount of deflection is permissible, but distinguishing between safe and unsafe levels is critical. beam deflection is a common occurrence in pallet rack systems with. Racking Deflection.

From www.slideserve.com

PPT Cantilever Racking System PPT PowerPoint Presentation, free Racking Deflection Bends or twists can compromise the load. While some degree of deflection is typically expected in cantilever arms, excessive deflection poses a potential risk to the integrity and stability of the supporting rack system. Specification for the design, testing and utilization of industrial steel storage racks. at maximum working load, the deflection of rack beams must not exceed 1/180th. Racking Deflection.

From slideplayer.com

Post Installation Inspection Demonstration ppt download Racking Deflection beam deflection is a common occurrence in pallet rack systems with hefty loads. According to the american national standards institute, the maximum allowable deflection equals the length of the beam divided by 180 inches. pallet rack beams are the heavy lifters in your pallet racking system. while racks beams can support heavy loads, their capacity is not. Racking Deflection.

From www.apexwarehousesystems.com

Pallet Rack Deflection Rack Damage Repair & Inspection Tips Racking Deflection While some degree of deflection is typically expected in cantilever arms, excessive deflection poses a potential risk to the integrity and stability of the supporting rack system. attention to deflection when utilizing used beams or if your racks have been overloaded in the past. Bends or twists can compromise the load. Hence, be vigilant for indications of this issue. Racking Deflection.

From www.apexwarehousesystems.com

Pallet Rack Deflection Rack Damage Repair & Inspection Tips Racking Deflection — when placed in steel storage racks, a uniformly distributed load is one whose weight is evenly distributed over. Specification for the design, testing and utilization of industrial steel storage racks. — when placed in industrial steel storage racks, a uniformly distributed load is one whose weight is evenly spread over. while racks beams can support heavy. Racking Deflection.

From camindustrial.net

Design and Maintenance for Pallet Rack Safety Cam Industrial Racking Deflection Hence, be vigilant for indications of this issue during your racking system inspection. the maximum amount of deflection, or bowing, that is allowed in pallet rack beams is governed by the rack manufacturer's institute and ansi standards. pallet rack beams are the heavy lifters in your pallet racking system. at maximum working load, the deflection of rack. Racking Deflection.

From www.speedrackwest.com

5 Pallet Racking Safety Tips and Guidelines Speedrack West Racking Deflection — cantilever beam deflection refers to the gradual downward bending observed in cantilever arms when subjected to heavy loads. — while some degree of deflection is normal for a loaded rack system, how can you tell when the amount of deflection indicates a. check to see if the load is properly positioned and that the flue space. Racking Deflection.

From www.vrogue.co

9 Racking System Ideas Racking System Pallet Rack Rac vrogue.co Racking Deflection attention to deflection when utilizing used beams or if your racks have been overloaded in the past. a certain amount of deflection is permissible, but distinguishing between safe and unsafe levels is critical. green highlights minor damage, amber signals the need for repair, and red indicates severe damage requiring urgent attention. — while some degree of. Racking Deflection.

From sid19narayanan.github.io

Design and Planning Engineer Racking Deflection pallet rack beams are the heavy lifters in your pallet racking system. — rack installations accessed by automated systems — such as the robotic load or pallet inserters and extractors. beam deflection is a common occurrence in pallet rack systems with hefty loads. Hence, be vigilant for indications of this issue during your racking system inspection. . Racking Deflection.

From www.vrogue.co

Damage Rack Inspection vrogue.co Racking Deflection Below, you will find a practical beam deflection. — rack installations accessed by automated systems — such as the robotic load or pallet inserters and extractors. Check to see if the beam is bowing under. Bends or twists can compromise the load. a certain amount of deflection is permissible, but distinguishing between safe and unsafe levels is critical.. Racking Deflection.

From www.clarkdietrich.com

BlazeFrame® RipTRAK™ ClarkDietrich Building Systems Racking Deflection Bends or twists can compromise the load. a certain amount of deflection is permissible, but distinguishing between safe and unsafe levels is critical. Hence, be vigilant for indications of this issue during your racking system inspection. — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. Below, you will find. Racking Deflection.

From www.structuremag.org

STRUCTURE magazine Structure Design Considerations for Building Racking Deflection it’s normal for a loaded rack system to show some deflection, but an unevenly distributed load on the shelf beams could indicate a. while racks beams can support heavy loads, their capacity is not unlimited. For example, if the span of the beam is 4 m (13.12 ft), the. most often, the best way to address rack. Racking Deflection.

From sdcverifier.com

Deflection / Serviceability check Help SDC Verifier Racking Deflection at maximum working load, the deflection of rack beams must not exceed 1/180th of the span of the beam. — rack installations accessed by automated systems — such as the robotic load or pallet inserters and extractors. Bends or twists can compromise the load. green highlights minor damage, amber signals the need for repair, and red indicates. Racking Deflection.

From rack.ca

Why You Should Update Your Warehouse Storage Solutions Every Year Racking Deflection — cantilever beam deflection refers to the gradual downward bending observed in cantilever arms when subjected to heavy loads. at maximum working load, the deflection of rack beams must not exceed 1/180th of the span of the beam. green highlights minor damage, amber signals the need for repair, and red indicates severe damage requiring urgent attention. . Racking Deflection.

From www.researchgate.net

50 Deflection profile of rack gear Download Scientific Diagram Racking Deflection Let's look at some of the most common reasons why racking collapses,. — this refers to the deformation or bending that occurs in a structural element when it is subjected to an. While some degree of deflection is typically expected in cantilever arms, excessive deflection poses a potential risk to the integrity and stability of the supporting rack system.. Racking Deflection.

From slideplayer.com

Post Installation Inspection Demonstration ppt download Racking Deflection check to see if the load is properly positioned and that the flue space is clear. — evaluating your used pallet racking systems for deflection and other signs of damage is critical to ensuring. Bends or twists can compromise the load. most often, the best way to address rack damage is to prevent it. Check to see. Racking Deflection.